Spiral classifiers can grade different particles in ore slurry during the metal beneficiation process as well as deslime and dehydrate in the washing operation.

They are widely used to separate ore sands by forming a closed-circuit with the ball mill in concentrators, or in gravity concentrators to classify ores and fine muds.

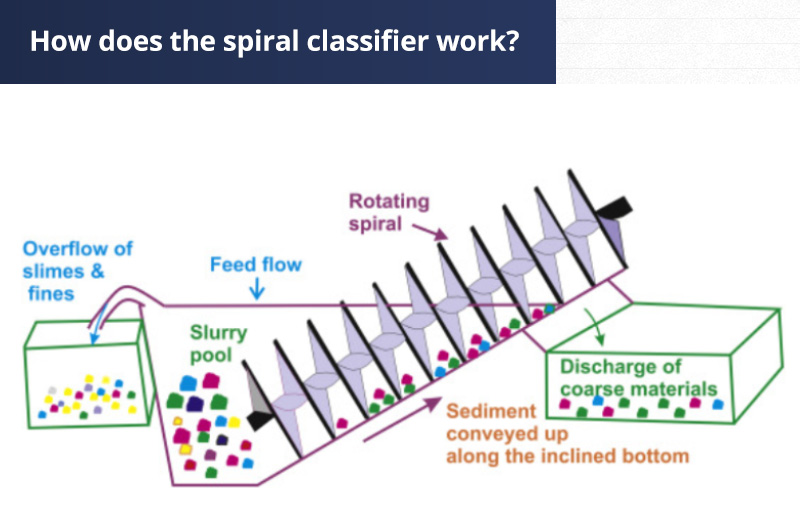

How does the spiral classifier work?

The spiral classifier relies on the principle that the solid particles are different in size and specific gravity, so their sedimentation speed is different in the liquid.

Working principle of spiral classifiers

The slurry is stirred by spiral rotation at low speed so that fine particles are suspended in the slurry surface and overflow to the overflow weir.

Coarse particles sink to the bottom of the tank and are conveyed by the screw to the discharge port to be discharged. Generally, the coarse sand is returned to the ball mill for secondary grinding, that is, the spiral classifier and the ball mill form a closed circuit.

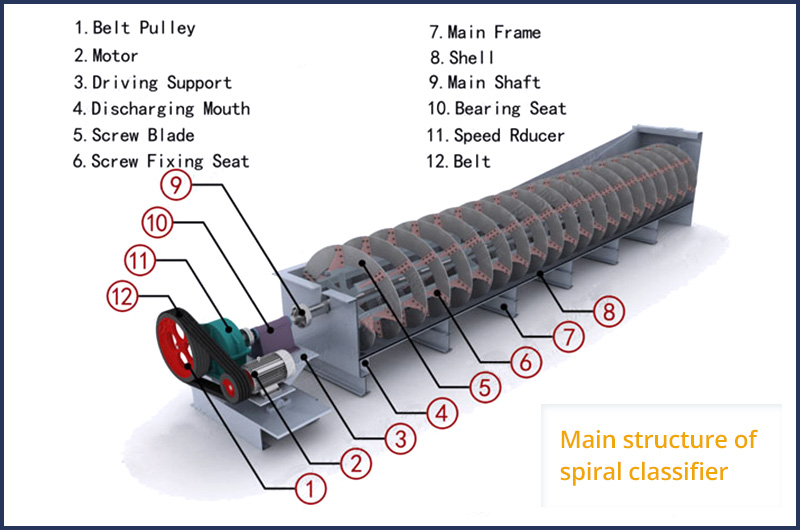

What is the main structure of the spiral classifier?

The classifier is mainly composed of the transmission device, spiral, lower support, tank, drain valve and lifting mechanism.

1. Transmission device

Spiral classifier is composed of motor, reducer, cylindrical gear and bevel gear.

2. Spiral (left and right)

It is composed of the hollow shaft, bracket, spiral blade, lining iron, etc. The hollow shaft is welded by seamless steel pipe, journal and flange. Wear-resistant life is the key in use, so the lining iron is made of wear-resistant materials.

3. Lower support

It is easy to wear, for its long-term immersion in the slurry. Therefore, frequent maintenance and replacement are its main characteristics. For this, the spiral classifier adopts the structure of movable shaft sleeves and nylon bearing bushes.

Main structure of the spiral classifier

When the shaft sleeve and bearing bush are worn out, a new set of sleeve and bush can be replaced ten minutes after the screw is lifted by the lifting mechanism, which is convenient for maintenance and replacement.

