What is a sand making machine?

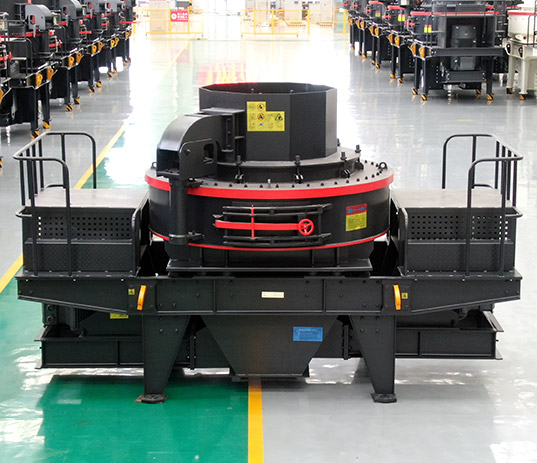

A sand making machine, also known as a vertical shaft impact crusher, is a type of equipment used to crush or shape rocks into sand particles. Its main purpose is to produce well-shaped sand products that can be used as a substitute for natural sand.

FTM Machinery sand maker has been upgraded many times to achieve green sand making. It provides high-quality sand and gravel aggregates for high-rise buildings, highways and railways, municipal engineering, water conservancy facilities, concrete mixing stations, and manufacturing industries.

Why choose FTM Machinery sand making machines?

FTM Machinery sand making equipment can offer numerous advantages for your various applications:

- With the optimized design of the deep cavity rotor, the material throughput is increased by about 30%.

- The new impeller design of the sand making machine optimizes material flow and the output is as high as 650 t/h.

- The machine has the functions of fine crushing and coarse grinding. The product is in the form of a cube, with good particle size and extremely low flake content.

- The crushing structure of "rock on rock" and "rock on iron" can be selected, with high crushing efficiency.

- Sand maker is green and environmentally friendly. The airflow in the vortex chamber is automatically circulated, and it is equipped with a dust-proof device.

- Thin-oil lubrication system and automatic maintenance. Under the same capacity, power consumption can be reduced by 10%–40%.

- Protecting plates can be turned around after partial wear to extend their service life. Only the worn parts need to be replaced, which can reduce the use cost by 30%.

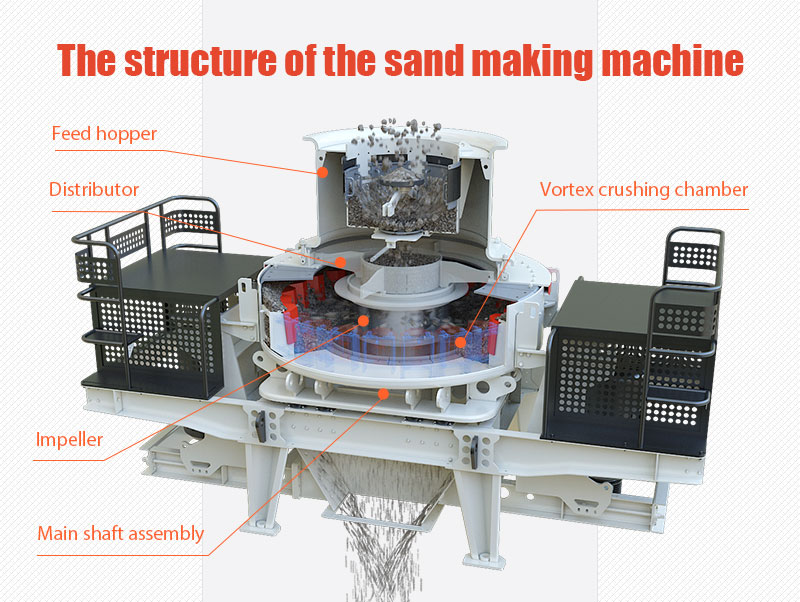

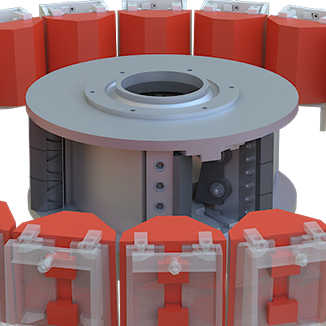

The structure of the sand making machine

The sand making machine is composed of the feed hopper, distributor, vortex crushing chamber, impeller, main shaft, pulley, base, transmission device, lubrication system, etc. The following are the key parts of the impact sand making machine:

