What is a hammer crusher?

Hammer crusher is also called hammer mill, or hammer mill crusher. It is a crusher that uses a series of rotating hammers to crush materials (600–1,800 mm) into smaller pieces (below 25 or 25 mm).

The hammer crusher is very suitable for medium and fine crushing of medium-hard and brittle materials. It is known for providing greater crushing ratios in a variety of materials for the aggregate and industrial markets.

Applicable materials

Hammer crushers can be used for dry and wet crushing. This requires that the compressive strength of the materials

is less than 200 Mpa and that the water content is not more than 15%.

You can crush glass, limestone, concrete aggregate, coal, gypsum, bauxite, construction waste, cement clinker, slag, coke, phosphate, dolomite, river pebbles, marble, basalt, shale, etc.

Not sure whether your materials can be processed or not?Contact us for Free Sample Testing!

Application of hammer crushers

Many of our customers from the U.S., India, the Philippines, and Kazakhstan use hammer crushers as rock and limestone crushers. It has many other uses:

- Glass sand plants

- Ceramic production plants

- Highways and railways

- Buildings and municipal engineering

- Cement plants that crush and grind limestone, coal, gypsum, shale, and clay

- Chemical plants producing various carbonate powders

- Drywall manufacturers begin by cooking and milling gypsum

Why FTM Machinery hammer crushers?

As a leading hammer mill manufacturer, FTM Machinery has over 40 years of experience and refinement. Engineers have designed three series of hammer mills, which adopt the most advanced technology and scientific design to make your crushing easier.

If you are looking for reliable performance and a solid return on your investment, FTM Machinery hammer mills are the perfect answer for you.

- With large feed size, high productivity, and large crushing ratio (generally 10–25, even to 50), it is often used in large-scale and high-yield production lines.

- Scientific crushing cavity design and no sieve plate structure can reduce clogging and increase output by 1.4–1.6 times.

- It can reduce the cost by about 40% by one-time molding without primary and secondary crushing and shaping processes.

- The price is cheap. FTM Machinery's machine price is 10% lower than the market price.

- The discharging particle size is small, uniform, and cubic with less over-crushing.

- A variety of hammer sizes, models, and grate gaps are available for accurate final product sizes to meet the different needs of different users.

- Easy to operate. It can work continuously and reliably, saving energy and electricity. Besides, its wearing parts are easy to repair and replace, and the maintenance cost is low.

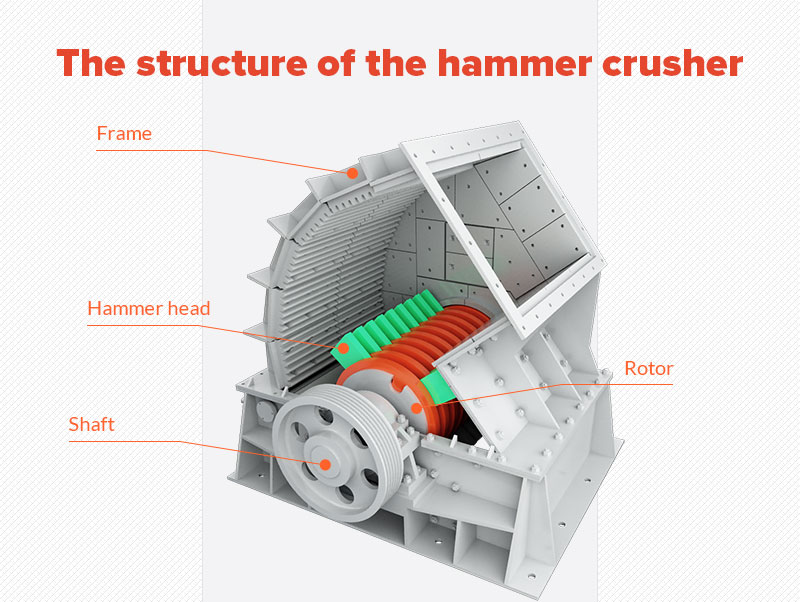

The structure of the hammer crusher

The hammer crusher has a simple and compact structure designed for superior operation and a long lifespan. It is easy to operate and maintain and has high wear resistance.

A hammer mill crusher is mainly composed of the frame, rotor, hammer head, main shaft, and other components.

