Phosphate rock is mined and processed for phosphate fertilizers and industrial phosphorus products. With the growing demand for phosphate rock powder, many investors are attracted to join the phosphate rock grinding production industry.

High-grade phosphate deposits are limited, while low-grade phosphate deposits are abundant. How can you grind them efficiently? Read this blog to find the value of phosphate rock, the rock grinding process, and suitable grinding mills.

What is rock phosphate?

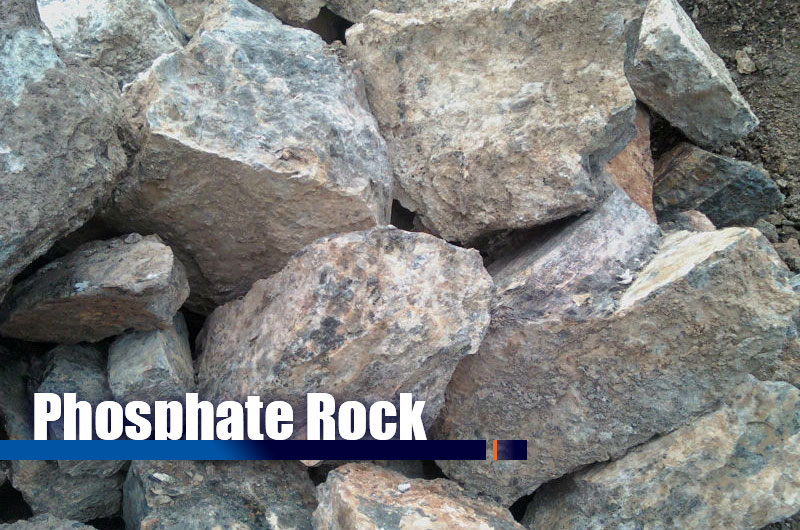

Rock phosphate or phosphate rock, is a sedimentary rock containing high concentrations of phosphate minerals. Most minerals in phosphate rock belong to the phosphorite group. The natural rock phosphate formula is Ca5(PO4)3F.

Here are the physical properties of phosphate rock:

- Element: Phosphate minerals are primarily composed of the elements phosphorus (P), oxygen (O), and other elements such as calcium (Ca), fluorine (F), and chlorine (Cl).

- Color: Phosphate rock ranges in color from light to dark, including brown, green, gray, and black.

- Hardness: Phosphate rock hardness is generally low, and the Mohs hardness is 5–5.5.

- Density: Phosphate rock is generally less dense than metallic minerals, with a range of 1.5–3.5 g/cm³.

- Luster: Phosphate rock luster can be dull to submetallic, depending on the mineral content.

How is rock phosphate formed? It forms through the accumulation of organic remains, such as marine organisms and plants, in ancient oceanic environments.

Over time, these organic materials accumulate on the seafloor, forming organic debris and sediments—subsequent mineralization into phosphate rock within the sedimentary layer.

Where is rock phosphate found?

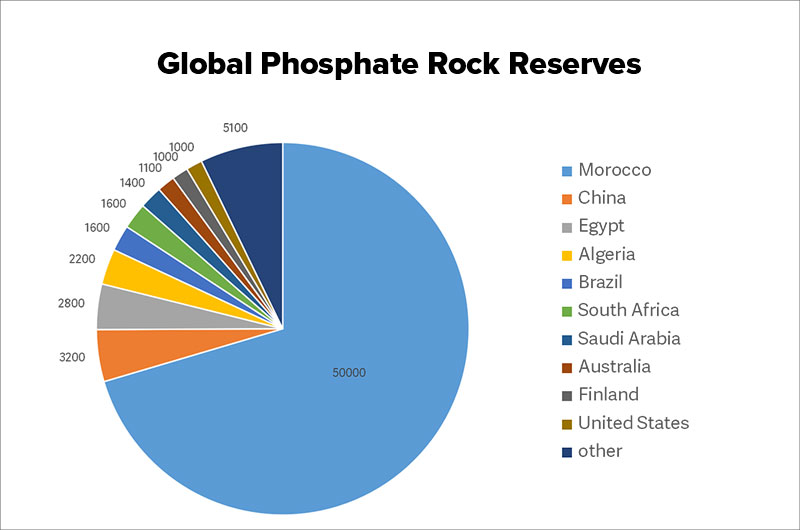

The distribution of phosphate deposits, mainly sedimentary marine phosphate rock, in the world is extremely uneven. The total global reserves of phosphate rock are about 71 billion metric tons.

Morocco (approximately 50 billion tons) has more than 70% of the phosphate rock reserves, becoming the country with the largest phosphate reserves in the world.

Although China ranks second, its absolute reserves are relatively small, with basic reserves of about 3.7 billion tons, accounting for only about 5% of the global total. Followed by Egypt, Algeria, Brazil, South Africa, the United States, etc.

In addition to sedimentary rock deposits, igneous phosphate deposits are also found worldwide. Although less common, the large-scale phosphate mining process is carried out in countries such as Brazil, Canada, Finland, Russia, and South Africa.

How to grind phosphate rock successfully?

