The mobile crusher, also called the mobile crushing station, is a tracked mobile crusher developed by FTM Machinery. It is designed for crushing work that requires fast and easy site mobility. The mobile crusher can replace stationary crushing plants, thereby reducing transport and operating costs.

The outstanding feature of the mobile crusher is that it can move freely according to the project’s progress and provide high productivity, regardless of whether the crushing environment is harsh.

Unique designs of FTM Machinery mobile crushers

- It can be flexibly customized according to the customer's material type and product requirements.

- Lightweight, small footprint, especially suitable for working in narrow fields.

- Strong mobility and can be used directly on the spot. This can reduce set-up time and construction work costs.

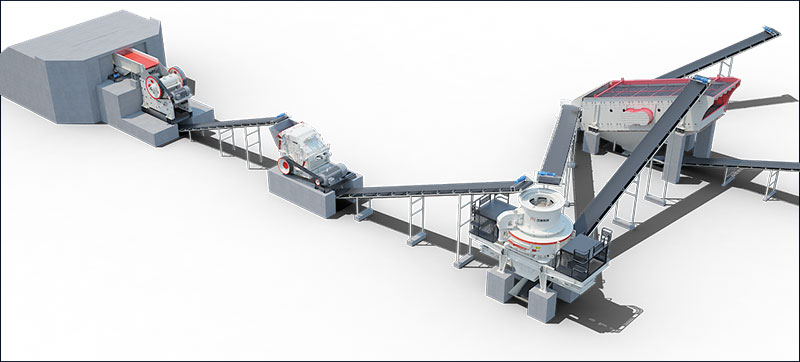

- It can form a complete system of coarse crushing - medium crushing - fine crushing – mobile screening plant.

- Adopt modular assembly method to improve assembly speed and shorten delivery time.

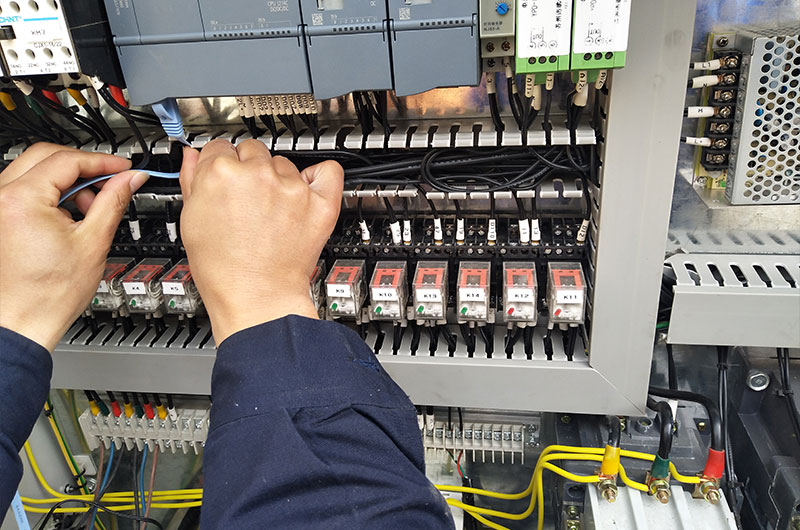

- Advanced engine, hydraulic powder system, and wireless remote control.

- Adopt composite materials instead of metal to manufacture machine parts. This can reduce the machine’s weight and simplify maintenance.

- The machine fuel saving rate is up to 25%. It does not damage the road surface and is equipped with multiple functions.

- Energy saving and environmental protection. Machine materials can reduce noise and dust, especially suitable for working in residential areas and crushing urban construction waste.

How many types does mobile crushers have?

FTM Machinery tracked mobile crushers have the same parts as stationary crushers, but with the added advantage of being fully mobile. All models are compatible with each other. You can crush materials on one crusher, or use multiple machines to crush materials together.

The mobile crushers are highly customizable, covering mobile jaw crushers, cone crushers, impact crushers, hammer crushers, fine crushers, sand making machines, vibrating screens, conveyor belts, etc.

