What is a portable crusher?

A portable rock crusher, also named wheeled mobile crusher or wheeled crushing plant, can be freely moved with the mining process. The most prominent feature of the portable crusher is the use of vehicle traction, which can be flexibly moved from one location to another.

The wheeled crushing station is a large-scale mobile crushing equipment designed by FTM Machinery, which can carry different types of main engines. Portable crushers are used in building materials, metallurgy, aggregate, mining, and recycling, especially in areas such as roads, railways, construction waste, etc. that require relocation of processed materials.

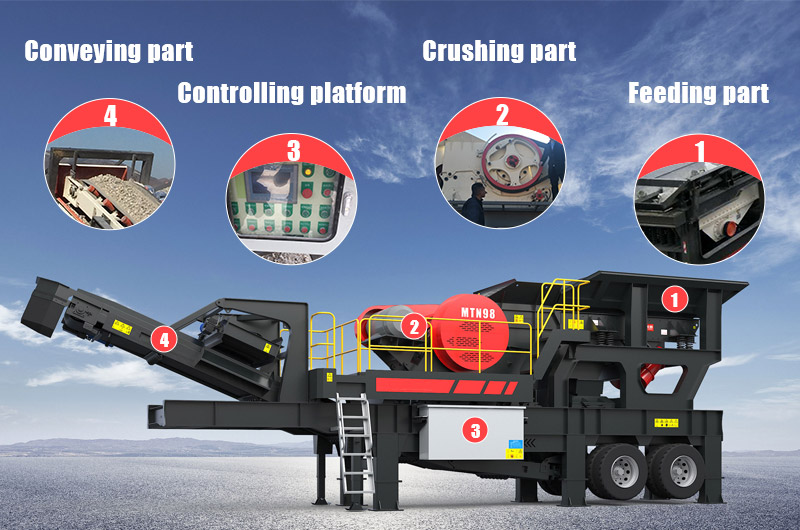

4 important modules of portable crusher

1. Feeding part

The feeding part is responsible for delivering the raw materials to the crusher chamber for processing. It typically consists of a vibrating feeder that extracts and regulates the flow of material into the crusher.

2. Crushing part

The core equipment in the crushing platform is the crusher machine, which is related to the processing capacity of the crushing system. The crusher type used in the portable machine can vary depending on the specific application and desired final product.

3. Controlling platform

In the control room, the operation of the crusher, feeder, and conveyor is controlled by PLC. Operators can know the operating voltage and current of each drive device, and can also timely oversee the material crushing process.

4. Conveying part

Conveying part is responsible for transmitting crushed material to the next crushing stage and hopper. It includes components such as conveyor belts, belt pulleys, and drive systems.

Types of portable rock crushers

1. Portable jaw crusher

A portable jaw crusher is used for the coarse crushing of materials, also called a wheeled jaw crusher plant. It has the characteristics of a large crushing ratio and deep crushing cavity, and it mainly crushes large rocks.

Matching method: Jaw crusher + feeder + conveyor belt + vehicle body

Common jaw crusher models: HD86, HD98, HD110, HD125

Maximum feed size: ≤800 mm

Output size: 50–225 mm

Capacity: 85–650 t/h

2. Portable cone crusher

A portable cone crusher is used for medium and fine crushing of materials, also called a wheeled cone crusher plant. It is suitable for crushing materials with small particle sizes and high hardness, often used as a secondary crusher after the jaw crusher.

Matching method: Cone crusher + vibrating screening machine + conveyor belt + vehicle body

