What is a Raymond mill?

The Raymond mill, or Raymond roller mill, is an efficient, eco-friendly, closed-cycle mill. It integrates grinding, classification and drying (if necessary) to produce powders of precise sizes.

The Raymond mill is widely used in cement, chemicals, mining, construction, and metallurgy industries. It is ideal for grinding non-flammable and explosive non-metallic minerals with a Mohs hardness below 7 and a humidity below 6%, such as gypsum, limestone, kaolin, and coal.

The output of FTM Machinery Raymond mill can reach 8–176 t/shift (1–22 t/h), and the finished product fineness is 0.173 mm–0.044 mm (80–325 mesh).

| Model | 4525 | 4119 |

| Feeding Size(mm) | ≤30 | ≤25 |

| Output Size(mm) | 0.173-0.044 | 0.173-0.044 |

| Shift Output of Different Material Fineness(t) | 16-176 | 8-78 |

| Rotation Speed of Central Shaft(r/min) | 82 | 105 |

| Main Motor(kw) | Y315M-4-132 | Y280S-4-75 |

| Fan Motor | Y315M-4-132 | Y280S-4-75 |

| Model | Output Size(mm) | Shift output of different material fineness(t) |

| 4525 | 0.173-0.044 | 16-176 |

| 4119 | 0.173-0.044 | 8-78 |

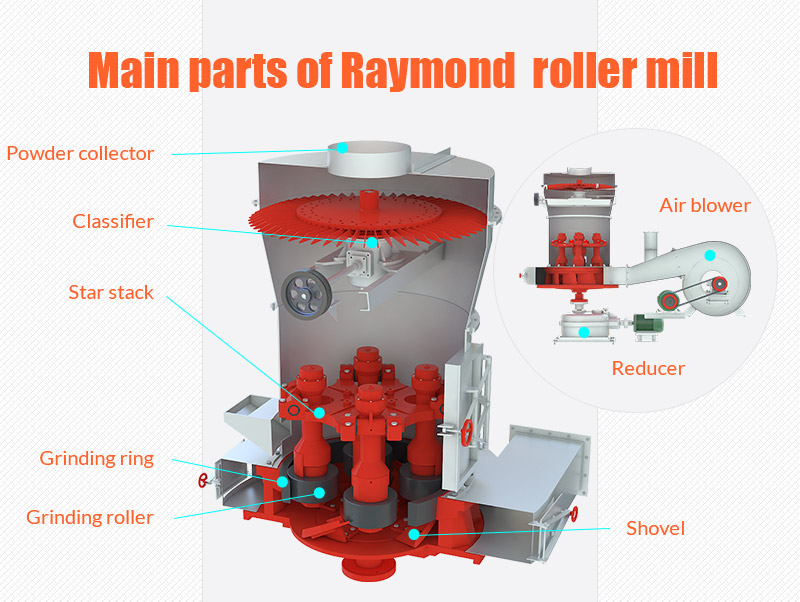

Raymond mill parts

The Raymond mill adopts a compact vertical structure, which occupies a small area and is easy to operate.

A Raymond mill is mainly composed of grinding roller, grinding ring, star stack, shovel, air blower, classifier, reducer, and air collector.

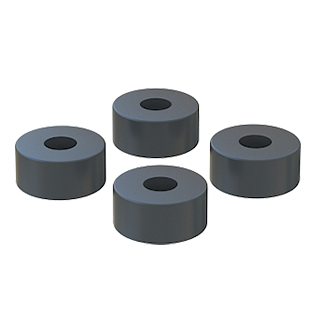

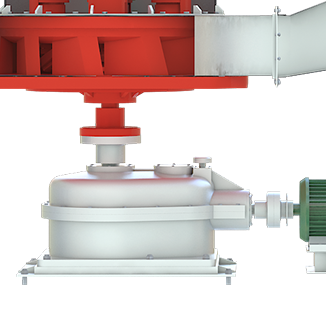

1. Grinding roller

Grinding roller is the part that grinds the material. Generally, 3–6 grinding rollers are used, which rotate around the grinding ring. As the wearing part of Raymond mill, it adopts more wear-resistant alloy steel or high-quality alloy carbon steel.

2. Grinding ring

The grinding ring is a fixed part located under the grinding roller. The material is ground between the grinding roller and the grinding ring. The grinding ring is made of manganese alloy steel and is suitable for soft or low hardness materials.

