How is lime produced by limestone?

Lime is made of limestone which needs to be calcinated with a temperature over 900℃. Limestone is a kind of sedimentary rock that is alkaline, and the main component is calcium carbonate, calcium magnesium carbonate, or a mixture of calcium carbonate and magnesium carbonate. The reaction formula from limestone to lime is: CaC03 =Ca0+CO2↑

There are two types of lime: one is quick lime and the other is slaked lime(also called hydrated lime. Quick lime is made by calcinating the limestone in the rotary kiln, and it is white power which often used as building material. The slaked lime produced by the reaction between quick lime and water. The main component of slaked lime is calcium hydroxide (Ca(OH)2), and it is often applied as coating materials and tile adhesives.

The industrial production line of lime

The whole lime production line includes: mining, crushing, screening and calcinating.

Mining high-quality limestone

First, limestone is quarried from mines with the help of big machines and blasting. In this stage, limestone with big blocks which are not suitable for putting in a kiln. Limestone with high calcium has high density and is not easy to calcine, but the calcined lime has good ash quality. On the contrary, limestone with low calcium content has a low density and is easy to calcine, but the calcined ash quality is poor.

High-quality limestone generally contains Ca0 more than 52%, less than 3% Mg0, and Si02 less than 1%.

Crushing and screening

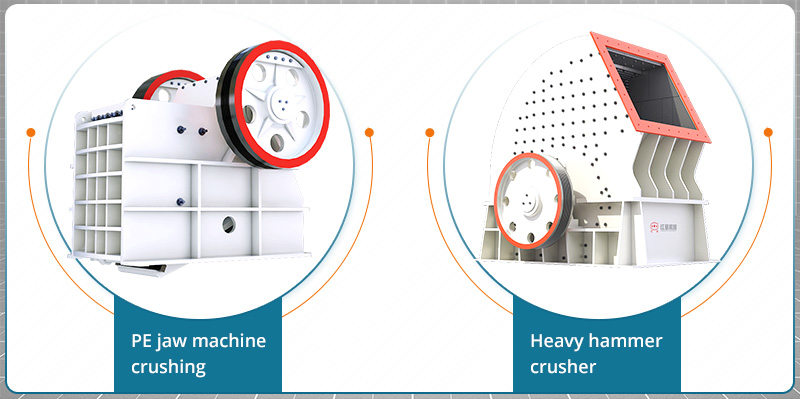

The mined limestone is of various quality, so it should be crushed into smaller size then being sent to the vibrating screen by conveyor belt. After screening and classifying, the selected high-quality limestone product can be discharged to the silo, while rejected material being sent to another silo.

After the first screening process, the primarily qualified limestone would be sent to the hammer crusher for fine crushing. The limestone material discharged from a hammer crusher will be further screened to get qualified material for the next step.

Best crushing and equipment of Fote ManufacturerPE jaw crusher: It weighs 1.5t, and is driven by a 20-horsepower electric motor and powered by a 30-kilowatt generator. Its high manganese steel jaws plates will harden over time so the bite force will become stronger and stronger. PE jaw crusher is an ideal primary crushing equipment, which can reduce the various rocks into the desired size.

Heavy-duty hammer crusher: With high productivity and a large crushing ratio (usually 10-25, sometimes even 50), a heavy-duty hammer mill is often used in large-scale stone crushing lines. In addition, it can reduce the cost by 40% because of the outstanding ability to produce beautiful particle shapes with only one-time crushing. The final particle size is small, uniform, cubic, and less needle sheet.

Vibrating Screen: Practical screen tensioning system. Modular-type drive system/shaft line positioned at the center of gravity resulting in a perfect circular motion. Adjustable counterweights allow for easy stroke adjustment good screening efficiency.

Calcinating limestone in the lime kiln

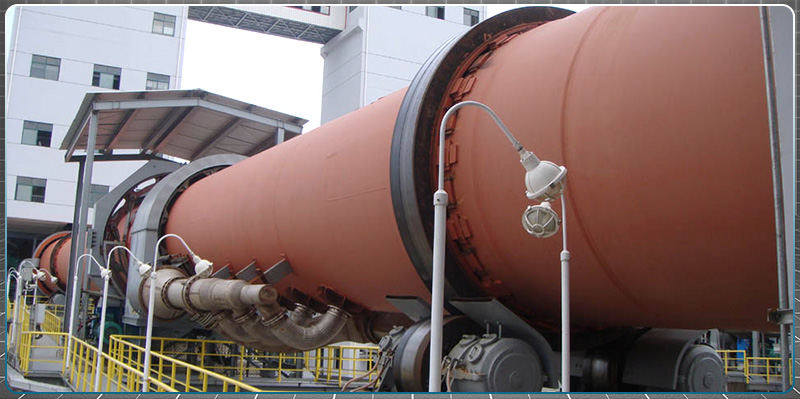

The next step is to transport the limestone to the buffer hopper then conveying it to the top of the rotary kiln for calcination. During the process, the crushed limestone mixed with the coal in a ratio of 4 is to 1. It can also be mixed with petrol coke, but ratio will have to be altered then it is burnt in a kiln to release carbon dioxide reaction, which requires very heat input to produce a ton of quick lime.

The reaction only begins when the temperature is around 900 degrees. Once the reaction starts, the temperature must be maintained above the required temperature. This process is called calcination, by which, quick lime is taken out from the kiln. It creates different types of quick lime depending on the concentration of magnesium carbonate on a limestone.

Rotary kiln equipment recommendation

The most commonly used lime kiln is rotary kiln. Fote rotary kiln has the following advantages:

- High refractoriness. It can be operated in a high temperature environment above 850℃ for a long time without softening caused by load.

- Good wear resistance and flexural strength. It can make the whole kiln body withstand the maximum stress without breaking.

- Good chemical stability. It can prevent the erosion and thinning of acid, alkali metal and other substances in high-temperature flue gas.

- Good thermal stability. Withstand the alternating thermal stress of incineration, and has good thermal shock resistance.

- Porosity is low. Low corrosiveness to refractory materials greatly extends the life of the machine.

In conclusion, the operation process of the Fote lime production line is totally sealed. The flue gas is discharged from the exhaust pipe then being processed by dust collector to achieve pollution-free discharge.

What problems should be paid attention to when producing limestone?

Impacts of limestone impurities

Because limestone (CaCO3) is a natural mineral, it contains some impurities that are not conducive to calcination. Impurities are mainly SiO2, AL2O3, Fe2O3, K2O, P, S, etc.

The amount of these impurities directly affects the output and quality of calcined lime, so choosing high-quality limestone is more critical.

Grain size of limestone

- 1In the process of calcination, the granularity of the raw limestone affects the whole process a lot. Since the separation of CO2 proceeds slowly from the surface of the limestone to the inside, the calcination of large particle size is more difficult than that of small ones, and it takes a longer time.

- 2Through analysis of the scientific experiment, the calcination time at a certain temperature is proportional to the square of the thickness of limestone. Compared with the 40mm stone, the former requires 4 times the calcination time of the latter.

- 3The practice has proved that a shaft furnace is best for limestone with a size of 40-80mm while a rotary kiln is ideal for limestone with 10-30mm.

Fote Company manufactures various crushing and mining equipment over fourty years, if you need any machine to process limestone, please click Fote Engineer Online to get machine information and latest price.