What is a pulse jet dust collector?

A pulse jet dust collector is a self-cleaning dry filtration system. It is also referred to as a pulse jet baghouse, a pulse jet filter, or a pulse jet fabric filter. It is designed to safely collect and remove dust created during industrial product manufacturing or processing.

Applications of pulse jet dust collector

High collection efficiency and low maintenance costs make pulse jet dust collectors a common dry air pollution control device in industrial plants. The following are examples of pulse dust collector applications:

- Food processing plants

- Steel mills

- Asphalt plants

- Power plants

- Recycling facilities

- Pharmaceutical factories

- Paper mills

- Cement plants

- Mining and minerals

How does a pulse jet dust collector work?

A pulse jet dust collector uses a series of bags to capture and filter out dust particles from a contaminated air stream. Here is a general overview of how a pulse jet dust collector works:

1. Contaminated air enters the dust collector through an inlet and is drawn into a chamber containing a series of filter bags.

2. The dust particles in the air stream are trapped on the surface of the filter bags, while the clean air passes through and is released back into the environment.

3. Over time, the dust particles build up on the surface of the filter bags, reducing their filtering efficiency and increasing the pressure drop across the system.

4. When the pressure drop reaches a predetermined level, the pulse jet dust collector triggers a cleaning cycle. During the cleaning cycle, compressed air is released into the system, creating a shock wave that dislodges the dust particles from the surface of the filter bags.

5. The dislodged dust particles fall into a hopper or collection bin, where they can be safely disposed of.

Important pulse jet dust collector parts

The important parts of a pulse jet dust collector include:

1. Filter bag

The filter bag is the primary component of a pulse jet dust collector. It is made of fabric or felt and is used to capture and filter the dust particles from the air.

2. Filter cage

The filter cage supports the filter bag and prevents it from collapsing or bulging due to the airflow or the accumulation of dust particles.

3. Pulse jet valve

The pulse jet valve controls the release of compressed air into the filter bags during the cleaning cycle. The compressed air creates a shock wave that dislodges the accumulated dust particles from the filter bag and releases them into the hopper below.

4. Differential pressure sensor

The differential pressure sensor detects the pressure drop across the filter media and sends a signal to the injection valve to initiate a cleaning cycle.

5. Venturi tube

The venturi tube is usually located at the bottom of the pulse jet cleaning assembly and its purpose is to create a pressure differential between the clean air chamber and the dirty air chamber.

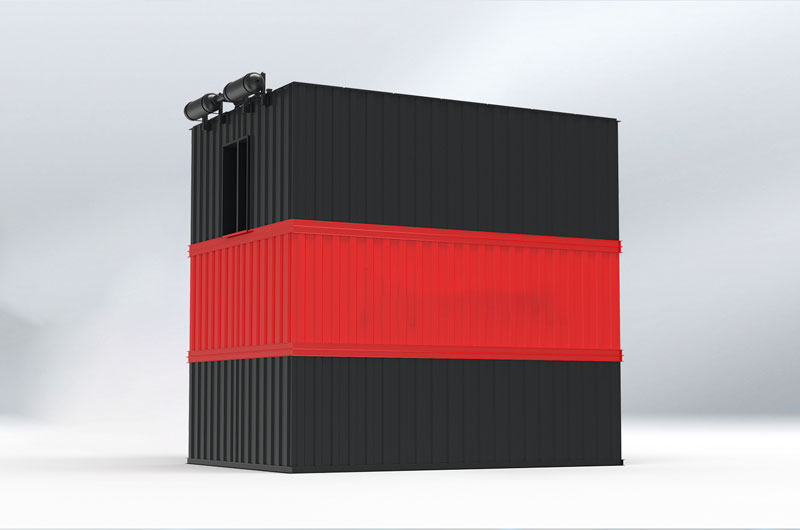

Types of FTM Machinery Pulse Dust Collectors

As a professional mining equipment manufacturer, FTM Machinery provides DMC series single-unit pulse dust collectors, PPCS series air box pulse dust collectors, and HLMC series line-spray off-line pulse dust collectors according to customer needs.