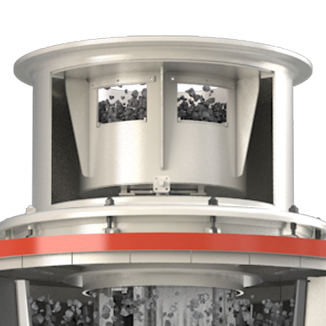

1. Feed hopper

The structure of the feed hopper is an inverted prism (or cylinder), equipped with a wear-resistant ring. It is a large container, and the material enters the crusher through the feed hopper.

2. Distributor

The distributor is on the upper part of the vortex crushing chamber. Its role is to divide the material so that a part of the material directly enters the impeller and is ejected out. The other part is impacted and crushed by the high-speed material ejected from the impeller.

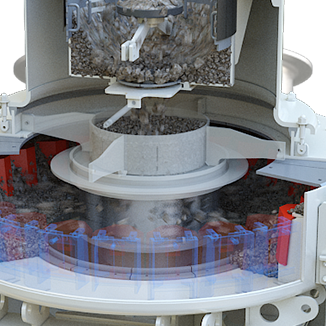

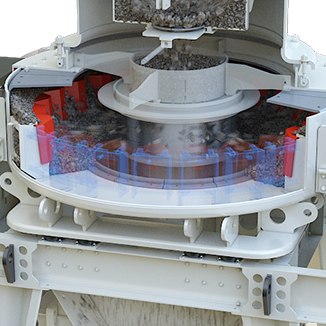

3. Vortex crushing chamber

The vortex crushing chamber is an annular space composed of two cylinders, where the materials' crushing process occurs. The material lining layer separates the crushing action of the crushing chamber wall, so the crushing is limited to the materials and plays the role of wear resistance and self-lining.

4. Impeller

The impeller, a hollow cylinder made of special materials, is the key element of the sand maker. The impeller accelerates the material to a speed of 60-75 m/s and ejects it. The impeller rotor is generally made of high-strength steel, equipped with rotor tips made of high-chrome steel or tungsten carbide materials.

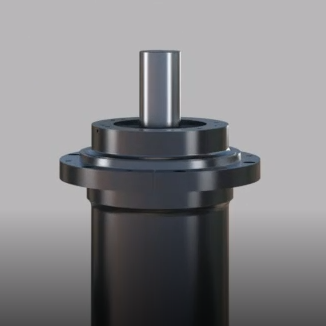

5. Main shaft assembly

The main shaft assembly is composed of the main shaft itself, bearings, bearing housings, etc. It connects the rotor to the power source (electric motor) and makes the rotor spin. The main shaft is usually made of high-quality alloy steel.

Other components of the sand making machine:

- Transmission device: The belt transmission mechanism driven by a single or double motor (above 75 kW) is adopted.

- Lubrication system: It adopts special-grade centralized lubrication with automotive greases. The lubrication parts are the spindle mechanism's upper and lower bearings.

- Base: The center of the base is used to install the spindle mechanism, and the discharge channel is formed on both sides. The dual motors are installed on the longitudinal ends of the base.

Hot types of sand making machines

Based on the introduction of German technology, FTM Machinery has developed 3 types of high-performance sand making equipment: VSI sand maker, HVI sand maker, and mobile sand maker.

1. VSI series sand making machine

VSI sand making machine is a common gravel-making machine in the market. VSI sand maker has a deep cavity rotor design with a large passing capacity. Compared with traditional sand making machines, it can save energy by 50%, and the sand-forming rate is 20% higher.

Maximum feed size: Hard material <45 mm, soft material <50 mm

Capacity (feed at center): 40–365 t/h

Capacity (feed at center and sides): 80–650 t/h

Motor power: 4P 500 kW

2. HVI series sand making machine

HVI sand making machine is the latest equipment with two functions of sand making and shaping. The finished product is uniform, with a beautiful size and better grain shape. It adopts the best design of the material impact angle of the crushing chamber.

