What is a lime rotary kiln?

A lime kiln is used to produce quicklime (calcium oxide) by the calcination of limestone which is calcium carbonate. Lime rotary kiln is the prevalent type, accounting for about 90 percent of all lime plants.

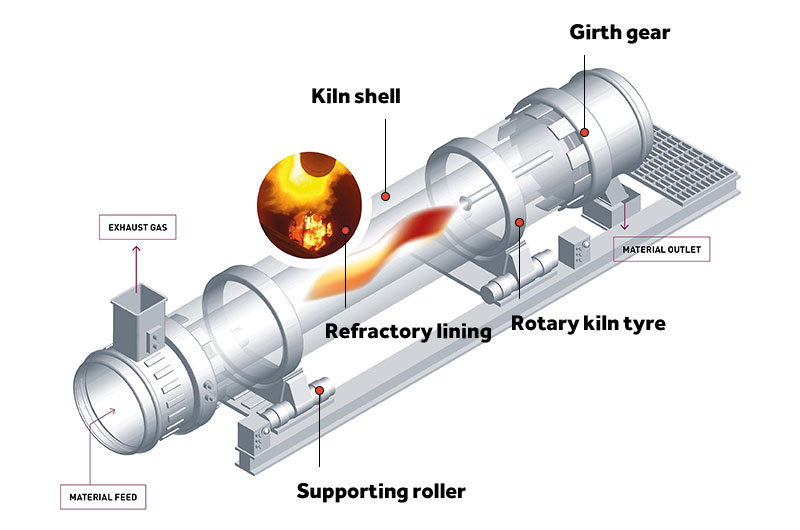

A lime rotary kiln is a long cylindrical, slightly inclined, refractory-lined furnace, through which the limestone and hot combustion gases pass counter-currently.

The lime rotary kiln is always the heart for active lime in lime plants. Ftmmachinery is a reliable lime kiln manufacturer that specializes in designing and constructing automatic, environmentally friendly lime rotary kilns.

Why choose Ftmmachinery lime kilns?

- Low energy consumption: The lime kilns are equipped with a vertical preheater and waste heat recovery system, effectively utilizing the high-temperature flue gas generated during the calcination process. This minimizes fuel consumption and reduces operating costs.

- Good sealing performance: The lime rotary kiln is designed with an advanced structure and reliable combined scale-like seals on both ends, ensuring that the air leakage coefficient remains below 10 percent.

- New technology: The main drive system adopts a new type of AC frequency conversion speed regulation technology. Compared with traditional electromagnetic speed regulation and DC speed regulation, it is more energy-saving and environmentally protection and has a wide range of speed regulation, high efficiency, high-speed regulation precision, and stable operation.

- Process control and automation: Lime rotary kilns provide precise control over temperature, fuel efficiency, key process parameters, and emissions.

- Safety features: The lime kilns are equipped with temperature monitoring systems, gas detection mechanisms, emergency shut-off systems, and other safety measures to protect personnel and equipment.

- High-quality lime products: Ftmmachinery's lime kilns ensure the even and thorough calcination of limestone through advanced burners, optimized kiln design and parameter operation, as well as detection and control systems. This makes them particularly suitable for manufacturing highly active lime used in steelmaking.

How does a lime rotary kiln work?

Lime is the high-temperature product of the calcination of limestone. It is manufactured in limestone calcination kiln by the following reaction:

CaCO3 + heat → CO2 + CaO (high calcium lime)

Here's a step-by-step process of how limestone is converted to lime in a kiln:

Step 1. Raw material preparation: Limestone is crushed, screened, and ground to the required particle size.

Step 2. Charging and preheating: Feed the prepared limestone evenly into the preheater. Inside the preheater, imestone is heated to about 900°C by 1150°C kiln flue gas, reaching approximately 30% decomposition.

Step 3. Calcination: The preheated limestone moves along the kiln's axis from the tail to the head, rolling along the circumference due to the kiln's tilt and slow rotation. Fuel is injected through the burner at the kiln head, undergoing combustion. And the heat is transferred to the limestone through radiation, convection, and conduction. Limestone is calcined into quicklime while moving and discharged from the kiln head.

Step 4. Cooling: The quicklime enters a lime cooler where it is cooled to below 100°C using cold air. Subsequently, it is discharged from the cooler.

