An ultrafine grinding mill (also called an ultrafine grinder, micro powder mill, or superfine powder grinding mill) is designed to provide extremely fine powders or micron-sized particles for industries such as construction, metallurgy, mining, chemicals, cement, fertilizers, and ceramics.

HGM ultrafine powder grinder is an upgraded version of the Raymond mill, featuring a modernized design and improved structure. It delivers up to 15% more capacity while reducing wear part replacement costs by over 50%.

- Max feeding size:≤40 mm

- Capacity:0.4–40 t/h

- Output size:0.25–0.015 mm (80–800 mesh)

What you can process with an ultrafine grinding mill?

The ultrafine grinding mill can process over 100 types of non-flammable, non-explosive minerals with Mohs hardness <9.3 and moisture <7%. It is ideal for producing fine powders for different industries.

- Mining: Quartz, feldspar, iron ore, bauxite, coal gangue

- Industrial: Talc, bentonite, ceramics, barite

- Construction: Limestone, marble, granite for fillers and cement

- Energy: Barite and bentonite powders for drilling and refining

- Chemical: Ultrafine powders for plastics, coatings, pharmaceuticals

See the full technical specs below to find the best model for your needs: Request a Quote

| Model | HGM 88 | HGM 100 | HGM 130 | HGM 160 | HGM 190 |

| Feeding size(mm) | <20 | <25 | <25 | <30 | <40 |

| Output size(mm) | 0.25-0.015 | 0.25-0.015 | 0.25-0.038 | 0.25-0.038 | 0.25-0.038 |

| Processing capacity(t/h) | 0.4-5 | 0.8-10 | 1.6-21 | 2.7-28 | 5-40 |

| Number of pulverizing roller | 3 | 3 | 4 | 5 | 4 |

| Main motor power(kw) | 22 | 45 | 75 | 132 | 280 |

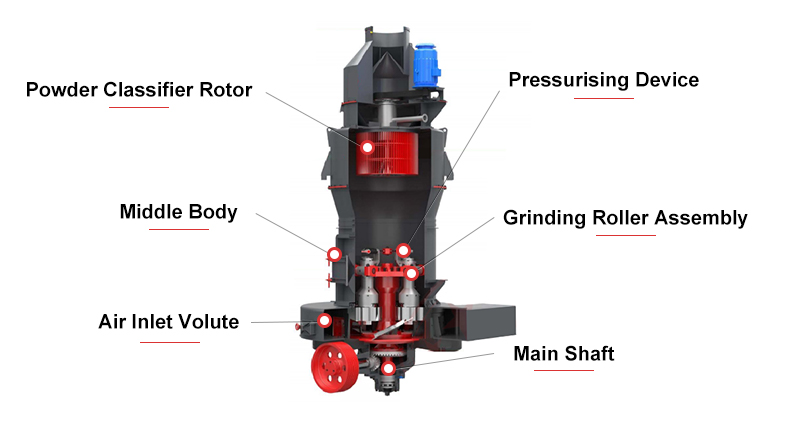

Optimized structural design of the ultrafine grinding mill

The HGM ultrafine grinding mill adopts an advanced vertical integrated design, combining crushing, grinding, classification, static pressure, and conveying into one unit.

With a smaller footprint, higher efficiency, and stable operation, it is a reliable solution for ultrafine grinding and fine powder processing across multiple industries.

The machine's core components have been fully optimized to deliver higher output, lower energy consumption, and longer service life, making it one of the most efficient fine grinding machines on the market.

1. High-efficiency cage classifier

Equipped with a high-precision cage classifier, allowing flexible adjustment of final product fineness from 80–800 mesh.

Soft connection between classifier and main housing significantly reduces noise and vibration.

Enhanced sealing design improves durability and extends the lifespan of the ultrafine powder grinder.

2. Split grinding rollers & wear-resistant shovel blades

Made from high-strength wear-resistant steel, improving fine grinding efficiency.

Split roller design allows easier replacement of wear parts.

Maintenance costs reduced by 50%+, longer overall service life

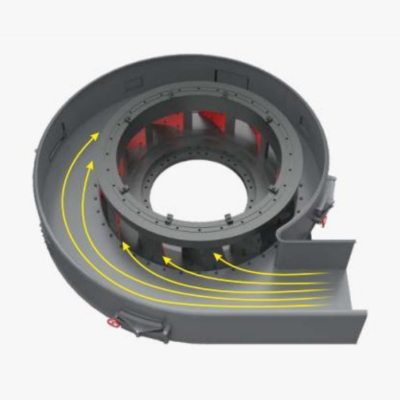

3. Arc-shaped air duct & resistance-free scroll housing

Arc-shaped air duct minimizes airflow loss and enhances material flow.

Resistance-free scroll housing boosts processing capacity by 15%.

Multi-blade curved impeller fan, ensuring high airflow and low noise operation.

4. Enlarged cyclone collector & automatic discharge device

Equipped with an electric airlock valve for automatic, continuous discharge.

Significantly improves powder collection rate while minimizing material backflow.

Supports extended, uninterrupted operation with reduced manual intervention, making it a reliable fine grinder solution.

