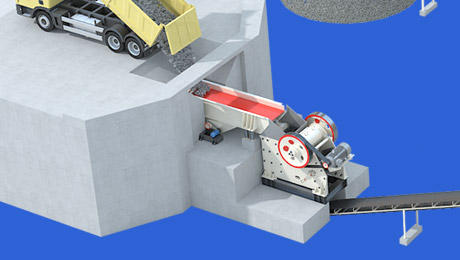

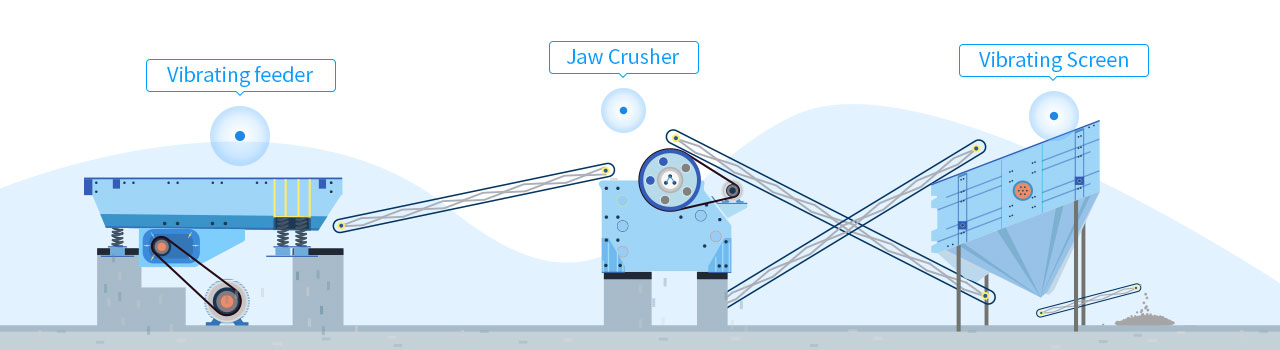

Mini (5 TPH) stone crusher plant in Pakistan

![]() Video

Video

- Capacity: 5 TPH

- Raw material: Limestone

- Estimated investment: $ 6,700-$ 7,800

| Raw material hardness | Soft |

| Feeding size | ≦200 mm |

| Type of production line | Fixed |

| Floor area | About 50*5 m |

| Types of finished products | 1 |

| Finished product specifications | 0-24 mm |

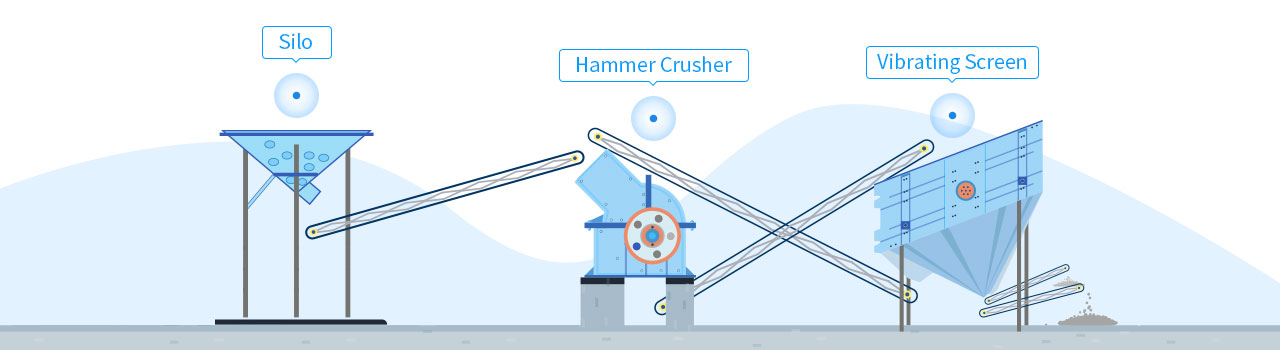

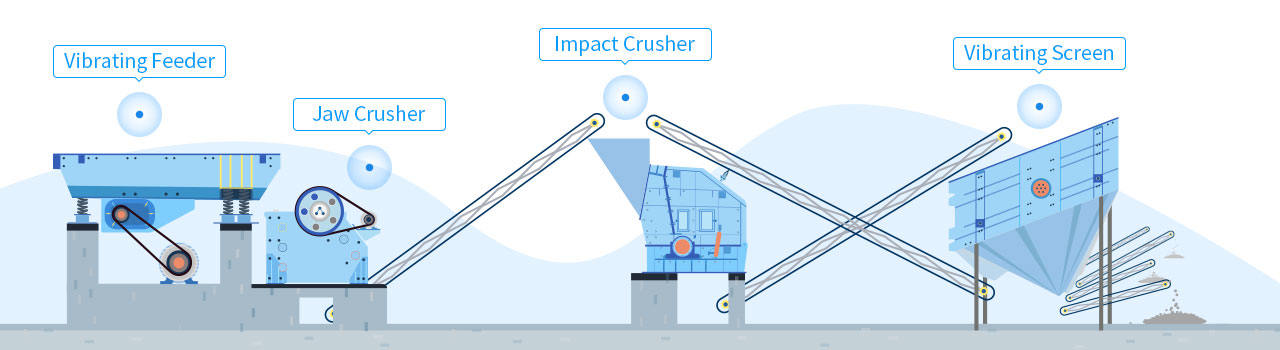

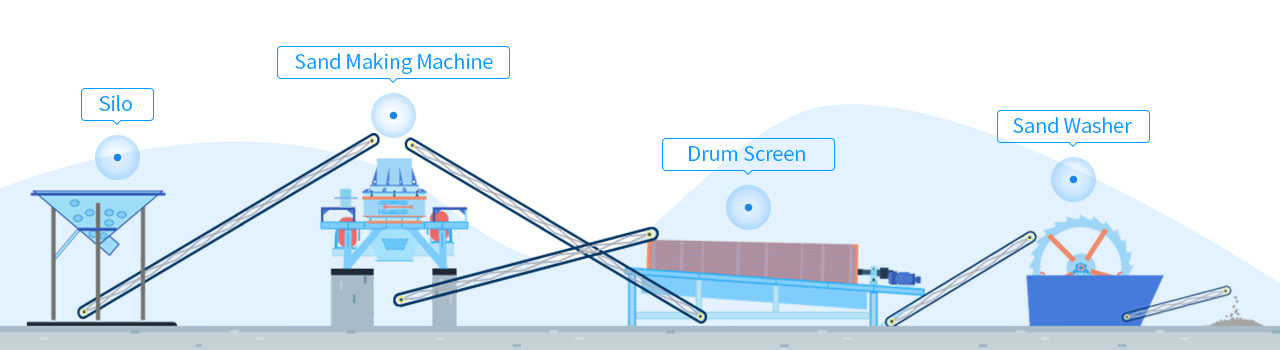

Stone crusher plant machine: Silo, GZ2 electro-vibrating feeder, PE250×400 jaw crusher, B500×22 m belt conveyor, B500×15 m belt conveyor, B500x16 m belt conveyor, 2YK1225 vibrating screen, B500x10 m belt conveyor.