DMC series single-unit pulse jet dust collector

The DMC series single-unit pulse jet dust collector adopts the pulse jet dust removal method, which has the characteristics of high dust removal efficiency, appropriate air volume, long filter bag life, small maintenance workload, and safe and reliable operation. It is suitable for dust removal of non-fibrous industrial dust in various industrial and mining enterprises.

PPCS series air box pulse dust collector

PPCS series air box pulse bag filter is widely used in building materials, cement, metallurgy, chemical, and refractory industries. It is especially suitable for dust collection in crushers, packing machines, silo roof, clinker coolers, and various mills in cement plants.

HLMC series line spray off-line pulse dust collector

HLMC series line spray off-line pulse jet dust collector is a new type of efficient bag dust collector developed based on conventional pulse bag dust collectors.

HLMC series line spray off-line pulse jet dust collectors serve casting, metallurgy, machinery, electric power, building materials, mining, cement, chemical, and other industries with their excellent performance. It is suitable for integrated dust collection in factories with large air volume, high dust concentration and limited space. Sand making plants often apply this dust collector.

Why choose FTM Machinery pulse jet dust collectors?

FTM Machinery is a professional mining equipment manufacturer in China. The pulse jet dust collector produced by our company has the following outstanding advantages:

- The housings for the units can be manufactured in different sizes and shapes, allowing for a dust collection system that fits within individual space constraints.

- The heavy-duty construction is all-welded, so there are no joints that can come apart due to screws or other fasteners failing over time leading to leakage in the system.

- Materials of construction can include carbon steel, stainless steel, or other special alloys to conform with the airstream and dust characteristics for any application.

- Equip suitable filter bags and filter cages according to dust characteristics.

- Apply PLC control system to realize automatic dust removal, automatic temperature control, and over-temperature alarm.

- The offline dust cleaning method enables cleaning or maintenance without shutting down the system, ensuring that the dust collector is always running at optimal efficiency, and the dust removal efficiency is as high as 99.99%.

- The air box structure ensures that the airflow is evenly distributed on the filter bag, which improves dust removal efficiency and reduces maintenance costs. Filter bags etc. are usually located in an accessible area for easier maintenance.

Frequently asked questions about pulse jet dust collectors

1. How to choose the right filter bag media?

- There are several types of filter bag media used in pulse dust collectors. The selection of filter bag media depends on the specific application and the dust characteristics. Here are some common types of filter bag media:

- 1. Polyester: Polyester filter bags are commonly for collecting dry dust particles. They have good abrasion resistance with temperature ratings up to 150°C and are for the mining industry and quarries.

- 2. Polypropylene: Polypropylene filter bags are similar to polyester filter bags but have better resistance to chemicals with temperature ratings up to 90°C and are for the chemical and pharmaceutical industries, food and beverage processing plants.

- 3. Aramid: Aramid filter bags are used for high-temperature applications and can withstand temperatures up to 204°C. They are commonly used in cement and asphalt plants.

- 4. PPS (Polyphenylene Sulfide): PPS filter bags are used in dust collection applications for asphalt plants, cement mills, incinerators, and coal-fired boilers.

- 5. PTFE (Polytetrafluoroethylene): PTFE filter bags are suitable for collecting wet or sticky dust particles and can withstand temperatures up to 260°C. They are for the mining, chemical, and pharmaceutical industries.

- 6. Fiberglass: Fiberglass filter bags are used in high-temperature applications and can withstand temperatures up to 260°C. They are for foundries and metalworking facilities.

- 7. Acrylic: Acrylic filter bags have good acid and alkali resistance with temperature ratings up to 130°C, and are often used in cement plants.

- 8. Nomex: Nomex filter bags are suitable for high-temperature applications up to 204°C and have good abrasion resistance. They are for asphalt plants and the chemical industry.

2. Can pulse jet dust collectors handle explosive and corrosive gases?

- Pulse jet dust collectors are not suitable for use with corrosive or reactive gases, these gases can damage equipment and pose a safety hazard. It is also not suitable for handling hazardous or explosive dust. In such cases, specialized equipment such as explosion-proof dust collectors or inertial separators may be required to safely handle the dust.