Commonly cone crusher models: GYS300, GYS400, HP300

Maximum feed size: ≤190 mm

Output size: 3–51 mm

Capacity: 36–445 t/h

3. Portable impact crusher

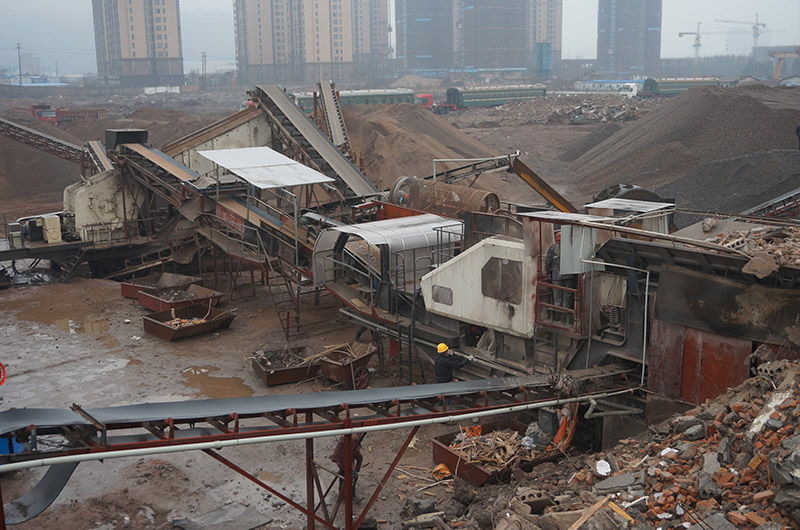

A portable impact crusher is a secondary crushing equipment, also called a wheeled impact crusher plant. Its most common application is the recycling of construction waste, which not only has a high output but also has a certain plastic effect.

Matching method: Impact crusher + vibrating screening machine + conveyor belt + vehicle body

Common impact crusher models: PF1210, PF1214, PF1315, HD1110, HD1315

Maximum feed size: ≤700 mm

Capacity: 70–280 t/h

Weight: 39–62 t

4. Portable sand maker

A portable sand maker is a professional sand making equipment, also called a wheeled vertical shaft impact crusher. It is used for fine crushing in the final stage of the crushing process, producing a precisely shaped cubic end product.

Matching method: Sand making machine + vibrating screening machine + conveyor belt + vehicle body

Common sand maker models: HVI0815, HVI0922, HVI1032

Maximum feed size: <45 mm

Capacity: 60–585 t/h

Weight: 31–49 t

For detailed portable mobile crusher parameters, please click here!

Why choose FTM Machinery portable crushers?

Portable rock crusher machines have the following performance advantages:

- Modular design: It adopts a modular and universal design, and each part is independent. The host can be replaced to realize the conversion between different models and shorten the delivery cycle.

- Unique integration: The fully automatic wheel mobile crushing station is composed of feeding, crushing, screening, conveying, and other systems to realize online integrated production.

- Foundation-free installation: Vehicle-mounted mobile does not need to build a large area of concrete foundation, reducing labor and lowering the requirements for the work site.

- Fully intelligent control: The equipment adopts PLC centralized control and a touchscreen display to detect the operation of the machine at any time. Equipped with an independent electronic control system, it is easy to operate.

- Convenient transition: The equipment is between 12-16 meters long, easy to move. The conveyor belt can be retracted and folded to reduce the high transportation cost of materials.

FTM Machinery portable rock crushers for sale: Get Discounted Price

Can FTM Machinery help you save costs?

Yes! FTM Machinery portable crusher machines can help you reduce your investment.

-

1Reduce transportation costs

A portable rock crusher can freely enter the crushing site and move flexibly according to the raw material mining progress. The material can be crushed on site, which can save transportation costs of 50% to 70%. -

2Reduce labor costs

Small footprint, low labor intensity, and intelligent control platform only need a few people in the project, thus greatly reducing labor costs. -

3Reduce costs of spare parts

There is no need for piling and building large-scale foundations, which greatly reduces the cost of spare parts.

Successful cases of FTM Machinery customers

80–100 t/h construction waste portable crusher in the Philippines

- Purchased equipment: FTM3S1860V09 portable rock crusher

- Configure machines: Jaw crusher + sand maker + vibrating screen + trommel screen + sand washing machine

- Transport length: 12,000 mm

- Maximum feed size: 350 mm

- Production capacity: 70–130 tons/hour

- Weight: 39 tons

Customer feedback

"The portable construction waste crusher provided by FTM Machinery ensured production efficiency and continuously reduced operating costs."

"I was very glad to see that there was no dust during the production process of the entire production line. Because of its free movement, it also reduced cement consumption cost, saving me a lot of money for the whole production cost."

