For some unusual failures of industrial dryers, people without rich experience will have no way to deal with them. As a professional manufacturer of industrial dryer equipment, Fote has rich experience in troubleshooting problems of industrial dryers. Today we will introduce the analysis and solutions of industrial dryer failures.

1. The dryer does not rotate.

Fault causes:

- 1 The motor of the dryer is burnt out.

- 2 The fuse is burned out.

- 3 The belt is loose or broken.

Solutions:

- 1 Replace the motor or adjust the position of the motor.

- 2 Replace the fuse.

- 3 Replace the belt.

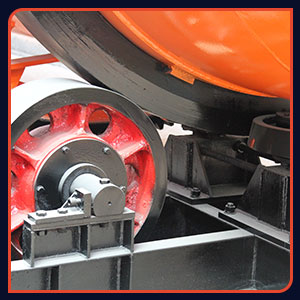

Industrial dryer motor

2. The temperature of the dryer is too high or too low.

Fault causes:

1 The fan blade of the industrial dryer is reversed.

2 The heating tube or the conductive wire is burnt out.

Solutions:

1 Adjust the phase line of the power supply and change the rotation direction of the motor.

2 Replace the heat tube or its conductive wire.

3. The industrial dryer has large noise.

Fault causes:

1 The workpieces are placed unevenly or the drum dryer is installed unstably.

2 The bearing loses oil or is damaged.

3 The fixing bolt of the bearing seat is loose.

Solutions:

1 Stop the machine and place the workpieces evenly, or reinstall the dryer stably.

2 Replace the bearing of the industrial dryer.

3 Tighten the fixing bolt of the bearing seat firmly.

4. The braking of the industrial dryer doesn't work.

Fault cause:

The wear of the brake pads of the industrial dryer is serious.

Solutions:

Replace the brake pads.

5. The raw materials cannot be dried at one time.

Fault causes:

- 1 The dryer is too small but it contains too many raw materials.

- 2 The calculation of ventilation network, wind pressure or flow is incorrect.

- 3 Improper use of dryer.

Solutions:

- 1 Replace the dryer with a larger one or load less each time. You can also increase the temperature of the dryer, but this method is easy to cause a fire in the dryer, so you can also change the dryer.

- 2 Ask the dryer manufacturer to recalculate the wind pressure and flow rate, and then provide a design change plan according to the actual situation.

- 3 Negotiate with the industrial dryer manufacturer to obtain the equipment manual to learn the correct way to use the dryer.

Industrial dryer

6. The raw material of the dryer is on fire.

Fault causes:

- 1 The raw materials cannot be sucked away, resulting in fire in the dryer.

- 2 The dryer equipment is too small to achieve the drying effect and it is forced to be heated, which may cause a fire.

- 3 It may be caused by the improper use of dryer equipment.

- 4 There is something wrong with the design principle of the dryer equipment.

Solutions:

- 1 Check whether the dryer equipment is installed correctly or there is air leakage.

- 2 Modify the dryer or replace it with a larger one.

- 3 The operator can re-learn the operation precautions of the dryer.

- 4 Ask the manufacturer to replace or renovate the dryer.

7. The industrial dryer blasts.

Fault causes:

- 1 The drying temperature is too high, causing fire and combustion in the drying equipment.

- 2 The industrial dryer is blocked.

Solutions:

- 1 Reduce the drying temperature.

- 2 Clean the drying equipment.

The drying equipment

8. The material cannot be sucked away.

Fault causes:

- 1 There is air leakage or incorrect installation.

- 2 There is problem in the design of the drying equipment and the wind pressure is not enough.

Solutions:

- 1 Check whether the installation is correct according to the installation drawings and check the pipeline-interface for leaks.

- 2 Coordinate with the manufacturer.

9. The chimney of the separator discharges or its lower outlet steams.

Fault causes:

1 The separator is too small or there is a problem with the separator design.

2 The calculation of ventilation network and wind pressure is wrong.

Solutions:

1 Replace or transform the separator.

2 Negotiate with the manufacturer.

10. The materials are not evenly wet and dry.

Fault causes:

- 1 The drying equipment is used improperly.

- 2 The raw materials are agglomerated.

Solutions:

- 1 It is necessary to strengthen the technical training of operators to make them proficient in operation skills.

- 2 Break the raw materials into pieces before drying them.

11. The fuel is wasted.

Fault causes:

- 1 The thermal insulation performance of industrial dryer equipment is poor.

- 2 There is a problem in the design and manufacture of the furnace.

Solutions:

- 1 Pack a layer of thermal insulation material to improve the working condition of the drying equipment.

- 2 Consult the manufacturer for improvement methods.

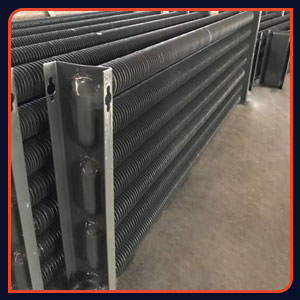

Industrial dryer thermal insulation material

12. The rolling ring oscillates to the cylinder.

Fault cause:

The concave joint side of the rolling ring is not tightened.

Solution:

Tighten it a little, but not too tight. Otherwise it is prone to cause accidents.

13. The gap between the large gear and the small one of the dryer is destroyed.

Fault causes:

- 1 The supporting wheel is worn out.

- 2 The catch wheel is worn out.

- 3 The pinion is worn out.

Solutions:

- 1 Firstly analyze whether the wear is serious. If so, replace it.

- 2 If it is not serious, lathe work will be enough. It can also be installed on the reverse side.

- 3 If you are afraid of its instability, you can replace them in pairs.

14. The barrel of the dryer vibrates.

Fault causes:

- 1 The connection between the supporting wheel device and the base of the equipment has been damaged.

- 2 There is wear on the side of the rolling ring.

Solutions:

- 1 Correct and reinforce it.

- 2 Only turning operation is needed if its wear condition is not serious, and it will be replaced if it is serious.