What is a bucket elevator?

A bucket elevator (grain leg) is a continuous conveying machine that vertically lifts bulk materials by a series of buckets fixed on the traction.

What is the application scope of bucket elevators?

The bucket elevator is suitable for vertical transportation of bulk materials with a bulk density less than 2 t/m3 and temperature not exceeding 250°C, including medium and small granular materials and powdered materials, such as coal, cement, limestone, sand, clay, ore, slag, aggregates, animal feeds, fertilizer, woodchips, gypsum, clinker, coal ash, coke, grain, etc.

Not sure whether your material can be processed or not? Contact us for a Free Sample Testing!

The application of bucket elevator

Bucket elevators are widely used in food, medical, chemical, mining, metallurgy, building materials, coal and hydropower industries.

What are the advantages of bucket elevators?

- Wide lifting range. It can be widely used to lift powdery, small granular materials, etc.

- Large lifting height and conveying capacity.

- Vertical handling, compact and simple structure and small floor space.

- No dust leakage with good sealing, clean and environmental protection.

- According to the characteristics of the material and the lifting height, the discharge methods such as mixed, gravity, and centrifugal can be flexibly selected.

- The middle casing is welded by bending components, so the elevator casing has high overall rigidity and reliability.

- The high-reliability backstop can prevent sudden load shutdown, causing the traction and buckets to move backwards, which may cause accidents.

What are the main components of bucket elevators?

The main components of the bucket elevator include the traction, elevators, head, elevator casing, drive package, take-up assembly and heavy-duty roller bearings.

Traction

There are three types of traction: belt, round link chain and plate chain.

Therefore, bucket elevators are divided into belt bucket elevators, round link chain bucket elevators and plate chain bucket elevators according to the traction.

Belt

The belt is fixed by screws and elastic gaskets. The bandwidth should be 30–40 mm larger than the width of the elevator. Generally, the rubber belt can transport materials with the temperature not exceeding 60°C and the heat-resistant belt can transport materials up to 150°C.

Materials: cotton rubber belt, nylon tape, steel tape

Advantages of belt bucket elevators

- Low cost, low dead weight, stable and noiseless work.

- Higher working speed and production efficiency, less wear.

Disadvantages of belt bucket elevators

The buckets are weakly fixed on the belt, so they have low strength. Therefore, the belt bucket elevator is mainly used to transport powdery and granular materials with low or medium density for medium and small conveying capacity (within 60–80 m3/h) and medium lifting height (usually within 30 m).

Round link chain

The traction is a forged round link chain.

Advantages of round link chain bucket elevators

The round link chain is a commonly used traction part with simple structure and manufacturing. It has a strong connection with the elevator.

Disadvantages of round link chain bucket elevators

The round link chain is easy to wear due to mutual contact, resulting in its reduced strength and unstable operation.

Plate chain

The traction is the plate chain.

Advantages of plate chain bucket elevators

The plate chain, relatively sturdy in structure, is suitable for large lifting handling.

Disadvantages of plate chain bucket elevators

The adjustable fittings of the plate chain bucket elevator are easy to be worn by materials, so its manufacturing and maintenance are complicated.

Chain (round link chain and plate chain) bucket elevators are mainly used for conveying materials with high productivity and large lifting height. It can be used to transport bulk materials with high density and strong abrasiveness, and also for lifting relatively hot materials with the temperature up to 250°C.

Buckets

The bucket is the bearing carrier of the elevator and is usually made by welding or stamping with steel plates with a thickness of 2–6 mm.

According to the characteristics of materials and different loading and discharging methods, buckets are often made into three types: deep bucket, shallow bucket and sharp-angled bucket with the guide slot.

Buckets of the bucket elevator

Deep bucket

The front wall and the backwall of the bucket generally form an angle of 65°, and the depth is large, so it is suitable for conveying dry, loose, and easy-to-discharge materials, such as cement, crushed coal, dry sand, crushed stone, etc.

Shallow bucket

The front wall and the backwall of the bucket generally form an angle of 45°, and the depth is small, so it is suitable for conveying wet, easily agglomerated, and difficult to discharge materials, such as wet sand, molding sand, clay, etc.

Sharp-angled bucket with the guide slot

The bucket is continuously arranged on the traction so that the material can slip down the back of the bucket during discharging. This kind of bucket can lift heavy, semi-abrasive and large abrasive bulk materials.

