What is a jaw crusher?

A jaw crusher is a primary stone crushing machine used for crushing minerals or rocks into smaller sizes or graves. It is a must-have machine in a wide range of fields like mining, quarrying, road aggregate, and construction industries.

Jaw crusher video animation

With more than 40 years of experience in crushing engineering, FTM Machinery has specially developed high-performance jaw crushers, bringing breakthroughs to stone production lines.

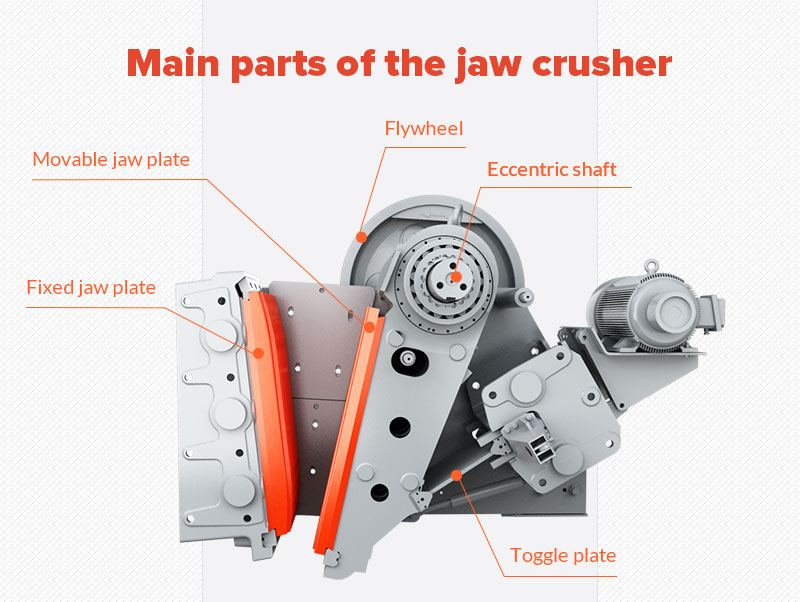

Main parts of the jaw crusher

A jaw crusher consists of several main parts that work together to provide crushing functionality.

The basic structure of a jaw crusher includes the fixed jaw plate, movable jaw plate, toggle plate, eccentric shaft, flywheel, etc.

1. Fixed jaw plate

The fixed jaw plate is a stationary, rigid plate that forms the upper surface of the crushing chamber. It remains fixed in its position and does not move during the crushing process. It is made of high manganese steel or other wear-resistant materials.

2. Movable jaw plate

The movable jaw plate, also called the swing jaw, is the reciprocating part of the jaw crusher. It moves back and forth against the fixed jaw plate, exerting pressure on the materials and crushing them. The movable jaw generally adopts a casting structure.

3. Toggle plate

The toggle plate is also known as the thrust plate. It allows the jaw to move up and down, controlling the movement of the jaw to regulate the size of the crushed material. Toggle plates are commonly made of cast iron or high manganese steel.

4. Eccentric shaft

The eccentric shaft is the main shaft of the crusher, which bears a huge bending force. It can transmit the rotational motion of the motor to the movable jaw. The eccentric shaft is made of high-carbon steel for durability and resistance to bending.

5. Flywheel

The flywheel forms inertial force through rotation and stores energy, which transmits power during the crushing process to ensure the smooth and continuous operation of the machine. Flywheels are typically made of cast iron or cast steel.

Among these parts, jaw plates (one fixed, one movable) are the most easily worn parts in the jaw crusher. Therefore, the jaw plate should be checked and replaced regularly to use the machine efficiently. Learn How to Choose the Right Jaw Plate.

Other part names and functions of the jaw crusher:

- Frame: Keep the machine in place and protect it to reduce abrasion.

- Bearing: Support the rotating components of the jaw crusher, such as the eccentric shaft and flywheel.

- Tension rod: Control the movement of the movable jaw and prevent it impact the front main frame in any situation.

