FTM Machinery is one of the leading professional industrial drying equipment manufacturers and it can fully meet all the industrial drying needs.

With over 40 years of industrial drying experience, we provide cost-effective dryers to the United States, Brazil, South Korea, Russia, the United Kingdom, the Philippines, India, and other countries, helping optimize drying efficiency and increase profits.

Drying equipment

The dryer, also known as a drum dryer, uses drum drying to dry high-moisture dispersed solid materials below 50 mm. It supports direct or indirect heating, and the drying temperature can reach 800°C without causing deterioration or damage to the dried materials.

What Benefits Can You Get from Us?

Our dryer equipment helps industries like mineral processing, cement, fertilizer, agriculture, and construction to reduce moisture in bulk solids, from grains and minerals to powders and granules. We offer customized industrial drying solutions:

- Materials with any moisture level can be processed, with moisture controlled to 0.5%–1% for grinding, briquetting, and cement production

- Save time with high efficiency and quick drying

- Controllable drying temperature and drying time

- Affordable dryers starting at $1,000 with durable wear-resistant parts

- Zero dust, low noise, and 20%–30% energy savings

Drying Equipment for Sale

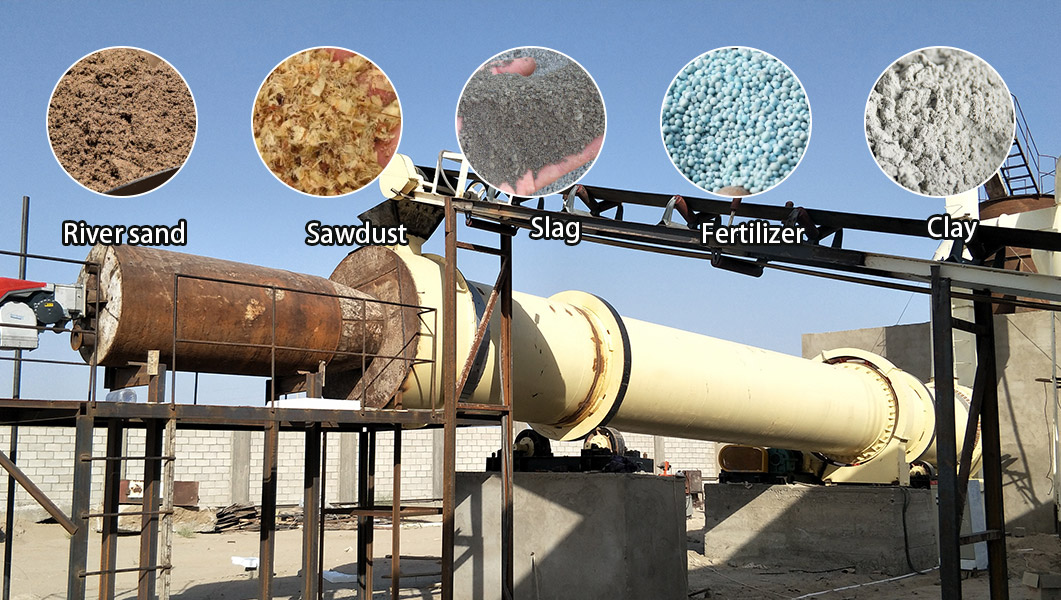

Depending on the materials, you can choose a suitable dryer machine type.

We offer the sand dryer for natural sand and M sand, rotary dryer, and other drying equipment for metal ores, non-metallic ores, sawdust, coal, cement, slag, manure, fertilizer, etc. GET A FREE QUOTE!

1. Rotary Dryer

The rotary dryer, known as the workhorse of the chemical industry, is ideal for drying high-moisture, viscous materials.

Applicable materials: fertilizers, sand, sawdust, limestone, slag, kaolin clay, iron ore, gold ore, clay, and other industrial bulk solids.

Special features:

- Types of dryer: ①Direct Rotary Dryers: High efficiency for fertilizers, minerals, and specialty chemicals. ②Indirect Rotary Dryers: Preferred for small/medium batches of fine materials like flammable materials, grains, pulp, and pigments.

- Large drying capacity: 1.9–76 t/h

- Heat source: gas, diesel, coal, wood, steam, etc.

