What is a magnetic drum separator?

A magnetic drum separator, also known as a drum magnet, is a machine that uses magnetic force to separate magnetic materials from non-magnetic ones, enhancing the purity of materials and improving the quality of mineral concentrates.

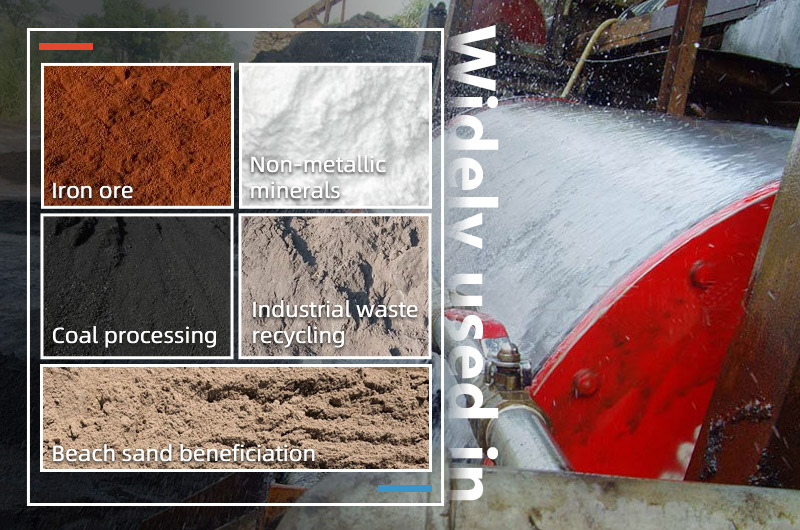

Magnetic drum separators are widely used in industries such as mining and minerals, aggregates, coal, recycling, and construction materials.

Key applications include iron ore beneficiation, impurity removal from non-metallic minerals, coal processing, industrial waste recycling, and beach sand separation.

- Iron ore: Magnetic drum separators are used to separate iron ores like magnetite, hematite, and limonite. Through high-intensity magnetic fields, iron ore particles are attracted, enhancing the purity of ores.

- Non-metallic minerals: Magnetic separation machines can remove magnetic impurities from non-metallic minerals such as quartz sand, feldspar, and mica, thus improving product purity.

- Coal processing: During coal processing, magnetic separators are used to remove iron-based impurities, enhancing the coal’s combustion efficiency.

- Industrial waste recycling: In metallurgy and construction materials industries, magnetic separators recover iron and magnetic substances from waste, promoting resource reuse and reducing disposal costs.

- Beach sand beneficiation: Magnetic separator machines separate magnetic minerals such as ilmenite, rutile, zircon, and garnet from heavy mineral sands, collecting high-purity magnetic concentrates.

How does a magnetic drum separator work?

The magnetic drum separator uses a magnetic field to separate magnetic and non-magnetic materials. When material enters the separator, magnetic particles are attracted to the drum's strong magnetic field and adhere to its surface, while non-magnetic particles continue to fall along their path to a separate outlet.

As the drum rotates, magnetic particles are carried to the opposite end, where they are removed with water flow or a brush roller and collected in a designated area. This process effectively separates magnetic minerals, improving material purity and beneficiation efficiency.

To meet diverse production needs, FTM Machinery offers a range of magnetic drum separator models and configurations, ensuring customers can choose the most suitable equipment. Detailed specifications for each model are provided below.

| Model | Feeding size(mm) | Processing capacity(t/h) | Power(kw) |

| CTB6012 | 2-0 | 10-20 | 1.5 |

| CTB7518 | 2-0 | 20-45 | 2.2 |

| CTB9021 | 3-0 | 45-60 | 3 |

| CTB9024 | 3-0 | 45-70 | 4 |

| CTB1018 | 3-0 | 50-75 | 5.5 |

| CTB1021 | 3-0 | 50-100 | 5.5 |

| CTB1024 | 3-0 | 60-120 | 5.5 |

| CTB1224 | 3-0 | 85-180 | 7.5 |

| CTB1530 | 3-0 | 170-280 | 11 |

For additional options and custom solutions, please contact our expert team for detailed support and consultation. Contact our experts to learn more!

Why FTM Machinery magnetic drum separators?

- The permanent magnet system uses high-quality ferrite or a composite of ferrite and rare earth magnets, ensuring magnetic stability under high-flow conditions and excellent separation results.