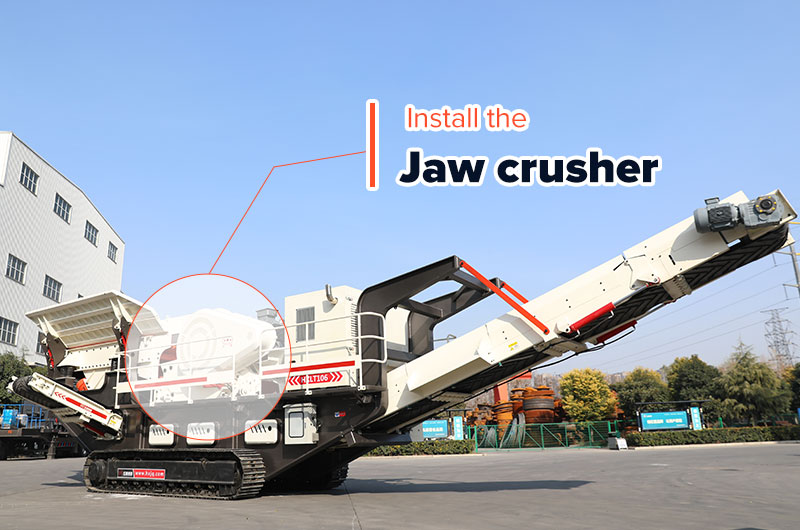

1. Mobile jaw crusher

The mobile jaw crusher is a multifunctional primary crusher that is used for crushing large, hard, or highly abrasive materials in complex and harsh environments. It can be perfectly compatible with other FTM Machinery mobile equipment for multi-stage crushing processes and also as an independent unit.

FTM Machinery offers the most complete series of mobile jaw crushers in the market, among which the best-selling Wotetrack Jaw Crushers are best sold. The crushers are hydraulically driven to ensure smooth running and free adjustment according to the actual requirements.

2. Mobile cone crusher

The mobile cone crusher is ideal for secondary, tertiary, and quaternary crushing of the hardest materials. The crusher is durable and has a powerful crushing ability. It is one of the best medium and fine crushers. Each model can produce 0-40 mm fine particles with good cube shape.

If you want to easily and efficiently crush granite, concrete, asphalt, construction waste, or coal, mobile cone crushers are ideal for you.

The device is equipped with an automatic setting and adjustment system, a remote camera, and a leveler, which can monitor and optimize production in time. The added benefit of tracking lining wear helps minimize downtime.

3. Mobile impact crusher

The mobile impact crusher has two forms: open type and closed type. It is used for secondary and tertiary crushing of medium hardness materials, such as limestone, concrete, and construction waste. The final product is fine-grained and has a precise shape, so it is popular with the aggregate production, mining, and recycling industries.

Dual-fuel and electric drive improves fuel efficiency and reduces operating costs. Moreover, the mobile impact crusher adopts modular components, which are easy to maintain and operate.

The selection of the crushing system depends on the material properties (hardness, moisture, shape, and impurity content), feed size, output size, plant capacity, and other factors.

Mobile crusher applications

1. Mining crushing

In open-pit mining, the mobile crusher can freely adjust the production position according to the mining progress.

It can crush gold ore, copper ore, iron ore, manganese ore, rare earth ore, and other minerals to the required particle size, and then send them to a ball mill through a conveyor belt for grinding and beneficiation.

2. Quarry stone crushing

The mobile rock crusher is also suitable for aggregate crushing.

Crushed aggregates like limestone, basalt, granite, cobblestone, ballast, dolomite, and talc can be used to pave roads, highways, railways, water conservancy, and concrete mixing plants.

3. Recycling

The mobile crusher is ideal crushing equipment for recycling tailings, asphalt, concrete construction waste, slag, and other waste.

The mobile crushing plant integrates the functions of receiving, crushing, transmitting, processing, and reprocessing. By combining with other equipment, it forms a high-capacity production line. This can perfectly finish the shift to the new building material industry chain and low-carbon economy.

You may want to know about:

FTM Machinery mobile crushing plant for sale

After more than 40 years of research and testing, FTM Machinery helps customers maximize their production efficiency. We provide end-to-end services ranging from installation test machines, machine inspection, fault diagnosis, parts maintenance, shutdown solutions, planning as well as emergency services.

Besides, we also provide the most professional training to ensure that the project can be carried out safely and effectively.

Our mobile crushers are exported to the whole world where and the best-selling countries are Indonesia, India, the United States, the United Kingdom, South Africa, the Philippines, Australia, etc.

At the same time, we adopt the fastest and most convenient transportation according to the different conditions of each country and aim to keep your project starting on schedule. If you like our mobile crushers, we sincerely welcome your visit and consultation.

