What is a hydraulic cone crusher?

Multi-cylinder hydraulic cone crusher is a new type of cone crusher developed based on the introduction of new German technology, with higher crushing capacity and crushing efficiency. It is used for secondary crushing, fine crushing, and ultra-fine crushing of hard materials with a particle size of 0–385 mm.

FTM Machinery Hydraulic Cone Crusher Price: From $5,000 / Set Get the Latest Price

Hydraulic cone crusher for various processing plants

Multi-cylinder hydraulic cone crusher is a brand-new product that replaces the spring cone crusher in today's mining construction industry. It is ideal equipment for large stone quarries and mining crushing.

Hydraulic cone crusher machines are used to crush medium hardness ores and rocks, such as pebble, granite, basalt, limestone, quartzite, diabase, iron ore, gold ore, copper ore, etc. Applications are especially common in these industries:

- Mining factory

- Quarry factory

- Aggregate factory

- Road building

- Construction work

- Energy and chemistry

Performance advantages of hydraulic cone crusher

The performance features of FTM Machinery multi-cylinder hydraulic cone crusher are highlighted in the following aspects:

- Production capacity

- Automation

- Finished grain shape

- Discharge port

- Lubrication system

- Service life

Large production capacity

Large production capacity

The multi-cylinder hydraulic cone crusher perfectly combines the crushing stroke, crushing speed, and crushing cavity shape. Under the same fixed cone diameter, the output is 30%–60% higher than the spring cone crusher.

High degree of automation

High degree of automation

The automatic control system can realize overload protection, over-iron protection, hydraulic cavity clearing, and discharge port adjustment. The high degree of automation reduces downtime and improves work efficiency.

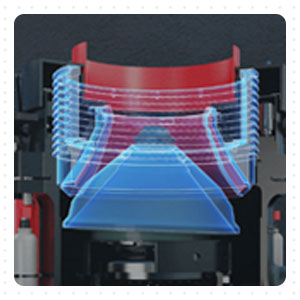

Good grain shape of finished products

Good grain shape of finished products

The machine adopts a special crushing cavity and lamination crushing principle, which significantly increases the proportion of cubes in the finished products. Needle-shaped stones are reduced and the particle size is more uniform.

Discharge port adjustment

Discharge port adjustment

The discharge port is hydraulically adjusted to control the discharge size in time. Easy operation and high reliability. The crusher can be operated with full feed, reducing operating costs.

Unique lubrication system

Unique lubrication system

Unique hydraulic and lubrication system design, with double insurance. Protects the hydraulic cone crusher when overloaded, and the bearings are well lubricated.

Less wear and long service life

Less wear and long service life

The wearing parts are made of wear-resistant high-manganese steel, which has small loss and greatly improves the service life of the equipment. Maintenance is simple, bringing considerable economic benefits to customers.