- Various drum diameters are available (600 mm–1500 mm) with speeds up to 35 rotations per minute, allowing flexibility for different processing volumes and separation needs.

- A wide magnetic field angle with smooth transitions increases separation area length and magnetic reversal frequency, delivering high-grade, high-recovery output.

- Drum surface average magnetic induction intensity ranges from 100–600μm, with a demagnetization rate of no more than 5% over 8 years.

- Adaptable to variations in feed volume, particle size, and slurry concentration, with each series of equipment usable independently or in combination.

- The magnetic system is covered with non-magnetic stainless steel to prevent magnet wear, extending equipment life.

Types of magnetic drum separators

Based on the dry or wet processing methods in mineral separation, magnetic drum separators are classified into two types: dry magnetic drum separators and wet drum magnetic separators.

1. Dry magnetic drum separator Get a Quote

Dry drum magnetic separators operate without water or liquid media, using magnetic field strength, gradient, and gravity to separate and move particles. They are especially suitable for efficient separation in dry environments.

Dry magnetic drum separators are ideal for roughing or primary ore beneficiation, commonly used to separate large, coarse particles of strongly magnetic ores and fine, weakly magnetic ores.

During operation, dry material is fed onto a rotating drum, where magnetic particles attach to the drum's surface due to the magnetic field, while non-magnetic particles fall off under gravity and mechanical force. Magnetic particles are then carried to the discharge point and released or brushed off, ensuring optimal production efficiency.

Advantages of dry magnetic drum separator:

- Water-saving and environmentally friendly: Requires no water source, reducing wastewater issues, and is suitable for areas with limited water resources.

- Low maintenance: With a simple structure and fewer parts, it has a low failure rate and reduced maintenance costs.

- Easy to move: Compact and lightweight, making it easy to install and relocate.

- Low energy consumption: Typically consumes less energy compared to wet magnetic separation.

2. Wet magnetic drum separator Get a Quote

Wet magnetic drum separators operate in the presence of water or liquid media, handling wet materials or slurries. Water is used to wash and transport the materials, allowing for better separation while they are in a wet state.

This type of magnetic separator has excellent separation selectivity and is commonly used for separating fine strongly magnetic ores and fine weakly magnetic ores, effectively increasing the recovery rate of fine and powdered materials.

Depending on the flow direction of the slurry (or material) relative to the magnetic field, wet magnetic separators can be classified into cocurrent magnetic drum separators, semi-countercurrent magnetic drum separators and countercurrent magnetic drum separators.

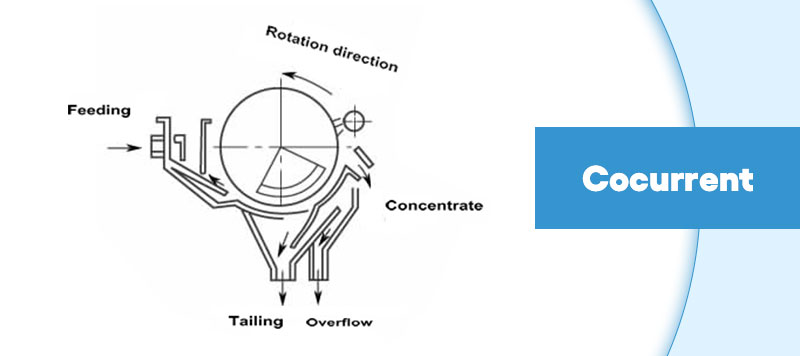

a) Cocurrent magnetic drum separator

In a cocurrent magnetic separator, the slurry flows in the same direction as the magnetic field. Material enters from the feed end and moves in sync with the magnetic drum. Magnetic particles are attracted to the drum surface by the magnetic field and move with the drum to the discharge end.

Cocurrent magnetic separators are mainly suitable for processing coarse particles, offering high separation efficiency, though some magnetic material may remain in the tailings.

