What is a single-cylinder cone crusher?

A single-cylinder cone crusher, also known as a single-cylinder hydraulic cone crusher, is a high-efficiency rock crushing machine commonly used in ore crushing, aggregate production, and construction waste recycling.

It is mainly used for secondary and tertiary crushing and can sometimes be applied to quaternary crushing stages. This crusher is especially effective for breaking medium to hard rocks, stones, and minerals.

A single-cylinder cone crusher is widely used for crushing metallic and non-metallic ores such as iron ore, copper ore, and quartz. It is also suitable for aggregates like granite and basalt, as well as construction waste like concrete and asphalt.

However, it is not suitable for soft, wet, or sticky materials (e.g., clay or shale), as these can clog the machine and reduce efficiency.

The cone crusher manufactured by FTM Machinery offers a high output range from 25 to 2181 tons per hour, with a discharge size ranging from 4 mm to 41 mm. This flexibility makes it suitable for various medium and fine crushing needs. Below is the model specification for the medium and fine crushing series.

SC Single Cylinder Cone Crusher Medium Crushing Series

| Model | Cavities | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Capacity(t/h) |

| SC100S | C1 | 175 | 22 | 85-170 |

| C2 | 160 | 19 | 70-130 | |

| SC250S | C1 | 360 | 35 | 265-524 |

| C2 | 320 | 29 | 225-448 | |

| SC450S | C1 | 480 | 44 | 498-1500 |

| C2 | 385 | 41 | 454-1274 |

SC Single Cylinder Cone Crusher Fine Crushing Series

| Model | Cavities | Maximum Feeding Size (mm) | Minimum Discharging Size (mm) | Capacity (t/h) |

| SC100 | F1 | 120 | 10 | 45-135 |

| F2 | 70 | 10 | 43-118 | |

| F3 | 40 | 6 | 25-40 | |

| SC250 | F1 | 190 | 16 | 116-396 |

| F2 | 110 | 13 | 97-346 | |

| F3 | 55 | 9 | 90-251 | |

| SC750 | F1 | 295 | 25 | 394-2181 |

| F2 | 240 | 19 | 342-2020 | |

| F3 | 185 | 16 | 267-1814 | |

| F4 | 95 | 13 | 248-1165 | |

| F5 | 70 | 10 | 185-1170 |

For more information about additional models or to request free customization, feel free to contact our sales team. We are always ready to assist you! Contact us now

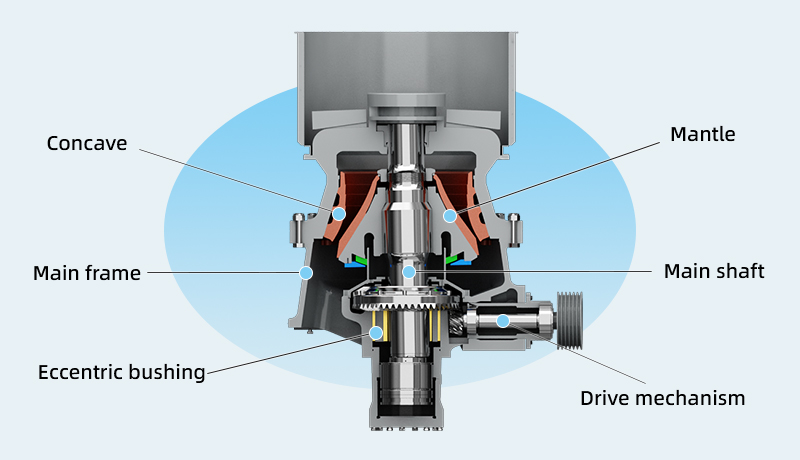

Main components of a single-cylinder cone crusher

A cone crusher consists of key parts including the main shaft, mantle, bowl liner, concave, eccentric bushing, and drive mechanism.

1. Main shaft

Made of high-strength steel, the main shaft provides stability and load-bearing capacity. It supports the swinging motion of the mantle and crushes material through eccentric movement.

2. Main frame

The main frame is the primary structural support of the crusher. It holds key components, such as the concave and eccentric bushing, and bears various loads during the crushing process.

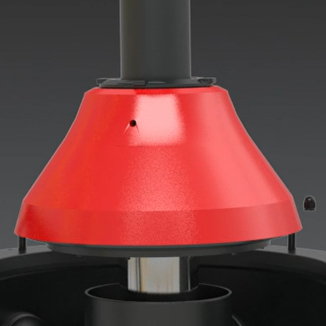

3. Mantle

Working with the concave, the mantle crushes material by compression. Made of high manganese steel, it offers excellent wear resistance and longer service life.

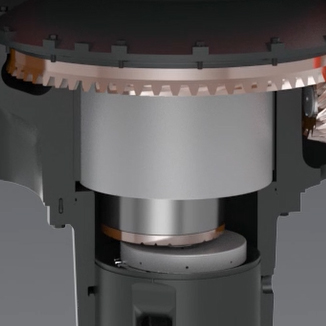

4. Concave

The concave is cast as a single piece to provide stable support for the bowl liner, ensuring the durability of the crushing chamber.

5. Eccentric bushing

The eccentric bushing converts the motor's rotation into the mantle's eccentric swing. Made of high-carbon steel with a bronze inner sleeve, the eccentric distance can be adjusted using different-sized bushings.