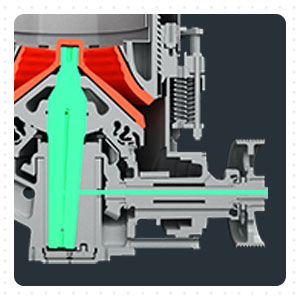

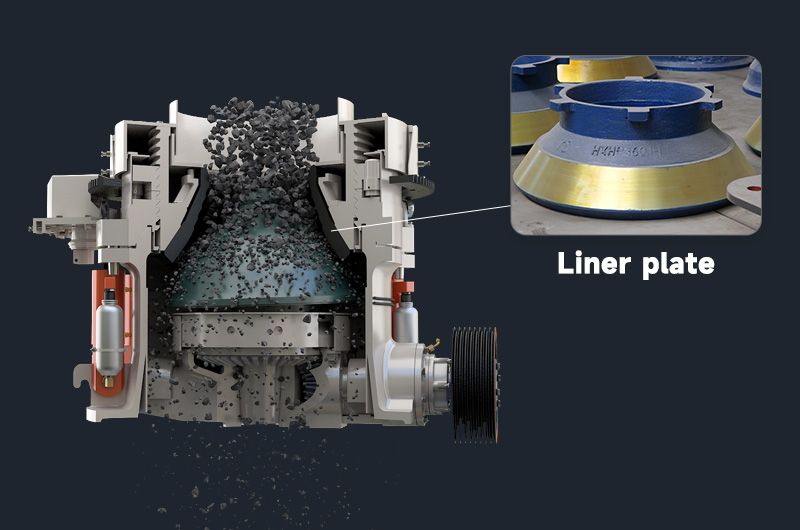

Hydraulic cone crusher working principle

The structure of the multi-cylinder hydraulic cone crusher is more complicated. When working, the motor drives the transmission shaft through the pulley or coupling. The moving cone does periodic rotation-swing movement under the force of the eccentric sleeve. The raw materials are squeezed, impacted, and finally broken in the crushing chamber.

Maintain your wear parts

Liner plate is a wearable part in the production of hydraulic cone crusher machine, which is affected by factors such as ore hardness, particle size, compressive strength, feeding method, and working condition.

You can maintain consumable parts and improve crusher performance by paying attention to the following factors:

- 1Correctly select the crushing cavity for the crushed materials.

- 2The feeding particle size ratio is appropriate.

- 3Control the feeding amount.

- 4The crusher discharge area is unobstructed.

- 5Uniform feeding within the 360° range of the crushing cavity.

- 6Select the appropriate size of screening equipment.

- 7The specifications of the conveyor are adapted to the maximum processing capacity of the crusher.

FTM Machinery case—350 T/H crushing plant in Mongolia

350 T/H crushing plant in Mongolia

| Project | Mongolia 350 T/H crushing plant |

| Material | Basalt |

| Capacity | 350 T/H |

| Input size | ≤300 mm |

| Discharge size | 2–5 mm, 5–10 mm, 10–20 mm, 20–40 mm |

| Production line type | Stationary |

Customer review

"This cone-crushing production line exceeded my expectations. The finished products after processing are of good quality, and the cubic content of the products is more than 85%. After selling them, the profit is high. I am very grateful to FTM Machinery and will continue to expand the business in the future."

350 T/H stone crushing solution Yes, I am interested!

Mobile hydraulic cone crusher for sale

In addition to multi-cylinder hydraulic cone crushers for sale, FTM Machinery also launched the mobile hydraulic cone crushing plant. It is often used in the processing of materials that need relocation, such as construction waste and urban infrastructure.

When you encounter the dilemma that the site is not large enough, the mountain road is difficult to walk, or the material is too difficult to break, it will help you get it all done. At present, it is in great demand in the fields of roads, railways, water conservancy, electric power, tunnels, and so on.

Parameter

- Multi-Cylinder Hydraulic Cone Crusher

- Hydraulic Cone Crusher

| Model | Cavities | Broken cone big end diameter(mm) | Feeding size(mm) | Maximum Feeding size(mm) | Adjusting Range of Discharge port(mm) | Capacity(t/h) | Power(kw) | Weight of main machine(t) |