Rock phosphate mining is often done by open-pit mining with shovels and excavators to remove overburden (soil, rock, and vegetation) of the phosphate mine. The rock is then trucked or conveyed to a rock grinding plant. Reclamation is required after mining.

-

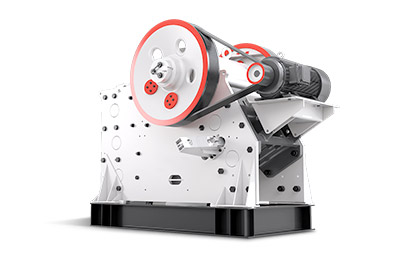

Phosphate rock crushing

Phosphate rock crushing

The mined phosphate ore (350-1,200 mm) is conveyed by the vibrating feeder to the jaw crusher for coarse crushing, and then sent to the cone crusher for fine crushing and shaping.

-

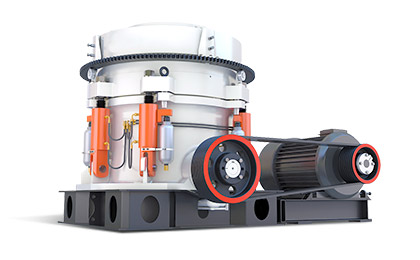

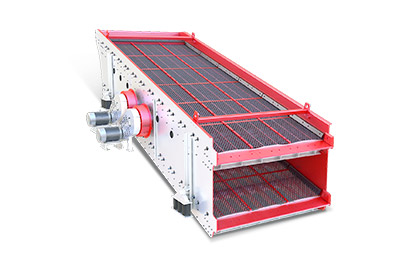

Phosphate rock screening

Phosphate rock screening

After being screened by a vibrating sieve, the phosphate rock meeting the input particle size (15-45 mm) is waiting to be sent to the mill. The phosphate rock that does not meet the particle size is returned to the cone crusher for crushing again.

-

Phosphate rock grinding

Phosphate rock grinding

Phosphate rock in small pieces (<45 mm) is sent to the storage hopper by the elevator, and then evenly sent to the mill room by the feeder for grinding. The ground material is classified by the classification system.

-

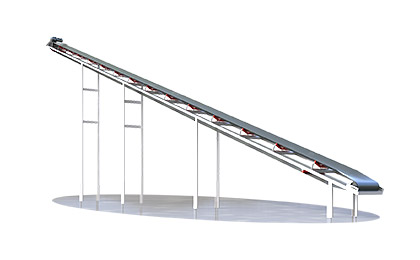

Phosphate rock collecting

Phosphate rock collecting

Phosphate powder that meets the fineness enters the dust collector with airflow for separation and collection. It is then sent to the finished product silo by the belt conveyor. The closed-loop rock grinding process achieves a powder extraction rate of up to 90%.

The following is the equipment required for phosphate rock grinding:

Want to improve the purity of rock phosphate powder? You can learn about phosphate ore beneficiation methods.

Phosphate rock grinding mill is the key to success

The phosphate rock mill is a grinding mill machine that can process rock phosphate into powder.

As a grinding mill manufacturer with many years of manufacturing experience, FTM Machinery offers various types of grinding mills, including the Raymond mill, ultrafine mill, and vertical roller mill.

Each mill has its unique features and advantages for grinding phosphate rock. Other rock and mineral grinding lines can be customized to your grinding needs.

1. Raymond mill Get the Latest Price

Phosphate Raymond mill is a traditional mill with reliable performance and a simple structure. Raymond mill price is relatively low, and it is suitable for phosphate rock grinding plants with a low budget.

- Product model: Raymond Mill

- Key part: Raymond rollers. Uses 3–6 pieces of wear-resistant alloy steel vertical rollers rotating around a grinding ring.

- Grinding particle size: ≤30 mm

- Grinding moisture: <10%

- Capacity: 0.6–176 t/h

- Finished product size: 0.173–0.044 mm (80–325 mesh)

2. Ultra-fine powder grinder Get the Latest Price

Phosphate ultrafine mill, also known as ultrafine micro powder mill, is a new type of mill upgraded based on the Raymond mill. HGM ultrafine mill is suitable for producing fine powder and superfine powder.

- Product model: HGM ultra fine grinder

- Grinding particle size: <40 mm

- Grinding moisture: <6%

- Capacity: 0.4–40 t/h

- Finished product size: 0.25–0.015 mm (60–800 mesh)

- The one-time screening rate can reach D97≤5μm

3. Vertical roller mill Get the Latest Price

A phosphate vertical roller mill is a kind of vertical mill. This grinding mill is known for its high grinding efficiency and handling of a wide variety of materials, including hard and abrasive substances.

The vertical mill utilizes the relative movement of the vertical roller and grinding table to carry out dry fine grinding and ultra-fine grinding of materials.

- Product model: HLM vertical roller mill. Based on the applicable materials, it can be divided into the coal vertical mill, mineral vertical mill, vertical cement mill, and slag vertical mill.