3. Star Stack

When the mill is running, the star stack is driven by the main shaft to realize the rotation of the grinding roller and the grinding ring.

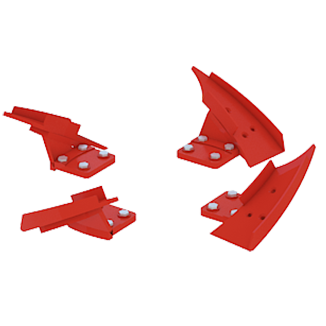

4. Shovel

The material is scooped up and moves forward along the grinding ring at high speed, and then thrown into the gap between the grinding roller and the grinding ring to complete the grinding process. The shovel is made of wear-resistant alloy material.

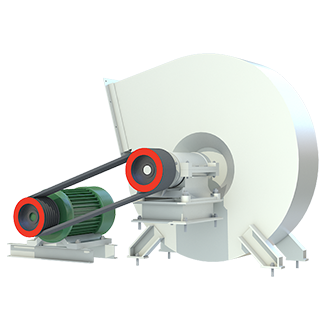

5. Air blower

The blower generates airflow to blow the ground powder to the upper classifier for classification.

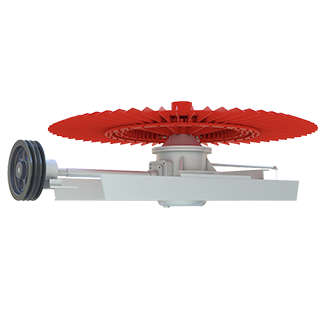

6. Classifier

The classifier is used to classify the ground powder by particle size. The rotation speed controls the fineness of the product. The fine powder is collected by the cyclone collector, while the coarse powder is returned for re-grinding.

7. Reducer

The speed converter of the gear can reduce the speed of the motor, thereby obtaining a power transmission mechanism with greater torque.

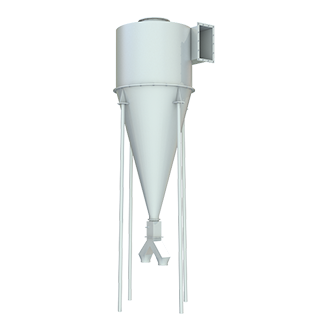

8. Air collector

The powder is separated from the air and falls from the discharge port, while the air with fine particles enters the dust collector and is discharged after being processed.

Raymond mill working principle

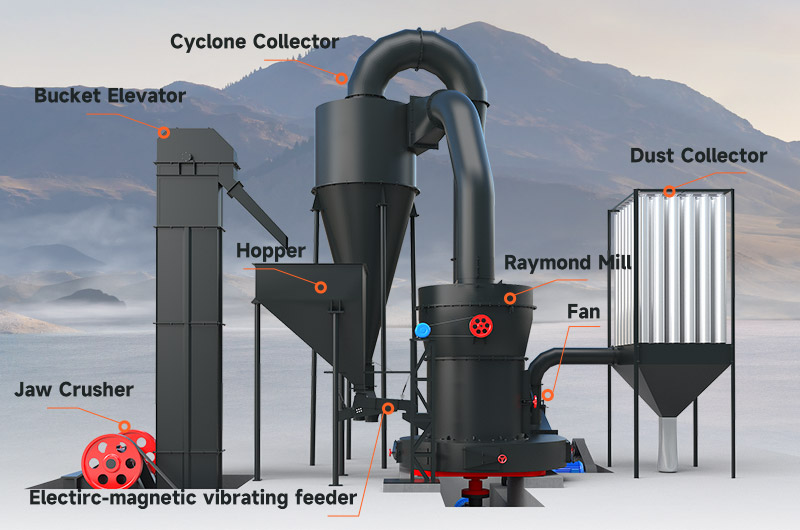

The powder production process of Raymond mill is feeding-crushing-grinding-selecting-collecting, forming an independent production system, among which grinding and collecting are the core links.

How does a Raymond mill work?

Step 1The raw materials are crushed into specified particle sizes by a jaw crusher, lifted to the hopper by a bucket elevator, and then fed into the mill evenly and quantitatively by a feeder.

Step 2Inside the mill, the main shaft rotates to generate centrifugal force, causing the grinding roller to swing outward and press against the grinding ring. The rotating shovels scoop up raw materials and project them between the rollers and the ring where the grinding takes place.