| HPM200 | C1 | 900 | 185 | 145 | 22 | 160~250 | 160 | 11 |

| C2 | 125 | 100 | 18 | 145~250 | ||||

| C3 | 95 | 75 | 14 | 120~250 | ||||

| F1 | 76 | 60 | 12 | 108~210 | ||||

| F2 | 54 | 45 | 10 | 81~210 | ||||

| HPM300 | C1 | 1100 | 235 | 190 | 26 | 230~445 | 220 | 20 |

| C2 | 211 | 170 | 20 | 200~445 | ||||

| C3 | 150 | 120 | 16 | 180~445 | ||||

| F1 | 107 | 85 | 14 | 160~220 | ||||

| F2 | 53 | 40 | 12 | 140~220 | ||||

| HPM400 | C1 | 1400 | 299 | 240 | 35 | 270~630 | 315 | 27 |

| C2 | 198 | 160 | 25 | 243~630 | ||||

| C3 | 111 | 90 | 18 | 210~630 | ||||

| F1 | 92 | 75 | 15 | 162~370 | ||||

| F2 | 52 | 40 | 13 | 126~370 | ||||

| HPM500 | C1 | 1500 | 335 | 270 | 38 | 365~790 | 400 | 40 |

| C2 | 286 | 230 | 30 | 328~790 | ||||

| C3 | 204 | 165 | 22 | 280~790 | ||||

| F1 | 133 | 105 | 20 | 202~450 | ||||

| F2 | 95 | 75 | 16 | 158~450 | ||||

| HPM800 | C1 | 2000 | 353 | 280 | 38 | 616~1100 | 630 | 70 |

| C2 | 297 | 240 | 38 | 522~1100 | ||||

| C3 | 219 | 175 | 22 | 380~1100 | ||||

| F1 | 155 | 125 | 20 | 328~730 | ||||

| F2 | 92 | 75 | 16 | 270~730 | ||||

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cavities | Maximum Feeding size(mm) | Capacity(t/h) |

| HPM200 | C1 | 145 | 160~250 |

| C2 | 100 | 145~250 | |

| C3 | 75 | 120~250 | |

| F1 | 60 | 108~210 | |

| F2 | 45 | 81~210 | |

| HPM300 | C1 | 190 | 230~445 |

| C2 | 170 | 200~445 | |

| C3 | 120 | 180~445 | |

| F1 | 85 | 160~220 | |

| F2 | 40 | 140~220 | |

| HPM400 | C1 | 240 | 270~630 |

| C2 | 160 | 243~630 | |

| C3 | 90 | 210~630 | |

| F1 | 75 | 162~370 | |

| F2 | 40 | 126~370 | |

| HPM500 | C1 | 270 | 365~790 |

| C2 | 230 | 328~790 | |

| C3 | 165 | 280~790 | |

| F1 | 105 | 202~450 | |

| F2 | 75 | 158~450 | |

| HPM800 | C1 | 280 | 616~1100 |

| C2 | 240 | 522~1100 | |

| C3 | 175 | 380~1100 | |

| F1 | 125 | 328~730 | |

| F2 | 75 | 270~730 | |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Cavities | Broken cone big end diameter(mm) | Feeding Size(mm) | Max.feeding Size(mm) | Adjusting Range of Discharge Opening(mm) | Processing capacity(t/h) | Power(kw) | Weight of main machine(t) |

| GYS 300 | C1 | 910 | 175 | 140 | 13-38 | 81-180 | 90 | 10 |

| C2 | 102 | 80 | 9-22 | 60-180 | ||||

| F1 | 76 | 60 | 3-16 | 36-145 | ||||

| F2 | 41 | 30 | 3-13 | 36-130 | ||||

| GYS 400 | C1 | 1200 | 241 | 190 | 19-51 | 207-400 | 200 | 20 |

| C2 | 210 | 168 | 16-38 | 162-350 | ||||

| C3 | 137 | 110 | 13-31 | 126-310 | ||||

| F1 | 105 | 85 | 8-25 | 109-230 | ||||

| F2 | 89 | 70 | 6-16 | 82-230 | ||||

| F3 | 64 | 50 | 3-16 | 40-230 | ||||

| GYS 500 | C1 | 1600 | 269 | 215 | 25-64 | 280-650 | 280 | 40 |

| C2 | 241 | 190 | 22-51 | 258-450 | ||||

| C3 | 209 | 170 | 16-38 | 180-410 | ||||

| F1 | 133 | 105 | 10-25 | 162-355 | ||||

| F2 | 89 | 70 | 6-19 | 136-330 | ||||

| F3 | 70 | 55 | 5-13 | 90-300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max.feeding Size(mm) | Processing capacity(t/h) |

| GYS 300 | 140 | 81-180 |

| 80 | 60-180 | |

| 60 | 36-145 | |

| 30 | 36-130 | |

| GYS 400 | 190 | 207-400 |

| 168 | 162-350 | |

| 110 | 126-310 | |

| 85 | 109-230 | |

| 70 | 82-230 | |

| 50 | 40-230 | |

| GYS 500 | 215 | 280-650 |

| 190 | 258-450 | |

| 170 | 180-410 | |

| 105 | 162-355 | |

| 70 | 136-330 | |

| 55 | 90-300 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.