What is a rotary kiln?

A rotary kiln, also known as a rotary calciner, is a rotating cylindrical reactor with an inclination of 3–3.5%, in which the furnace charge moves continuously. It is an environmentally friendly heat treatment furnace used for continuously calcining or sintering solid materials to cause a chemical reaction or physical change.

Common applications of rotary kilns

The rotary kiln is only used as a container to cause chemical reactions or phase changes. Some processes using rotary kilns are described below.

1. Calcination

It is the process of heating materials (such as limestone, dolomite, and magnesite) to a specific temperature for chemical dissociation. It also removes bound moisture, such as that chemically attached to the borax.

2. Reduction Roasting

Rotary kilns are used as reduction furnaces to remove oxygen (O2) from the ore composition using reducing agents such as carbon monoxide (CO). The common processes include the reduction of iron ore pellets, barite, and zinc-lead residues.

3. Rotary kiln pyrolysis (Thermal desorption)

Thermal desorption adopts heat to drive off a volatile component, but the material has no contact with the flame. It is the best way to process non-metallic minerals like Kaolin, agricultural waste, mineral coatings, and sewage sediments.

The most common rotary kiln used is an indirect rotary kiln designed according to physical and chemical properties and the calcination curve of raw materials.

4. Organic combustion

When the waste material is bulky and difficult to handle, organic combustion can turn the material into light ashes. Thus, the organic combustion method allows the waste material to be deposited more efficiently in the landfill.

5. Sintering/Hardening

Sintering is the process of heating the material to a certain temperature before melting to increase its strength. Its most common use is in the manufacture of artificial proppants (a solid material, usually sand or man-made ceramic material, designed to keep induced hydraulic fractures open during or after a fracturing treatment).

In addition, rotary kilns have other applications, such as the oxidation of ilmenite, calcined petroleum coke, and volatilized zinc.

Three types of FTM Machinery rotary kilns

According to different materials, FTM Machinery rotary kilns can be divided into 3 types: lime kiln, cement kiln, and metallurgical chemical kiln. The kilns have capacities ranging from 180 tons to 10,000 tons per hour.

1. Lime kiln

A lime kiln (also known as an active lime kiln) is the core equipment for calcining active lime and lightly burned dolomite used in iron and steel plants, ferroalloy plants, calcium carbide plants, and magnesium metal plants.

A lime kiln is used to convert limestone (calcium carbonate, CaCO3) to quicklime (calcium oxide, CaO) by heating. How to make lime?

- 1Rotary lime kiln calcines high-calcium and dolomitic limestone above 900°C and then cools below 100°C to produce quicklime. Quicklime is used in building materials, steelmaking, and flue gas desulfurization.

- 2Quicklime reacts with water to produce slaked lime (calcium hydroxide, Ca(OH) 2), which is commonly used in industries such as soil stabilization, cement, water purification, steel, and alumina production.

You may be interested in:

2. Cement kiln

Cement kilns are cement machines used for producing cement clinker, which can be divided into dry and wet cement kilns. The clinker includes limestone, clay, gypsum, shale, etc. Limestone is the critical cement raw material and calcined clay is often used as a clinker substitute in many countries.

Clay calcination is a sintering process in a cement rotary kiln at 1450°C to produce a highly reactive clay for use as a clinker substitute in the range of up to 25%. This contributes to a substantial reduction of CO2 emissions from finished cement products.

The calcined clinker has a stable size, high strength, and easy processing. Therefore, it is very popular among Portland cement plants.

You may be interested in:3. Metallurgical and chemical kiln

Metallurgical and chemical kilns can roast kaolin, magnesite, bauxite, lithium ore, lean iron ore, chromium ore, nickel-iron ore, and other minerals for steel plants, refractory plants, and chemical plants. It also determines the performance of the Lightweight Expanded Clay Aggregate (LECA).

Rotary kilns help magnesite to change mineral properties and easily separate dolomite impurities. It also produces magnesia and magnesium oxide for use in agriculture, livestock, chemistry, construction, and manufacturing.