Frequently asked questions about Mobile crushers

1. Mobile crushers Vs. Stationary crushers

- The traditional crushers are all fixed or stationary and are mostly used for short-distance crushing sites. They can also be combined with some auxiliary crushing equipment to form a complete rock crushing line, but this assembly is only suitable for large-scale worksite.

-

- The mobile crushers are different from traditional crushing equipment. In fact, the mobile crushing station is equivalent to a crushing production line that integrates multiple crushing types of equipment including crushing and screening machines. The mobile crusher can freely move to the crushing site for processing materials directly without transporting material back and forth.

-

2. How to maintain mobile crushers?

- Regular Maintenance. Small and medium-sized mobile crushers are mainly lubricated with grease and lubricating oil regularly.

- If cone and large jaw crushers are installed, there is generally a forced lubrication system on the mobile crusher. At this time, you should always observe the oil temperature, oil pressure, flow, and other parameters and loose fasteners.

-

- Pay attention to the noise and vibration. If there is excessive noise or vibration, you should shut down the mobile crusher immediately for further inspection. After removing the fault, please restart the machine with no load according to the startup sequence.

- Please notice the quality and yield of the product. The reason is that there may be problems such as blockage of the crusher and damage of the screening machine if product quality and yield are abnormal.

3. How to repair mobile crushers?

- Overhaul. To maintain the good performance of the equipment, the equipment must also be subject to minor repairs, intermediate repairs, and major repairs as planned.

- a. Minor repair. It belongs to the planned pre-repair process. The purpose of minor repair is to deal with the partial damage caused by wear during the use of the equipment. The adjustment or replacement of wearing parts can help the mobile crusher work normally.

- b. Intermediate repairs. First, you must stop the machine to do the intermediate repair. The purpose is to check the wear situation of the important components in detail, replace some parts, and coordinate the service life of various components. At this level, you should disassemble the entire unit and clean the parts.

- c. Major repairs. It is carried out when the equipment is stopped for a long time. During the overhaul, all parts must be disassembled and carefully checked. Repair and update all components to restore the equipment to its normal state and working ability.

Parameter

- Wotetrack Mobile Jaw Crusher

- Wotetrack Mobile Cone Crusher

- Wotetrack Mobile Impact Crusher

| SPECIFICATIONS | WT96 | WT106 | WT120 | |

| Feeding Device | Maximum Feeding Size(mm) | 480 | 560 | 700 |

| Feeding Height(mm) | 3700 | 4000 | 4300 | |

| Hopper Volume(m³) | 5 | 6.5 | 8 | |

| Vibrating Feeder | W×L(mm) | 950×3800 | 1060×4200 | 1160×4500 |

| Side Conveyor | W×L(mm) | 500×4000 | 650×4000 | 650×4500 |

| Discharging Height(mm) | 2200 | 2400 | 2500 | |

| Mainframe of Crusher | Model | CJ96 | CJ106 | CJ120 |

| Feeding Opening size(mm) | 930×580 | 1060×700 | 1200×870 | |

| Weight(t) | 10.3 | 14.5 | 26 | |

| Drive Mode | Hydraulic V-belt | Hydraulic V-belt | Hydraulic V-belt | |

| Main Belt Conveyor | W×L(mm) | 800×10500 | 1000×11000 | 1200×11500 |

| Discharging Height(mm) | 3300 | 3600 | 4000 | |

| Powertrain | Driving Mechanism of Crusher | Diesel-Hydraulic Drive | Diesel-Hydraulic Drive | Diesel-Hydraulic Drive |

| Engine | Cummins 163kW | Cummins 264kW | Cummins 264kW | |

| Overall Dimension of Transportation | Length(mm) | 13500 | 15100 | 16000 |

| Width(mm) | 2600 | 2800 | 3000 | |

| Height(mm) | 3300 | 3500 | 3800 | |

| Weight(t) | 32 | 42 | 60 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

WT96 and WT106

| SPECIFICATIONS | WT96 | WT106 | |

| Feeding Device | Maximum Feeding Size(mm) | 480 | 560 |

| Feeding Height(mm) | 3700 | 4000 | |

| Hopper Volume(m³) | 5 | 6.5 | |

| Vibrating Feeder | W×L(mm) | 950×3800 | 1060×4200 |

| Side Conveyor | W×L(mm) | 500×4000 | 650×4000 |

| Discharging Height(mm) | 2200 | 2400 | |

| Mainframe of Crusher | Model | CJ96 | CJ106 |

| Feeding Opening size(mm) | 930×580 | 1060×700 | |

| Weight(t) | 9.8 | 14.5 | |

| Drive Mode | Hydraulic V-belt | Hydraulic V-belt | |

| Main Belt Conveyor | W×L(mm) | 800×10500 | 1000×11000 |

| Discharging Height(mm) | 3300 | 3600 | |

| Powertrain | Driving Mechanism of Crusher | Diesel-Hydraulic Drive | Diesel-Hydraulic Drive |