300 t/h limestone portable rock crusher in Australia

- Purchased equipment: FTM3S216GYS400 portable cone crusher

- Configure machines: Jaw crusher + cone crusher + vibrating screen

- Transport length: 15,200 mm

- Maximum feed size: 800 mm

- Production capacity: 280–650 tons/hour

- Weight: 65 tons

Customer feedback

"Since I have bought these portable crushing machines designed by FTM Machinery with affordable prices, I was very satisfied with their performance. It not only has a reasonable configuration, but also very thoughtful after-sales service."

"The important thing is that it allows me to obtain considerable profits. My original plan was to recover the cost within two years, but now it seems that I can get the return within one year."

Frequently asked questions about portable crushers

1. Are portable rock crushers environmentally friendly?

- Compared to traditional stationary crushers, portable rock crushers can offer certain environmental benefits.

- a. Enhanced sealing: To ideally control dust flying and noise, experts enhance sealing to the parts which produce dust, and that's why a portable rock crusher can meet the international environmental standard.

- b. Install dust collector device: A pulse dust removal device is installed to collect dust, which can reduce the fine dust rate higher by 99%.

- c. Spray atomization device: Spray atomization devices are added to the feeding port, discharging port, and conveyor belt, which contributes to protecting the environment.

- d. Dural drive mode: A portable rock crusher can use city electricity or diesel to generate the machine, which makes the operation smooth even in the case of power failure or no electricity in the suburbs.

2. How to maintain my portable rock crushers?

- Proper maintenance is essential to ensure the efficient and reliable operation of a portable rock crusher.

- a. As per the professional's recommendations, regularly lubricate all moving parts and bearings of the crusher, reducing friction.

- b. Replace worn parts, such as crusher jaw plates, impact bars, or cone mantles, as needed to maintain the desired crushing performance.

- c. Examine conveyor belts for signs of wear, damage, or misalignment. Adjust or replace belts as necessary to maintain proper tension and prevent unexpected breakdowns.

- d. Inspect electrical connections, wires, and control panels. Tighten loose connections and repair any damaged electrical components to avoid electrical issues.

Parameter

- Portable Jaw Crusher

- Portable Impact Crusher

- Portable Sand Crusher

- Portable Cone Crusher

| Model | FTM938HD86 | FTM1149HD98 | FTM1349HD110 | FTM1349HD125 |

| Transportation lenght(mm) | 12600 | 13500 | 14500 | 15200 |

| Transportation Width(mm) | 2600 | 2700 | 2800 | 2900 |

| Transportation Height(mm) | 3870 | 4200 | 4450 | 4500 |

| Maximum Lenght(mm) | 12500 | 14000 | 16100 | 16700 |

| Maximum Width(mm) | 4100 | 4500 | 5100 | 5100 |

| Maximum Height(mm) | 4100 | 4900 | 5000 | 5300 |

| Weight(t) | 39 | 57 | 55 | 65 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial | Triaxial |

| Jaw Crusher | HD86 | HD98 | HD110 | HD125 |

| Maximum Feeding Size(mm) | 500 | 550 | 660 | 800 |

| Discharge opening range | 50-150 | 75-175 | 100-200 | 125-225 |

| Capacity(t/h) | 85-275 | 110-350 | 215-510 | 280-650 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m | B650×4m | B650×4m |

| Gensrt(optional) | 200KW | 250KW | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-10 | RCYD(C)-12 |

Model FTM938HD86 and FTM1149HD98

| Model | FTM938HD86 | FTM1149HD98 |

| Transportation lenght(mm) | 12600 | 13500 |

| Transportation Width(mm) | 2600 | 2700 |

| Transportation Height(mm) | 3870 | 4200 |

| Maximum Lenght(mm) | 12500 | 14000 |

| Maximum Width(mm) | 4100 | 4500 |

| Maximum Height(mm) | 4100 | 4900 |

| Weight(t) | 39 | 57 |

| tIRE Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD86 | HD98 |

| Maximum Feeding Size(mm) | 500 | 550 |

| Discharge opening range | 50-150 | 75-175 |

| Capacity(t/h) | 85-275 | 110-350 |

| Vibrating Feeder | ZSW380×95 | ZSW420×110 |

| Main Belt Conveyor | B800×8.5m | B1000×9.5m |

| Side-opening Belt conveyor(optional) | B500×3m | B650×3.5m |

| Gensrt(optional) | 200KW | 250KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-10 |

