What is a river sand dryer?

River sand dryers have long been the industrial dryer of choice for handling sand and gravel in various industries. The sand dryer is highly targeted, and the dried sand has a wide range of applications.

The river sand dryer is mainly used to dry materials within a certain humidity range, also known as the sand dryer or sand rotary dryer. The drying temperature of the dryer can reach up to 800°C, and it generally dries lumps, granules, or powders less than 50 mm.

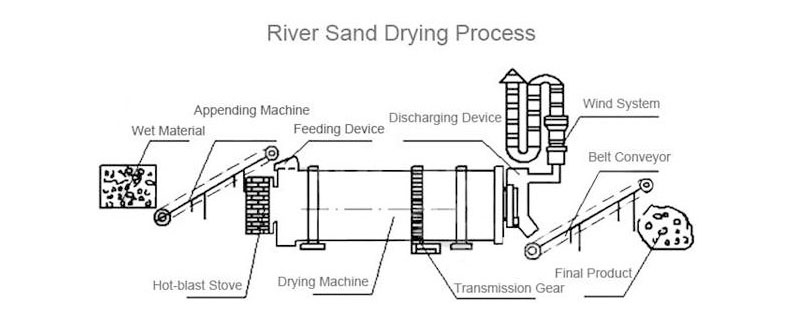

River sand dryer's working principle: During the drying process of the river sand dryer, through the continuous rotation of the cylinder, the wet materials in the cylinder are continuously scattered and thrown, and fully contacted with the hot air flow. The moisture contained is gradually dried to achieve the purpose of drying.

Tip: The dryer cylinder is inclined and placed at an angle of 5° to the ground, which is convenient for discharging.

Applications of river sand dryer

After drying, materials are widely used in construction, chemical industry, casting, metallurgy, and other industries. Such as various sands in the dry powder mortar industry; small-grained clay in the building materials and cement industry; heat-resistant and dust-proof materials in the chemical industry.

FTM Machinery sand dryer

The following are the particle size and drying temperature of normally dried materials:

| Common materials | Particle size | Drying temperature |

| River sand | 4–20 mm | 80–180°C |

| Quartz sand | 0.6–4 mm | 60–80°C |

| Limestone | 16–32 mm | 150–400°C |

| Aggregate | 4–32 mm | 250–750°C |

| Bauxite | 4–8 mm | 250–850°C |

| Clay | 0.2–1 mm | 50–150°C |

River sand dryer price

River sand dryer price is a concerning issue for many customers, but due to various factors, the price can change. Factors that affect the price of dryers:

-

1Yield factor

Different purchasers have different output requirements for drying equipment, ranging from 1.9–65 t/h. The higher the output, the higher the performance requirements of the equipment and the higher the price. -

2Model size

There are many models of sand dryers, and the price of different types of dryers is different. In general, the price of large machines will be higher than the price of small machines. -

3Production cost

The main material of the river sand dryer is steel, and steel price directly affects the manufacturing cost of the sand dryer. -

4Market demand

The fluctuating market demand is also a factor in the unstable price of river sand dryers.

FTM Machinery can independently develop and produce various dryers with complete models, which can effectively control production costs. Therefore, the price of FTM Machinery sand dryers is more reasonable and cost-effective, which greatly reduces the investment cost of users.

FTM Machinery river sand dryer price: Get the Latest Price

Components of river sand dryer

River sand dryer is simple in its structure and mainly divided into 4 parts:

Drum body

The drum body is the main part of the sand dryer, equipped with the feed and discharge cases and sealing gaskets. The spiral plates are welded in the feed port, the lifting blades are equipped in the drum body, and the blocking ring is welded in the discharge port.

Support system

The support system consists of rollers, catch wheels and riding wheels, etc. The rollers are placed around the barrel and rotate along with it. The riding wheels support the barrel, while catch wheels prevent the barrel from displacement.

Transmission system

The transmission system includes big gear, pinions, motor, and gear reducer. The drum body is driven by the motor through a triangular belt, gear reducer, pinions, and big gear.

Thermal system

The thermal system is mainly divided into two types: thermal cotton and galvanized thermal plate. The thermal cotton is made of basalt, dolomite, and binder by high-temperature melting.

Drying process auxiliary equipment

The drying production line is composed of a feeder, conveyor, ID fan (induced draft fan), air heating furnace, and cyclone dust collector. According to user needs, FTM Machinery can provide you with belt conveyors, quantitative feeders, supporting elevators, dust collectors, etc.