1. Frame

The inner wall of the hammer mill is inlaid with wear-resistant steel lining plates. The impact plate is replaceable when worn.

Bearing supports are installed on the left and right-side walls for placing carbon steel welded bearings and supporting the rotor. The base of the frame is directly placed on the concrete foundation, with anchor bolts.

The left and right-side walls and the rear cover are welded with steel plates. To prevent dust leakage, a shaft sealing device is installed where the frame contacts the shaft.

2. Rotor

The rotor is the main working part of the crusher, which consists of the rotor shaft and hammer head.

The motor drives the rotor directly through the elastic coupling. Then the materials are crushed due to the impact of the hammer on the crushing plate caused by the rotor rotation.

By adjusting the rotor speed, you can change the output size.

3. Hammer head

The hammer head, also known as the crusher hammer, is the main wearing part of the hammer crusher.

It is fixed on the rotor and crushes the material by impacting it. After crushing, the qualified materials are discharged from the grate bar.

The weight and material of the hammer head affect the capacity. Therefore, the hammer weight should be moderate (no more than 80 kg), and a good material should be selected.

The choice of the hammer head

| Types of hammer head | Features | Disadvantages |

| High manganese steel hammer head | Good toughness and wear resistance, low price, and wide application | If the impact force is insufficient or the contact stress is small, its wear resistance cannot be exerted |

| Low alloy steel hammer head | Less wear and tear, and longer service life than high manganese steel | Complicated technology |

| High-chromium iron hammer head+high manganese steel or carbon steel hammer handle | Good wear resistance of hammer head and high toughness of hammer handle | Complicated technology |

FTM Machinery uses the third type of hammer head, the high-chromium iron hammer head. This type of hammer head uses a chromium alloy containing 20%-27% chromium and is cast with new technology. Therefore, it has a low problem rate and long service life.

Check the hammer regularly. Once worn enough, turn it over and use it on the other side. The worn hammer can be welded with a wear-resistant electrode to restore it. The weight of the replacement hammer head should be as equal as possible, and the deviation should be less than ±0.1 kg.

4. Main shaft

The main shaft is part of the hammer mill supporting the rotor.

The mass of the rotor and hammer head, as well as the impact force and torque generated during rotation, are borne by the main shaft.

Therefore, the main shaft needs to have high strength and toughness, and FTM Machinery adopted the high manganese steel forgings.

In addition, FTM Machinery has also designed a dust seal and overload protection devices to ensure the environmental protection and reliability of the crushing process.

How does a hammer mill work?

The working principle of the hammer mill is to crush materials by the impact energy of the high-speed rotating hammer head.

When working, the motor drives the rotor to rotate at a high speed, and the materials are evenly sent into the crushing cavity. The high-speed rotating hammer heads impact and crush the minerals. The crushed materials rush to the impact plate and grate bar at high speed. At the same time, the materials impact each other and are crushed many times.

After that, the materials smaller than the size of the grate gap are discharged. The grate gap determines the final product size, any remaining material continues to be crushed until it is discharged.

Models of FTM Machinery hammer crushers

Hammer crushers

The normal hammer crushers are mainly PC series, used for small-scale production with low cost. The maximum feed size is 300 mm and the maximum capacity is 95 t/h.

PC Hammer Crusher is known for crushing glass, coal, concrete stone, and road rocks.

Hot Sale Models of PC Hammer Crushers:

- PCΦ400×300, PCΦ600×400: Small hammer mills with small power consumption and low cost.

- PCΦ1000×800, PCΦ1000×1000: Hammer mills with a large capacity and high efficiency.

Heavy hammer crushers

Heavy hammer crushers are an upgraded version of the PC Hammer Crushers, providing PCX and PCZ series. They are specially designed for large and medium production lines.

PCZ Heavy Hammer Crusher combines the advantages of the jaw crusher, hammer crusher, and impact crusher. It has a larger input size ((≤1,000 mm) and greater capacity (≤3,000 t/h).

PCX Heavy Hammer Crusher has a smaller feed size (≤300 mm) and smaller capacity(≤1,200 t/h), but a finer output size (≤40 mm). It is an all-in-one crushing and shaping machine, which is used as a secondary crushing and shaping machine in large-scale production lines.