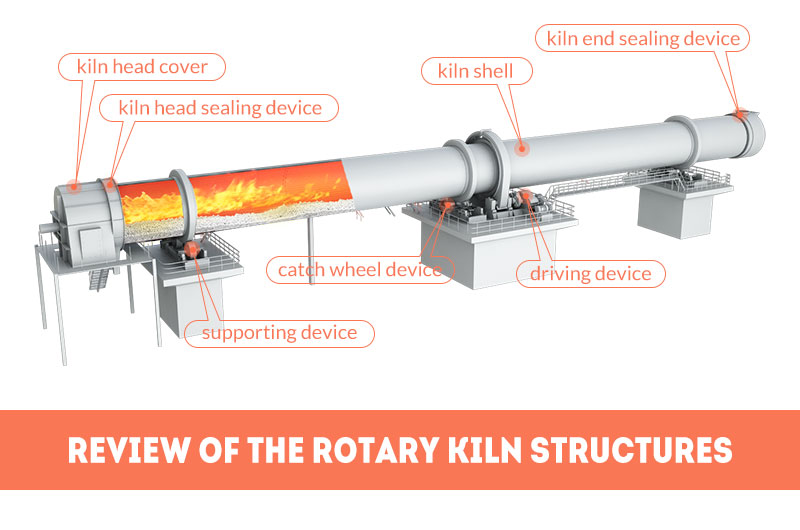

You may be interested in:The structure of a rotary kiln

A rotary kiln has a simple structure that is composed of a kiln lining, kiln shell, gear ring, driving device, supporting device, catch wheel device, sealing device, and other main parts. The whole machine adopts a fully automatic control system, which is reliable in operation.

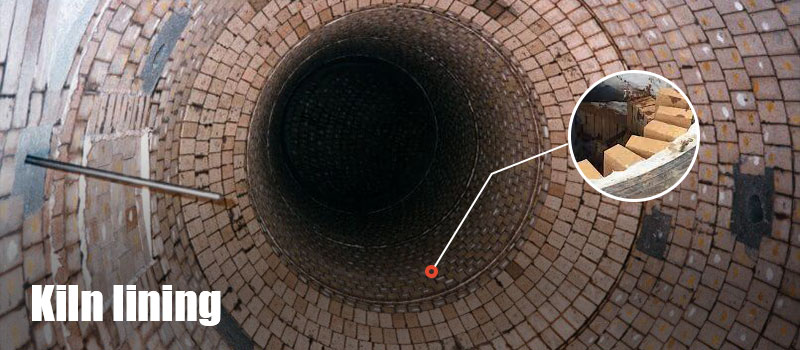

1. Kiln lining

The refractory lining is crucial to prolong the service life of the rotary kiln, as it can prevent the whole body from corroding by the chemical reaction between high-temperature gas and the material. 70% alumina grade refractory brick is the most common refractory lining.

As a thermal media, composite refractories can absorb a portion of the heat and transfer the heat to the material through conduction and radiation. Therefore, insulating refractory materials can reduce the loss of heat radiation and protect the whole machine through thermal insulation.

FTM Machinery expert found:- Aluminosilicate refractory bricks are suitable for the firing system of the cylinder, conveyor, and the whole precalciner kiln.

- In the upper transition zone near the firing zone, the refractory lining must withstand flame temperatures up to 20000°C and material temperatures of 1350–1400°C.

- The refractory lining also faces the challenge of sulfur-alkali compounds and clinker liquid corrosion. Only basic refractory bricks can meet the stringent requirements.

In addition, FTM Machinery has equipped the rotary kiln with an infrared scanner to give early warning of hot spots and help register refractory failures.

2. Kiln shell

The kiln shell is made of high-quality low-carbon steel plates, and the longitudinal and circumferential gaps of the shell are automatically welded.

There are two solid tires on the shell to ensure the rigidity of the cross-section and reduce the stress on the supporting device. It solves the problem of thermal expansion and deformation of the rotary kiln during operation.

The kiln shell is installed tilted on a few support wheels and covered with several rectangular tires along the length of the kiln body. These tires bear the weight of all rotating parts such as the machine body, material, and kiln lining, and transfer the weight to the supporting device.

3. Rotary kiln girth gear

There are fixed large ring gears fixed on the kiln shell to torque.

Large ring gear connects with the kiln shell by the tangential spring plate. The connection generates enough space between the big ring gears for heat dissipation, easing the deformation problem which would affect occlusion accuracy, playing an important role in cushioning shock, and extending the service life of the kiln lining.

4. Drive device

The complete drive device consists of the main drive and auxiliary drive. The main drive is composed of a main motor, final reducer, pinion, and flexible coupling.