- Controllable drying process

- Robust construction with 10 mm thick 20g boiler steel plate

- Effectively prevents material from sticking on the wall

2. Rotary Drum Dryer

The rotary drum dryer can dry fertilizer, coal, copper ore, river sand, clay, sawdust, slag, and other materials with a size below 20 mm.

The fuels are anthracite bituminous coal, combustible gases (natural gas, biogas, etc.), and biomass fuel made of wood raw materials.

Special features:

- Up to 80% thermal efficiency

- Large capacity (1.9–76 tons/hour) with low drying cost

- Adjustable particle size and moisture (slime drying: moisture <8%, particle size <8 mm)

- Enhanced wear resistance (3–5x) and extended service life (over 3x)

- Zero dust pollution; exhaust gas converts to water vapor

3. River Sand Dryer

The river sand dryer is the first choice for drying 20–40 mm sand used in construction and industrial processes. The sand in dryer can be used as raw material for glass production or as a proppant for hydraulic fracturing.

Applicable materials: river sand, quartz sand, silica sand, frac sand, foundry sand, construction sand, glass sand, yellow sand, sea sand, manufactured sand, dolomite sand, dry mixed mortar, garnet sand, zircon sand, washed sand, carborundum, cinder, etc.

Special features of sand dryers:

- Good sand drying effect. The drying temperature can reach 800°C to ensure the final moisture is 0.5%–1% or less.

- Short sand drying time (0.5–5 seconds). The sand in dryer still retains its physical and chemical properties.

- Strong wear resistance, which is 3–4 times that of ordinary steel plate.

4. Lignite Dryer

The lignite dryer, also known as the coal dryer, is ideal for drying coal materials. It adopts the low-temperature four-class drying process, which can greatly increase the calorific value and combustion efficiency of coal.

Applicable materials: raw coal, lignite, orchid charcoal, coal slurry, slime, fly ash, anthracite, bituminous coal, washed coal, coke, petroleum coke, coal slurry, slime, carbon black pellets, activated carbon, etc.

Special features:

- Supported fuels: steam waste heat, coal gas, natural gas, coal, and other fuels.

- The moisture content of coal materials is reduced from 20%–70% to below 13% and the particle size can be controlled below 8 mm

- The output material is lower than 60℃ and no cooling is required after drying

- It eliminates the sticking phenomenon on the inner wall of the cylinder

- Large processing capacity and low drying cost

- Easy to install and small footprint

5. Mineral Dryer Equipment

Mineral dryer equipment, or ore dryer, is used for mineral drying. The minerals to be dried are metal ores, non-metallic ores, salts, secondary minerals, and other industrial by-products.

Applicable materials: gold ore, iron ore, copper ore, tungsten ore, lithium ore, limestone, quartz stone, marble, dolomite rock, clay, kaolin clay, rock phosphate, potash ore, fluorite, gypsum, coal powder, fly ash, coal gangue, sludge, slag, etc.

Special features:

- Mineral dryer uses corrosion-resistant stainless-steel material to dry corrosive or easy-to-agglomerate minerals.

- The rotary drum uses multi-layer lifting plates to make minerals fully in contact with hot air, achieving 80% thermal efficiency.

- Drying time is 0.5–5 seconds for uniform drying, with final moisture under 1%. Capacity is up to 76 tons/hour.

- Drying temperature varies by material, ranging from 800°C for mineral sands to under 300°C for sawdust and gypsum.

- Affordable heat sources include natural gas, coal, anthracite, biogas, diesel, methane, or biomass.

- Below 60°C, the mineral drying machine requires no cooling and can be used directly or for further processing.

6. Gypsum Dryer

The gypsum dryer is one of the best-sold mineral dryers on the market. It is widely used in the metallurgy industry, chemical plants, power plants, cement plants, etc.

This gypsum dryer is not only especially used for drying gypsum, but also can dry limestone, fly ash, talc, molybdenum ore, calcium carbonate, Phosphate, tungsten concentrate, silica lime, tailings, dolomite, calcite, and other metal concentrate materials.

Special features:

- The heat carriers include hot air, flue gas, etc

- The moisture content of dried material can be adjusted to 0.5–1%

- The output temperature is under 50°C, allowing direct storage

- The thermal efficiency reaches 80%, over 45% higher than the traditional single-drum dryers.