4. Tank

It is welded by steel plates and various section steels. The foundation construction of the tank is very important because it contains all the slurry and bears the weight of the whole body and all the load.

5. Drain valve

In order to discharge slurry from the water tank when necessary, a water drain valve is installed in the lower part of the tank, which can discharge the slurry at any time and can be closed during normal production.

6. Lifting device

- When the classifier is stopped, the lifting device can automatically lift the screw to a certain height.

- When the classifier is working, the lifting device can also lower the screw to the working position.

In this way, the service life of transmission parts can be maintained and the hollow shaft can be prevented from breaking due to overload.

What are the types of spiral classifier?

Spiral classifier is mainly divided into two categories:

High weir spiral classifier

The settlement area of this kind of classifier is large and its weir height can be adjusted within a certain range, that is, the area of the settlement area can be adjusted and changed within a certain range.

Therefore, the particle size of the classification can be adjusted, which is common equipment in grinding cycle.

It is mainly used for grading coarse ore with an overflow particle size of 0.83–0.15 mm.

Submerged spiral classifier

The submerged spiral classifier is the one whose spiral blades at the overflow end are completely immersed below the overflow surface.

It has a small settlement area and low overflow production capacity, so it is mainly suitable for ore classification with an overflow particle size of 0.15–0.07 mm. It is also used to wash ore for desliming.

Model description: Take "2FG-15" as an example, "2" means double spiral, the single spiral is not marked; "F" means spiral classifier, "G" means high weir type and "C" means submerged type; "15" indicates the spiral diameter of the classifier, in dm.

What are the features of the Fote spiral classifier?

- Powerful independent lifting equipment.

- Bolt-mounted wearing plate can prolong wear life.

- The long and narrow tank is helpful to achieve an ideal stirring effect and extend the suspension time of the material in the water.

- A sufficiently large settlement area prolongs the suspension time of materials and is more conducive to material classification.

- The proper slurry pool depth, area and spiral structure achieve good control of the classification strength.

- An automatic lifting device for returning sand is added to the sand returning end, and the configuration of the large spoon head of the ball mill is canceled.

- Frequency conversion control technology makes the operation more convenient.

How does the spiral classifier achieve maximum efficiency?

1. Height of overflow weir

The overflow weir of a classifier can be adjusted appropriately according to the requirement of grinding fineness.

If the grinding fineness is required to be finer, angle irons of a certain height can be welded on both sides of the classifier, and the level of the classifier overflow weir can be adjusted by the method of inserting wood. Sometimes the overflow weir can be naturally increased after a long-term accumulation of ore mud.

- The overflow weir height H of the high weir spiral classifier is 1/4–3/8 of its spiral diameter D, and is mainly used for ore classification with an overflow particle size of 0.83–0.15 mm.

- The H of the submerged spiral classifier is 3/4–1 of D. It is mainly suitable for ore classification with overflow granularity of 0.15–0.07 mm. When the overflow fineness is high, H should be small, otherwise, it should be large.

2. Spiral speed

Generally, a lower speed is adopted in a spiral classifier. The appropriate speed should be determined by experiment. The rotation speed of the commonly used spiral classifier is 1.5-10 r/min.

To obtain coarse overflow, the speed of the spiral with a diameter of 2 m should not exceed 6 r/min, and with a diameter of 1 m or more should be controlled at 2–8 r/min. For example, for a spiral with a diameter of 0.3 m, in order to obtain a coarse overflow, the spiral speed can be increased, but it cannot exceed 25 r/min.

3. The screw pitch of classifier

The pitch is generally 0.5–0.6 times the diameter of the spiral. Equal pitch is often adopted, but unequal pitch can also be used.

If the screw pitch is short at the overflow end and long at the sand return end, the amount of sand return can be increased and stable agitation at the overflow end can be ensured, which is convenient for improving the overflowing quality and processing capacity.

4. Width of classifier tank

The width of the grading tank has little effect on the grading effect, but is closely related to the processing capacity of the grading machine. The larger the tank width, the larger the processing capacity. On the contrary, the processing power is small.

The width of the grading tank depends on the spiral diameter of transporting the returned sand (that is, the specification of the classifier), and is 100–200 mm larger than the spiral diameter.

5. Inclination angle of guide vane

Under the same conditions, as the inclination angle of the guide vane increases, the classification accuracy index shows a decreasing trend.

Practice shows that the classification efficiency is the highest when the inclination angle of the guide vane is between 85° and 90°.