| Engine | Cummins 163kW | Cummins 264kW | |

| Overall Dimension of Transportation | Length(mm) | 13500 | 15100 |

| Width(mm) | 2600 | 2800 | |

| Height(mm) | 3300 | 3500 | |

| Weight(t) | 32 | 42 | |

WT120

| SPECIFICATIONS | WT120 | |

| Feeding Device | Maximum Feeding Size(mm) | 700 |

| Feeding Height(mm) | 4300 | |

| Hopper Volume(m³) | 8 | |

| Vibrating Feeder | W×L(mm) | 1160×4500 |

| Side Conveyor | W×L(mm) | 650×4500 |

| Discharging Height(mm) | 2500 | |

| Mainframe of Crusher | Model | CJ120 |

| Feeding Opening size(mm) | 1200×870 | |

| Weight(t) | 26 | |

| Drive Mode | Hydraulic V-belt | |

| Main Belt Conveyor | W×L(mm) | 1200×11500 |

| Discharging Height(mm) | 4000 | |

| Powertrain | Driving Mechanism of Crusher | Diesel-Hydraulic Drive |

| Engine | Cummins 264kW | |

| Overall Dimension of Transportation | Length(mm) | 16000 |

| Width(mm) | 3000 | |

| Height(mm) | 3800 | |

| Weight(t) | 60 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| SPECIFICATIONS | WT 200/S | WT 300/S | WT 160/S | WT 250 | |

| Feeding Device | Maximum Feeding Size(mm) | 185 | 200 | 200 | 215 |

| Feeding Height(mm) | 2600 | 2700 | 2700 | 2900 | |

| Hopper Volume(m³) | 5 | 6 | 6 | 6 | |

| Feeding Conveyor | W×L(mm) | 1000×5500 | 1200×6000 | 1200×6000 | 1200×6000 |

| Mainframe of Crusher | Model | HPM200 | HPM300 | SC160 | SC250 |

| Feeding Opening size(mm) | 210 | 230 | 230 | 250 | |

| Weight(t) | 10.4 | 15.8 | 11 | 16 | |

| Drive Mode | Hydraulic V-belt | Direct Drive | Direct Drive | Direct Drive | |

| Main Belt Conveyor | W×L(mm) | 1000×10500 | 1200×11500 | 1200×11000 | 1200×12000 |

| Discharging Height(mm) | 3300 | 3500 | 3500 | 3500 | |

| Screening System | Type | Single-deck Vibrating Screen | Single-deck Vibrating Screen | Single-deck Vibrating Screen | |

| Screening Surface Size(mm) | 1500×3000 | 1500×3600 | 1500×3000 | ||

| Size of Return Belt Conveyor(mm) | 500×8000 | 500×9000 | 500×8000 | ||

| Size of Fine Product Conveyor(mm) | 1200×5000 | 1200×5500 | 1200×5000 | ||

| Fine Product ConveyorDischarging Height(mm) | 3000 | 3200 | 3000 | ||

| Powertrain | Driving Mechanism of Crusher | Diesel-Hydraulic Drive | Diesel-Direct Drive | Diesel-Direct Drive | Diesel-Direct Drive |

| Engine | Cummins 264kW | Cummins 391kW | Cummins 335kW | Cummins 391kW | |

| Overall Dimension of Transportation | Length(mm) | 14500/16400 | 15200/17800 | 15000/17000 | 15500 |

| Width(mm) | 2700/3000 | 3000/3200 | 3000/3200 | 3000 | |

| Height(mm) | 3500 | 3600 | 3600 | 3700 | |

| Weight(t) | 35/41 | 45/54 | 38/45 | 46 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

