A brief introduction to powder grinding production line

A powder grinding production line produces fine and ultra-fine powders, with particle sizes ranging from 80 to 2,500 mesh. It is widely used in industries like cement, coal, building materials, chemical engineering, chemicals, mining, and construction.

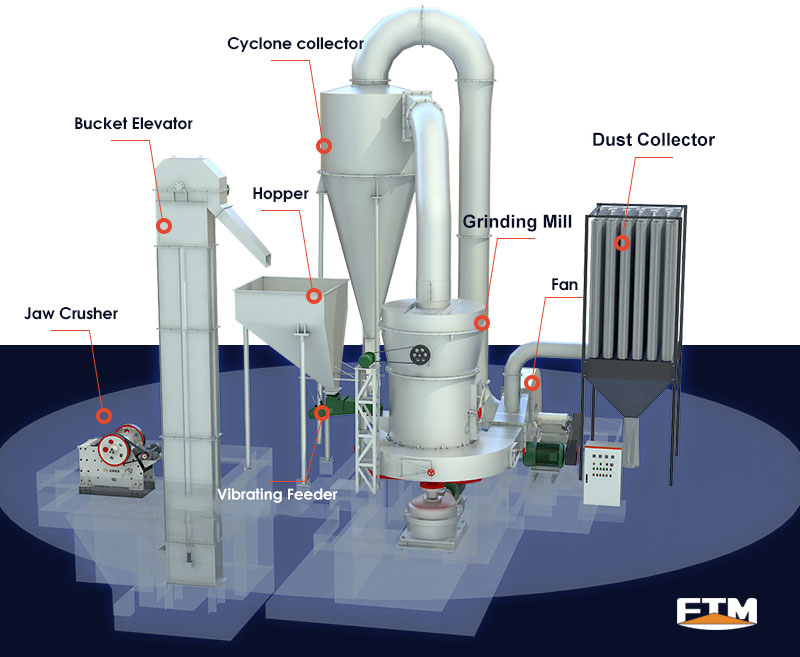

The powder grinding plant is equipped with a full set of machines, including the jaw crusher, hopper, bucket elevator, classifier, dust collector, high-pressure mill, vibrating feeder, and more. These machines are optimized for stable, high-quality performance.

Composition of powder grinding line

At FTM Machinery, our powder grinding mills and industrial grinders precisely produce coarse, fine and ultra fine powders. Depending on your production needs, we offer a variety of powder milling equipment:

- Raymond Mill: A reliable fine powder grinding machine for non-metallic materials with less than 8% moisture. It grinds particles between 80–325 mesh (0.173–0.033 mm) and is more space-saving compared to traditional ball mills.

- Ultrafine Mill: An upgraded ultra fine powder grinder ideal for producing fine powders and micro powders, achieving sizes between 60–800 mesh (0.25–0.015 mm).

- Vertical Mill: Suitable for large-scale production, delivering high efficiency with output up to 420 t/h and material sizes as fine as 2,500 mesh.

Want to know more about powder pulverizers? Click here!

Our grinding mill machines use a closed-air loop system for eco-friendly, precise, and efficient operation, offering low investment, simple processes, and stable granularity for high profitability.

Materials handled by powder grinding line

The fine grinding mill and ultra fine powder grinder in our production lines handle the non-flammable, non-explosive materials with hardness under Mohs 8 and moisture below 6%.

Applications of powder grinding line

The materials include rocks, metal ores, and non-metallic minerals such as coal, cement, phosphate, gypsum, limestone, calcite, calcium carbonate, dolomite, feldspar, talc, barite, fluorite, rare earth, marble, ceramics, manganese ore, carbon black, kaolin, etc.

Powder milling process

The powder milling process is usually divided into three key stages: crushing, grinding and collecting. The main phase is grinding and processed by a powder grinding machine.

1. Crushing

The large stones or minerals are fed into the jaw crusher by a vibrating feeder.

After primary crushing, materials (under 25–30 mm) are stored in a bin via a bucket elevator.

Related equipment: Vibrating feeder, jaw crusher, bucket elevator

2. Grinding

The material in the stock bin is uniformly transferred into a grinding mill machine by an electric-magnetic vibrating feeder.

Using various fine powder grinders or ultra fine grinders, powders are milled to sizes between 80–3,000 mesh.

Related equipment: electric-magnetic vibrating feeder, grinding machine, analyzer

3. Collecting

After classification, the qualified milling powder is collected by a powder collector and sent into another bin through the pipeline.

This streamlined process ensures high-quality, fine, and ultra-fine powders suitable for various industries.

Related equipment: Powder collector, dust collector

This streamlined process ensures high-quality, fine, and ultra-fine powders suitable for various industries.

Why choose FTM Machinery Powder Grinding Plant?