- Adjusting set: Change the discharging opening size of the crusher to satisfy different customers' requirements.

Hot types of jaw crusher

Jaw crusher machine was first invented by Whitney Blake in 1858. On this basis, FTM Machinery introduces advanced technology and gradually launches 4 hot types of jaw crushers: PE/PEX series, HD German version series, CJ European version series, and mobile jaw crushers.

1. PE/PEX jaw crusher

PE/PEX jaw crusher is an earlier type with a simple structure. The PE type is a primary jaw crusher, and the PEX type is a secondary jaw crusher. It is the main crushing equipment in the small stone production lines.

- Maximum feed size: ≤1,200 mm

- Discharge particle size: 10–350 mm

- Capacity: 1–1,200 t/h

2. HD German type jaw crusher

HD series jaw crusher is developed by FTM Machinery combined with German crushing technology. The large inclination angle of the toggle plate makes the output higher and the particle size more uniform. It optimizes the crusher cavity and performs well in processing hard materials.

- Maximum feed size: ≤900 mm

- Discharge particle size: 45–225 mm

- Capacity: 50–750 t/h

3. CJ European type jaw crusher

CJ series jaw crusher is a crushing equipment with advanced technology, which has the advantages of small space occupation, large crushing ratio, and high processing capacity. It is the best choice for large and medium-sized stone production lines.

- Maximum feed size: ≤1,040 mm

- Discharge particle size: 60–300 mm

- Capacity: 105–1,280 t/h

4. Mobile jaw crusher

It is composed of a jaw crusher, vibrating feeder, screening equipment, conveying equipment, etc., and becomes a walking coarse crushing production line. Its application saves time spent on material transportation and production costs.

Click here to get the detailed parameters of jaw crushers!

In addition, according to the different ways of moving, jaw crushers in the market can also be divided into these 4 types: Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher, and mobile jaw crusher. Read The Comparison of the Four Jaw Crushers.

Why choose FTM Machinery jaw crushers?

FTM Machinery is a high-quality jaw crusher manufacturer integrating R&D, production, sales, and service. The jaw crusher machines have the following outstanding advantages:

- High crushing capacity: Jaw crushers can handle large feed sizes and have a high crushing capacity. They efficiently process materials with compressive strength up to 320 MPa.

- Durable construction: Jaw crushers are built with robust and heavy-duty base construction. The use of high-quality components ensures their durability and extended operational life.

- Adjustable output size: The wedge adjusts the discharge opening, and the discharge size can be controlled to meet the different requirements of users.

- Versatile jaw plate options: Different jaw plate configurations can be used to suit specific applications. Types of jaw plates, such as high manganese steel, alloy steel, or composite materials, are used to enhance wear resistance.

- Automatic lubricating device: They are equipped with a safe and reliable lubricating system to improve equipment utilization and reduce maintenance costs.

- High efficiency and energy saving: The jaw crusher can deliver up to 25% more tones per hour than other comparable crushers. Stand-alone energy-saving 15%–30%.

FTM Machinery jaw crushers for sale:Get the Latest Price

How does a jaw crusher work?

The working principle of a jaw crusher is to crush and break the material through the moving jaw plates. The belt and the pulley are driven by the motor, and the movable jaw is fixed to reciprocate up and down through the action of the eccentric shaft. The moving track of the movable jaw is an arc with the mandrel as its center.

Customer case—Jaw crusher for sale in Indonesia

In June 2022, a customer from Indonesia bought a jaw crusher to process limestone. According to his production and final product demand, we recommend him this jaw stone crusher with a capacity of 800 t/h. The specific information is as follows:

| Project | Indonesia crushing production line |

| Raw material | Limestone |

| Hardness | Relatively soft |

| Model | PE1200×1500 |

| Capacity | 800 T/H |

| Feeding size | ≤1,020 mm |

| Production line type | Fixed |

| Finished products | 0–10 mm, 10–20 mm, 20–40 mm, 40–80 mm |

The quality of jaw crushers produced by FTM Machinery is guaranteed and always gains good feedback from the market. Jaw crushers are also exported to the United States, Britain, Russia, the Philippines, Vietnam, and other countries in South Asia, Southeast Asia, Africa, and America.

