FTM Machinery specializes in gravity, magnetic, and flotation separation, efficiently extracting high-grade concentrates from raw ores by recovering valuable metals like gold and copper.

We Process Most Minerals

FTM Machinery mineral processing equipment can recycle and process various materials:

• Metal ores: Gold ore, hematite, magnetite, copper ore, chromium ore, lithium ore, manganese ore, bauxite, galena, tungsten ore, tin ore, nickel ore, molybdenum ore, cobalt ore, etc.

• Non-metallic ores: Limestone, dolomite, barite, apatite, graphite, wollastonite, marble, garnet, fluorite, feldspar, clay, talc, etc.

• Others: Granite, coal, cement, ceramics, potash fertilizer, refractory materials, etc.

Before the mining and mineral processing of gold, lithium, or other rocks, we offer free mineral testing to help you quickly identify and maximize mineral grade and concentration.

Mineral processing plant

We Help You Design the Best Mineral Processing Plant

With over 40 years of experience, FTM Machinery customizes mineral processing plants, offering full equipment, spare parts, and troubleshooting services to maximize output. Our comprehensive engineering and after-sales services ensure worry-free operation.

Our popular mineral processing plants:

- 10 Best Ore Beneficiation Plants

- Gold Processing Plant and Machines

- Lithium Ore Processing

- Extraction of Copper

- How to Process Manganese Ore?

- Chrome Processing Plant

- How to Process Dolomite Rock?

- Iron Extraction from Hematite

- How to Process Alluvial Tin Ore in Indonesia?

- How to Process Tungsten Ore?

Mineral Processing Equipment for Sale

After stone crushing process, choose our mineral processing equipment for efficiency, minimal downtime and long service life—all at an affordable price. Achieve high-grade concentrates through effective grinding, screening, ore beneficiation, and dehydration.

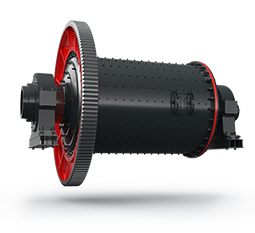

1. Grinding Equipment

Grinding equipment is the key equipment for grinding materials like iron ore after crushing process. It can reduce the particle size by dry or wet grinding.

- Applicable materials: Metal ores, non-metallic ores, cement, fertilizers, silicate products, building materials, refractory materials, ceramics, glass, and other non-flammable and explosive materials.

- Grinding medium: Ceramic balls and steel balls

- Grinding type: Dry grinding and wet grinding

- Feed size: <25 mm

- Output size: 0.074–0.89 mm (20–200 mesh)

- Loading capacity: 1.1–208 tons/hour

- It prevents iron pollution and is especially suitable for grinding glass and ceramics.

- The grinding medium is ceramic grinding balls (white aluminum balls) with a diameter between 0.5–120 mm.

- Feeding capacity: 0.05–15 tons/time

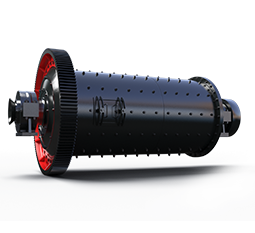

③ Rod Mill

- Similar to a ball mill but uses steel rods for coarse grinding or as the first stage in two-stage grinding.

- Ideal for brittle, low-hardness materials, such as rare metal ores (e.g., tungsten ore, tin ore), gold ore, iron ore, copper ore, quartz, feldspar, coal, glass, construction waste, cement clinker, fertilizer, etc.

- The maximum feed size is 50 mm. The capacity reaches180 tons/hour, with an output size of 20–100 mesh (0.833–0.147 mm).

- The grinding balls include forged grinding steel balls and cast grinding steel balls.

- Ball size: Small steel balls (40 mm or 60 mm), medium balls (80 mm), large steel balls (100 mm or 120 mm), and super large balls (130 mm to 150 mm).

- ball proportion: Large, medium, and small balls are required for proportioning. Click to see the ball proportion.

2. Screening and Classification Equipment

The screening/sizing machine can screen materials of different particle sizes. It has high screening efficiency and is not easy to get clogged.

- Applicable materials: Slag, coal gangue, quartz sand, topsoil, gravel aggregate, and other sticky materials.

- Feed size: 50–150 mm

- Capacity: 2 mm screen can process 4–35 t/h. 30 mm screen can process 16–175 t/h, suitable for large-scale production.

