In recent years, the gypsum industry has developed rapidly. Gypsum building materials are increasingly welcomed by the market and recognized by society, and gypsum powder applications are becoming more and more widespread.

According to the US Mining forecast, the world's gypsum demand will increase at a rate of 2.5% in the next few years. It is estimated that the world's gypsum demand will reach 300 million tons in 2030. The total annual consumption of the gypsum board will reach 2.04 billion square meters.

Learning about gypsum mineral

Gypsum is a common soft mineral found in sedimentary rocks, particularly in beds of evaporite minerals. The general term gypsum refers to two minerals, raw gypsum, and anhydrite. Raw gypsum is calcium dihydrate (CaSO4·2H2O), also known as dihydrate gypsum or plaster. Anhydrite is anhydrous calcium sulfate.

| Gypsum | Physical properties |

| Hardness | Mohs hardness is 2 |

| Density | 2.3 to 2.8 g/cm³ |

| Luster | Vitreous, pearly, or waxy |

| Structure | Massive or fibrous |

| Crystal system | Monoclinic |

| Transparency | Transparent to translucent |

| Color | White, colorless, or transparent (called selenite) |

The production process of gypsum powder

The gypsum powder production line is usually divided into gypsum mining, crushing, grinding, and calcination processes according to technical requirements.This is an on-site video of a gypsum production line and shows the entire process of gypsum powder.

1. Gypsum mining process

The gypsum is typically extracted from the ground using one of two main methods: underground mining or open-pit mining.

- Underground mining involves creating shafts and tunnels to access the gypsum deposits. The gypsum is then mined using heavy equipment such as continuous miners, longwall mining machines, rotary drilling rigors, or room and pillar mining techniques.

- Open-pit mining involves removing the overlying soil and rock to expose the gypsum deposits. The gypsum is then extracted using excavators or bulldozers. Excavators are the ideal stripping and mining equipment for large open-pit mines.

2. Gypsum crushing process

Large blocks of gypsum of 300 to 500 mm need to be crushed by crushers to gypsum stone particles of 30 to 50 mm. After sieving with the vibrating screen, the finished material conforming to the size is sent to the finished product area, while the large material is returned for being crushed again until it meets the required size.

A. Gypsum jaw crusher Get Machine Price

The common gypsum crushing equipment is a jaw crusher with a crushing ratio of 4-6. The jaw crusher, which is often used as the primary crushing equipment, can crush large pieces of gypsum into 150 mm particle size.

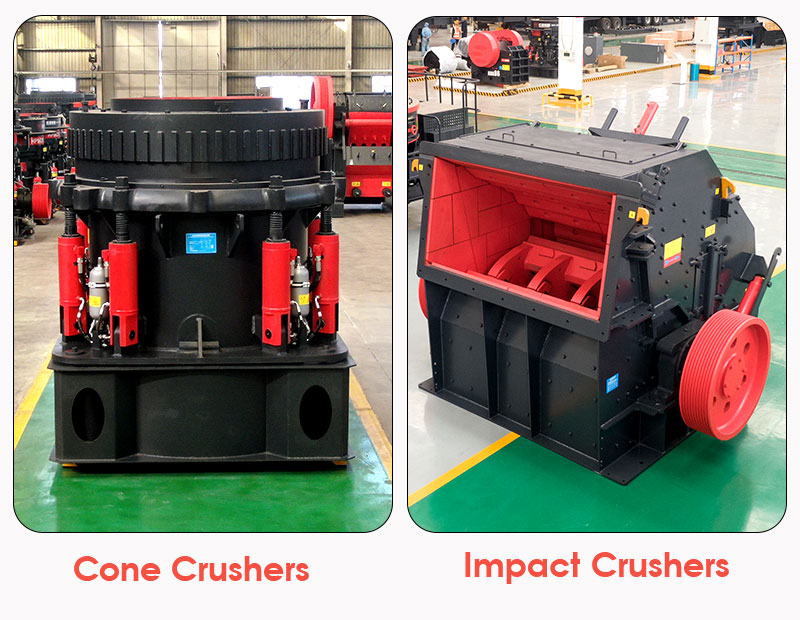

B. Gypsum cone or impact crusher Get Machine Price

If the crushed gypsum cannot meet the particle size requirements, secondary gypsum crushing equipment such as cone crushers or impact crushers can be equipped to carry out further medium and fine crushing of gypsum. Specific equipment should be configured depending on the actual needs of the customer.

3. Gypsum grinding process

The crushed gypsum is sent to a ball mill for grinding until 90% of it is less than 149 μm (100 mesh). The ground gypsum powder leaves the mill in the form of airflow and is collected in the cyclone separator.

A. Gypsum ball mill Get Machine Price

A ball mill is mainly a machine for dry or wet grinding of crushed gypsum. The machine is mainly used for repeated grinding of the raw materials in the barrel through the steel ball media to complete the ball grinding operation.