WT 200/S and WT 300/S

| SPECIFICATIONS | WT 200/S | WT 300/S | |

| Feeding Device | Maximum Feeding Size(mm) | 185 | 200 |

| Feeding Height(mm) | 2600 | 2700 | |

| Hopper Volume(m³) | 5 | 6 | |

| Feeding Conveyor | W×L(mm) | 1000×5500 | 1200×6000 |

| Mainframe of Crusher | Model | HPM200 | HPM300 |

| Feeding Opening size(mm) | 210 | 230 | |

| Weight(t) | 10.4 | 15.8 | |

| Drive Mode | Hydraulic V-belt | Direct Drive | |

| Main Belt Conveyor | W×L(mm) | 1000×10500 | 1200×11500 |

| Discharging Height(mm) | 3300 | 3500 | |

| Screening System | Type | Single-deck Vibrating Screen | Single-deck Vibrating Screen |

| Screening Surface Size(mm) | 1500×3000 | 1500×3600 | |

| Size of Return Belt Conveyor(mm) | 500×8000 | 500×9000 | |

| Size of Fine Product Conveyor(mm) | 1200×5000 | 1200×5500 | |

| Fine Product ConveyorDischarging Height(mm) | 3000 | 3200 | |

| Powertrain | Driving Mechanism of Crusher | Diesel-Hydraulic Drive | Diesel-Direct Drive |

| Engine | Cummins 264kW | Cummins 391kW | |

| Overall Dimension of Transportation | Length(mm) | 14500/16400 | 15200/17800 |

| Width(mm) | 2700/3000 | 3000/3200 | |

| Height(mm) | 3500 | 3600 | |

| Weight(t) | 35/41 | 45/54 | |

WT 160/S and WT 250

| SPECIFICATIONS | WT 160/S | WT 250 | |

| Feeding Device | Maximum Feeding Size(mm) | 200 | 215 |

| Feeding Height(mm) | 2700 | 2900 | |

| Hopper Volume(m³) | 6 | 6 | |

| Feeding Conveyor | W×L(mm) | 1200×6000 | 1200×6000 |

| Mainframe of Crusher | Model | SC160 | SC250 |

| Feeding Opening size(mm) | 230 | 250 | |

| Weight(t) | 11 | 16 | |

| Drive Mode | Direct Drive | Direct Drive | |

| Main Belt Conveyor | W×L(mm) | 1200×11000 | 1200×12000 |

| Discharging Height(mm) | 3500 | 3500 | |

| Screening System | Type | Single-deck Vibrating Screen | |

| Screening Surface Size(mm) | 1500×3000 | ||

| Size of Return Belt Conveyor(mm) | 500×8000 | ||

| Size of Fine Product Conveyor(mm) | 1200×5000 | ||

| Fine Product ConveyorDischarging Height(mm) | 3000 | ||

| Powertrain | Driving Mechanism of Crusher | Diesel-Direct Drive | Diesel-Direct Drive |

| Engine | Cummins 335kW | Cummins 391kW | |

| Overall Dimension of Transportation | Length(mm) | 15000/17000 | 15500 |

| Width(mm) | 3000/3200 | 3000 | |

| Height(mm) | 3600 | 3700 | |

| Weight(t) | 38/45 | 46 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| SPECIFICATIONS | WT1110/S | WT1213/S | WT1316 | |

| Feeding Device | Maximum Feeding Size(mm) | 400 | 500 | 600 |

| Feeding Height(mm) | 3900 | 4300 | 4400 | |

| Hopper Volume(m³) | 5 | 7 | 8 | |

| Vibrating Feeder | W×L(mm) | 950×3800 | 1160×4200 | 1160×4200 |

| Side Conveyor | W×L(mm) | 500×4000 | 650×4000 | 650×4000 |

| Discharging Height(mm) | 2200 | 2400 | 2400 | |

| Mainframe of Crusher | Model | CI1110M | CI1213M | CI1316 |

| Feeding Opening size(mm) | 1020×820 | 1320×880 | 1540×980 | |

| Weight(t) | 9.5 | 13 | 16 | |

| Rotor Size(mm) | Φ 1100×1000 | Φ 1200×1300 | Φ 1300×1500 | |

| Drive Mode | Hydraulic V-belt | Direct Drive | Direct Drive | |

| Vibrating Discharge Chute | W×L(mm) | 1200×2030 | 1500×2370 | 1600×2500 |

| Main Belt Conveyor | W×L(mm) | 1000×8500 | 1200×9000 | 1200×9500 |

| Discharging Height(mm) | 3300 | 3500 | 3600 | |

| Screening System | Type | Single-deck Vibrating Screen | Single-deck Vibrating Screen | |