- Price: $15,620/set (the lowest price)

- Applicable materials: Iron ore, tin ore, tungsten ore, tantalum ore, niobium ore, and other small and heavy materials.

- Capacity: 15–48 t/h

- Price: $2,000/set (the lowest price)

- Classifying minerals and fine muds as well as desliming and dewatering.

- Type: Single spiral classifier and double spiral classifier

3. Mineral Separation Equipment

Mineral separation equipment uses various ore dressing methods to concentrate and grind minerals into fine powders:

• Magnetic separation: Separates magnetic minerals with or without water.

• Flotation separation: Using chemicals to remove impurities or extract minerals.

• Gravity separation: Separating minerals economically based on their specific gravity.

- Mainly used for dry and wet magnetic separation of iron ores, such as magnetite, hematite, ilmenite, chromite, pyrrhotite, roasted ore, coltan, etc.

- Also used for iron removal and purification from other minerals, such as manganese ore, rutile, quartz, feldspar, kaolin, coal, etc.

- Maximum feed size: 3 mm

- Capacity: 10–280 tons/hour

- More efficient than other beneficiation methods in processing fine-grained lean ores, and requires the addition of reagents.

- Almost all minerals can be floated, such as copper ore, gold ore, iron ore, lithium ore, lead-zinc ore, nickel ore, fluorite, molybdenum ore, barite, antimony ore, feldspar, phosphate ore, aluminum ore, quartz, etc.

- Production capacity calculated by slurry volume: 0.18–38 m³/min

- Effective cubage: 0.35–38 m³

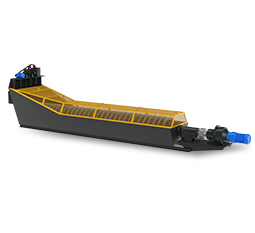

- It is the most widely used gravity separation equipment, using mechanical vibration and water washing to separate minerals of different densities from each other.

- It consumes no medicine and little power.

- Applicable materials: Coal, metal ores (gold ore, chrome ore, tin ore, tungsten ore, tantalum ore, niobium ore, etc.), non-metallic ores (talc, limestone, garnet, etc.), and other minerals with large differences in ore density.

- Feed size: 0.15–2 mm

- Feeding amount: 10–60 tons/day

- Bed surface water quantity: 10–150 tons/day

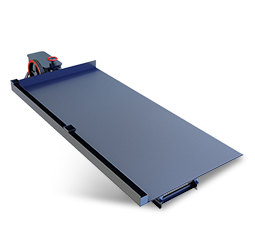

- Specially used for placer mining on seashores, riversides, sand beaches, and streams.

- Applicable materials: Coal, gold ore, iron ore, mineral sand, chromite ore, ilmenite, pyrite, platinum ore, zircon, rutile, monazite, tungsten ore, tin ore, tantalum ore, and other minerals with large density differences.

- Feed size: 0.02–0.3 mm

- Capacity: 2–40 t/h

4. Equipment for Ore Concentration and Dewatering

The minerals and their tailings after the beneficiation method are concentrated and dehydrated to obtain the final concentrate product.

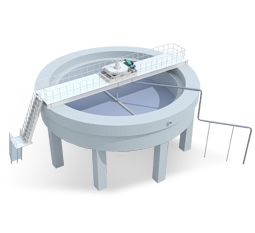

① High Efficiency Concentrator

- Price: $15,620/set (May vary)

- Removing moisture from concentrates and tailings in ore dressing plants, and recycling water for ore dressing.

- Increasing slurry concentration to 40–70%, helping clean production.

- Capacity: 5.6–3,030 t/d

5. Auxiliary Equipment

① Mixer

- Ideal for mixing materials and reagents before mineral processing, particularly in flotation separation, and for blending ingredients in various chemical industries.

- Applicable materials: Quartz, gold ore, carbon black, hematite, limonite, molybdenum ore, gold ore, iron ore, etc. (concentration can reach 30%, particle size within 1mm)

- Effective cubage: 0.58–135.4 m³

- Rotate speed: 24.4–390 r/min

- Applicable materials: Fertilizer, coal powder, fly ash, clay powder, mineral powder (iron ore, limestone, limestone, gypsum, etc.), and other non-sticky powders.

- Feed size: no more than 50 mm

- Capacity: 4–24 tons/hour

- The granulation rate is as high as over 95%, and 90% of the particles are 3–5 mm in diameter.