Advantages of Ftmmachinery ball mill

- The ball mill can control the grinding time flexibly and reduce the labor input.

- The barrel, liner, milling media, and other parts of the machine are all made of high-quality materials, with strong mechanical load-bearing capacity and long service life.

- The actuator has the characteristics of good technology, low operating current, short time, less power consumption, and low cost.

B. Gypsum cyclone separator Get Machine Price

The cyclone separator adopts a vertical cylindrical structure. It is suitable for purifying non-viscous, non-fibrous dry dust larger than 1-3 microns, such as gypsum. It is purification equipment with a simple structure, convenient operation, high-temperature resistance, and low equipment cost.

Separation effect of cyclone separator

- Under the design pressure and air volume conditions, solid particles ≥10 μm can be removed.

- At the operating point, the separation efficiency is 99%, and within ±15% of the operating point, the separation efficiency is 97%.

- Under normal working conditions, the pressure drop of a single cyclone separator at the operating point is not greater than 0.05 MPa.

4. Gypsum calcination process

The gypsum material is transported into the top silo of the rotary kiln lifted by an elevator. It is evenly distributed into rooms through the feeding pipe. In the preheater, gypsum is heated to about 900 °C by the roasting kiln at 1150 °C, and about 30% of it is decomposed. Then, gypsum is pushed into the rotary kiln by a hydraulic push rod.

β-type hemihydrate gypsum (180~240 ℃), anhydrous gypsum (350 ℃) and overfired gypsum (450~700 ℃) can be produced. After calcining and decomposing, gypsum powder is sent to the cooler to be cooled to below 100 °C by the cold air blown and discharged. Finally, the cooled gypsum is sent to the product warehouse.

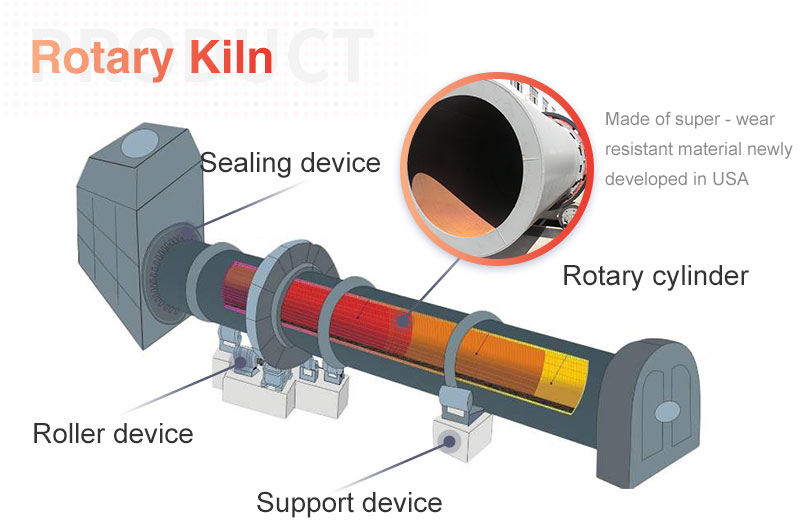

A. Gypsum rotary kiln Get Machine Price

Gypsum rotary kiln is a kind of thermal equipment for calcining gypsum. The gypsum powder is heated in a rotary kiln to remove the water from crystallization. Its main structure includes a kiln head, kiln tail sealing device, rotary cylinder, supporting device, backup roll device, etc.

Advantages of Ftmmachinery rotary kiln

- The finished gypsum clinker calcined by the gypsum rotary kiln has the characteristics of good taste, high purity, and high clinker strength grade.

- The temperature and residence time in the rotary kiln can be controlled to ensure that the gypsum is calcined to the desired form and properties.

- The production process is easy to control. The calcination process has less fly ash, and the price is reasonable.

B. Gypsum pulse dust collector Get Machine Price

The pulse dust collector can effectively reduce the waste of gypsum, reduce the harm of dust to the human body, and better protect the environment.

Market demand for gypsum powder affects its price

With the increase in the market demand for gypsum powder, the requirements for its production technology are getting higher and higher, so the price has risen accordingly. The price of gypsum powder is generally calculated in tons.

Its price varies with its accuracy and use. The price of gypsum powder is between $28.8-$403.6 per ton according to its whiteness and fineness. The cooked gypsum powder is about $ 28.8-$ 158.6 per ton. The cooking gypsum powder is about $72.1-$317.2 per ton. The refined gypsum powder is about $201.8-$720.8 per ton.

How to obtain the total cost of gypsum supply? There are two examples.

1. The ex-factory price of gypsum mined in New South Wales is $15 per ton, plus $40.00 per ton freight, which is $60.00 per ton at the farm gate, and $11.00 per ton to spread. Its purity is measured at 15% S wet weight. The total cost of gypsum supply and application per ton of pure CaSO4.2H20 = (15+40+11) × 18.6 ÷ 15 = $81.84 per ton.