FTM Machinery has carried out fine treatment and high-frequency quenching on the pinion, strengthening its tooth hardness to HRC (40-50), which finally extended the service life of the pinion by nearly 5 times.

The auxiliary drive includes an auxiliary motor, reducing gear, and brake. The power of the auxiliary motor comes from the self-provided generator to ensure normal operation when the mains power fails. There is a brake on the auxiliary motor to prevent the kiln body from reversing when the main motor stops accidentally.

5. Supporting device

The supporting device bears almost the total weight of the machine, and it is used for positioning the kiln and ensuring safe and stable operation. The supporting device consists of a support wheel bearing and welding seat base.

The support wheel sets in the large model generally include a support wheel, support wheel axle, axle tile, spherical tile, and bearing seat. Each bearing seat is equipped with two thermal resistances inspecting respectively lubricants' oil temperature and axle tile temperature.

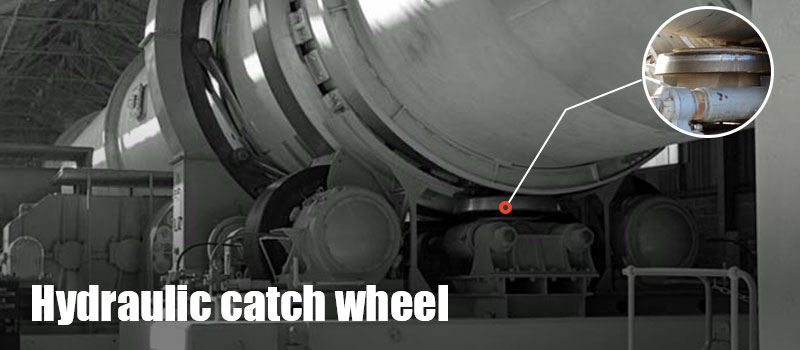

6. Hydraulic catch wheel

According to the force condition and mode of action, the catch wheel can be divided into mechanical and hydraulic catch wheels. The large model rotary kiln is equipped with a hydraulic catch wheel.

The hydraulic catch wheel mainly consists of a catch wheel, catch wheel axle, bearing body, guide axle, ball bearing, and catch wheel limit switch.

The hydraulic catch wheel withstands the sliding force of the rotary kiln, moving the kiln body upward, forcing the tire and kiln to make a reciprocating motion along the kiln center direction, and making the tire and support wheel can evenly wear at full width.

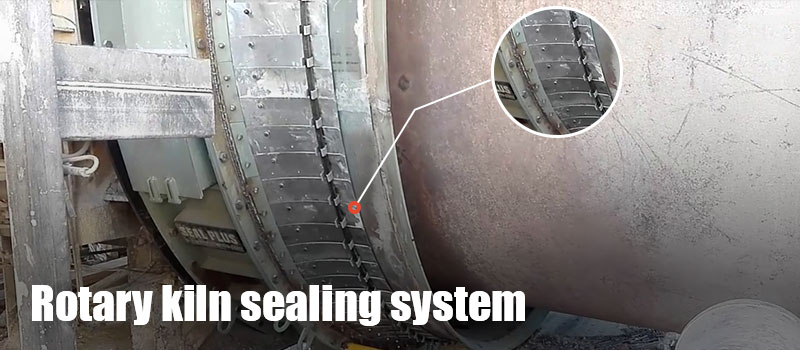

7. Rotary kiln sealing system

To prevent cold air from entering and flue gas dust from overflowing the cylinder, reliable kiln tail and kiln head sealing devices are installed at the feed end (tail) and discharge end (head) of the cylinder.

Reliable combined scale-like seals at both ends of the rotary kiln are used to ensure that the air leakage coefficient is less than 10%, so the sealing is good.

How does a rotary kiln work?

The working principle of the rotary kiln is as follows:

- 1The raw material is fed into the kiln body from the high end of the feeder.

- 2With the help of the slow rotation of the kiln, the raw material rolls in the circumferential direction of the kiln and moves from the high end to the low end along the axial direction.

- 3The coal injection combustion at the kiln burner head generates a large amount of heat, which is transferred to the material through the radiation of the flame and the convection of the hot gas. The material is decomposed by heating and undergoes a chemical reaction, eventually changing its state.

- 4TThe calcined material becomes the clinker. It is discharged from the lower end of the kiln barrel and enters the next stage.