Step 5. Transfer to the finished product warehouse: The cooled lime is sent to the lime finished product warehouse through the vibrating feeder, chain bucket conveyor, bucket elevator, and belt conveyor. Add screening process according to customer requirements.

Key parts of the rotary lime kiln

1. Kiln shell

The rotary kiln shell refers to the cylindrical outer structure of a rotary kiln. It is typically made of steel plates that are joined together either through welding or riveting.

The kiln shell is a vital component of the rotary kiln, and its deformation directly affects the operation rate of the rotary kiln.

Based on extensive practical experience, Ftmmachinery produces kiln shells with enhanced cross-sectional rigidity and improved longitudinal flexibility.

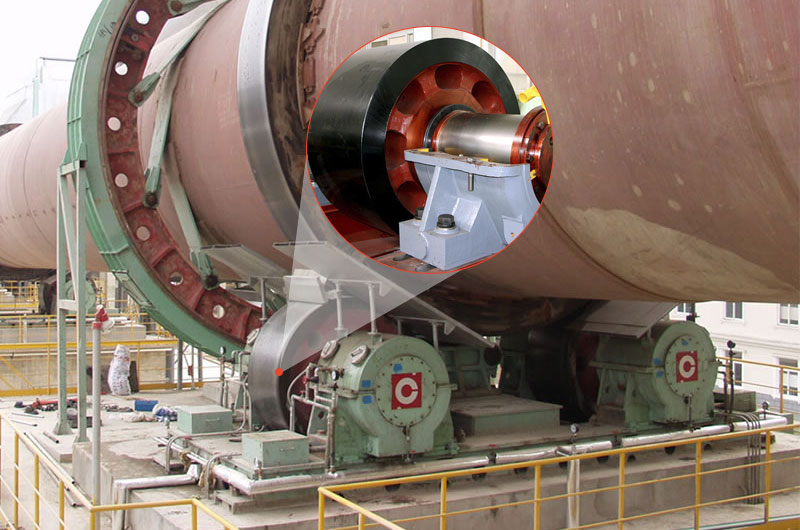

2. Supporting roller

The supporting roller bears the weight of the entire rotating part and provides directional support to ensure smooth rotation of the kiln shell and kiln tyres.

Ftmmachinery's supporting rollers are made of high-quality materials like ZG55 and ZG42CrMo, offering significant load-bearing capacity, excellent impact resistance, high hardness, and exceptional wear resistance.

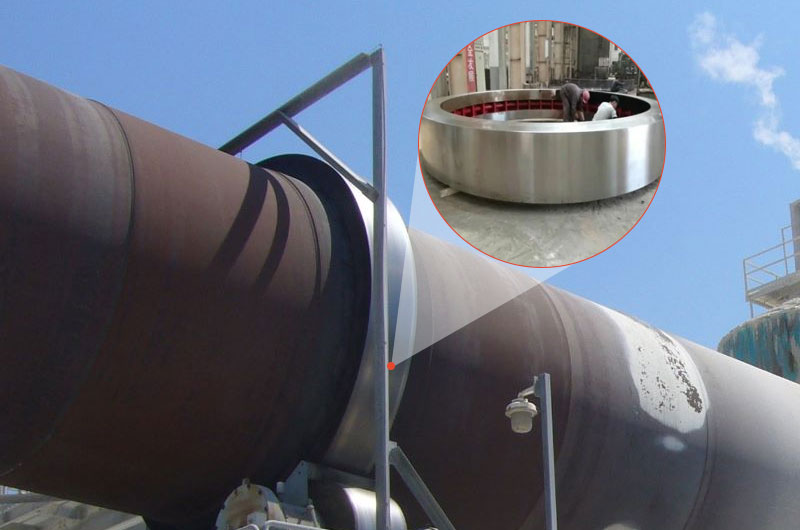

3. Kiln tyre

The kiln tyre, also known as the kiln ring tyre or riding ring, is a circular steel ring that is placed around the circumference of a rotary kiln and is secured to the kiln shell.

As a crucial part of the rotary kiln, the kiln tyre must possess sufficient rigidity, strength and durability.