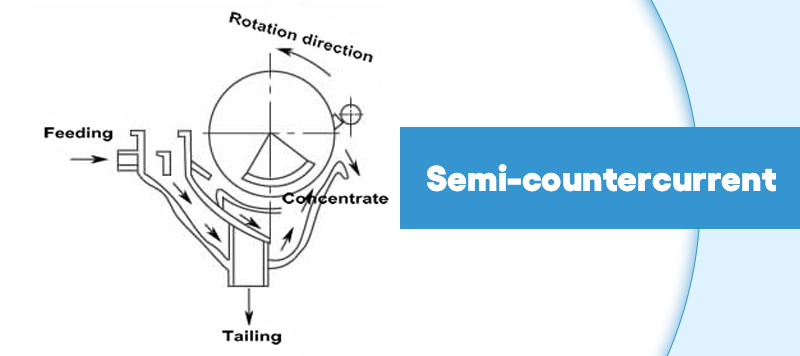

b) Semi-countercurrent magnetic drum separator

In a semi-countercurrent magnetic separator, the slurry flows at an angle partially against the rotation direction of the drum surface. When the material enters the separator, part of the slurry flows with the drum while part flows against it. Magnetic particles attach to the drum surface and are carried to the discharge point as the drum rotates.

Semi-countercurrent magnetic separators are ideal for medium-sized particles and are effective for roughing and concentration processes, providing good separation results.

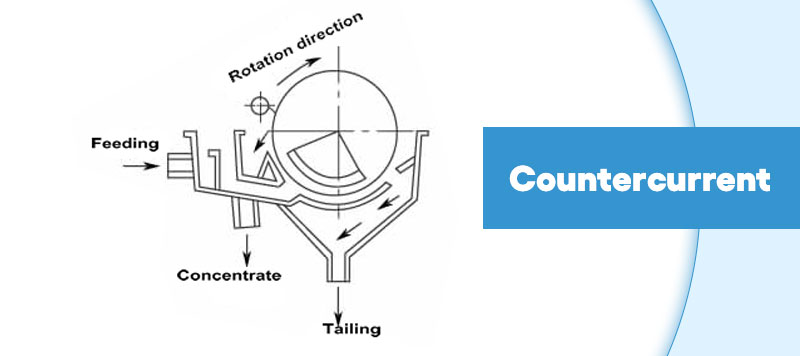

c) Countercurrent magnetic drum separator

In a countercurrent magnetic separator, the slurry flows in the opposite direction to the drum rotation. The slurry flows upward, and magnetic particles move against the flow, attaching to the drum surface and moving to the discharge point with the drum.

Countercurrent magnetic separators are suited for processing fine particles and is commonly used for concentration and roughing processes, providing more thorough ore separation.

Advantages of wet magnetic separators:

- High separation efficiency: Wet magnetic separators are usually more efficient than dry types, especially for fine, weakly magnetic, and clay-rich minerals like hematite and magnetite.

- Suitable for moist materials: Wet separators can handle wet materials without needing additional drying.

- High-grade concentrate: The fully magnetic design increases the contact area between slurry and working surface, allowing for extended separation and increasing concentrate grade by 2%–4%.

- Low dust pollution: As wet separation takes place in water, there is no dust pollution, meeting environmental requirements.

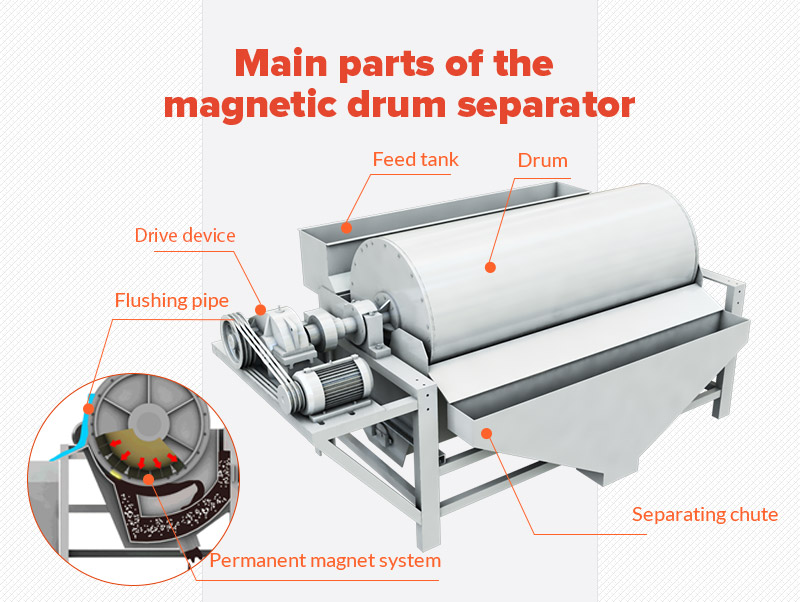

Key parts of a permanent magnetic drum separator

FTM Machinery is dedicated to providing high-quality permanent magnetic drum separators for customers. They are mainly composed of the permanent magnetic system, rotating drum, separating chute, drive device, and discharge device.