Maximum feed size: Hard material <50 mm, soft material <55 mm

Sand shaping capacity: 50–498 t/h

Sand making capacity: 90–585 t/h

Motor power: 2×315 kW

3. Mobile sand making machine

Both HVI and VSI sand making machines can be equipped with mobile crushing stations. The mobile sand making machine can be driven to the site to start sand making and screening work directly. It not only effectively improves work efficiency, but also facilitates user operation.

Production capacity: 40-650 t/h

Equipped with machines: Feeder, sand making machine, vibrating screen, conveyor, etc.

It can be composed of tire-type and crawler-type sand making machines to meet the needs of various coarse, medium, and fine sand production plants.

FTM Machinery sand making machines for sale:Get the Discounted Price

How to choose the sand maker that benefits you most?

| Types | HVI sand making machine | VSI sand making machine | Mobile sand making machine |

| Similarity |

1. Both models have "rock on rock" and "rock on iron" can be selected. 2. The material can be crushed into 0-5 mm sand, and the output size can be adjusted. 3. Both types of sand making machines have many models, which can be suitable for all of you. |

Both can be equipped with a mobile crushing station to form a mobile sand making plant. | |

| Unique advantage | Two remarkable functions of sand making and shaping | 10% higher output than that of HVI sand making machine | Applied to various operations with greater mobility |

| Price | High price | Moderate price | Higher price |

From this:

- If you pursue high-cost performance, you can choose a VSI sand making machine.

- If you have high requirements for finished products and a sufficient budget, you can choose a technologically advanced HVI sand making machine.

- If you need a mobile operation, a mobile sand making machine is very suitable for you.

How does a sand making machine work?

The sand making machine uses the working principle of high-speed impact and crushing:

- 1First the material flows into the vortex crushing cavity from the feed hopper. The high-speed rotating impeller crushes the material scattered around the impeller in the form of an umbrella.

- 2After the materials collide with each other, the material layer between the impeller and the casing will form a vortex flow for multiple collisions, friction, and crushing.

- 3Then the material is discharged from the lower discharge hopper to complete the crushing process. The particle size of the finished product is controlled by the screening machine.

Successful case of FTM Machinery sand making machine

200 TPH river pebble sand production line in Indonesia

- Processed material: River pebble

- Feed size: ≤630 mm

- Capacity: 200–350 TPH

- Main equipment: Jaw crusher, cone crusher, HVI sand making machine

- Auxiliary equipment: Vibrating feeder, vibrating screen (2 sets), conveyor belts (several)

Advantages of river pebble sand production line

1 Simple process and easy operation

With the combination of crushers, the sand making process is simple and highly automated. The whole set production line only needs 1-2 people to complete the whole processing flow of river pebbles.

2 High sand making efficiency

The sand crusher machine is the core equipment of the whole sand production process. The efficiency of sand making is increased by more than 40%, saving a lot of manpower, material, and financial resources for the enterprise.

3 Good sand making effect

The processed river pebbles not only reach the standard of building sand in terms of hardness and strength, but also have good grain shape.

4 Environmental protection

The overall energy and power consumption is about 30% lower than that of the ordinary river pebble sand production line. In addition, the sand making process realizes the ideal production state of zero dust and zero noise.

FTM Machinery sand making manufacture

As a professional sand maker supplier, FTM Machinery has its production workshop and R&D organization. You can get the following services for free:

- Provide users with free guidance on the selection of sand makers.

- Design economical sand production line solutions according to your needs.

- Come to the factory and visit the production workshop and working site.

- Enjoy the free test of the sand making machine with your material.

- Dispatch engineers to your working site to guide the installation and train the operators.

Frequently asked questions about sand making machines

1. How to choose between "rock on rock" and "rock on iron" crushing methods?

- The sand crusher machine has two crushing methods "rock on rock" and "rock on iron".

- "Rock on rock" is suitable for materials above medium hard with high abrasion resistance, such as basalt, quartz, granite, etc. Under the working condition of "rock on rock", the finished product has a better grain shape and more powder content.

- "Rock on iron" is suitable for materials below medium hard with low abrasiveness, such as limestone, dolomite, etc. Under the working condition of "rock on iron", the crushing efficiency is higher. But the finished grain shape is slightly worse and the wear cost of protecting plates is higher.