Head

The head is composed of the head pully, casing, discharge chute and transmission device. The elevator is equipped with a backstop on the head roller to prevent the equipment from malfunctioning during operation and causing material blocking.

Elevator casing

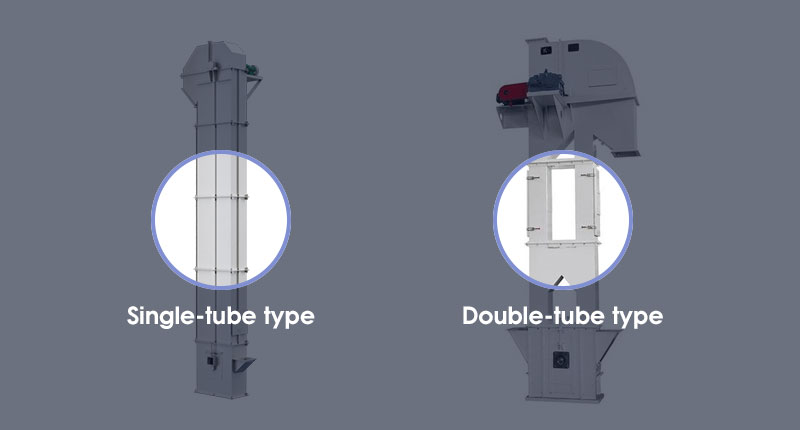

The elevator casing, the middle part of the chassis, can be divided into the single-tube type (for low-speed bucket elevator) and double-tube type (for high-speed bucket elevator in dust environment). The elevator casing should ensure that the bucket does not collide when running in it.

Single-tube type elevator casing and double-tube type elevator casing

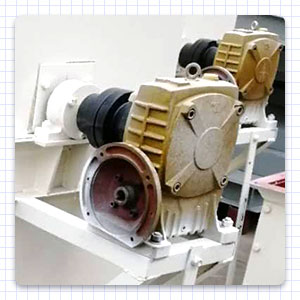

Drive package

The drive pulley or drive sprocket of the bucket elevator is installed at the upper discharge port of the bucket elevator.

In addition to the gear reducer, the transmission part of the drive package is also equipped with transmission devices such as exposed gears or belt pulleys.

Take-up assembly

The take-up assembly is equipped at the lower part of the elevator casing. There are three types of take-up assemblies: screw take-up assembly, spring take-up assembly and heavy-duty take-up assembly, among which the spiral take-up assembly is the most commonly used type.

How does the bucket elevator work?

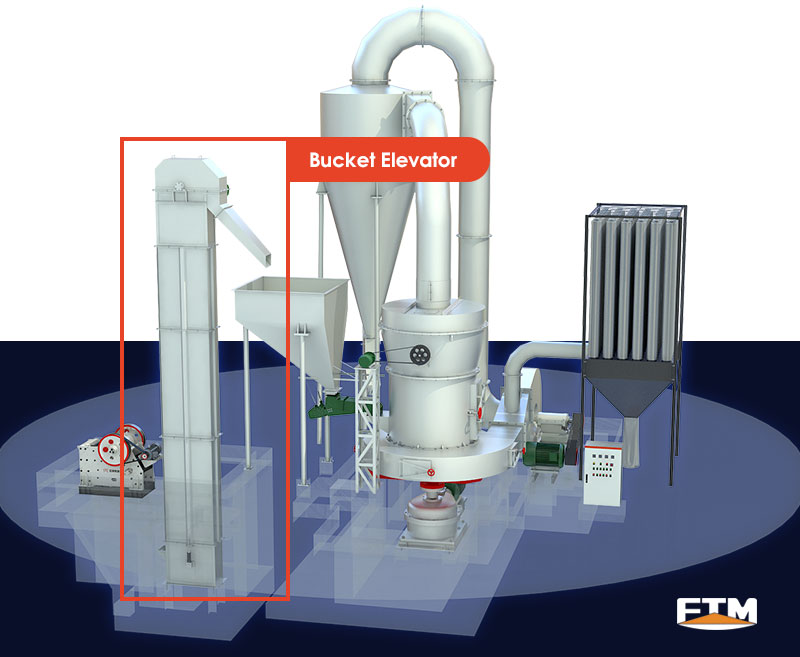

The bucket elevator is a widely used mechanical conveying equipment. The conveyed materials are evenly fed from the inlet chute during working.