Portable hammer mills

All the hammer mills can be designed as mobile models according to user needs. They can be operated by one person, flexible and convenient.

Frequently asked questions about the hammer crushers

1. Differences between the hammer crushers

- In terms of applicability and principle, there is almost no difference between the three models of hammer crushers, except the differences lie in the following two aspects.

- a. Different positions in the production line. As the large feed inlet of the heavy hammer crusher, it is often used for coarse crushing. In projects, especially in large-scale crushing production lines, PC Hammer Crushers are often used in conjunction with heavy hammer crushers for medium or fine crushing.

- b. Different hammer performances. The hammer head of the heavy hammer mill is heavier, generally higher than 20 kg, so it has a larger crushing ratio and higher efficiency. The PCZ hammer crusher has the largest capacity, while the PCX hammer crusher has finer products, with a good shaping effect.

2. What factors affect the output of a hammer crusher?

- a. The hardness of the processed materials. The hardness of the crushed materials must be within the crushing range of the hammer stone crusher.

- b. The humidity of processing raw materials. If the humidity of the raw materials is too high, there may be a bonding phenomenon when the hammer crusher works and the particle size of the finished product will not be uniform.

- c. System capability. The improper installation of the spare parts may result in insufficient production capacity of the whole system.

- d. Feeding. The feeding should be uniform and the amount of feeding should be appropriate.

- e. Hammer head of the hammer crusher. The wear of hammer head not only affects the production capacity and output particle size of hammer crusher, but also accelerates the wear of equipment.

3. How to adjust the finished product size?

- The output size depends on a few variables of the crusher: the number and size of hammers; the rotor speed; the settings of the grinding plate; the size of the openings in the perforated screens.

- The industrial hammer mill is often used for crushing and grinding material to particles smaller than 10 US mesh. Learn more about Size Reduction.

4. What do we use first, the hammer mill or the jaw crusher?

- It depends on two factors, one is the properties of your materials, especially the level of silica. The other is the input size and output size of your materials.

- If your materials have smaller input and low hardness (silica levels under 40%), you can use only the hammer mill. If your materials are very big and hard, a jaw crusher is ideal for coarse crushing.

Customer case—FTM Machinery heavy hammer crushers sold to Zimbabwe

| Project | Quartz stone crushing and screening production line |

| Project location | Zimbabwe |

| Raw materials | Quartz stone |

| Capacity | 600 TPH |

| Types of the production line | Fixed |

| Feed size | ≤1,200 mm |

| Finished products specification | 0–3 mm, 5–10 mm, 20–30 mm |

| Quatz stone crushing equipment | PCZ1716 Heavy Hammer Crusher, PCZ1213 Heavy Hammer Crusher,ZSW600×150 Vibrating Feeder,Vibrating Screen,Belt Conveyor, etc. |

| Estimated cost | $220,000–$265,000 |

- Simple and reasonable production line configuration. The heavy hammer crusher is a one-time forming crusher that can realize the coarse and medium-fine crushing and shaping of quartz stone without sand making machine.

- Cost-saving. The quartz stone crushing line is mainly composed of two heavy hammer crushers and auxiliary equipment, which simplifies the process and saves costs.

- High-quality finished products. Equipped with heavy hammer crushers, the product has a good grain shape with fewer edges and low powder content, realizing precise processing of quartz.

- Heavy hammer crushers, same as other crushing equipment, should be equipped with iron removal equipment to ensure the safe operation of the equipment.

- The water content of the feeding material should be controlled below 12% to avoid blockage.

- During the replacement of toothed and smooth hammer heads, each piece should be weighed. The total weight error of the two groups of symmetrical hammer heads should be controlled within 0.1 kg.

- Frequently check the wear of the hammer head and adjust the adjustment mechanism in time.