3. How do I choose the right size pulse jet dust collector for my application?

- Selecting the right size pulse jet collector for your application involves several factors. The following steps can help you determine the right size:

- 1. Determine the air volume: The first step is to determine the volume of air to be filtered, which is typically measured in cubic feet per minute (CFM). You can use an anemometer or consult an expert to determine the air volume of your application.

- 2. Identify the type of dust: Different types of dust have varying densities, particle sizes, and characteristics that can impact dust collection efficiency. Knowing the type of dust will help in selecting the correct filtration media and pulse jet cleaning frequency.

- 3. Determine the air-to-cloth ratio: The air-to-cloth ratio refers to the amount of air passing through each square foot of filter media per minute. Typically, the air-to-cloth ratio should be between 1:1 to 1.5:1 for a pulse jet dust collector. A higher ratio may cause the filter to become overloaded with dust, while a lower ratio can reduce the cleaning efficiency of the pulse jet system.

- 4. Determine the appropriate filter area: The filter area is dependent on the air-to-cloth ratio and the CFM. The formula is as follows: Filter area (in square feet) = CFM/Air-to-cloth ratio.

Parameter

- DMC single pulse dust collector

- PPCS series air box type pulse dust collector

- HLMC Series line jet off-line pulse dust collector

| Model |

Filter area (m²) |

Processing air volume (m³/h) |

Filtered air speed (m/min) |

Fan Power (kW) |

Number of filter bags |

Inlet dust concentration (g/Nm³) |

| DMC24 | 18 | 864~2160 | 0.8~2 | 1.5 | 24 | <200 |

| DMC36 | 27 | 1296~3240 | 0.8~2 | 3 | 36 | <200 |

| DMC48 | 36 | 1728~4320 | 0.8~2 | 4 | 48 | <200 |

| DMC64 | 48 | 2304~5760 | 0.8~2 | 4 | 64 | <200 |

| DMC80 | 60 | 2880~7200 | 0.8~2 | 5.5 | 80 | <200 |

| DMC96 | 72 | 3456~8640 | 0.8~2 | 7.5 | 96 | <200 |

| DMC112 | 84 | 4032~10080 | 0.8~2 | 7.5 | 112 | <200 |

| DMC128 | 96 | 4608~11520 | 0.8~2 | 7.5 | 128 | <200 |

| DMC150 | 112.5 | 5400~13500 | 0.8~2 | 15 | 150 | <200 |

| DMC180 | 135 | 6480~16200 | 0.8~2 | 18.5 | 180 | <200 |

| DMC220 | 165 | 7920~19800 | 0.8~2 | 30 | 220 | <200 |

| Model |

Filter area (m²) |

Processing air volume (m³/h) |

Filtered air speed (m/min) |

Fan Power (kW) |

| DMC24 | 18 | 864~2160 | 0.8~2 | 1.5 |

| DMC36 | 27 | 1296~3240 | 0.8~2 | 3 |

| DMC48 | 36 | 1728~4320 | 0.8~2 | 4 |

| DMC64 | 48 | 2304~5760 | 0.8~2 | 4 |

| DMC80 | 60 | 2880~7200 | 0.8~2 | 5.5 |

| DMC96 | 72 | 3456~8640 | 0.8~2 | 7.5 |

| DMC112 | 84 | 4032~10080 | 0.8~2 | 7.5 |

| DMC128 | 96 | 4608~11520 | 0.8~2 | 7.5 |

| DMC150 | 112.5 | 5400~13500 | 0.8~2 | 15 |

| DMC180 | 135 | 6480~16200 | 0.8~2 | 18.5 |

| DMC220 | 165 | 7920~19800 | 0.8~2 | 30 |

| Model | Air volume (m³/h) | Filtration velocity (m/min) | Total filtra tion area (m²) | Net filtration area (m²) |