Bucket elevator working in powder grinding production line

Driven by the drive pulley, the buckets fixed on the conveyor belt pick up the materials and then rise with the belt conveyor. When they rise above the top drive pulley, the buckets turn over.

Then the materials are discharged from the discharge port to be sent to the next process under the action of centrifugal force or gravity.

How to choose a bucket elevator?

As a commonly used lifting equipment, the selection of bucket elevator is restricted by many factors. The wrong model will bring endless trouble to users. Generally, the selection of bucket elevator depends on the following factors:

- Material form: Whether the material is powdery, granular or small blocky.

- The physical properties of the material: Whether the material has adsorption or viscosity, and whether it contains water.

- The specific gravity of materials: Generally, bucket elevators are designed for materials with a bulk density less than 1.6. If the specific gravity of materials is too large, the traction and the tensile strength of the transmission part must be calculated.

- Delivery volume in unit time.

Generally speaking, the material form directly determines the discharging mode of the material. The powder material is often discharged by centrifugal discharge, while the bulk material by gravity discharge.

The different discharging methods determine the different bucket type of bucket elevators. Shallow bucket and arc bucket are mostly used for centrifugal discharging, while the deep bucket for gravity discharging.

The buckets used by the bucket elevator is different, so it is the material conveying volume lifted per unit time. The final conveying capacity of the bucket elevator is a comprehensive parameter that depends on the bucket type, speed, material specific gravity, material properties and bucket quantity.

The selection process is as follows: material specific gravity → transmission mode → material property → discharging method → bucket type → lifting capacity of this series bucket elevator → model determination.

How to remove the belt fault of bucket elevators?

Belt slip

- Re-adjust the take-up assembly. At this time, the unused tensioning stroke of the adjusting screw of the take-up assembly should not be less than 50% of the full stroke.

- The bucket elevator is overloaded. At this time, the materials should be fed evenly with reduced quantity.

- The head pulley transmission shaft and the inner surface of the bucket belt are too smooth, which reduce the friction between them. At this time, a layer of glue can be spread on the inner surface of the transmission shaft and the bucket belt to increase the friction.

Belt deviation

The drive shafts of the head pulley and the bottom wheel should be installed in the same vertical plane and a horizontal position. The vertical deviation of the centerline of the whole machine at a height of 1,000 mm should not exceed 2 mm, and the accumulated deviation should not exceed 8 mm.

How to maintain the bucket elevator?

- The upper and lower bearings should be lubricated regularly to maintain good working conditions.

- Check the lubrication of the reducer regularly, keep the oil amount appropriate, and replace the oil on time.

- Maintain and clean moving parts, check the wear of chains, sprockets, transmission belts, roller and buckets regularly.

- Regularly check and adjust the take-up assembly. When the tightening stroke is less than 1/5 of the specified length, a length of the traction (usually a pitch of buckets) can be cut off to restore the tightening stroke.

- Regularly check the abrasion of the backstop. When the ratchet, pawl and roller are severely worn, replace them to keep the backstop working reliably.

Why choose FTM Machinery bucket elevator manufacturer?

Favorable priceGet the Latest Price

FTM Machinery is a professional manufacturer of bucket elevators. The supplier FTM Machinery sells directly to ensure that the factory price is provided to customers, so the price is much cheaper than other manufacturers.

Quality assurance

The bucket elevator manufactured by FTM Machinery is popular among customers due to its good quality, high-cost performance and low maintenance cost. It has been exported to hundreds of countries such as India, Philippines, Pakistan, Egypt, Vietnam, Saudi Arabia and the United States.

FTM Machinery bucket elevator manufacturer

Perfect service

FTM Machinery can provide customers with bucket elevator accessories and on-site installation guidance by engineers. Customers are also welcome to the factory for a free trial.