Frequently asked questions about jaw crushers

1. What model jaw crusher do I need?

- Determining the model of the jaw crusher depends on various factors:

- a. Feed size: The material size should not exceed the maximum feed size of the crusher model.

- b. Desired product size: Different models have different maximum output sizes. Ensure it can produce the final size.

- c. Capacity demand: Consider the required production capacity, such as tons per hour needing to be crushed.

- d. Material hardness: Harder materials require higher crushing forces and more robust crushers.

2. How to adjust the discharge size of the crusher?

- The discharge size of a jaw crusher can be adjusted by changing the size of the opening between the jaws. This can be done using a hydraulic system or adjusting shims or adjusting wedge block.

3. Can a jaw crusher be customized to specific needs?

- Yes, we can offer customization options to tailor the jaw crusher to your specific requirements. This includes modifications to the jaw plates, motor power, and additional features based on your application requirements.

4. How do I maintain my jaw crusher?

- Regular maintenance of your jaw crusher is essential to ensure optimum performance and long service life. This includes checking worn parts, maintaining jaw plates, ensuring lubrication, tightening bolts, and cleaning on time. Refer to the user manual for detailed maintenance.

Parameter

- PE/PEX Jaw Crusher

- HD Series Jaw Crusher

- CJ Series Jaw Crusher

| Model | Feed opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port (mm) | Capacity(t/h) | Rotation speed of eccentric shaft(r/min) | Power (kw) | Dimensions(L×W×H) (mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 1-3 | 268 | 4P 5.5 | 760×700×860 |

| PE 200×300 | 200×300 | 180 | 15-50 | 2-6 | 260 | 4P 7.5 | 915×780×990 |

| PE 200×350 | 200×350 | 180 | 18-60 | 3-10 | 276 | 4P 11 | 1000×914×1112 |

| PE 250×400 | 250×400 | 210 | 20-70 | 5-21 | 300 | 6P 15 | 1100×1032×1285 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-64 | 270 | 6P 30 | 1623×1736×1615 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 268 | 6P 55 | 1920×1850×1920 |

| PE 600×750 | 600×750 | 500 | 150-200 | 80-240 | 268 | 6P 55 | 2020×1850×1920 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-160 | 254 | 6P 55 | 2530×1900×2340 |

| PE 750×1060 | 750×1060 | 630 | 80-180 | 110-320 | 245 | 8P 110 | 2680×2380×2785 |

| PE 900×1200 | 900×1200 | 750 | 100-200 | 220-380 | 208 | 8P 110 | 3470×2876×3330 |

| PE1200×1500 | 1200×1500 | 1020 | 150-350 | 400-1000 | 180 | 8P 160-245 | 4850×3220×3680 |

| PE1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1200 | 180 | 8P 280-380 | 5160×3660×4248 |

| PEX 150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 4P 15 | 1170×1575×1030 |

| PEX 250×750 | 250×750 | 210 | 25-60 | 13-35 | 320 | 6P 22 | 1550×1730×1470 |

| PEX 250×1000 | 250×1000 | 210 | 25-60 | 16-52 | 330 | 6P 30 | 1580×2006×1390 |

| PEX 250×1200 | 250×1200 | 210 | 25-60 | 20-61 | 330 | 6P 37 | 1780×2214×1430 |

| PEX 300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 6P 55 | 2210×2320×1723 |

Note: Processing Capacity May Vary with Different Materials and Feeding Sizes.