| PPCS 32-3 | 6900 | 1.2-2.0 | 93 | 62 |

| PPCS 32-4 | 8930 | 124 | 93 | |

| PPCS 32-5 | 11160 | 155 | 124 | |

| PPCS 32-6 | 13390 | 186 | 155 | |

| PPCS 64-4 | 17300 | 248 | 186 | |

| PPCS 64-5 | 22300 | 310 | 248 | |

| PPCS 64-6 | 26700 | 372 | 310 | |

| PPCS 64-7 | 31200 | 434 | 372 | |

| PPCS 64-8 | 35700 | 496 | 434 | |

| PPCS 96-4 | 26800 | 372 | 279 | |

| PPCS 96-5 | 33400 | 465 | 372 | |

| PPCS 96-6 | 40100 | 557 | 465 | |

| PPCS 96-7 | 46800 | 650 | 557 | |

| PPCS 96-8 | 53510 | 744 | 650 | |

| PPCS 96-9 | 60100 | 838 | 744 | |

| PPCS96-2X5 | 66900 | 929 | 838 | |

| PPCS96-2X6 | 80700 | 1121 | 1028 | |

| PPCS96-2X7 | 94100 | 1308 | 1215 | |

| PPCS96-2X8 | 107600 | 1494 | 1401 | |

| PPCS96-2X9 | 121000 | 1681 | 1588 | |

| PPCS96-2X10 | 134500 | 1868 | 1775 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Air volume (m³/h) | Filtration velocity (m/min) | Total filtra tion area (m²) | Net filtration area (m²) |

| PPCS 32-3 | 6900 | 1.2-2.0 | 93 | 62 |

| PPCS 32-4 | 8930 | 124 | 93 | |

| PPCS 32-5 | 11160 | 155 | 124 | |

| PPCS 32-6 | 13390 | 186 | 155 | |

| PPCS 64-4 | 17300 | 248 | 186 | |

| PPCS 64-5 | 22300 | 310 | 248 | |

| PPCS 64-6 | 26700 | 372 | 310 | |

| PPCS 64-7 | 31200 | 434 | 372 | |

| PPCS 64-8 | 35700 | 496 | 434 | |

| PPCS 96-4 | 26800 | 372 | 279 | |

| PPCS 96-5 | 33400 | 465 | 372 | |

| PPCS 96-6 | 40100 | 557 | 465 | |

| PPCS 96-7 | 46800 | 650 | 557 | |

| PPCS 96-8 | 53510 | 744 | 650 | |

| PPCS 96-9 | 60100 | 838 | 744 | |

| PPCS96-2X5 | 66900 | 929 | 838 | |

| PPCS96-2X6 | 80700 | 1121 | 1028 | |

| PPCS96-2X7 | 94100 | 1308 | 1215 | |

| PPCS96-2X8 | 107600 | 1494 | 1401 | |

| PPCS96-2X9 | 121000 | 1681 | 1588 | |

| PPCS96-2X10 | 134500 | 1868 | 1775 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model |

Processing air volume (m³/h) |

filtration velocity (m/min) |

Total filtering area (m²) |

Net filtering area (m²) |

Dust concentration of imported air (g/Nm³) |

Dust concentration of outlet air (g/Nm³) |

Clean compressed air | |

| Pressure (Pa) | Air consumption(Nm³/min) | |||||||

| HLMC1000 | 48000~120000 | 0.8~2.0 | 1100 | 1000 | <1000 | <0.02 | (5~7) x 105; | 2.1 |

| HLMC1400 | 67200~168000 | 1500 | 1400 | <1000 | <0.02 | 2.1 | ||

| HLMC1700 | 81600~204000 | 1820 | 1700 | <1000 | <0.02 | 3 | ||

| HLMC2100 | 100800~252000 | 2280 | 2100 | <1000 | <0.02 | 3 | ||

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model |

Processing air volume (m³/h) |

filtration velocity (m/min) |

Total filtering area (m²) |

Dust concentration of imported air (g/Nm³) |

| HLMC1000 | 48000~120000 | 0.8~2.0 | 1100 | <1000 |

| HLMC1400 | 67200~168000 | 1500 | <1000 | |

| HLMC1700 | 81600~204000 | 1820 | <1000 | |

| HLMC2100 | 100800~252000 | 2280 | <1000 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.