With the increasing demand for infrastructure construction, the construction of numerous new buildings and roads, as well as the demolition of old structures, has led to a sharp rise in construction and demolition waste.

Although waste is generally unwelcome, it contains a large amount of recyclable resources.

What is construction and demolition waste (C&D waste)?

Construction and demolition waste (C&D waste) is solid waste generated from various construction activities, including demolition, building, renovation, and repair.

These wastes typically consist of a variety of materials, such as concrete, asphalt, metal, gypsum, wood, bricks, glass, and plastic.

However, according to statistics, despite the massive volume of construction waste worldwide, the overall utilization rate is less than 10%, leading to severe resource wastage.

Problems and disposal of construction and demolition waste

Construction and demolition waste mainly present problems such as large quantities, environmental pollution, resource wastage, and high transportation costs.

In some areas, the regulations and policies for disposing of construction waste are inadequate, leading many construction units to prefer dumping, piling, or incinerating construction and demolition waste.

These unfavorable disposal methods can result in:

- Contamination of groundwater and soil quality

- Reduced water body's regulation capacity

- Emission of organic pollutants and toxic gases, such as dioxins, carbides, nitrides, and sulfides

- Residual solid waste, such as fly ash and slag from burning

Fortunately, through the processing of modern C&D recycling equipment, such as mobile crushers and portable crushers, most of this waste can be reused or recycled into new products.

Discarded concrete and bricks can be crushed and processed into recycled aggregates for manufacturing new bricks. Waste steel, rebar, and other metal materials can be directly reused or remelted. Discarded asphalt pavement mixtures can be proportionally reused for recycled asphalt concrete.

How to effectively recycle construction and demolition waste?

FTM Machinery's mobile crushers, portable crushers, and high-efficiency screening machines are renowned for their versatility and high performance, designed to handle various types of construction waste.

They are equipped with advanced dust and noise control systems, automatic feeding devices, and a range of optional attachments to ensure minimal environmental impact while maximizing production efficiency.

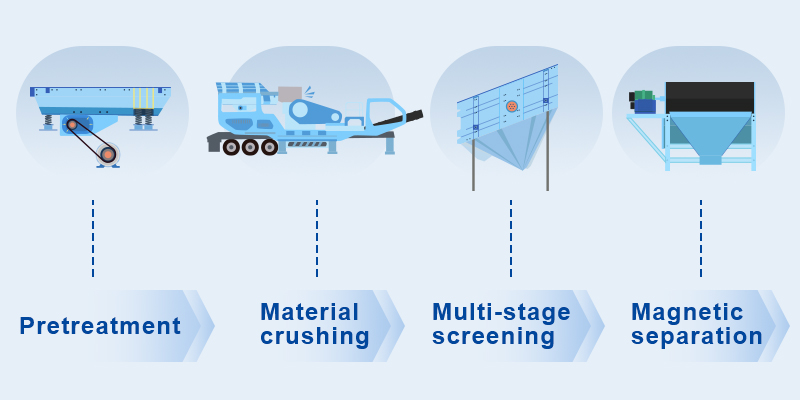

Here is how mobile equipment efficiently processes construction waste:

1. Pre-treatment

The vibrating feeder first performs coarse screening of the construction waste, removing large non-metallic debris such as wood, rubber, and plastic.

2. Material crushing

According to specific needs, crushing equipment break construction and demolition waste into smaller sizes to obtain recycled aggregates.

Recycling of construction and demolition waste is often carried out on-site. Compared to fixed crushers, mobile crushers and portable crushers offer higher flexibility and ease of installation, allowing for quick movement to different construction sites and reducing material transportation costs.

Mobile crushers and portable crushers can be equipped with different types of main engines and screening machines, forming a complete system for coarse, medium, and fine crushing and screening of construction waste with just one device, achieving efficient resource recovery and utilization.

More than 80% of the crushed particles are smaller than 10mm, while traditional construction waste processing equipment can only achieve 40%.

Both mobile crushers and portable crushers come in different production capacities, including 50 t/h, 100 t/h, 150–200 t/h, and 300 t/h.

For crushing machines with a capacity of less than 50 t/h, only one vehicle is needed. For capacities greater than 50 t/h, two or more vehicles are required.

For example, equipment with a capacity of 50 t/h can typically be equipped with a GZD850*3000 vibrating feeder, a PE-500*750/HD72 jaw crusher, a PSG900 cone crusher, and a 1545 vibrating screen/1010 impact crusher to help you achieve construction waste crushing and screening.

Contact us now to find the perfect mobile or portable crushing solution for your construction and demolition waste recycling needs! Contact us

3. Multistage screening

The screening machine precisely classifies the crushed material based on particle size, separating fine aggregates (particle size not greater than 4.75 mm) and coarse aggregates (particle size greater than 4.75 mm).

- Fine Aggregates: Used in the production of concrete, mortar, etc.

- Coarse Aggregates: Used in infrastructure construction like roads and bridges.

4. Magnetic separation

FTM Machinery recommends using specific iron removal equipment, such as dry magnetic separators, to accurately extract metals and other high-value recyclable components.

These resources can be directly sold to recycling companies or reintroduced into manufacturing, further enhancing resource utilization and economic benefits.

Despite the large volume of construction and demolition waste and its environmental impact, with proper handling, it can be transformed into valuable materials.

Common C&D Waste materials recycling

1. Concrete waste recycling

Recycled concrete aggregate (RCA) is produced by crushing concrete recycled from demolished roads, buildings, etc. It has the many advantages:

- Much cheaper than the conventional concrete aggregate and save you lots of money.

- Best substitution of natural gravel resources.

- Its processing machine—mobile or portable crushers reduce your transportation needs, which means lower fuel consumption.

- You will never see waste material dumpeded on the land again.

2. Asphalt recycling

Asphalt made by combining a binding material (called a bitumen) with an aggregate becomes sticky at high temperatures, and coupled with the limitations of previous technologies, people usually think that waste asphalt is worthless.

With mature recycling technology, an advanced asphalt station can create a new asphalt mix with up to 70% of the recycled asphalt which can be used for paving a driveway.

The cost benefits of asphalt recycling are expected to provide a profit or savings potential of $30.00 to $80.00 per ton. Naturally, product quality depends on the combination of ingredients used in the recycling and production process.

Asphalt crushing can be accomplished using the following two methods:

- Impact crusher: Used for primary crushing and shaping. This method is highly efficient and can quickly crush large chunks of asphalt into excellent cubic forms, making it suitable for larger-scale asphalt processing projects.

- Jaw crusher and cone crusher: The jaw crusher performs the coarse crushing, followed by the cone crusher for fine crushing of the asphalt. This combination method is ideal for projects requiring detailed processing and high-quality recycled asphalt.

3. Plaster and gypsum board recycling

Since gypsum has a wide range of applications, it is relatively easy to recycle.

- 1Use a crusher such as a jaw crusher or impact crusher to crush the waste board

- 2Then collect the dust by a bag filter

- 3Adopt the scrap collection device to collect the crushed plaster or gypsum

- 4You can also use Raymond mill to grind gypsum scraps into a powder or pellets

- 5Powder and scrap can mix with desulfurized gypsum as raw materials for reuse.

Gypsum possesses many attributes making it an attractive construction material. Plaster and gypsum board recycling can not only solve the shortage of resources, but also save a lot of costs and improve resource utilization.