- Grinding particle size: ≤55 mm

- Grinding moisture: ≤15%

- Capacity: 10–320 t/h

- Finished product size: 0.84–0.37 mm (20–400 mesh). Screen passing rate of 10-40 μm is 97%

- Strong drying capacity: Direct contact with the internal hot air enables strong drying, reducing the moisture from 15% to 1%. Air temperature is controllable.

- Eco-friendly & energy-saving: Fully sealed, negative pressure system with 99.9% dust removal. Uses 30–50% less energy than a ball mill.

How to choose the best phosphate grinding mill? FTM Machinery suggests:

- If the grinding fineness is not high with a low price, and it is easy to maintain, choose a Raymond mill.

- If the fineness of grinding is high and the output is small, choose an HGM ultra-fine grinding machine.

- If you need both fine powder and high output, please choose HLM vertical roller mill. It is popular in cement plants, coal plants, and mineral grinding plants.

What is phosphate used for?

The milling powder of the phosphate rock can be manufactured into various phosphorus products. You can find wide rock phosphate uses in agriculture, industry, construction, and other industries.

Phosphate fertilizer

The main use of phosphate rock powder is in agriculture, where it is a key raw material for fertilizer production. Almost all fertilizers are marked with an "NPK" grade. "P" stands for phosphorus, an essential nutrient for healthy plant growth and high crop yields.

In addition to phosphorus, rock phosphate fertilizer composition also contains trace elements, such as zinc, copper, and manganese. It can meet the needs of plants for these elements, increase the phosphorus content of the soil, and promote plant growth.

Types of phosphate fertilizers:

- Diammonium Phosphate (DAP): A widely used granular fertilizer supplying essential nutrients for plant growth.

- Monammonium Phosphate (MAP): A phosphorus-rich and nitrogen-rich fertilizer ideal for crops needing high phosphorus requirements.

- Triple Superphosphate (TSP): A high-phosphorus fertilizer made from phosphate rock and sulfuric acid, used for crops in phosphorus-poor soil.

Industrial phosphorus products

Ground phosphate rock powder can be used in various industrial applications, most commonly in the production of phosphoric acid, water treatment processes, and as a flux in metallurgy.

- Phosphoric acid: A key industrial chemical made by treating phosphate rock with sulfuric acid. It is used in fertilizers, food additives, animal feed, electronic products, etc.

- Water treatment: Phosphate rock powder is used in water treatment processes to remove contaminants like heavy metals by forming insoluble precipitates.

- Metallurgy: Phosphate rock acts as a fluxing agent in metallurgical processes, helping to lower the melting point of metals during smelting.

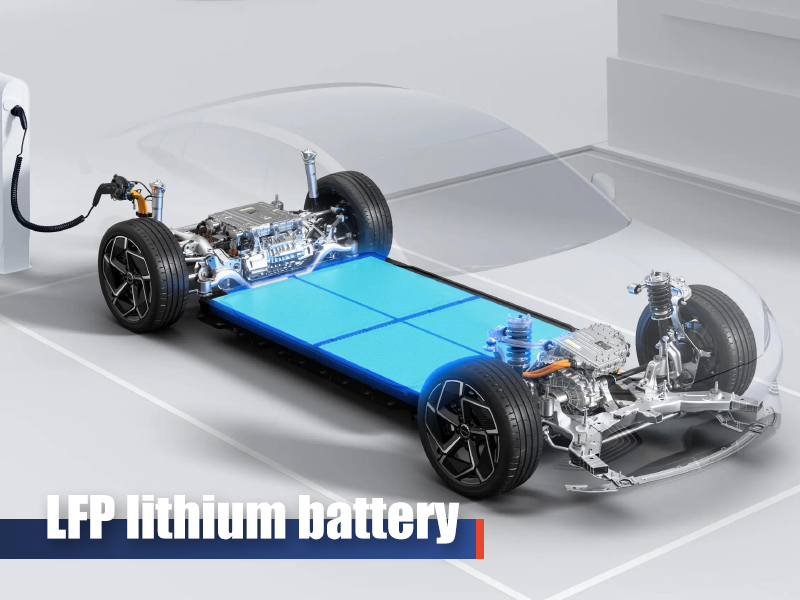

LFP lithium battery

Rock phosphate is now used to produce lithium-iron-phosphate (LFP) batteries. This type of lithium battery is becoming increasingly popular in electric vehicles (EVs) due to its higher energy density, longer life, and improved safety compared to traditional lithium batteries.

Building materials

Phosphate rock powder is an important raw material of building materials. It can be used to produce phosphate cement, phosphate glass, phosphate ceramics, and other products.

Phosphate rock powder can be used in the construction industry to improve the properties of concrete and other building materials. Phosphate rock can contribute to the binding and strength of cement mixes.

Conclusion

Rock phosphate is a non-renewable resource. It has great potential in a wide range of industries. From agricultural fertilizers to industrial phosphorus products, the phosphate rock powder grinding process is the key.

The efficient phosphate mining process and grinding process—crushing, screening, grinding, and powder collection—is essential for sustainable use. With our advanced phosphate rock grinding mills, you can maximize the value of rock phosphate.