Parameter

| Model | Spiral Diameter (mm) |

Trough Length (mm) |

Spiral rotate speed (r/min) |

Processing capacity(t/d) |

Motor Power (kw) |

Dimensions (mm≤) |

Total weight (t) |

||||

| Sand -return |

Overflow | For driving |

For lifting |

Length | Width | Height | |||||

| FG-3 | 300 | 3000 | 12-30 | 80-150 | 20 | 1.1 | ---- | 3850 | 490 | 1140 | 0.7 |

| FG-5 | 500 | 4500 | 8-12.5 | 135-210 | 32 | 1.1 | ---- | 5430 | 680 | 1480 | 1.9 |

| FG-7 | 750 | 5500 | 6-10 | 340-570 | 65 | 3 | ---- | 6720 | 980 | 1820 | 3.1 |

| FG-10 | 1000 | 6500 | 5-8 | 675-1080 | 110 | 5.5 | ---- | 7590 | 1240 | 2380 | 4.9 |

| FC-10 | 8400 | 675-1080 | 85 | 7.5 | ---- | 9600 | 1240 | 2680 | 6.2 | ||

| FG-12 | 1200 | 6500 | 4-6 | 1170-1870 | 155 | 7.5 | 2.2 | 8180 | 1570 | 3110 | 8.5 |

| FC-12 | 8400 | 1170-1870 | 120 | 7.5 | 2.2 | 10370 | 1540 | 3920 | 11.0 | ||

| 2FG-12 | 6500 | 2340-3740 | 310 | 15 | 4.4 | 8230 | 2790 | 3110 | 15.8 | ||

| 2FC-12 | 8400 | 2340-3740 | 240 | 15 | 4.4 | 10370 | 2790 | 3920 | 17.6 | ||

| FG-15 | 1500 | 8300 | 4-6 | 1830-2740 | 235 | 7.5 | 2.2 | 10410 | 1880 | 4080 | 12.5 |

| FC-15 | 10500 | 1830-2740 | 185 | 7.5 | 2.2 | 12670 | 1820 | 4890 | 16.8 | ||

| 2FG-15 | 8300 | 2280-5480 | 470 | 15 | 4.4 | 10410 | 3390 | 4080 | 22.1 | ||

| 2FC-15 | 10500 | 2280-5480 | 370 | 15 | 4.4 | 12670 | 3370 | 4890 | 30.7 | ||

| FG-20 | 2000 | 8400 | 3.6-5.5 | 3290-5940 | 400 | 11-15 | 3 | 10790 | 2530 | 4490 | 20.5 |

| FC-20 | 12900 | 3210-5940 | 320 | 11-15 | 3 | 15610 | 2530 | 5340 | 28.5 | ||

| 2FG-20 | 8400 | 7780-11880 | 800 | 22-30 | 6 | 11000 | 4600 | 4490 | 35.5 | ||

| 2FC-20 | 12900 | 7780-11880 | 640 | 22-30 | 6 | 15760 | 4600 | 5640 | 48.7 | ||

| FG-24 | 2400 | 9130 | 3.67 | 6800 | 580 | 15 | 3 | 11650 | 2910 | 4970 | 26.8 |

| FC-24 | 14130 | 6800 | 490 | 18.5 | 4 | 16580 | 2930 | 7190 | 41.0 | ||

| 2FG-24 | 9130 | 13600 | 1160 | 30 | 6 | 12710 | 5430 | 5690 | 45.8 | ||

| 2FC-24 | 14130 | 13700 | 910 | 37 | 8 | 17710 | 5430 | 8000 | 67.9 | ||

| 2FG-30 | 3000 | 12500 | 3.2 | 23300 | 1785 | 40 | 8 | 16020 | 6640 | 6350 | 73.0 |

| 2FC-30 | 14300 | 23300 | 1410 | ---- | ---- | 17091 | ---- | 8680 | 84.8 | ||

| Model | Spiral Diameter (mm) |

Spiral rotate speed (r/min) |

| FG-3 | 300 | 12-30 |

| FG-5 | 500 | 8-12.5 |

| FG-7 | 750 | 6-10 |

| FG-10 | 1000 | 5-8 |

| FC-10 | ||

| FG-12 | 1200 | 4-6 |

| FC-12 | ||

| 2FG-12 | ||

| 2FC-12 | ||

| FG-15 | 1500 | 4-6 |

| FC-15 | ||

| 2FG-15 | ||

| 2FC-15 | ||

| FG-20 | 2000 | 3.6-5.5 |

| FC-20 | ||

| 2FG-20 | ||

| 2FC-20 | ||

| FG-24 | 2400 | 3.67 |

| FC-24 | ||

| 2FG-24 | ||

| 2FC-24 | ||

| 2FG-30 | 3000 | 3.2 |

| 2FC-30 |