Ftmmachinery manufactures rotary kiln tyres from high-quality cast steel materials, employing strict control measures at each stage to ensure that the kiln tyres exhibit the necessary rigidity, strength, and durability.

4. Girth gear

The girth gear is a large gear ring that is mounted on the outer surface of the kiln shell. Its primary function is to transmit torque from the kiln drive system to the kiln shell, facilitating rotation.

Ftmmachinery's girth gears undergo tempering, normalization, and precise machining to meet national standards and are capable of meeting the requirements for lime rotary kilns.

5. Refractory lining

The interior of the kiln shell is lined with refractory bricks or castable refractories. These linings can withstand the high temperatures in the kiln and offer insulation to reduce heat loss. They also protect the kiln shell from the corrosive action of lime and other materials.

Ftmmachinery provides a variety of refractory materials to cater to user needs, including magnesia refractory materials, high alumina refractory materials, clay refractory materials, thermal insulation refractory materials, chromium-containing refractory materials, etc.

Choose the right refractory lining

| Types | Features | Applications |

| Magnesia refractories | Excellent resistance to high temperatures and alkaline environments, good thermal shock resistance | Suitable for burning zone and transition zone of the kiln |

| High-alumina refractories | Good thermal stability, high mechanical strength, and resistance to chemical attack | Suitable for areas that are subjected to lower temperatures and less severe chemical conditions, such as the cooling zone |

| Insulating refractories | Low thermal conductivity | Suitable for outer layers of the kiln lining, providing insulation and preventing excessive heat transfer to the kiln shell |

| Chromium-containing refractories | Resistant to high temperatures, corrosion and mechanical stress | Resist chemical attack and maintain lining integrity with chromium-containing refractories |

| Clay refractories | Good thermal insulation properties and moderate resistance to thermal shock | Suitable for areas where the temperature is lower, such as the cooler discharge zone |

Frequently asked questions about lime kilns

1. How long does it take to produce lime in a rotary kiln?

- The residence time of limestone in a rotary kiln may vary depending on kiln design (length, diameter, inclination, and rotational speed), operating conditions (temperature, air flow rate), limestone properties (particle size, porosity, and reactivity), and lime product quality.

- Generally, the residence time in a limestone calcination kiln can range from a few hours to several days. The specific residence times may vary widely depending on the factors mentioned above as well as specific kiln design and operating conditions.

2. What is the energy consumption of the lime rotary kiln?

- Limestone calcination is an energy-consuming process. Ftmmachinery is committed to providing customers with low-energy consumption lime manufacturing kilns.

-

1. Optimize kiln design

Optimize the design of the rotary kiln according to the actual production situation, including length, diameter, speed, etc. -

2. Waste heat recovery systems

Integrate waste heat recovery systems, such as preheaters or waste heat boilers, to capture and utilize heat from flue gases to preheat combustion air or other processes. -

3. Optimize the combustion process

Using advanced burners, controlling the mixing ratio of fuel and air, and controlling the temperature of the combustion zone to ensure efficient combustion of fuel. -

4. Use advanced process control

Implement advanced process control systems to monitor and optimize key operating parameters such as temperature, airflow, and fuel consumption.

3. What are the emission control measures in place?

- Emission control measures are essential to minimize the environmental impact of lime rotary kilns. Ftmmachinery takes the following measures to ensure compliance with environmental regulations and promote sustainable lime production.

- 1. Install state-of-the-art baghouse and pulse filters to capture particulate matter (dust) emitted from the kiln.

- 2. Install a CEMS to continuously monitor and measure emissions from the kiln. They provide real-time data on pollutant concentrations and help ensure compliance with emission limits.

- 3. Use advanced monitoring and control systems to continuously monitor key process parameters such as temperature, pressure and gas composition. Real-time data can help optimize the operation of kilns and emission control systems, adjusting operating parameters in a timely manner to keep emissions within compliance.

4. Can the kiln be customized to specific requirements?

- Yes, lime rotary kilns can often be customized to specific requirements. You can discuss your specific requirements with Ftmmachinery engineers. Below are some examples.

