What is a gypsum dryer?

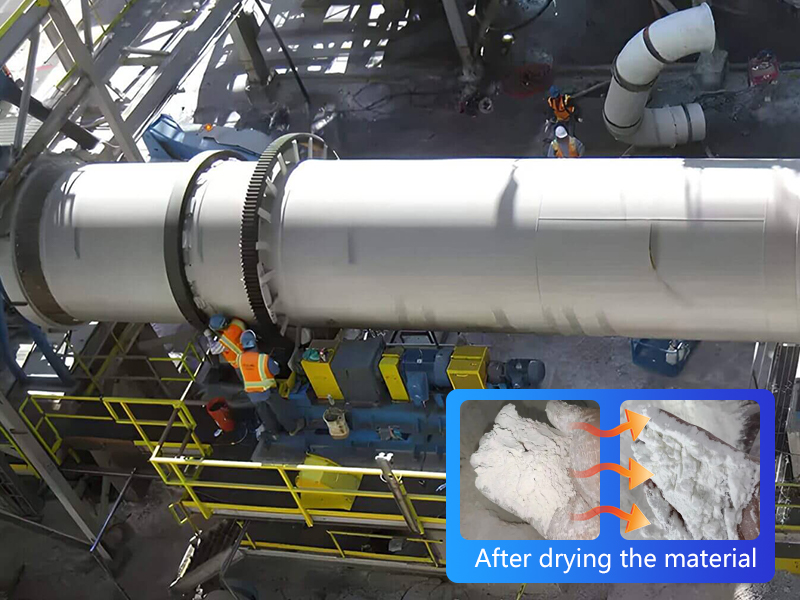

A gypsum dryer is a high-efficiency rotary drying machine used to remove moisture from gypsum and other mineral materials. It is widely used in building materials, mining, chemical production, and industrial waste treatment.

This drying machine is suitable for different types of natural gypsum (such as fibrous gypsum and transparent gypsum) and many industrial by-product gypsums, including flue gas desulfurization gypsum, phosphogypsum, fluorogypsum, gypsum slag, and gypsum sludge.

In addition, gypsum dryers can also be used to dry many other mineral materials:

- Metal minerals: iron ore, copper ore, lithium ore, manganese ore, gold ore, zinc ore, chromite, bauxite, etc.

- Non-metal minerals: quartz, limestone, barite, talc, slag, phosphate rock, bentonite, borax, feldspar, basalt, etc.

- Industrial waste: coal gangue, fly ash, clay, and more.

By reducing the moisture content, the gypsum dryer helps improve the efficiency of further processing steps. It is an ideal solution for continuous and efficient drying operations.

Below are the main technical specifications of gypsum dryers:

| Spec./m(Dia.×Length) | Shell Cubage(m³) | Capacity(t/h) | Highest Inlet Air Temperature(℃) |

| Φ1.2×8.0 | 9.0 | 1.9–2.4 | 700–800 |

| Φ2.2×14 | 53.2 | 11.4–14.2 | 700–800 |

| Φ2.4×20 | 90.4 | 19.3–24.1 | 700–800 |

| Φ3.0×20 | 141.3 | 30.1–37.7 | 700–800 |

| Φ3.6×28 | 285 | 60.8–76.0 | 700–800 |

If you are planning to build a plant or choose equipment, just tell us your material and daily output. We can help recommend the right dryer for you. Contact us

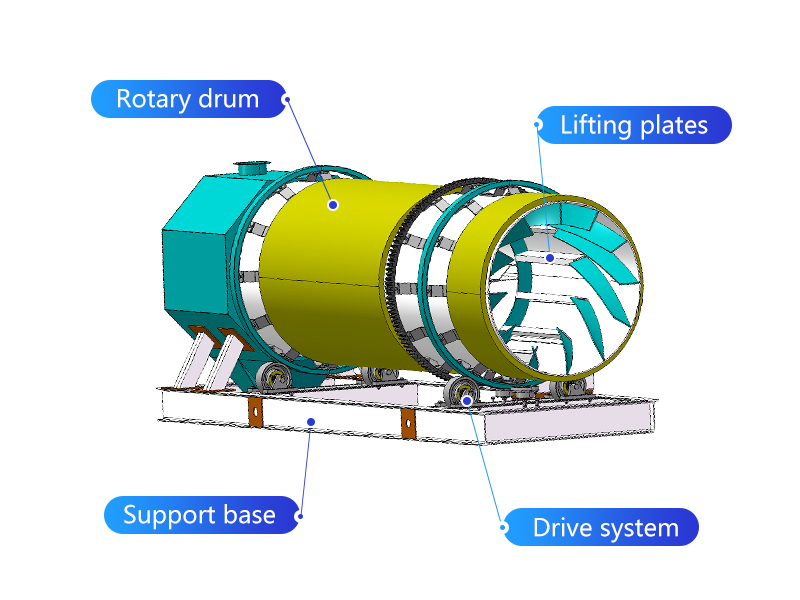

Main components of a gypsum dryer

A gypsum dryer consists of several key parts, including the rotary drum, lifting plates, drive system, and support base. Each part plays a vital role in the drying process.