2. The ex-factory price of Australian recycled gypsum is $35.00 per ton, plus $25 per ton freight, which is $60.00 per ton at the farm gate, and $10.00 per ton to spread. Its purity is measured at 17% S wet weight. The total cost of gypsum supply and application per ton of pure CaSO4.2H20 = (35+25+10) × 18.6 ÷ 17 = $76.59 per ton.

Buying and using gypsum powder

The world's major producing gypsum countries are the United States, Iran, China, Brazil, Canada, Mexico, Spain, Thailand, etc. They are rich in gypsum resources. Some countries have the highest reserves in the world, for example, there are 1.3 billion tons in Brazil, 700 million tons in the United States, and 450 million tons in Canada.

The largest consumption area of gypsum is the building decoration industry. In many countries, the manufacture of slabs accounts for more than 80% of gypsum consumption.

How to choose gypsum powder? Matters needing attention:

- The fineness. In general, the extra-hard white plaster is usually about 1100 mesh, while the gypsum plaster is about 300 mesh.

- Strength. Generally, the 3-hour compressive strength of gypsum for construction is about 4.9 MPa. The compressive strength of different types of gypsum powder is different.

- Flexural strength. The flexural strength of gypsum powder for construction is 8.4 MPa.

- Bonding strength. The bonding strength of different kinds of gypsum powder is different.

Uses of gypsum powder

Gypsum is a very important industrial raw material that is widely used in construction, food, agriculture, artistic models, pharmaceutical, chemical industry, and other industries. The uses of gypsum powder can be divided into the following 5 main aspects:

1. Gypsum powder uses in construction

In construction, gypsum powder is a popular material due to its fire-resistant properties, durability, and low cost. It is commonly used as a building material for various purposes such as plasterboards (drywalls), plaster blocks, and plaster finishes. It is also used as a binder in cement and concrete to enhance their properties.

At present, the gypsum powder on the market is divided into raw gypsum powder and plaster of Paris. The plaster of Paris (also known as hemihydrate gypsum) is heated at a high temperature of 105-200 ℃, and divided into α-type gypsum powder and β-type gypsum powder.

The physical properties of the two gypsum powders are different. The α-type gypsum powder has good crystallinity and solidity, so it can be used in ceramic molds, sculptures, gypsum lines, and high-end buildings. The β-type gypsum powder is mainly used for mortar leveling, gypsum board production, painting, etc.

Advantages of gypsum powder for construction:

- It has excellent fire resistance. Gypsum board is a non-combustible material with a certain fire performance. Some can even be used as the fire protection layer of a steel structure.

- It has warm and breathing characteristics. It can meet the functional requirements of indoor heat preservation, sound insulation, fire protection, waterproofing, flexible separation, etc. It is also a good indoor ornamental material.

- No environmental pollution. The production process of gypsum building materials does not emit waste gas, waste residue, wastewater, and substances.

- It can be recycled. The discarded gypsum materials can be used as raw materials for the production of gypsum building materials after being crushed, screened, and calcined, without generating construction waste.

2. Gypsum powder uses in food

Can gypsum be used in food? Is gypsum powder safe to eat? Is gypsum harmful to humans? Here is a video about how gypsum is used, including its uses in toiletries, food additives, fertilizers, chalks, etc.

In the food industry, the official name of gypsum powder is called food additive calcium sulfate, commonly known as edible gypsum. Gypsum powder is used as a coagulant in the production of tofu and other soy products, as well as in the production of beer and other beverages.

3. Gypsum powder uses in agriculture

Gypsum powder can be used as a Portland cement retarder in the concrete industry. In agriculture, because gypsum powder is alkaline, it is possible to sprinkle it into the acidic soil to integrate the pH value of the soil, thus making a lot of land use.

4. Gypsum powder uses in medicine

In the pharmaceutical industry, gypsum is the main medicine in the famous Chinese medicine "Baihu Tang", which has a good effect in treating acute high fever and thirsty irritable. In addition, dentists use plaster to make models of gums, and surgeons also use plaster to repair fractures.

5. Gypsum powder uses in chemical industry

Gypsum powder is used in a variety of chemical and industrial applications, such as in the production of cement and fertilizer. It is used as a filler for plastics, rubber, paper, and paints.

Conclusion

The large demand and wide application of gypsum powder have stimulated the prosperity of many industries and fields. Therefore, the production of high-quality gypsum powder is the general trend of the gypsum industry in the future.

As a major mining machinery manufacturer in China, Ftmmachinery has 38 years of experience and provides customers with high-quality gypsum production equipment, such as crushing, grinding, and calcination machines. Any questions about gypsum powder, please ask our professional engineers.