The mobile crushing station, mounted on wheels or tracks, can do mobile crushing or portable crushing between sites to form an efficient crushing and screening plant.

It can be used for coarse, medium, fine crushing or sand making of hard rocks and minerals on any harsh site, with an output range of 10 to 650 tons/hour.

Compared to the mining crushing station (fixed crushing plant), the mobility of the mobile crushing station reduces transport costs and boosts efficiency, making it ideal for remote areas.

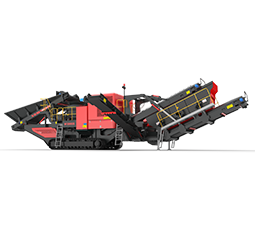

Mobile crushing plant

Application of Mobile Crushing Station

The mobile crushing station is widely used for crushing and screening minerals, rocks, and other aggregates as well as recycling solid waste:

• Rock crushing: Limestone, granite, basalt, gabbro, pebbles, dolomite, silica sand, talc, quartz, bluestone, etc.

• Mining crushing: Coal, gold ore, iron ore, copper ore, manganese ore, lithium ore, lead and zinc ore, etc.

• Solid waste recycling: Concrete, construction waste, slag, tailings, demolition waste, etc.

• Infrastructure projects: Road construction, aggregate production, railway development, airport expansion, etc.

Mobile Crushing Station for Sale

Our mobile crushing plants are custom-made and can be designed as wheeled or tracked. Both can be equipped with different rock crushers and screens to complete primary, secondary, or tertiary crushing of hard rock, stone, or other minerals.

1. Mobile Crusher

- Also known as the tracked crusher. It can move by itself by wireless remote control (hydraulic drive crawler) and is ideal for harsh and complex sites like mines, mountains, slopes, and wetlands.

- Types: Mobile jaw crusher, mobile cone crusher, mobile impact crusher, mobile hammer crusher

- Maximum feed size: 185–700 mm

- Capacity: 10–650 t/h

- Weight: 9.5–60 tons

- Price: Get a Customized Price

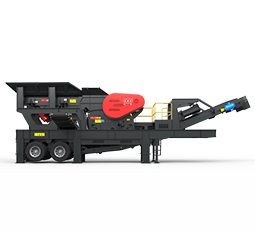

2. Portable Rock Crusher

- Also called the wheel crusher. It is moved by towing on a vehicle and is suitable for crushing sand and gravel such as construction waste, urban facilities, and road construction.

- Types: Portable jaw crushers, portable cone crushers, portable impact crushers, portable hammer crushers

- Maximum feed size: 300–800 mm

- Capacity: 10–650 t/h

- Weight: 31–65 tons

- Price: Get a Customized Price

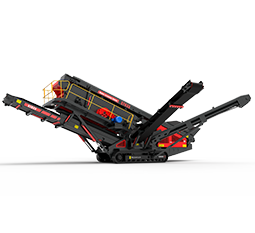

3. Mobile Screening Station

- High-performance mobile screening plants can realize multi-stage screening.

- Length: 10,280–11,800 mm

- Width: 2,830–3,970 mm

- Height: 4,350–6,500 mm

- Weight: 16–19 tons

- Price: Get a Customized Price

The above mobile crushing plants offer various power systems: full hydraulic, D-type hybrid, and E-type external power supply. Customers can select the best option based on fuel cost, operating cost, and electricity availability.

Advantages of FTM Machinery Mobile Crushing Stations

Compared with other mining crushing stations, our mobile crushing plants have obvious advantages:

1. High mobility: The operation site can be moved at any time, adapting to various operating environments, and convenient for road transportation and installation.

2. Integrated design: It has a compact structure and can be flexibly equipped with various equipment to achieve crushing, sand making, screening, and transportation functions.

3. Flexible combination: The rock crushers and screens can be flexibly equipped according to different coarse, medium, and fine crushing production needs.

4. Cost savings: It can directly enter the on-site processing to reduce the material transportation cost. It adopts wireless remote control, fast installation and removal, and reduces labor and maintenance costs.

Common Configurations of Mobile Crushing Station

When setting up a mobile crushing station, consider the types of crushers, material characteristics (such as hardness, moisture, feed size, output size, etc.), capacity needs, energy consumption, plant budget, and the size of the production site.

The capacity typically ranges from 40–50 tons per hour. With options from 30–100 TPH up to over 350 TPH. Small crushing plants often have one mining crushing station, while large ones need multiple.

Our customers use the wheeled or tracked mobile crushers and screens for primary, secondary, and tertiary crushing.

1. Jaw Crusher Machine + Cone Crusher: Ideal for hard rock processing, such as granite, basalt, river pebbles, diabase, iron ore, and other hard rocks. The jaw crusher is used for primary crushing, and the cone crusher is used for secondary crushing.

2. Jaw Crusher Machine + Impact Crusher Machine: Best for soft rock and stone, such as limestone, dolomite, gypsum, bluestone, coal gangue, calcium carbonate, etc. The impact crusher shapes particles well.

3. Hammer Crusher + Sand Making Machine: Suitable for crushing brittle materials, and producing high-quality fine manufactured sand.

4. Jaw Crusher/Impact Crusher Machine + Vibrating Screen: For crushing and screening rocks, producing aggregates and sand of different particle sizes.