1. Permanent magnetic system

This is the core part of the separator, consisting of multiple arranged permanent magnets. The magnets are made from high-quality ferrite materials or a composite with rare-earth magnetic steel, generating a powerful magnetic field to attract magnetic minerals.

2. Rotating drum

Typically made from 2-3 mm stainless steel or other wear-resistant materials, the drum serves to carry and transport materials within the separator.

3. Separating chute

Magnetic and non-magnetic materials are separated here based on their response to the magnetic field.

4. Drive device

This includes the motor, gearbox, and pulleys. The motor provides power, which is transmitted through the gearbox and pulleys to rotate the drum at the correct speed.

5. Discharge device

Designed to remove the magnetic materials attracted to the magnetic drum, this can include scrapers, brushes, or water-wash systems.

Case studies—Reliable magnetic separation solutions

1. Dry magnetic drum separator for Indian iron ore processing

A customer in India purchased a permanent dry magnetic separator for processing iron ore sand. The separation process is roughly as follows:

Step 1Ore crushing and grinding: The iron ore is first crushed into fine powder to increase surface area and enhance the magnetic separation effect.

Step 2Uniform feeding: A vibrating feeder evenly feeds the iron powder into the magnetic separator.

Step 3Magnetic concentrate separation: Magnetic particles cling to the drum and are released at the discharge point as concentrate. This concentrate is then dried, ground, and gravity-separated to enhance iron content and remove impurities.

Step 4Tailings processing: Non-magnetic particles are discharged as tailings. These may contain trace valuable minerals and can undergo additional processing if needed.

2. Wet magnetic drum separator for Australian tailings processing

An Australian customer needed to separate vanadium-titanium magnetite from tailings. To reduce production costs, FTM Machinery provided a customized separation solution with the following steps:

Step 1Grinding: Tailings are ground to the proper particle size in a wet ball mill, releasing valuable minerals.

Step 2Magnetic separation: The slurry is fed into a wet magnetic separator to recover magnetic minerals like magnetite.

Step 3Concentrate processing: Techniques such as flotation, leaching, and roasting are applied to the magnetic concentrate to extract vanadium and titanium minerals.

Step 4Final Product: The refined vanadium and titanium concentrates yield high-purity vanadium pentoxide and titanium dioxide.

This separation solution increased recovery rates by 10%–25% and boosted the customer's annual titanium concentrate production from 50,000 tons to 500,000 tons. The magnetic drum separators manufactured by FTM Machinery significantly improved classification efficiency, enhanced recovery rates and product quality, and optimized resource utilization.

Frequently asked questions about magnetic drum separators

1. Which industries use magnetic separators?

- Magnetic separation technology is applied in various industries, including mining, recycling, food processing, water treatment, pharmaceuticals, biotechnology, and carbon.

2. What is a permanent magnet? Is it really permanent?

- A permanent magnet is a material that can maintain its magnetism for a long time, usually made from specific alloys or compounds like ferrite, neodymium-iron-boron, and aluminum-nickel-cobalt.

- While its magnetism may weaken or be lost under high temperatures, severe shock, or strong magnetic fields, a permanent magnet can keep its magnetism for a long time under normal use and storage, typically meeting most application needs.

3. Can magnetic drum separators handle high-temperature materials?

- The temperature limit for magnetic drum separators depends on their design and materials. Standard separators can withstand temperatures of 80–150°C (176–302°F), though this may vary. For high-temperature materials, use heat-resistant materials or cooling systems to prevent overheating damage.

4. How to maintain a magnetic separator?

- Magnetic drum separators typically have low maintenance requirements. Common tasks include:

- a. Regular cleaning: Clean the drum surface to remove accumulated ferrous contaminants, following safety procedures to prevent injury.

- b. Inspection and maintenance: Regularly check the condition of magnetic components, drum surfaces, bearings, seals, and other parts for signs of wear, damage, or misalignment. Repair or replace them promptly to maintain optimal function.

- c. Follow the manufacturer's guidelines: These may include cleaning procedures, maintenance intervals, inspection standards, and any specific recommendations for the model of magnetic drum separator you are using.