Why FTM Machinery rotary kilns?

FTM Machinery is one of the leading rotary kiln suppliers. Our rotary kilns have the following unique advantages:

- Highly intelligent. The heating temperature, rotation speed, and axial movement of the cylinder are controllable.

- High capacity with 180–10,000 tons per hour.

- Designed for particularly demanding applications, from corrosive materials to harsh process environments.

- Three heating methods of calcination, sintering, and pyrolysis are adopted, with uniform heat distribution and low heat consumption.

- Good wear resistance, bending strength and refractoriness, reliable operation, and longer service life.

- Low failure rate, easy installation, and maintenance.

- Good sealing, equipped with a new type of dust collector to achieve zero pollution production.

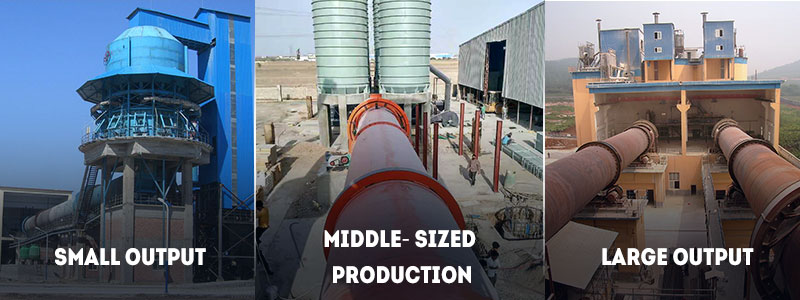

How much is a rotary kiln system?

The final price of a rotary kiln depends on the production requirements. FTM Machinery rotary kiln manufacturer provides you with the most reasonable prices based on three different product ranges. Besides, all the rotary kilns for sale can also be customized based on customer-specific requirements.

| Category | Small output | Middle-sized production | Large output |

| Capacity (t/d) | 180–800 | 1,000–3,200 | 4,000–10,000 |

| Diameter (m) | Φ2.5×40–Φ3.0×60 | Φ3.2×50–Φ4.3×60 | Φ4.5×66–Φ6.0×95 |

| Motor power (kW) | 55–100 | 125–375 | 560–950*2 |

| Total weight (t) | 149.61–310 | 278–583 | 710.4 –1,659 |

| Price range (USD) | $5,000–$95,000 | $100,000–$130,000 | $100,000–$130,000 |

Successful customers' cases

1. Indonesian customers purchased a cement rotary kiln

Our Indonesia client Mr. Cokorda needs to process limestone with a production of 650 t/h. After the on-site survey and the customer’s output requirements, we recommend him a cement rotary kiln with a small diameter.

- Diameter: Φ3.0×60

- Preheater: Grate, gas-suspension

- Heating types: Direct rotary kiln

- Heating method: Counter current

- Temperature range: 1050–1150℃

2. Pakistani customer purchased a metallurgical chemical rotary kiln

Another rotary kiln plant is in Pakistan. He needs to iron ores with an output requirement of 1,000 t/h, so he wants to buy a metallurgical chemical kiln. We recommended him the middle-sized model Φ3.2×50.

The working principle of the rotary kiln is removing oxygen from the ore composition through carbon monoxide. Finally, this metallurgical chemical kiln ideally reduced and roasted hematite-containing materials to produce magnetite.

- Diameter: Φ3.2×50

- Temperature range: 800–1200℃

- Fuel: Crude gas

- Coal ash melting point: 1200°C

- Oxidation degree of crude gas: 15%

- Pressure: 0.1–4 MPa

Frequently asked questions about rotary kilns

1. Why is the rotary kiln alignment so important?

- The rotary kiln alignment is very important. Horizontal and vertical misalignment issues with rotary kilns can lead to reduced reliability and safety issues if left unaddressed. Alignment is also a key factor in extending equipment life and optimizing maintenance costs.

- The benefits of keeping critical components aligned include: a. Reducing power consumption. B. Reducing wear rates on gears, bearings, etc. C. Reducing the risk of causing damage due to refractory failure. D. Reducing the risk of unplanned shutdowns.

2. How to maintain the rotary kiln?

- Regular rotary kiln maintenance is essential. It eliminates failures and safety issues on time, minimizing your operating expenses. FTM Machinery provides end-to-end services for rotary kilns as well as complete pyro-processing systems. The following are maintenance recommendations:

- Daily checks: Check the lubrication levels of load-bearing rollers and gears, axial position of kiln shell, idler cooling water flow, fuel and air connections to burners for leaks and flame shape, etc.