| Screening Surface Size(mm) | 1500×3000 | 1500×3600 | ||

| Size of Return Belt Conveyor(mm) | 500×8000 | 500×8000 | ||

| Size of Fine Product Conveyor(mm) | 1200×5000 | 1200×5500 | ||

| Fine Product ConveyorDischarging Height(mm) | 3000 | 3200 | ||

| Powertrain | Driving Mechanism of Crusher | Diesel-Hydraulic Drive | Diesel-Direct Drive | Diesel-Direct Drive |

| Engine | Cummins 264kW | Cummins 335kW | Cummins 391kW | |

| Overall Dimension of Transportation | Length(mm) | 13000/15500 | 14500/17000 | 15000 |

| Width(mm) | 2700/3200 | 3000/3460 | 3150 | |

| Height(mm) | 3400 | 3650 | 3700 | |

| Weight(t) | 35/42 | 46/55 | 52 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

WT1110/S and WT1213/S

| SPECIFICATIONS | WT1110/S | WT1213/S | |

| Feeding Device | Maximum Feeding Size(mm) | 400 | 500 |

| Feeding Height(mm) | 3900 | 4300 | |

| Hopper Volume(m³) | 5 | 7 | |

| Vibrating Feeder | W×L(mm) | 950×3800 | 1160×4200 |

| Side Conveyor | W×L(mm) | 500×4000 | 650×4000 |

| Discharging Height(mm) | 2200 | 2400 | |

| Mainframe of Crusher | Model | CI1110M | CI1213M |

| Feeding Opening size(mm) | 1020×820 | 1320×880 | |

| Weight(t) | 9.5 | 13 | |

| Rotor Size(mm) | Φ 1100×1000 | Φ 1200×1300 | |

| Drive Mode | Hydraulic V-belt | Direct Drive | |

| Vibrating Discharge Chute | W×L(mm) | 1200×2030 | 1500×2370 |

| Main Belt Conveyor | W×L(mm) | 1000×8500 | 1200×9000 |

| Discharging Height(mm) | 3300 | 3500 | |

| Screening System | Type | Single-deck Vibrating Screen | Single-deck Vibrating Screen |

| Screening Surface Size(mm) | 1500×3000 | 1500×3600 | |

| Size of Return Belt Conveyor(mm) | 500×8000 | 500×8000 | |

| Size of Fine Product Conveyor(mm) | 1200×5000 | 1200×5500 | |

| Fine Product ConveyorDischarging Height(mm) | 3000 | 3200 | |

| Powertrain | Driving Mechanism of Crusher | Diesel-Hydraulic Drive | Diesel-Direct Drive |

| Engine | Cummins 264kW | Cummins 335kW | |

| Overall Dimension of Transportation | Length(mm) | 13000/15500 | 14500/17000 |

| Width(mm) | 2700/3200 | 3000/3460 | |

| Height(mm) | 3400 | 3650 | |

| Weight(t) | 35/42 | 46/55 | |

WT1316

| SPECIFICATIONS | WT1316 | |

| Feeding Device | Maximum Feeding Size(mm) | 600 |

| Feeding Height(mm) | 4400 | |

| Hopper Volume(m³) | 8 | |

| Vibrating Feeder | W×L(mm) | 1160×4200 |

| Side Conveyor | W×L(mm) | 650×4000 |

| Discharging Height(mm) | 2400 | |

| Mainframe of Crusher | Model | CI1316 |

| Feeding Opening size(mm) | 1540×980 | |

| Weight(t) | 16 | |

| Rotor Size(mm) | Φ 1300×1500 | |

| Drive Mode | Direct Drive | |

| Vibrating Discharge Chute | W×L(mm) | 1600×2500 |

| Main Belt Conveyor | W×L(mm) | 1200×9500 |

| Discharging Height(mm) | 3600 | |

| Screening System | Type | |

| Screening Surface Size(mm) | ||

| Size of Return Belt Conveyor(mm) | ||

| Size of Fine Product Conveyor(mm) | ||

| Fine Product ConveyorDischarging Height(mm) | ||

| Powertrain | Driving Mechanism of Crusher | Diesel-Direct Drive |

| Engine | Cummins 391kW | |

| Overall Dimension of Transportation | Length(mm) | 15000 |

| Width(mm) | 3150 | |

| Height(mm) | 3700 | |

| Weight(t) | 52 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.