1. Rotary drum

The rotary drum is the main part of the dryer. It is a large, round tube where the drying happens. Wet materials enter the drum and move through it as the drum slowly rotates. Inside, the drum spreads the materials evenly and heats them with hot air. The drum works well because it keeps the materials in contact with hot air. This speeds up drying, making the material ready for use in factories.

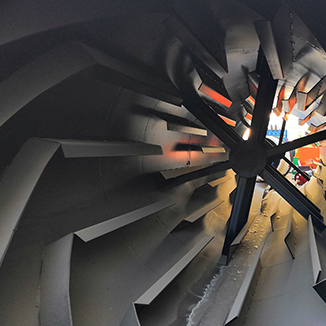

2. Lifting plates

Lifting plates are placed inside the rotary drum. These plates lift and spread the wet material as the drum spins. This creates a "curtain" of material, letting hot air reach all parts of it. This makes drying quicker and better. The plates work together with spiral blades to stop air holes from forming. This design helps the hot air flow evenly and improves heat transfer.

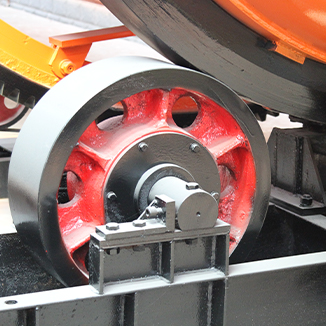

3. Drive system

The drive system makes the drum rotate at the right speed. A good transmission system matches the drum's speed with the material's feeding rate and hot air volume. This balance saves energy and improves drying. Without the drive system, the drum would not work, and drying would stop.

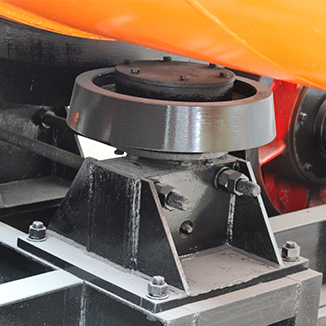

4. Support device

The support device holds the dryer steady. It prevents the drum from shaking or moving out of place. You can think of it as the base that keeps the machine fixed during operation. If the support system fails, the drum might shake too much, causing uneven drying or damage to the machine.

How does the gypsum dryer work?

Knowing how drying works can make dryers work better. This saves energy and gives better results.

This video demonstrates the working principle of the gypsum dryer:

- 1 Feeding: Wet gypsum is conveyed into the dryer drum via a belt conveyor.

- 2 Hot air drying: High-temperature air from the burner heats the material in the drum.

- 3 Drum rotation: The drum rotates slowly, with lifting plates tossing and rolling the material.

- 4 Even drying: The material fully contacts the hot air, causing rapid moisture evaporation.

- 5 Moisture removal: Wet air is removed through the dust collector and exhaust system.

- 6 Dry material discharge: Dried gypsum is discharged and sent to the next process.

Why choose FTM Machinery gypsum dryer?

FTM Machinery offers modern mineral dryers that spread heat evenly and reduce energy waste. This helps you save money and get a better return on investment (ROI).

- High drying efficiency: Over 80% heat efficiency, saving 20–30% energy compared to old dryers.

- Strong adaptability: The dryer can handle gypsum with high moisture (30–40%) and reduce it to below 1%.

- Wide capacity range: Models are available for 1.9 to 76 t/h, meeting needs from small plants to large factories.

- Durable structure: The drum uses wear-resistant alloy steel, which lasts long even with rough mineral materials.

- Flexible fuel options: Supports coal, biomass, natural gas, diesel, and more — easy to match local fuel conditions.

- Smart control system: Uses PLC to control feeding speed, temperature, and drum speed automatically. Less manual work is needed.

- Environmentally friendly: Equipped with cyclone dust collectors to meet national environmental standards.

To get the best results from your gypsum dryer, talk to our experts. We can help design the right solution based on your needs. Contact us

Customer case: Saudi Arabia desulfurized gypsum drying project

We built a 30 TPH gypsum drying system for a Saudi power plant. Moisture was reduced from 38% to below 1.5%, producing eco-friendly building powder.

The system uses a natural gas furnace, PLC control, and dust removal to meet local standards. It runs smoothly, outputting over 700 tons of dry gypsum daily.

"The dryer performs reliably under local climate conditions. Moisture control is accurate, and energy consumption is lower than expected. Installation and remote support were smooth. We are satisfied with the overall performance.

— Michael Tarek, Project Manager

Frequently asked questions about gypsum dryers

1. What affects the drying efficiency of a gypsum dryer?

- a) Moisture content: Higher moisture requires longer drying time and more energy.

- b) Hot air temperature & airflow: Higher, well-distributed temperatures improve efficiency but must be controlled to avoid over-drying or heat loss.

- c) Operating parameters: Drum speed, feed rate, and lifter design must match material properties for optimal heat exchange.

- d) Maintenance: Regular cleaning, sealing checks, and part inspections help maintain efficiency and stable operation.

2. How to maintain a gypsum dryer?

- Clean the drum and lifters regularly to prevent clogging. Check seals, fans, and bearings for wear. Lubricate moving parts and listen for unusual noises. Proper maintenance extends service life and reduces energy consumption.