A rod mill is one of the best sold grinding mill types. It is similar to the ball mill, but uses the rotating grinding steel rods for coarse grinding or as the first stage of a two-stage grinding process.

The rod mill offers high grinding efficiency, minimal over-grinding, and low costs. Its maximum feed diameter is 50 mm and its output size is 20–100 mesh (0.833–0.147 mm). The processing capacity can reach 180 tons per hour.

Applicable materials

Rod mills are widely used for low-hardness rocks, minerals, cement, silicate products, steel slag, building materials, refractory materials, fertilizers, glass, ceramics, and other materials.

1. Particularly suitable for grinding rare metal ores

Rod mills can grind various brittle materials, especially rare metal ores. In the gravity or magnetic separation plants for tungsten ore, tin ore, and other rare metal ores, rod mills are often used to prevent over-crushing.

2. Often used as the first-stage grinding

In a two-stage grinding process, rod mills are often used as the first-stage grinding equipment, providing coarse grinding of materials under 50 mm. They are then combined with ball mills or other fine grinding mills for fine grinding and ultrafine grinding.

3. Can replace the cone crusher for fine crushing

In some cases, the rod mill can replace short-head cone crushers for fine crushing. When processing soft or sticky rocks and ores like clay, rod milling is simpler and more economical than the closed-circuit crushing plant formed by the cone crusher and the vibrating screen.

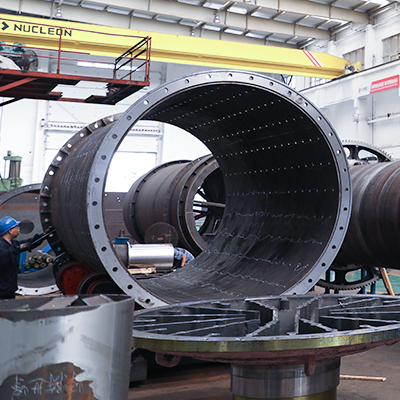

Rod mill diagram and working principle

This grinding mill mainly consists of the feeding device, rotary drum, grinding rod, large and small gears, and main bearing.

Feeding device

The feeding device is a shoe-shaped hopper, and the upper flange is connected with the feeding equipment to receive the fed material.

An inspection door on the back wall of the hopper can lead to a round tube and extend into the spiral barrel on the hollow shaft, guiding material into the mill.

Rotary drum

The rotary drum is a cylinder rolled and welded by the steel plates. A liner is arranged inside the drum to protect the rotary drum and lift steel rods to a suitable height.

The grinding drum contains the grinding steel rods. An acid and alkali resistant rubber pad is placed between the steel rod liner and the simplified end cover to reduce noise and vibration.

Grinding rod

The grinding media in the rod mill are 50–100 mm steel rods with a carbon content of 0.8% to 1%. The media fill rate is 35% to 45%. The length-to-diameter ratio of the rods is 1.5-2.0. This design ensures stable movement and reduces bending or breakage.

The grinding rods are made of high-carbon steel or 42CrMo steel. Both materials are wear-resistant, high-strength steels with a wear resistance 1.5 times greater than that of ordinary steel.

Large and small gears

The large and small gears are driven by helical gears with balanced work, small impact and long life.

It adopts spray lubrication and regular oil injection, which reduces the labor intensity of workers, has a good lubrication effect and reduces the consumption of lubricating oil.

Main bearing

The main bearing supports the weight of the rod grinding mill. The bearing bush rests on the spherical seat, allowing the self-defense function for the manufacturing and installation errors.

After the long-term work of the main bearing, the bearing bush will wear and tear, causing the hollow shaft to sink. The sealing bracket can be lowered to ensure the seal in good contact with the shaft.

Rod mill working principle

How does a rod mill work? Rod mill makes the mill run with the help of the reduction gears drove by dynamo or a low-speed synchronization electrical machine.

There are steel rods in the drum which are thrown at a certain high speed by centrifugal and friction force and then fall. The material to be ground continuously enters the cylinder and is crushed by the rotating rods into the desired powder.

FTM Machinery rod mills for sale

As a leading manufacturer of grinding mills, FTM Machinery has produced various models of rod mills. We have rich experiences, and the products are exported to the United States, Russia, Indonesia, South Africa, and other countries and regions.

The following are the technical parameters of the best-selling models:

| Model | Diameter(mm) | Length(mm) | Effective Volume(m3) | Max.Ball Loading(t) |

| MBS(Y)-1530 | 1500 | 3000 | 4.5 | 8 |

| MBS(Y)-2132 | 2100 | 3200 | 9.6 | 20 |

| MBS(Y)-2436 | 2400 | 3600 | 14 | 29 |

| MBS(Y)-3230 | 3200 | 3000 | 21 | 44 |

| MBS(Y)-3660 | 3600 | 6000 | 54 | 113 |

Why choose FTM Machinery rod mills?

1. High grinding efficiency, minimal over-grinding

A high crushing ratio ensures excellent grinding results. When the ore is ground by the steel rods, it is first crushed into coarse particles and then ground into fine particles, reducing the risk of over-grinding.

2. Adjustable discharge fineness

The rod mill is equipped with a fineness adjustment device and a discharge screening device, which operate simultaneously to adjust the discharge particle size according to user needs.

3. Uniform output particles

Rod mill changes the surface contact of the traditional ball mill to line contact. As the mill rotates, coarse particles are trapped between the rods for crushing, while fines pass through. This yields uniform, moderately fine powder with fewer over-crushed particles.

4. Low cost, eco-friendly

Simple configuration and easy operation. Low maintenance and approximately 50% energy savings compared to other grinding mills. Good sealing avoids dust and noise pollution to the environment. All of these save the customers many initial and maintenance costs.

Customer case

A Russian mineral processing company needed an efficient solution for grinding soft materials such as limestone and phosphate rock to produce the fine powders needed for its fertilizer production. After evaluating several options, the company chose our rod mill.

Project Information

- Location: Russia

- Industry: Cement and fertilizer production

- Materials: Limestone and phosphate rock

- Capacity: 80 t/h

- Feed particle size: ≤50 mm

- Discharge particle size: 5–10 mm

- Required equipment: Vibrating feeder, conveyor belt, jaw crusher, MBS(Y)-2436 rod mill

Customer feedback:

"The rod mill works efficiently and reliably. It produces a uniform particle size, is easy to operate, and has noticeably reduced our energy costs. We are very satisfied with its performance and the support we received from the supplier."

Frequently asked questions about rod mills

1. What are the differences between a rod mill and a ball mill?

- The main difference between a rod mill and a ball mill is the shape of their grinding media. Ball mills use spherical grinding media, while rod mills use rod-shaped grinding media.

- Secondly, a rod mill is a device between crushing and grinding. Its finished product is finer than crushing, but coarser than grinding.

- Thirdly, their shapes differ, with ball mills being thicker and shorter than rod mills.

- Finally, their internal media filling ratios differ: ball mills have a filling ratio of 40%-50%, while rod mills have a filling ratio of 35%-45%.

2. How much maintenance does a rod mill require?

- Rod mills are relatively low-maintenance; regular checks of the rods, liners, and bearings are sufficient to ensure stable operation.

3. Can rod mills handle wet or sticky materials?

- Rod mills can handle slightly moist materials, but very wet or sticky materials may require pre-drying to prevent clogging. The pre-drying can be done by a dryer machine.