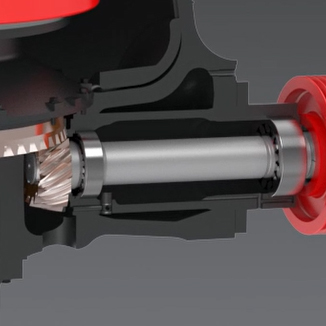

6. Drive mechanism

The drive mechanism transfers power from the motor to the eccentric bushing, ensuring efficient crusher operation and reducing energy consumption.

Why FTM Machinery single-cylinder cone crusher?

As an experienced cone crusher manufacturer, FTM Machinery's single-cylinder cone crusher is widely trusted by customers in mining, recycling, and construction industries for its excellent performance, smart automation, low downtime, easy maintenance, and reasonable price.

What are the advantages of FTM Machinery's cone crushers?

- High efficiency: Combines advanced chamber design and high crushing frequency, reaching up to 2181 tons per hour.

- Better product shape: Uses intergranular lamination crushing to produce cubic-shaped final products with fewer needle-like particles.

- Easy maintenance: Components are easily removed from the top. Filler-free liners save replacement time and costs.

- Low downtime: Equipped with hydraulic and lubrication systems for dual protection, it handles overloads automatically and ensures continuous operation, reducing downtime.

- Dust protection: Positive pressure system blocks dust and debris, keeping parts clean and extending service life.

- Smart automation: Features an intuitive interface for quick discharge adjustment and precise size control. Automation boosts productivity by 15%-25%, simplifying complex operations.

How does a single-cylinder hydraulic cone crusher work?

The single-cylinder hydraulic cone crusher is an ideal choice for crushing medium to hard materials, thanks to its efficient performance and smart hydraulic system.

During operation, the motor drives the eccentric bushing to rotate, causing the crushing cone to move in an eccentric motion. Materials are repeatedly compressed and bent between the crushing cone and the bowl liner until they are crushed to the desired size and discharged.

The advanced hydraulic system allows precise adjustment of the discharge opening and provides overload protection, ensuring safe and reliable operation.

How to choose the right single-cylinder cone crusher?

When selecting a single-cylinder cone crusher, consider these key factors to ensure the equipment meets your production needs, lifespan expectations, and cost-efficiency:

- Production requirements: Determine your required capacity, such as daily or hourly output. FTM Machinery offers models with capacities ranging from 25 to 2181 t/h, suitable for various scales of production.

- Material size:Choose the right crushing chamber type—medium, medium-fine, fine, or extra-fine—based on the maximum feed size and desired discharge size.

- Material characteristics: Consider the hardness, moisture, and abrasiveness of the material. Single-cylinder cone crushers are ideal for medium to high-hardness materials like granite and basalt but are not suitable for sticky or wet materials.

- Investment costs: While the initial cost of a single-cylinder cone crusher is higher, it is a better fit for users with sufficient budgets.

- Ease of maintenance: The simple structure and filler-free design reduce liner replacement time. Equipped with a remote touchscreen control system, the machine allows eccentric adjustments without part replacement, increasing uptime.

- Manufacturer reputation: Choose a reliable manufacturer with good reviews and strong credentials. FTM Machinery operates four major production bases and exports its advanced single-cylinder cone crushers worldwide, trusted by customers globally.

Have questions about choosing the right cone crusher? Contact our sales experts for professional advice!Contact us now

Customer cases

1. Granite crushing plant in Singapore

| Raw material | Gypsum |

| Capacity | 500 t/h |

| Feeding size | ≤250 mm |

| Output Size | 5-20 mm |

| Material hardness | Hard |

| Production line type | Fixed |

| Equipment Purchased | Jaw crusher, single-cylinder cone crusher, vibrating screen, conveyor |

What our customers say:

"This cone crusher has been outstanding and has run smoothly for two years. It handles high-hardness granite efficiently with very little maintenance, which has greatly reduced our operating costs. This equipment has made a significant difference in boosting our business!"

2. Construction waste recycling plant in India

| Raw material | Construction waste |

| Capacity | 200 t/h |

| Feeding size | ≤180 mm |

| Output Size | 10-30 mm |

| Material hardness | Medium to hard |

| Production line type | Mobile |

| Equipment Purchased | Mobile single-cylinder cone crusher, multi-layer vibrating Screen |

What our customers say:

"In February 2022, I bought this machine from FTM Machinery for crushing construction waste at several project sites. It’s easy to move and delivers a stable output of about 200 tons per hour. We are very happy with its performance!"

Frequently asked questions about cone crushers

1. What is the main difference between a single-cylinder and a multi-cylinder cone crusher?

- a) Design structure: The single-cylinder cone crusher has one hydraulic cylinder, making it simple and easy to maintain. The multi-cylinder cone crusher has multiple hydraulic cylinders, suitable for higher strength crushing tasks.

- b) Performance: The single-cylinder cone crusher excels in medium and fine crushing, with high efficiency and low energy consumption. The multi-cylinder cone crusher performs more steadily in high output and high hardness material crushing.

- c) Price and maintenance: The single-cylinder cone crusher is more economical and has lower maintenance costs, while the multi-cylinder cone crusher has a higher initial cost but is more durable for heavy-duty tasks.

2. How to maintain and clean a cone crusher? Are maintenance costs high?

- Maintenance for cone crushers is relatively simple. Here are some daily maintenance tips:

- a) Regular lubrication: Check and replace the lubricating oil to ensure smooth operation and extend bearing life.

- b) Check wear parts: Regularly inspect the wear of liners and replace them as needed to avoid affecting crushing efficiency.

- c) Clean the crushing chamber: Periodically clean out residual materials from the crushing chamber to prevent blockages and damage.

- d) Check system operation: Monitor the automation system to ensure proper function, including discharge opening settings and overload protection.