Parameter

- PC Hammer Crusher

- PCZ Heavy Hammer Crusher

- PCX Heavy Hammer Crusher

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

Note: Capacity May Vary with Different Materials and Feed Sizes.

| Specification | Capacity(t/h) | Power (kw) |

| PC 400×300 | 3-10 | 4P 11 |

| PC 600×400 | 6-22 | 4P 22 |

| PC 800×600 | 10-40 | 4P 55 |

| PC 1000×800 | 15-50 | 4P 75 |

| PC 1000×1000 | 18-75 | 4P 90 |

| PC 1200×1200 | 22-95 | 4P 132 |

Note: Capacity May Vary with Different Materials and Feed Sizes.

| Model | Rotor diameter×length (mm) | Feed Opening Length×width(mm) | Feeding Size (mm) | Processing Capacity(t/h) | Power (kw) | Dimensions L×W×H (mm) |

| PCZ1308 | Φ1330×790 | 870×780 | ≤380 | 60-160 | 132 | 2880×2130×2390 |

| PCZ1410 | Φ1400×1000 | 1060×740 | ≤450 | 80-210 | 2×90(160) | 2830×2100×2485 |

| PCZ1610 | Φ1600×1000 | 1090×930 | ≤480 | 100-230 | 2×132 | 3370×2415×2750 |

| PCZ1612 | Φ1600×1200 | 1340×1140 | ≤500 | 120-350 | 2×160 | 3370×2613×2750 |

| PCZ1615 | Φ1600×1500 | 1570×1140 | ≤550 | 200-550 | 2×200 | 3370×2925×2750 |

| PCZ1716 | Φ1700×1600 | 1420×1200 | ≤600 | 400-850 | 2×250 | 3520×3000×3210 |

| PCZ1720 | Φ1700×2000 | 2030×1200 | ≤650 | 500-1000 | 2×400 | 3670×3390×3330 |

| PCZ1920 | Φ1900×2000 | 1980×1210 | ≤750 | 800-1500 | 2×500 | 4490×3910×3600 |

| PCZ2225 | Φ2200×2500 | 2530×1610 | ≤1000 | 1500-3000 | 1250 | 4890×5010×4560 |

Note: Capacity May Vary with Different Materials and Feed Sizes.

| Model | Feeding Size (mm) | Processing Capacity(t/h) |

| PCZ1308 | ≤380 | 60-160 |

| PCZ1410 | ≤450 | 80-210 |

| PCZ1610 | ≤480 | 100-230 |

| PCZ1612 | ≤500 | 120-350 |

| PCZ1615 | ≤550 | 200-550 |

| PCZ1716 | ≤600 | 400-850 |

| PCZ1720 | ≤650 | 500-1000 |

| PCZ1920 | ≤750 | 800-1500 |

| PCZ2225 | ≤1000 | 1500-3000 |

Note: Capacity May Vary with Different Materials and Feed Sizes.

| Model | Rotor diameter×Length(mm) | Feed Opening Length×Width(mm) | Feeding Size(mm) | Processing Capacity(t/h) | Power(kw) | Dimensions(L×W×H)(mm) |

| PCX 0706 | 700×570 | 618×510 | ≤150 | 30-70 | 75 | 1950×1340×1480 |

| PCX 0808 | 800×750 | 780×610 | ≤150 | 45-100 | 132 | 2280×1790×1570 |

| PCX 0910 | 900×1000 | 1070×750 | ≤200 | 70-200 | 2×110 | 2600×2200×1940 |

| PCX 1012 | 1000×1180 | 1315×900 | ≤200 | 130-300 | 2×132 | 2760×2430×2290 |

| PCX 1213 | 1260×1280 | 1430×1010 | ≤250 | 200-350 | 2×160 | 3067×2622×2580 |

| PCX 1216 | 1260×1490 | 1630×1010 | ≤250 | 230-500 | 2×200 | 3067×2832×2580 |

| PCX 1220 | 1260×1950 | 2090×1010 | ≤250 | 300-700 | 2×220 | 3067×3380×2580 |

| PCX 1622 | 1600×2150 | 2300×950 | ≤300 | 400-1200 | 2×315 | 4120×3680×3200 |

Note: Capacity May Vary with Different Materials and Feed Sizes.

| Model | Feeding Size(mm) | Processing Capacity(t/h) |

| PCX 0706 | ≤150 | 30-70 |

| PCX 0808 | ≤150 | 45-100 |

| PCX 0910 | ≤200 | 70-200 |

| PCX 1012 | ≤200 | 130-300 |

| PCX 1213 | ≤250 | 200-350 |

| PCX 1216 | ≤250 | 230-500 |

| PCX 1220 | ≤250 | 300-700 |

| PCX 1622 | ≤300 | 400-1200 |

Note: Capacity May Vary with Different Materials and Feed Sizes.