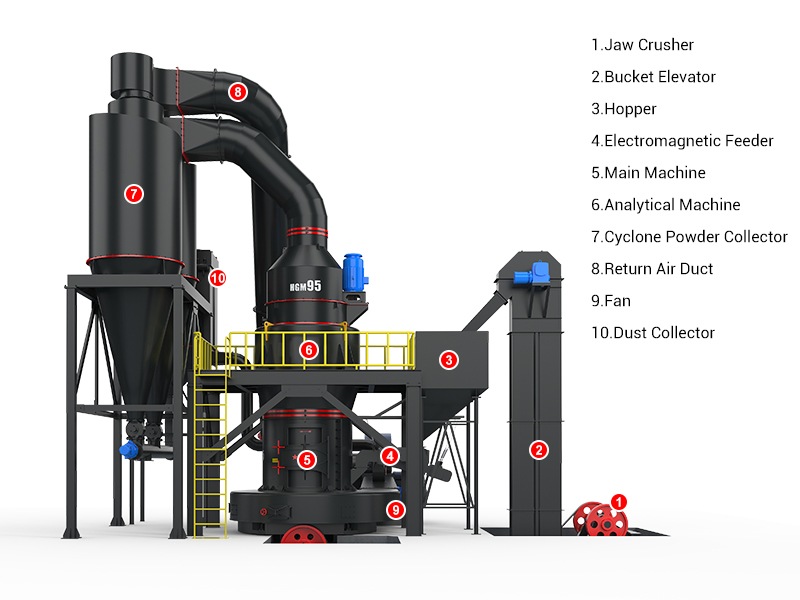

Complete ultrafine powder grinding solutions

In addition to the main mill, a complete ultrafine grinding mill production line includes a bucket elevator, electromagnetic feeder, cyclone collector, pulse dust collector, and other auxiliary devices.

This ensures high efficiency, continuous production, and eco-friendly powder grinding mill services.

How the ultrafine powder grinding process works?

- 1Raw material is lifted by the bucket elevator into the main chamber of the ultrafine grinder, where grinding rollers repeatedly press and grind the material against the grinding ring, turning it into fine or superfine powder.

- 2The powder classifier separates fine powder from coarse particles; fine particles are carried by airflow into the cyclone collector, while coarse material returns to the main mill for further grinding.

- 3Finished powder is automatically discharged through the electric airlock valve. Excess dust is captured by a high-efficiency pulse dust collector with a 99.99% dust removal rate, enabling clean and safe production.

Hot selling ultrafine powder production line: Phosphate Rock Grinding, Quartz Powder Grinding, Barite Powder Grinding, Calcium Carbonate Powder Production, Clay Grinding, Gypsum Grinding

Global customer success with ultrafine grinding mill

Case 1: Quartz ultrafine powder production – America

A leading mining company in America invested in a complete ultrafine grinding mill production line to process high-purity quartz. The line includes an HGM powder grinding mill, bucket elevator, electromagnetic feeder, cyclone collector, and pulse dust removal system.

- Output: 25 tons/hour

- Final Fineness: 600 mesh

- Purpose: Used in high-grade glass and ceramic manufacturing

After commissioning, the fine powder grinding machine increased production efficiency by 20% compared to their old Raymond mill, while maintenance costs dropped by 45%, delivering a strong return on investment.

Case 2: Calcium carbonate fine powder grinding – Malaysia

A building materials supplier in Malaysia installed two HGM fine powder grinding machines for large-scale calcium carbonate powder production. This complete ultrafine powder grinder line operates 24/7 and supplies fine powders for paints, plastics, and cement fillers.

- Output: 35 tons/hour

- Final Fineness: Adjustable from 400–800 mesh

- Purpose: Widely used in chemical and construction materials

By adopting our ultrafine grinder solution, the company achieved stable, high-quality micron-sized powders with 15% higher productivity and 50% lower wear-part costs, meeting growing market demands.

These successful installations prove how the HGM ultrafine grinding mill helps businesses achieve higher capacity, finer powder quality, and lower maintenance costs.

Ready to boost your production efficiency? Contact us today for a free quote and tailored grinding solution!

Frequently asked questions about ultrafine grinding mill

1. When should I choose an ultrafine grinding mill instead of a Raymond mill?

- When the required fineness is greater than 325 mesh (>325 mesh) or when higher production capacity is needed, it is recommended to use the HGM ultrafine grinding mill, which can reach a maximum fineness of 800 mesh, making it ideal for producing fine and ultrafine powders.

- If the final product fineness is 325 mesh or below (≤325 mesh) and the production demand is relatively low, a Raymond mill is usually the more economical choice.

2. Which materials cannot be processed with the ultrafine grinder?

- a. Flammable or explosive materials such as sulfur, phosphorus, phosphides, toluene, or solid amine compounds

- b. Non-mineral materials like wood, food, plastics, and synthetic fibers

- c. Pure metal materials such as refined iron ingots, steel, or copper ingots

- d. High-moisture materials should not be ground directly; instead, use a ball mill or pre-dry them.

3. How long can the HGM ultrafine powder grinder run continuously?

- The HGM ultrafine powder grinding machine can operate continuously for 24 hours.

- However, for optimal performance and longer lifespan, we recommend running it for 8–10 hours, then pausing for 1–2 hours of inspection and maintenance before restarting.