Step 3The pulverized powder is blown by the circulating air of the blower to the classifier for classifying. Under the action of the impeller of the classifier, the unqualified coarse powder would be sent back to the grinding chamber for re-grinding. The qualified powder is collected by the cyclone collector and discharged from the bottom as end products.

Step 4To ensure that the Raymond mill works under negative pressure, the increased airflow enters the pulse dust collector through the pipeline and is discharged into the atmosphere after purification. The dust-free operation in the workshop is realized by the pulse collector.

Why FTM Machinery Raymond mills?

Raymond mills are increasingly favored in the grinding industry due to their high efficiency, low energy consumption, and environmentally friendly production.

What are the advantages of FTM Machinery's Raymond mills?

- Automatic control: The electrical system adopts centralized control, the grinding workshop can be operated unmanned, and maintenance is simple and convenient.

- High grinding efficiency: Fan and analyzer control fineness, eliminating screens and blockages, producing uniform powder (80–325 mesh) with over 99% passing rate.

- Reduce costs: Integrate drying and grinding in one unit, eliminating the need for a separate dryer and reducing investment.

- Robust and Durable: With an integral gearbox, anti-vibration system, and parts like a grinding ring lasting 8,000 hours and a grinding roller up to 6,000 hours, this mill is designed to last over 30 years.

- Environmental protection: The grinding process uses a closed-loop circulation system with negative pressure to minimize dust and noise. With a full-pulse dust collector, 99% of dust is removed.

- Low energy consumption: Small footprint, high efficiency powder making, energy consumption is more than 60% lower than ball mill.

Customer cases

1. Gypsum grinding plant in South Africa

| Output | 10–15 t/h |

| Finished particle size | 80 mesh–325 mesh (0.173 mm–0.044 mm) |

| Raw material | Gypsum |

| Material hardness | Soft |

| Feed size | ≤30 mm |

| Production line type | Fixed |

| Purchasing equipment | PE-250×400 jaw crusher, 4525 Raymond mill, vibrating screen, conveyor, and dust collector |

Customer feedback

"I am really satisfied with the gypsum powder produced by the FTM Machinery Raymond mill. It's white with even particle size. I'm a gypsum powder supplier and committed to selling high-quality products to my clients, so I have a high requirement for fine powder."

10–15 TPH gypsum powder grinding process Yes! I'm interested

2. Coal slag grinding plant in Thailand

| Output | 300 kiloton/annually |

| Finished particle size | 100 mesh (0.149 mm) |

| Raw material | Coal slag |

| Material hardness | Soft |

| Feed size | ≤30 mm |

| Production line type | Fixed |

| Purchasing equipment | PE-250×400 jaw crusher, 4525 Raymond mill, vibrating screen, conveyor, and dust collector |

Customer feedback

"Concrete mixed with coal slag has good water retention, plasticity, less bleeding, which means only high-quality product can bring me more money. This Raymond grinding line did bring me considerable profit."

300 kiloton/annually coal slag grinding plant Yes! I'm interested

3. Quartz stone grinding plant in Pakistan

| Output | 300 t/h |

| Finished particle size | 325 mesh (0.044 mm) |

| Raw material | Quartz stone |

| Material hardness | Hard |

| Feed size | ≤25 mm |

| Production line type | Fixed |

| Purchasing equipment | CJ96 jaw crusher, 4119 Raymond mill, vibrating screen, conveyor, and dust collector |

Customer feedback

"With the same fineness and output of all quartz stone grinding machines, Raymond mill can save nearly half of the electricity, and the low energy consumption greatly saves electricity costs."

300 t/h quartz stone grinding solution Yes! I'm interested

Frequently Asked Questions about Raymond Mills

1. What is the difference between a ball mill and a Raymond mill?

- a. Materials: Raymond mill grinds minerals like gypsum and limestone, while ball mill processes metal ores and cement clinker.

-

b. Output: Raymond mill produces less than ball mill but uses less power.

- c. Dust pollution: Raymond mill has cleaner dust control, whereas ball mill is larger, harder to manage, and causes more dust pollution.

- d. Finished product quality: Ball mill produces less stable and uniform powder compared to Raymond mill because of less contact between balls and cylinder.

2. How to maintain the Raymond roller mill?

- The wearing parts are the grinding rollers, ring, and shovel. Excessive wear on these parts causes uneven product fineness and reduces scooping efficiency, affecting mill performance.

- After each use, clean rollers, guides, and gears with a brush or compressed air to remove debris and dust.

- For detailed maintenance and parts installation instructions, consult the maintenance guide.