Parameter

Technical parameters of ring chain bucket elevator

| Specification | Max.lifting Height (m) |

Conveying Capacity (m³/h) |

Max.size (mm) |

Pitch of Buckets (mm) |

Motor Prower (kw) |

| TH160 | 25 | 7-12 | 15-20 | 400 | 3-4 |

| TH200 | 28 | 8-15 | 20-30 | 500 | 3-5.5 |

| TH250 | 30 | 10-25 | 25-35 | 500 | 4-7.5 |

| TH300 | 30 | 25-35 | 30-40 | 500 | 5.5-11 |

| TH315 | 40 | 30-40 | 35-45 | 512 | 5.5-15 |

| TH400 | 40 | 45-60 | 40-55 | 512 | 11-22 |

| TH500 | 40 | 65-80 | 50-60 | 512 | 15-30 |

| TH630 | 40 | 100-120 | 60-65 | 688 | 18.5-37 |

| TH800 | 40 | 130-150 | 65-75 | 920 | 22-45 |

Technical parameters of wire belt bucket elevator

| Specification | Max.lifting Height (m) |

Conveying Capacity (m³/h) |

Max.size (mm) |

Bucket Volume (L) |

Motor Power (kw) |

| TDG160 | 80 | 34 | 0-20 | 2.6 | 2.2-11 |

| TDG200 | 80 | 45 | 0-25 | 4.1 | 3-15 |

| TDG250 | 80 | 71 | 0-30 | 6.5 | 5.5-22 |

| TDG315 | 80 | 101 | 0-35 | 10 | 7.5-30 |

| TDG400 | 80 | 158 | 0-40 | 16 | 15-45 |

| TDG500 | 80 | 218 | 0-45 | 25 | 18.5-55 |

| TDG630 | 80 | 345 | 0-50 | 40 | 30-90 |

| TDG800 | 80 | 491 | 0-50 | 61 | 45-132 |

Plate chain bucket elevator

| Specification | Max.lifting Height (m) |

Max.lifting Capacity (m³/h) |

Percentage Allowed(%) |

Pitch (mm) |

Motor Power (kw) |

||||

| 10 | 25 | 50 | 75 | 100 | |||||

| Max.size(mm) | |||||||||

| NE15 | 40 | 16 | 65 | 50 | 40 | 30 | 25 | 101.66 | 1.5-4 |

| NE30 | 59 | 31 | 90 | 75 | 58 | 47 | 40 | 152.4 | 2.2-7.5 |

| NE50 | 62 | 60 | 90 | 75 | 58 | 47 | 40 | 152.4 | 3-15 |

| NE100 | 58 | 110 | 130 | 105 | 80 | 65 | 55 | 200 | 7.5-30 |

| NE150 | 65 | 170 | 130 | 105 | 80 | 65 | 55 | 200 | 11-37 |

| NE200 | 73 | 220 | 170 | 135 | 100 | 85 | 70 | 250 | 18.5-75 |

| NE300 | 61 | 320 | 170 | 135 | 100 | 85 | 70 | 250 | 22-75 |

| NE400 | 47 | 420 | 205 | 165 | 125 | 105 | 90 | 300 | 45-90 |

| NE500 | 58 | 500 | 240 | 190 | 145 | 120 | 100 | 300 | 45-132 |

Technical parameters of ring chain bucket elevator

| Specification | Max.lifting Height (m) |

Conveying Capacity (m³/h) |

| TH160 | 25 | 7-12 |

| TH200 | 28 | 8-15 |

| TH250 | 30 | 10-25 |

| TH300 | 30 | 25-35 |

| TH315 | 40 | 30-40 |

| TH400 | 40 | 45-60 |

| TH500 | 40 | 65-80 |

| TH630 | 40 | 100-120 |

| TH800 | 40 | 130-150 |

Technical parameters of wire belt bucket elevator

| Specification | Max. lifting Height (m) |

Convrying Capacity (m³/h) |

| TDG160 | 80 | 34 |

| TDG200 | 80 | 45 |

| TDG250 | 80 | 71 |

| TDG315 | 80 | 101 |

| TDG400 | 80 | 158 |

| TDG500 | 80 | 218 |

| TDG630 | 80 | 345 |

| TDG800 | 80 | 491 |

Plate chain bucket elevator

| Specification | Max.lifting Height (m) |

Max. lifting Capacity (m³/h) |

| NE15 | 40 | 16 |

| NE30 | 59 | 31 |

| NE50 | 62 | 60 |

| NE100 | 58 | 110 |

| NE150 | 65 | 170 |

| NE200 | 73 | 220 |

| NE300 | 61 | 320 |

| NE400 | 47 | 420 |

| NE500 | 58 | 500 |