- Therefore, "rock on rock" is suitable for sand shaping, and "rock on iron" is suitable for sand making.

2. What are the factors that affect the sand production rate?

- a. The characteristics of materials: Crushed material hardness, strength, humidity, viscosity, composition, etc.

- b. Fineness of finished sand: The lower the fineness requirement for artificial sand, the lower the sand making rate may be.

- c. The feeding amount: Generally, the larger the feeding amount, the higher the efficiency. But there is an extreme point.

- d. The speed of the impeller: Higher impeller speeds typically result in higher sand production rates, but it can also affect sand production quality.

- e. Moisture content: High moisture content in the feed material can lead to clogging and reduced sand making machine efficiency.

Parameter

- Sand Making Machine

- VSI Sand Maker

- HVI Sand Making Machine

| Model specification |

Max.feeding size (mm) |

Power (kw) |

Rotation speed of impeller (r/min) |

Capacity (t/h) |

Overall dimension (L×W×H) (mm) |

| FTM-06 | 35 | 2P 37-55KW | 2000-3000 | 10-30 | 2500×1620×2600 |

| FTM-07 | 45 | 4P 55-75KW | 1500-2500 | 20-55 | 2700×1760×2800 |

| Model specification |

Capacity (t/h) |

| FTM-06 | 10-30 |

| FTM-07 | 20-55 |

| Model | VSI 7611 | VSI 8518 | VSI 9526 | VSI 1140 | VSI 1145 | VSI 1150 | |

| Capacity (t/h) |

Feed both at center and sides | 80-180 | 140-260 | 200-380 | 300-520 | 350-610 | 360-650 |

| Feed at center | 40-90 | 70-130 | 100-190 | 160-260 | 180-355 | 190-365 | |

| Max.feeding size (mm) |

Soft material | 35 | 40 | 45 | 50 | 50 | 50 |

| Hard material | 30 | 35 | 40 | 40 | 45 | 45 | |

| Rotation speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1150-1300 | 1150-1300 | 1150-1300 | |

| Motor power(kw) | 4P 110 | 4P 180 | 4P 264 | 4P 400 | 4P 440 | 4P 500 | |

| Overall dimension(L×W×H)(mm) | 4100×2250×2300 | 4160×2320×2900 | 4560×2450×2830 | 5500×2700×3100 | 5500×2700×3100 | 5500×2700×3100 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Capacity(t/h) | |

| Feed both at center and sides | Feed at center | |

| VSI 7611 | 80-180 | 40-90 |

| VSI 8518 | 140-260 | 70-130 |

| VSI 9526 | 200-380 | 100-190 |

| VSI 1140 | 300-520 | 160-260 |

| VSI 1145 | 350-610 | 180-355 |

| VSI 1150 | 360-650 | 190-365 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Hard material | Soft material | Sand Shaping | Sand Making | Motor Power(kw) |

| Max.Feeding Size (mm) | Throughput(t/h) | ||||

| HVI 0815 | <30 | <35 | 50-140 | 90-230 | 2×75 |

| HVI 0818 | <30 | <35 | 60-190 | 110-283 | 2×90 |

| HVI 0922 | <35 | <40 | 70-210 | 150-330 | 2×110 |

| HVI 0926 | <35 | <40 | 85-240 | 170-380 | 2×132 |

| HVI 1032 | <40 | <45 | 130-278 | 180-356 | 2×160 |

| HVI 1040 | <40 | <45 | 180-284 | 250-440 | 2×200 |

| HVI 1263 | <50 | <55 | 320-498 | 370-585 | 2×315 |

| Model | Sand Shaping | Sand Making | Motor Power (kw) |

| Max.Feeding Size (mm) | |||

| HVI 0815 | 50-140 | 90-230 | 2×75 |

| HVI 0818 | 60-190 | 110-283 | 2×90 |

| HVI 0922 | 70-210 | 150-330 | 2×110 |

| HVI 0926 | 85-240 | 170-380 | 2×132 |

| HVI 1032 | 130-278 | 180-356 | 2×160 |

| HVI 1040 | 180-284 | 250-440 | 2×200 |

| HVI 1263 | 320-498 | 370-585 | 2×315 |