-

1. Size and capacity

Lime kilns can be designed and manufactured in various sizes and capacities to accommodate different production requirements. The diameter, length, and overall dimensions of the kiln can be tailored to suit specific site constraints and production volumes. -

2. Lime kiln design and configuration

The design and configuration of the lime kiln can be customized based on factors such as the type of lime product, the desired lime quality, and the specific production process. -

3. Emission control equipment

Emission control measures, such as baghouse filters, pulse collectors, or wet scrubbers, can be integrated into the lime kiln design based on local environmental regulations and emission requirements. -

4. Material handling and feed systems

The feeding and discharge systems for limestone and other materials can be customized to suit specific process requirements, including the use of feed hoppers, conveyors, and rotary feeders. -

5. Auxiliary equipment and instrumentation

Additional equipment, such as kiln instrumentation, monitoring devices, safety systems, and ancillary components, can be customized to meet specific operational and safety requirements.

Project case: 500 t/d active lime production line in Thailand

In June 2019, a customer from Thailand inquired about the lime production line. According to his output and final product demand, we recommended this φ3.8m×58m rotary kiln to him. Specific information is as follows:

| Project | Active lime manufacturing |

| Raw material | Limestone (grain size 40–80 mm, CaO>52%, clay content ≤0.5%) |

| Fuel | Anthracite blocks, biomass briquette (grain size 15–30 mm) |

| Finished product requirements | Activated lime (lime activity is 320–360 ml) |

| Core equipment | φ3.8 m×58 m rotary kiln |

| Auxiliary equipment | Vertical preheater, grate cooler, flue gas treatment system, principle conveying system, finished product conveying system, raw coal grinding system |

| Estimated cost | $65,000.00–$65,922.00 |

Advantages of active lime production line

- Consistent product quality: The active lime production line ensures uniform and consistent product quality by precisely controlling parameters such as temperature, pressure, and residence time.

- Environmental friendliness: The active lime production line is equipped with a dust removal system to minimize air pollution, and a waste heat recovery system to reduce energy consumption and greenhouse gas emissions.

- Cost-effectiveness: Energy-saving measures reduce fuel consumption. Continuous operation reduces labor requirements and increases overall productivity. In addition, the scalability of the production line allows adjusting capacity to meet market demand, optimizing cost-effectiveness.

Parameter

| Design capacity (t/d) |

150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 750 | 800 | 1000 | |

| Product | Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

Active lime Calcined dolomite |

|

| Preheater | round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre-heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

round vertical pre- heater or polygonal vertical pre- heater |

Vertical Polygon preheater |

Vertical Polygon preheater |

Vertical Polygon preheater |

|

| Rotary kiln |

Specification (m) |

Φ2.5 × 40 |

Φ2.8 × 42 |

Φ3 × 46 |

Φ3.2 × 50 |

Φ3.5 × 54 |

Φ3.6 × 56 |

Φ3.8 × 58 |

Φ4×60 Φ4.2×50 |

Φ4.3 × 58 |

Φ4.3 × 64 |

Φ4.8 × 68 |

| Effective volume (m³) |

142 | 190 | 235 | 292 | 390 | 430 | 505 | 575/548 | 670 | 738 | 1005 | |

| Burning temperature (°C) |

1350/ 1250 |

1350/ 1250 |

1350/ 1250 |

1350/ 1250 |

1350 | 1350 | 1350 | 1350 | 1350 | 1350 | 1350 | |

| Cooler | Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

Vertical Square Cooler |

|

| Fuel | Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

Coal gas Coal powder |

|

| Heat rate ( KJ/KgC3O

) |

5300/ 5000 |

5300/ 5000 |

5300/ 5000 |

5300/ 5000 |

5225 | 5225 | 5100 | 5100 | 4810 | 4810 | 4810 | |

| Design capacity (t/d) | Preheater | Heat rate ( KJ/KgC3O

) |

| 150 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 200 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 250 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 300 | round vertical pre- heater or polygonal vertical pre- heater | 5300/ 5000 |

| 350 | round vertical pre- heater or polygonal vertical pre- heater | 5225 |

| 400 | round vertical pre- heater or polygonal vertical pre- heater | 5225 |

| 500 | round vertical pre- heater or polygonal vertical pre- heater | 5100 |

| 600 | round vertical pre- heater or polygonal vertical pre- heater | 5100 |

| 750 | Vertical Polygon preheater | 4810 |

| 800 | Vertical Polygon preheater | 4810 |

| 1000 | Vertical Polygon preheater | 4810 |