| Model | Max.Feeding size (mm) | Capacity (t/h) |

| PE 150×250 | 125 | 1-3 |

| PE 200×300 | 180 | 2-6 |

| PE 200×350 | 180 | 3-10 |

| PE 250×400 | 210 | 5-21 |

| PE 400×600 | 340 | 16-64 |

| PE 500×750 | 425 | 40-110 |

| PE 600×750 | 500 | 80-240 |

| PE 600×900 | 500 | 50-160 |

| PE 750×1060 | 630 | 110-320 |

| PE 900×1200 | 750 | 220-380 |

| PE 1200×1500 | 1020 | 400-1000 |

| PE 1500×1800 | 1200 | 500-1200 |

| PEX 150×750 | 120 | 8-25 |

| PEX 250×750 | 210 | 13-35 |

| PEX 250×1000 | 210 | 16-52 |

| PEX 250×1200 | 210 | 20-61 |

| PEX 300×1300 | 250 | 16-105 |

Note: Processing Capacity May Vary with Different Materials and Feeding Sizes.

| Model | Feeding opening size(mm) | Max.Feeding size (mm) | Adjustment range of discharge port(mm) | Capacity(t/h) | Power(kw) | Dimensions L×W×H (mm) |

| HD72(57) | 460×720 | 425 | 45-100 | 50-120 | 6P 55 | 2100×1556×1640 |

| HD86(69) | 580×860 | 500 | 50-150 | 60-280 | 8P 75 | 2200×1754×1810 |

| HD98(751) | 680×980 | 630 | 75-175 | 110-410 | 8P 110 | 2660×1960×2175 |

| HD110(912) | 850×1100 | 750 | 100-200 | 230-550 | 6P 132 | 2960×2381×2556 |

| HD125 | 950×1250 | 900 | 125-225 | 280-750 | 8P 160 | 3500×2614×2925 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Feeding opening size(mm) | Max.Feeding size(mm) | Capacity (t/h) |

| HD72(57) | 460×720 | 425 | 50-120 |

| HD86(69) | 580×860 | 500 | 60-280 |

| HD98(751) | 680×980 | 630 | 110-410 |

| HD110(912) | 850×1100 | 750 | 230-550 |

| HD125 | 950×1250 | 900 | 280-750 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Feeding opening size L×W(mm) | Adjustment range of discharge port(mm) | Capacity(t/h) | Power(KW) | Dimensions L×W×H(mm) |

| CJ96 | 480 | 930×580 | 60-175 | 105-390 | 4P 90 | 2850×2270×1950 |

| CJ106 | 560 | 1060×700 | 70-200 | 150-500 | 4P 110 | 3280×2580×2400 |

| CJ120 | 700 | 1200×870 | 70-200 | 175-610 | 4P 160 | 3700×2790×2950 |

| CJ125 | 760 | 1250×950 | 100-250 | 270-831 | 4P 160 | 4230×2780×2960 |

| CJ150 | 960 | 1400×1200 | 125-250 | 340-880 | 4P 200 | 5030×3440×3970 |

| CJ160 | 960 | 1600×1200 | 150-300 | 430-1145 | 4P 250 | 5780×3460×3580 |

| CJ200 | 1200 | 2000×1500 | 175-300 | 630-1590 | 6P 400 | 6600×3000×4400 |

| CJ1511 | 850 | 1500×1070 | 125-300 | 380-1080 | 6P 200 | 4130×3000×3330 |

| CJ1513 | 1040 | 1500×1300 | 150-300 | 480-1160 | 6P 200 | 4620×2890×4190 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feeding size(mm) | Capacity(t/h) |

| CJ96 | 480 | 105-390 |

| CJ106 | 560 | 150-500 |

| CJ120 | 700 | 175-610 |

| CJ125 | 760 | 270-831 |

| CJ150 | 960 | 340-880 |

| CJ160 | 960 | 430-1145 |

| CJ200 | 1200 | 630-1590 |

| CJ1511 | 850 | 380-1080 |

| CJ1513 | 1040 | 480-1160 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Download Jaw Crusher

4.61 MB

Download Jaw Crusher

4.61 MB