Model FTM1349HD110 and FTM1349HD125

| Model | FTM1349HD110 | FTM1349HD125 |

| Transportation lenght(mm) | 14500 | 15200 |

| Transportation Width(mm) | 2800 | 2900 |

| Transportation Height(mm) | 4450 | 4500 |

| Maximum Lenght(mm) | 16100 | 16700 |

| Maximum Width(mm) | 5100 | 5100 |

| Maximum Height(mm) | 5000 | 5300 |

| Weight(t) | 55 | 65 |

| Tire Configuration | Dualaxial | Dualaxial |

| Jaw Crusher | HD110 | HD125 |

| Maximum Feeding Size(mm) | 660 | 800 |

| Discharge opening range | 100-200 | 125-225 |

| Capacity(t/h) | 215-510 | 280-650 |

| Vibrating Feeder | ZSW490×130 | ZSW490×130 |

| Main Belt Conveyor | B1000×11m | B1200×11m |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 270KW | 400KW |

| Iron separator(optional) | RCYD(C)-10 | RCYD(C)-12 |

| Model | FTM938F1210 | FTM938F1214 | FTM1149F1315 | FTM938F1110 | FTM1349F1315 |

| Transportation length(mm) | 12000 | 12000 | 13900 | 15450 | 15450 |

| Transportation Width(mm) | 2550 | 2550 | 2900 | 2950 | 2950 |

| Transportation Height(mm) | 3900 | 3900 | 4450 | 4500 | 4500 |

| Maximum length(mm) | 12500 | 12500 | 13900 | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3260 | 3250 | 3250 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 | 62 | 62 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 | 400 | 700 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 | 112 | 280 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 | RCYD(C)-8 | RCYD(C)-12 |