- Weekly checks: Check the kiln tire creep, wearing parts, the kiln drive amperages for fluctuations, kiln seals and shell run-out on feed and discharge ends, drive bolt tightness, the kiln shell temperature profile for fluctuations in operating temperatures, etc.

- Monthly maintenance: Check the auxiliary drive motor, pitch line spacing between drive gears and pinions, gear reducer oil level, drive bearings at high operating temperatures, etc.

Parameter

| Product Specification (m) |

Kiln dimensions | Motor power (kw) |

Total weight (t) |

note | ||||

| Diameter (m) |

Length (m) |

Obliquity (%) |

Capacity (t/d) |

Rotation speed (r/min) |

||||

| Φ2.5×40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 149.61 |

----- |

| Φ2.5×50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187.37 | ----- |

| Φ2.5×54 | 2.5 | 54 | 3.5 | 280 | 0.48-1.45 | 55 | 196.29 |

outside disassemble kiln |

| Φ2.7×42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 198.5 | ------ |

| Φ2.8×44 | 2.8 | 44 | 3.5 | 450 | 0.437-2.18 | 55 | 201.58 |

outside disassemble kiln |

| Φ3.0×45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 210.94 | ------ |

| Φ3.0×48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

outside disassemble klin |

| Φ3.0×60 | 3 | 60 | 3.5 | 800 | 0.3-2 | 100 | 310 | ------ |

| Φ3.2×50 | 3.5 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

disassemble klin |

| Φ3.3×52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

kiln with preheater precalcine |

| Φ3.5×54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

kiln with prehrater precalcine |

| Φ3.6×70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

Generating klin for usimg ofterheat |

| Φ4.0×56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

klin with prehrater precalcine |

| Φ4.0×60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

klin with prehrater precalcine |

| Φ4.2×60 | 4.2 | 60 | 4 | 2750 | 0.41-4.07 | 375 | 633 |

klin with prehrater precalcine |

| Φ4.3×60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

klin with prehrater precalcine |

| Φ4.5×66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710.4 |

klin with prehrater precalcine |

| Φ4.7×74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

klin with prehrater precalcine |

| Φ4.8×74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |

klin with prehrater precalcine |

| Φ5.0×74 | 5 | 74 | 4 | 6000 | 0.35-4 | 710 | 944 |

klin with prehrater precalcine |

| Φ5.6×87 | 5.6 | 87 | 4 | 8000 | Max4.23 | 800 | 1265 |

klin with prehrater precalcine |

| Φ6.0×95 | 6 | 95 | 4 | 10000 | Max5 | 950×2 | 1659 |

klin with prehrater precalcine |

| Product Specification (m) |

Capacity (t/d) |

Rotation speed (r/min) |

| Φ2.5×40 | 180 | 0.44-2.44 |

| Φ2.5×50 | 200 | 0.62-1.86 |

| Φ2.5×54 | 280 | 0.48-1.45 |

| Φ2.7×42 | 320 | 0.10-1.52 |

| Φ2.8×44 | 450 | 0.437-2.18 |

| Φ3.0×45 | 500 | 0.5-2.47 |

| Φ3.0×48 | 700 | 0.6-3.48 |

| Φ3.0×60 | 800 | 0.3-2 |

| Φ3.2×50 | 1000 | 0.6-3 |

| Φ3.3×52 | 1300 | 0.266-2.66 |

| Φ3.5×54 | 1500 | 0.55-3.4 |

| Φ3.6×70 | 1800 | 0.25-1.25 |

| Φ4.0×56 | 2300 | 0.41-4.07 |

| Φ4.0×60 | 2500 | 0.396-3.96 |

| Φ4.2×60 | 2750 | 0.41-4.07 |

| Φ4.3×60 | 3200 | 0.396-3.96 |

| Φ4.5×66 | 4000 | 0.41-4.1 |

| Φ4.7×74 | 4500 | 0.35-4 |

| Φ4.8×74 | 5000 | 0.396-3.96 |

| Φ5.0×74 | 6000 | 0.35-4 |

| Φ5.6×87 | 8000 | Max4.23 |

| Φ6.0×95 | 10000 | Max5 |