Performance advantages of river sand dryers

1. Strong wear-resistance

The main wear parts of the dryers are the drum body and the lifting plates. They are made of wear-resisting manganese plates, which is 3–4 times the wear resistance of ordinary steel plate. The machines use wear-resistant materials, which improve the service life and reduce the maintenance cost.

2. High drying efficiency

The initial moisture content of the material is 15%, and the final moisture is guaranteed to be 0.5–1% or less. It is the first-choice product for drying projects. Stainless steel gaskets are used for sealing at both ports, which can efficiently prevent heat from escaping, and improve the utilization of the hot gas and the drying efficiency.

3. Stable performance

The sand dryers adopt a unique internal structure, which effectively avoids materials sticking to the inner plate. Robust stainless construction requires less maintenance and reduces wear on internal parts, making them more stable in operation.

4. Reliable cooling system

The discharge temperature of the environmentally friendly sand dryers is not higher than 60℃, and they can be directly fed into the material warehouse. The system can prevent the discharge of hot or wet sand under abnormal conditions.

5. Small floor area

Compared with the single-cylinder dryers, the river sand dryers reduce the floor area by about 40%. They are rotary drum horizontal loading machines, which occupy a smaller area while keeping the output unchanged.

6. Better fuel combustion

The sand dryers can burn natural gas, liquefied gas, diesel, methane, biomass pellets, and other fuels, without air leakage. Drying cost is reduced due to more complete combustion of the fuel.

What affects river sand dryer efficiency?

1. Heat source

If the heat source is different when drying sand, the temperature in the furnace is different, resulting in different airflow temperatures in the dryer. If the temperature is too low, the drying time is long, and the output of the equipment will also be affected.

2. Cylinder rotation speed

Generally speaking, the rotation speed of the cylinder determines the drying time of the product. The faster the rotation speed, the faster the materials move inside and are discharged from the cylinder.

3. Degree of moisture

The humidity of materials affects the drying rate of the river sand dryer, so it is generally not suitable to transport fluid materials into the drying equipment. If it contains too much water, a filter press can be installed before the dryer, which can remove a lot of water and improve the working efficiency of the later process.

4. Evaporation intensity of materials

Different materials have different evaporation intensities, which will affect the drying efficiency. The greater the evaporation intensity of the material, the higher the efficiency of the dryer.

Some materials' evaporation intensity

| Materials | Evaporation intensity | Materials | Evaporation intensity |

| River sand | 80–120 | Wood chips | 30–35 |

| Silica sand | 80–100 | Saw dust | 30–60 |

| Pyrites | 40–60 | Slag | 35–55 |

| Coal | 35–40 | Limestone | 40–60 |

| Phosphorite | 44–50 | Gypsum | 30–35 |

| Kaolin | 50–55 | Kieselguhr | 50–60 |

Why do I choose FTM Machinery sand dryer?

1. Production advantage: River sand dryer uses high-quality supporting equipment to ensure the service life of accessories and reduce the production cost for customers. Various types of sand dryers are produced to fully meet the customer's demand for output.

2. Technical advantages: We have professional engineers of sand drying machines, and research advanced production technology, which fully guarantees the quality of the dryers.

3. Scale advantage: FTM Machinery is a large-scale manufacturer of dryers, with a professional production team and workshop. Products are exported to the United States, Britain, Russia, Pakistan, Kenya, and other countries.

4. Service advantages: We can provide 24-hour service, complete drying solutions, and after-sales processing, and have more than 30 years of experience in the manufacture of dryers.Contact our engineers

FTM Machinery customer case in Indonesia

In January 2021, a customer from Indonesia contacted the customer service staff of FTM Machinery, hoping that we could provide him with a set of river sand dryer equipment. According to the data and information provided by the customer, the technician gave suggestions on appropriate drying equipment.

The specific data is as follows:

- Processing materials: River sand

- Initial humidity: 8–10%

- Final humidity: 1%

- Production capacity: 76 t/h

- Maximum temperature: 800°C

- Auxiliary equipment: Feeder, feed conveyor, discharge conveyor, induced draft fan, hot blast stove, and cyclone.

- Customer's feedback: The production line has a high heat utilization rate and less heat loss. And the whole drying process adopts automatic operation mode, saving a lot of labor costs.

Parameter

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |