Material that can be handled

The vibrating feeder (vibratory feeder) is suitable for bulk and granular materials such as limestone, calcite, dolomite, barite, talc, gypsum, quartz stone, river pebble, granite, basalt, construction waste, iron ore, coal, slag, etc.

It is widely used in crushing and screening combination equipment in steel plants, coal plants, foundries, artificial sand and gravel plants, cement, aggregates, glass and ceramics, construction waste recycling, building materials, chemicals, mineral processing and other industries.

Vibrating feeder (vibratory feeder): suitable for bulk and granular materials

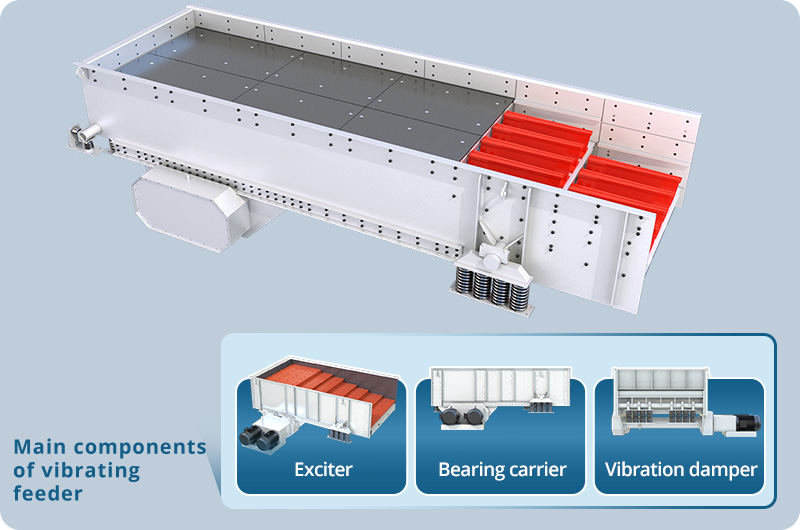

Main components of vibrating feeder

1. Vibration exciter

The magnitude of the excitation force generated by the vibratory feeder directly affects the amplitude of the carrier.

- Stable amplitude and good continuity. FTM Machinery adopts double eccentric shafts as the excitation source, which ensures the continuity of materials.

- Convenient and stable adjustment. The exciting force and flow can be changed and controlled at any time.

- Low noise. It is good for improving the working environment.

Main components of vibrating feeder

2. Bearing carrier

The bearing carrier refers to the part that the vibrating feeder directly bears the material, so it must have sufficient rigidity and strength. Generally, it is welded with carbon steel, low-alloy structural steel or stainless steel plate with a thickness of 2–10 mm.

| Types of bearing carrier | Slot | Tube |

| Sealing | Mostly open, can also be sealed | Sealed |

| Cross-section shape | Rectangle, trapezoid and triangle | Rectangle and circle |

3. Vibration damper

It not only supports the whole machine as a supporting device, but also absorbs vibration. The support mode of the vibrating feeder is divided into two types: hanging type and pedestal type.

The hanging device includes spiral compression springs, steel wire ropes, anti-swing hammers, rings, steel rope clamps and other parts.

The pedestal type support device is composed of a damping spring, upper and lower spring supports, locking blocks, screen box trunnions and friction dampers. The upper spring support is connected with the trunnion of the screen box.

How to install a vibratory feeder?

The vibrating feeder is mounted by the suspension. The suspension rod of the vibrator should be hung vertically. In order to reduce the lateral swing of the feeder, the suspension rod of the feeding trough should be installed with an outward opening of 10°.

The 4 suspension rods shall be hung on a structure with sufficient rigidity. For large feeders, in order to facilitate maintenance and replacement of the trough, a mobile carriage should be arranged.

How to set the inclination angle of the vibrating feeder?

When used for batching and quantitative feeding, it should be installed horizontally in order to ensure uniform and stable feeding as well as prevent the material from flowing by itself.

For continuous feeding of general materials, it can be installed with a downtilt angle of 10°.

How to set the inclination angle of the vibrating feeder?

For viscous materials and materials with large water content, it can be installed with a downtilt angle of 15°. However, it should not be too large, so as to avoid overloading and stop of the crusher due to excessive feed volume.

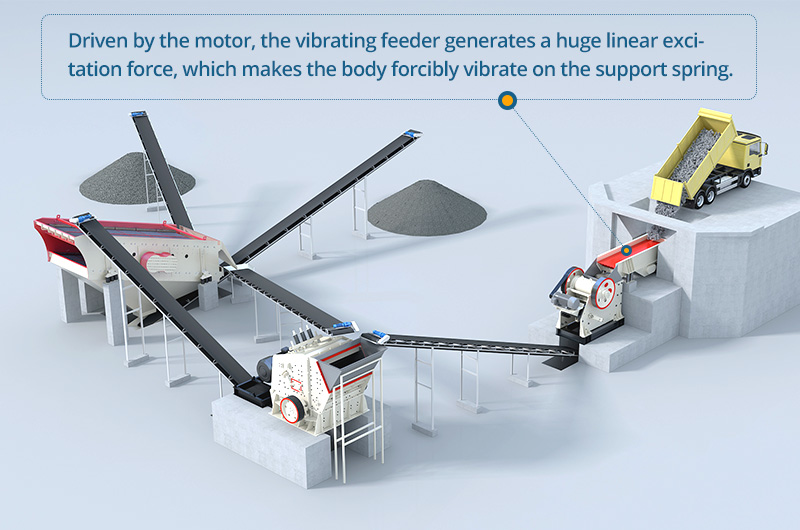

How does the vibrating feeder work?

Driven by the motor, the vibrating feeder generates a huge linear excitation force, which makes the body forcibly vibrate on the support spring.

The material is driven by this vibration to slide and throw on the material tank, then moves forward and achieve feeding purpose.

When the material passes through the screen bar on the tank, the smaller material can fall through the gap of the screen bar without going through the crushing process of the next step, which achieves the effect of screening and improves work efficiency.

How does the vibrating feeder work?

Performance advantages of FTM Machinery vibratory feeder

Strong adaptability with super heavy load-bearing structure

With a strong bearing structure, it can withstand large warehouse pressure, large impact load, high strength of the body, to meet the coarse section of various feeding conditions.

Efficient and reliable with super vibrator

Super vibrators can meet the requirements of higher performance, heavy load, frequent start and stop, frequency conversion and other bad application conditions. Different specifications of vibrators can meet the needs of different excitation forces. Its lubrication and maintenance interval can reach 1500 hours.

Wide range of uses with easy tilt adjustment

The spring support adopts the pin shaft structure, which is convenient to adjust the dip angle of the feeding box according to the working condition on the site. It can be adjusted from 0 to 20° to meet the feeding and screening requirements of different materials.

Performance advantages of FTM Machinery vibratory feeder

Using resonance phenomenon, low maintenance cost

Due to the use of resonance, the power consumption is small and very economical. The wear between the surface of the trough and the conveyed material is small. Even if it is used for a long time, the wear of the trough is also very small.

Longer motor service life with rubber spring parallel tensioning structure

The rubber spring parallel tension structure absorbs the influence of the vibration of the feed box on the motor, effectively prolongs the service life of the motor and the transmission belt, eliminates vibration noise, and makes the vibrating feeder run smoothly.

The feeding end is supported by a staggering spring, and the spring position is reserved, which is convenient to adjust the number of springs according to different warehouse pressures at any time to ensure that the vibrating feeder achieves good performance.

Large chance of passing through with large stepped anti-blocking screen

The screen bar, made from ZGMn13-4, has a stronger carrying capacity and longer life. It has a large drop height, which can increase the probability of passing it through.

Vibrating feeder in stock

The cam section makes the large particles and small particles layered, and reduces the friction between the material and the screen.

The comb-tooth shape of the sieve hole and the large drop of the screen bar can ensure that the material will not be stuck after passing through the screen bar.

Larger storage pressure and materials carrying with stable feeding box

The rectangular section is used as the feeding end support, so the structural strength of the vibratory feeder is strong.

The outside of the side plate is reinforced with angle steel, so the overall structure is compact, the force is even, and the side plate cracking caused by uneven stress is avoided.

Parameter

| Model | Max. Feeding Size (mm) | Processing Capacity (t/h) | Motor Power (kw) | Obliquity of material trough (°) | Trough size (mm) |

| GZD-650×2300 | 300 | 80-100 | 2×1.1 | 10-20 | 650×2300 |

| GZD-750×2500 | 350 | 100-130 | 2×1.1 | 10-20 | 750×2500 |

| GZD-850×3000 | 400 | 120-150 | 2×3 | 10-20 | 850×3000 |

| GZD-1000×3600 | 500 | 150-200 | 2×3.7 | 10-20 | 1000×3600 |

| GZD-1100×3600 | 580 | 240-300 | 2×3.7 | 10-20 | 1100×3600 |

| GZD-1300×3600 | 650 | 450-600 | 2×7.5 | 10-20 | 1300×3600 |

| GZD-1500×3600 | 1050 | 450-1000 | 2×7.5 | 10-20 | 1500×3600 |

| GZD-2000×3600 | 1200 | 550-1000 | 2×10 | 10-20 | 2000×3600 |

| GZD-2500×5000 | 1500 | 650-1500 | 2×18 | 10-20 | 2500×5000 |

| ZSW-380×95 | 500 | 100-280 | 8p 11 | 0-15 | 3800×280 |

| ZSW-490×110 | 630 | 150-400 | 6p 15 | 0-10 | 4900×1100 |

| ZSW-490×130 | 750 | 400-700 | 6p 22 | 0-10 | 4900×1300 |

| ZSW-600×130 | 750 | 400-700 | 4p 22 | 0-10 | 6000×1300 |

| ZSW-600×150 | 800 | 500-900 | 4p 30 | 0-10 | 6000×1500 |

| ZSW-600×180 | 900 | 700-1300 | 4p 37 | 0-10 | 6000×1800 |

| ZSW-600×200 | 1200 | 800-1500 | 4p 55 | 0-10 | 6000×2000 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Max. Feeding Size (mm) | Processing Capacity (t/h) |

| GZD-650×2300 | 300 | 80-100 |

| GZD-750×2500 | 350 | 100-130 |

| GZD-850×3000 | 400 | 120-150 |

| GZD-1000×3600 | 500 | 150-200 |

| GZD-1100×3600 | 580 | 240-300 |

| GZD-1300×3600 | 650 | 450-600 |

| GZD-1500×3600 | 1050 | 450-1000 |

| GZD-2000×3600 | 1200 | 550-1000 |

| GZD-2500×5000 | 1500 | 650-1500 |

| ZSW-380×95 | 500 | 100-280 |

| ZSW-490×110 | 630 | 150-400 |

| ZSW-490×130 | 750 | 400-700 |

| ZSW-600×130 | 750 | 400-700 |

| ZSW-600×150 | 800 | 500-900 |

| ZSW-600×180 | 900 | 700-1300 |

| ZSW-600×200 | 1200 | 800-1500 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

Download Vibrating Feeder

320.84 KB

Download Vibrating Feeder

320.84 KB