- The gypsum will not stick to the inner surface of the drying drum

7. Clay Dryer

The clay dryer is another type of mineral dryer. It can efficiently dry various sticky materials, such as clay, kaolin (china clay), bauxite, bentonite, Earthenware, Fire clay, Ball clay, Fuller, Stoneware, bauxite, and activated clay.

Special features:

- It reduces the adhesion of the inner cylinder wall

- Good drying effect and the final moisture is below 0.5%–1%

- Long drying cost

- No dust overflows

8. Slag Dryer

The slag dryer , or slag dryer machine, is used to dry slag. It is a cement dryer. Slag is a byproduct of metal smelting, coal combustion, and ore processing. It contains metal oxides, minerals, impurities, and moisture. Recycling dried slag supports sustainability.

Applicable materials: Slag, blast furnace slag, furnace slag, iron ore slag, steel slag, coal gangue, bauxite residue, alkali slag, acid slag, carbide slag, water slag, coal slag, tailings slag mud, raw ore sludge, tailings sludge, municipal sludge, domestic sludge, river sludge, oil sludge, etc.

Special features:

- Processing capacity: 1.9–76 tons/hour

- Supported fuels: natural gas, fuel, coal, biomass, and blended fuels

- It uses wear-resistant and high-temperature-resistant materials to improve drying efficiency by over 60%

- The high-temperature hot air-drying technology is used to reduce moisture content to 1%

- It features a lifting plate for even material flow and uniform drying at low costs

- No blockage, material returning, and uneven feeding

- It meets the large-scale production needs of cement, mineral processing, and other industries

9. Sludge Dryer

The sludge dryer, or slurry dryer, is a drying equipment that efficiently dries high-humidity and high-viscosity sludge. The dried sludge is used as an eco-friendly clean fuel, organic fertilizer, or building filler.

Applicable materials: municipal sludge, sewage sludge, wastewater treatment plant sludge, chemical plant sludge, paper mill sludge, dredged river sludge, oil sludge, red mud, spray painting factory sludge, and firecracker factory sludge.

Special features:

- Efficiently dries sticky, oily, and sandy sludge with a thermal efficiency of up to 85%.

- The dried sludge output reaches 76 tons/hour with moisture content below 10%.

- The rotary drum is made of wear-resistant and corrosion-resistant steel, lasting over 10 years.

- Supports multiple fuels like coal, biomass, gas, and diesel. Low consumption, with drying costs just one-third of similar products.

- Fully enclosed body, multi-stage exhaust filtration, no leakage.

10. Sawdust Dryer

The sawdust dryer, also known as the biomass dryer, is ideal for drying a wide range of biomass materials in the agricultural, feed, and fertilizer industries. The dried biomass can be used as a fuel for energy production or as a feedstock for the production of biofuels.

Applicable materials: sawdust, wood chips, corn straw, soybean straw, cotton straw, wheat straw, sorghum straw, forage grass, sugarcane residue, organic fertilizer, compound fertilizer, kitchen waste, fruit residue, wine residue, Chinese medicine residue, paper residue, bagasse, etc.

Special features:

- High drying efficiency: The moisture is below 12%

- Optimized structure and small covering area

- Save energy: The coal consumption is reduced by 60%

- Automatic control

11. Three-drum Dryer

If you are looking for a cheap sand drum dryer or coal slurry dryer, a three-drum dryer is a good choice.

It can also dry minerals, stone powder, metal powder, gypsum powder, clay, sawdust, wood chips, fertilizers, sludge, etc.

Special features:

- Drying capacity: 1.9–76 t/h

- High-quality steel structure and small footprint (only half of the single drum dryer)

- Controllable drying temperature and drying time

- Affordable heat resources, low energy consumption, and heat emissions

What You Should Know about Dryer Equipment?

- Use a Rotary Drum Dryer to Dry Fertilizers

- 4 Types of Coal and How to Dry Coal?

- Efficient Silica Sand Dryer

- Rotary Dryer: The Secret to Efficient Industrial Drying

- Which Industrial Dryer Works Best for My Drying Line?

- Single Drum Dryer Overview Manual

- 14 Common Industrial Dryers Faults and Solutions