Model FTM938F1210 and FTM938F1214 and FTM1149F1315

| Model | FTM938F1210 | FTM938F1214 | FTM1149F1315 |

| Transportation length(mm) | 12000 | 12000 | 13900 |

| Transportation Width(mm) | 2550 | 2550 | 2900 |

| Transportation Height(mm) | 3900 | 3900 | 4450 |

| Maximum Length(mm) | 12500 | 12500 | 13900 |

| Maximum Width(mm) | 3250 | 3260 | 3250 |

| Maximum Height(mm) | 5100 | 5200 | 5200 |

| Weight(t) | 39 | 44 | 54 |

| Impact crusher | PE-1210 | PE-1214 | PF-1315 |

| Maximum Feeding Size(mm) | 350 | 350 | 500 |

| Capacity(t/h) | 70-130 | 100-180 | 130-250 |

| Vibrating Feeder | ZSW950×3800 | ZSW950×3800 | ZSW110×4900 |

| Main Belt Conveyor | B800×8.5M | B800×8.5M | B1000×9.5M |

| Side-opening Belt conveyor(optional) | B500×3.2m | B500×3.2m | B650×4m |

| Gensrt(optional) | 320KW | 320KW | 400KW |

| iron separator(optional) | RCYD(C)-8 | RCYD(C)-8 | RCYD(C)-10 |

Model FTM938F1110 and FTM1349F1315

| Model | FTM938F1110 | FTM1349F1315 |

| Transportation length(mm) | 15450 | 15450 |

| Transportation Width(mm) | 2950 | 2950 |

| Transportation Height(mm) | 4500 | 4500 |

| Maximum Length(mm) | 15450 | 15450 |

| Maximum Width(mm) | 3250 | 3250 |

| Maximum Height(mm) | 5200 | 5200 |

| Weight(t) | 62 | 62 |

| Impact crusher | HD1110 | HD1315 |

| Maximum Feeding Size(mm) | 400 | 700 |

| Capacity(t/h) | 112 | 280 |

| Vibrating Feeder | ZSW130×4900 | ZSW130×4900 |

| Main Belt Conveyor | B800×11M | B1200×11M |

| Side-opening Belt conveyor(optional) | B650×4m | B650×4m |

| Gensrt(optional) | 320KW | 440KW |

| Iron separator(optional) | RCYD(C)-8 | RCYD(C)-12 |

| Model | FTM3S1848V08 | FTM3S1860V09 | FTM3S2160V103 |

| Transportation length(mm) | 13500 | 15600 | 15600 |

| Transportation Width(mm) | 2830 | 2830 | 3100 |

| Transportation Height(mm) | 4350 | 4350 | 4480 |

| Maximum Length(mm) | 14650 | 16300 | 16300 |

| Maximum Width(mm) | 3900 | 3900 | 3900 |

| Maximum Height(mm) | 5980 | 6400 | 6550 |

| Weight(t) | 31 | 36 | 49 |

| Tire Configuration | Biax Fitted | Biax Fitted | Biax Fitted |

| Sand maker | HVI0815 | HVI0922 | HVI1032 |

| Discharging Belt Conveyor | B800×2.2M | B800×2.5M | B1000×2.5M |

| Belt under vibrating screen | B800×7M | B800×8M | B1000×8M |

| Vibrating Screen | 3YZS1848 | 3YZS1860 | 3YZS2160 |

| Model | FTM3S1848V08 | FTM3S1860V09 | FTM3S2160V103 |

| Transportation length(mm) | 13500 | 15600 | 15600 |

| Transportation Width(mm) | 2830 | 2830 | 3100 |

| Transportation Height(mm) | 4350 | 4350 | 4480 |

| Maximum Length(mm) | 14650 | 16300 | 16300 |

| Maximum Width(mm) | 3900 | 3900 | 3900 |

| Maximum Height(mm) | 5980 | 6400 | 6550 |

| Weight(t) | 31 | 36 | 49 |

| Tire Configuration | Biax Fitted | Biax Fitted | Biax Fitted |

| Sand maker | HVI0815 | HVI0922 | HVI1032 |

| Discharging Belt Conveyor | B800×2.2M | B800×2.5M | B1000×2.5M |

| Belt under vibrating screen | B800×7M | B800×8M | B1000×8M |

| Vibrating Screen | 3YZS1848 | 3YZS1860 | 3YZS2160 |

| Model | FTM3S185GYS300 | FTM3S216GYS400 | FTM3S216HP300 |

| Transportation length(mm) | 14500 | 15000 | 16000 |

| Transportation Width(mm) | 3000 | 3000 | 4550 |

| Transportation Height(mm) | 4400 | 4500 | 4600 |

| Maximum Length(mm) | 17000 | 16000 | 17000 |

| Maximum Width(mm) | 3400 | 3900 | 6900 |

| Maximum Height(mm) | 5800 | 6500 | 4700 |

| Weight(t) | 34.5 | 49.5 | 41 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial |

| Cone crusher | GYS300 | GYS400 | HP300 |

| Discharging belt Conveyor | B650×15M×2 | B800×15M×2 | B800×15M×2 |

| Return belt conveyor | B650×14M | B800×14M | B800×16M |

| CONveyor Belt For Final Products | B500×15M | B800×6M | B650×15M×2 |

| Under Virbrating Screen | B800×7M | B800×8M | B800×9M |

| Vibrating Screen | 3YK1854 | 3YK2160 | 3YK2160 |

| Model | FTM3S185GYS300 | FTM3S216GYS400 | FTM3S216HP300 |

| Transportation length(mm) | 14500 | 15000 | 16000 |

| Transportation Width(mm) | 3000 | 3000 | 4550 |

| Transportation Height(mm) | 4400 | 4500 | 4600 |

| Maximum Length(mm) | 17000 | 16000 | 17000 |

| Maximum Width(mm) | 3400 | 3900 | 6900 |

| Maximum Height(mm) | 5800 | 6500 | 4700 |

| Weight(t) | 34.5 | 49.5 | 41 |

| Tire Configuration | Dualaxial | Triaxial | Triaxial |

| Cone crusher | GYS300 | GYS400 | HP300 |

| Discharging belt Conveyor | B650×15M×2 | B800×15M×2 | B800×15M×2 |

| Return belt conveyor | B650×14M | B800×14M | B800×16M |

| CONveyor Belt For Final Products | B500×15M | B800×6M | B650×15M×2 |

| Under Virbrating Screen | B800×7M | B800×8M | B800×9M |

| Vibrating Screen | 3YK1854 | 3YK2160 | 3YK2160 |