FTM Machinery is a professional grinding mill manufacturer, that combining with decades of experience and the current situation of the powder industry.

After introducing manufacturing techniques from German, FTM Machinery supports scientific powder grinding production line tailored for customers' actual needs, with the following advantages:

Advantages of FTM Machinery Powder Grinding Plant

- Excellent Grinding Effect: The finished powders are uniform in fineness, high in yield, and low in impurity content.

- High Efficiency: The grinding mill machines operate smoothly with low energy consumption, small floor space, and large output capacity.

- Long Service Life: Advanced powder grinding systems reduce maintenance frequency and extend equipment service life by over three times.

- Automatic Control: Our industrial grinding machines are highly automated, supporting remote operation and reducing labor and time costs.

- Environmental Protection: Our ultra fine powder grinders feature closed systems, low dust emissions, and low energy consumption.

- Competitive Price: Our powder grinding plants for sale are trusted by domestic and international customers for their affordability and quality.

If you are looking for a reliable powder grinding mill or complete powder grinding production line, FTM Machinery offers customized powder milling solutions.

Customer cases

10 TPH Limestone grinding line in Indonesia

10 TPH Limestone grinding line in Indonesia

Product Details:

| Application | Industrial |

| Material | Limestone |

| Capacity | 10 tons per hour |

| Driven type | Electric |

| Main equipment | Jaw crusher, Raymond grinding machine |

| Feed size | 30 mm |

| Output size | 30–200 mesh |

30 TPH gypsum powder grinding line in Russia

30 TPH gypsum powder grinding line in Russia

Product Details:

| Application | Industrial |

| Material | Gypsum |

| Capacity | 30 tons per hour |

| Driven type | Electric |

| Main equipment | HGM German high-efficiency powder grinding mill |

| Feed size | 25 mm |

| Output size | 100–200 mesh |

FAQs about powder grinding production line

1. How to choose the suitable powder grinding production line?

- The core machine in the powder grinding line is a powder grinding machine, which will influence the performance of the whole grinding line.

- There are two things to consider when choosing a suitable powder grinding mill:

- ① Discharge particle size: Different types of grinding mills have different discharge particle sizes. Ball mills are 150 to 250 mesh, Raymond mills are 80 to 325 mesh, HGM is 80 to 800 mesh, and three-ring medium-speed micro-powder mills can reach 2,000 mesh.

- ② Material properties: Ball mills are used for materials with high hardness. Raymond mills and HGM German high-efficiency grinding mills can be considered for materials with medium hardness.

2. What if the milling powder fineness does not meet the requirements of finished products?

- The powder milling fineness can be controlled by adjusting the speed of the powder concentrator and fan.

3. What is the optimum humidity for materials processed in the powder grinding production line?

- You had better keep the humidity below 7% to get the best grinding effects. If the material is too wet, the grinding mill machine will be locked to negatively influence the grinding efficiency and effect.

Parameter

| Model |

Feeding size (mm) |

Finished product size (mm) |

Capacity (t/h) |

Grinding ring diameter (mm) |

Number of grinding roller |

Power of main machine (kW) |

Blower power (kW) |

Analyzer power (kW) |

Transmission type |

| HGM88 | <25 | 0.25-0.015 | 0.4-5 | 908 | 3 | 22 | 22 | 5.5 | V-belt transmission |

| HGM95 | <25 | 0.25-0.015 | 0.6-7 | 1006 | 3 | 37 | 37 | 7.5 | |

| HGM120 | <25 | 0.25-0.015 | 1.2-15 | 1280 | 3 | 55 | 75 | 15 | Reducer transmission |

| HGM130 | <25 | 0.25-0.038 | 1.6-21 | 1400 | 4 | 75 | 90 | 18.5 | |

| HGM138 | <25 | 0.25-0.038 | 2-25 | 1510 | 4 | 90 | 110 | 22 | |

| HGM160 | <30 | 0.25-0.038 | 2.7-28 | 1770 | 5 | 132 | 160 | 22/30 | |

| HGM175 | <35 | 0.25-0.038 | 3-35 | 1900 | 5 | 185 | 200 | 30 | |

| HGM190 | <40 | 0.25-0.038 | 5-40 | 2040 | 4 | 250/280 | 250/280 | 45/55 |

| Model |

Capacity (t/h) |

Power of main machine (kW) |

| HGM88 | 0.4-5 | 22 |

| HGM95 | 0.6-7 | 37 |

| HGM120 | 1.2-15 | 55 |

| HGM130 | 1.6-21 | 75 |

| HGM138 | 2-25 | 90 |

| HGM160 | 2.7-28 | 132 |

| HGM175 | 3-35 | 185 |

| HGM190 | 5-40 | 250/280 |