The advantages and description of lignite dryer

Under the unchanged condition of the quality of dried lignite, lignite dryer adopts low temperature four class drying process to make the moisture content of lignite evaporated be below 13%.

It has the advantages of minimizing drying cost, maximizing safety of drying production, good quality of drying finished product, heavy drying strength, high drying efficiency, etc.

Drying display of lignite dryer

The performance characteristics of lignite dryer

- It reduces land area by 60% than single drum dryer. Thus, civil construction investment can be reduced by 60%. This tripe-pass dryer is very easy to be installed.

- No air-leakage solves the problem of sealing.

- Output material is lower than 60 centigrade, which is no need to be cooled after drying.

Drying process

Features

Minimizing drying cost, maximizing safety of drying production, good quality of drying finished product, heavy drying strength, high drying efficiency, etc.

Lignite dryer

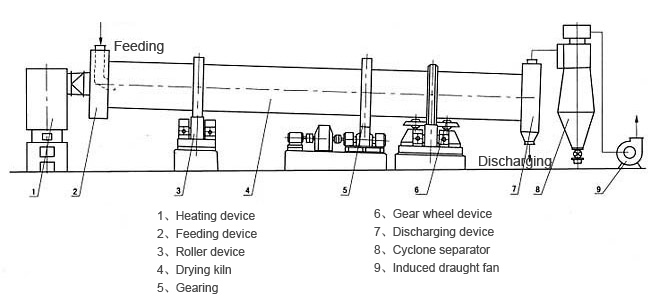

Working process

Lignite, coal ash and other materials are sent into feeder through the conveyor belt, and the coal ash is sent into drying roller through the feeder.

With the ruffle of uniformly distributed board device in drying roller of lignite drying machine, the coal ash is evenly contacted with hot air to transfer heat and is perfectly dried.

The dried coal ash is discharged into finished products via shredder at the end of the roller, and the dried products are discharged by the belt discharging machine.

Parameter

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

Installation

Obliquity (%) |

Highest Inlet

Air Temperature (℃) |

Main Motor

(kw) |

Weight

(t) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

3~5

|

700~800

|

7.5

|

9

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

3~5

|

700~800

|

7.5

|

11

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

3~5

|

700~800

|

15

|

18.5

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

3~5

|

700~800

|

15

|

19.7

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

3~5

|

700~800

|

15

|

20.5

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

3~5

|

700~800

|

18.5

|

21.5

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

3~5

|

700~800

|

18.5

|

23

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

3~5

|

700~800

|

22

|

33.5

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

3~5

|

700~800

|

22

|

36

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

3~5

|

700~800

|

22

|

38

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

3~5

|

700~800

|

37

|

45

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

3~5

|

700~800

|

37

|

49

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

3~5

|

700~800

|

45

|

54

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

3~5

|

700~800

|

45

|

58

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

3~5

|

700~800

|

55

|

73

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

3~5

|

700~800

|

75

|

85

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

3~5

|

700~800

|

75

|

95

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

3~5

|

700~800

|

90

|

110

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

3~5

|

700~800

|

160

|

135

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell Length (m) |

Shell cubage (m³) |

Shell obliquity |

Lifting blade form |

Highest inlet air temperature (℃) |

Dimensions (m) |

| Φ1.5×15m | 1500 | 500 | 15 | 20.27 | 3-5% | Lifting form | 850 | 16.2×2.7×2.7 |

| Φ1.5×17m | 17 | 22.97 | 18.2×2.7×2.7 | |||||

| Φ1.5×19m | 19 | 25.68 | 20.0×2.9×2.9 | |||||

| Φ1.8×21m | 1800 | 650 | 21 | 35.91 | 3-5% | Lifting form | 850 | 22.5×2.7×2.7 |

| Φ1.8×23m | 23 | 39.33 | 24.5×2.9×2.9 | |||||

| Φ1.8×25m | 25 | 42.75 | 26.5×2.9×2.9 | |||||

| Φ2.2×21m | 2200 | 800 | 21 | 58.10 | 3-5% | Lifting form | 850 | ---- |

| Φ2.2×23m | 23 | 63.61 | ||||||

| Φ2.2×25m | 25 | 69.15 |

|

Spec./m

(Dia.×Length) |

Shell Cubage

(m³) |

Capacity

(t/h) |

|

Φ1.2×8.0

|

9.0

|

1.9~2.4

|

|

Φ1.2×10

|

11.3

|

2.4~3.0

|

|

Φ1.5×12

|

21.2

|

4.5~5.7

|

|

Φ1.5×14

|

24.7

|

5.3~6.6

|

|

Φ1.5×15

|

26.5

|

5.7~7.1

|

|

Φ1.8×12

|

30.5

|

6.5~8.1

|

|

Φ1.8×14

|

35.6

|

7.6~9.5

|

|

Φ2.2×12

|

45.6

|

9.7~12.2

|

|

Φ2.2×14

|

53.2

|

11.4~14.2

|

|

Φ2.2×16

|

60.8

|

13.0~16.2

|

|

Φ2.4×14

|

63.3

|

13.5~16.9

|

|

Φ2.4×18

|

81.4

|

17.4~21.7

|

|

Φ2.4×20

|

90.4

|

19.3~24.1

|

|

Φ2.4×22

|

99.5

|

21.2~26.5

|

|

Φ2.6×24

|

127.4

|

27.2~34.0

|

|

Φ3.0×20

|

141.3

|

30.1~37.7

|

|

Φ3.0×25

|

176.6

|

37.7~47.1

|

|

Φ3.2×25

|

201

|

42.9~53.6

|

|

Φ3.6×28

|

285

|

60.8~76.0

|

Technical parameters of indirect heat dryer:

| Shell diameter ×shell Length Items |

Inside diameter of outer shell (mm) |

Inside diameter of inner shell (mm) |

Shell cubage (m³) |

| Φ1.5×15m | 1500 | 500 | 20.27 |

| Φ1.5×17m | 22.97 | ||

| Φ1.5×19m | 25.68 | ||

| Φ1.8×21m | 1800 | 650 | 35.91 |

| Φ1.8×23m | 39.33 | ||

| Φ1.8×25m | 42.75 | ||

| Φ2.2×21m | 2200 | 800 | 58.10 |

| Φ2.2×23m | 63.61 | ||

| Φ2.2×25m | 69.15 |