Are you struggling with low iron ore concentrate grades, high metal loss in tailings, or excessive energy consumption in your beneficiation circuit?

In mineral processing industry, a generic "one-size-fits-all" magnetic separation line often leads to wasted resources and thin profit margins.

How our magnetic separation plant solves your problems

At FTM Machinery, we provide high-efficiency, customizable Magnetic Separating Plants engineered to deliver a 90%+ recovery rate while significantly reducing your operational costs.

Ore-specific process design

Whether you are processing strongly magnetic magnetite or weakly magnetic hematite/limonite, we design the separation process based on your ore characteristics, including:

- Wet drum magnetic separators / dry magnetic separators

- Multi-stage magnetic separation (roughing, cleaning, scavenging)

- Seamless integration with crushing, grinding, and classification systems

Stable operation with high recovery & concentrate grade

- Adjustable magnetic field intensity: 100–600 mT (1,000–6,000 Gauss), suitable for complex ore conditions

- Magnetic system made of high-quality ferrite materials or rare-earth permanent magnets

- Designed for continuous, long-term industrial operation

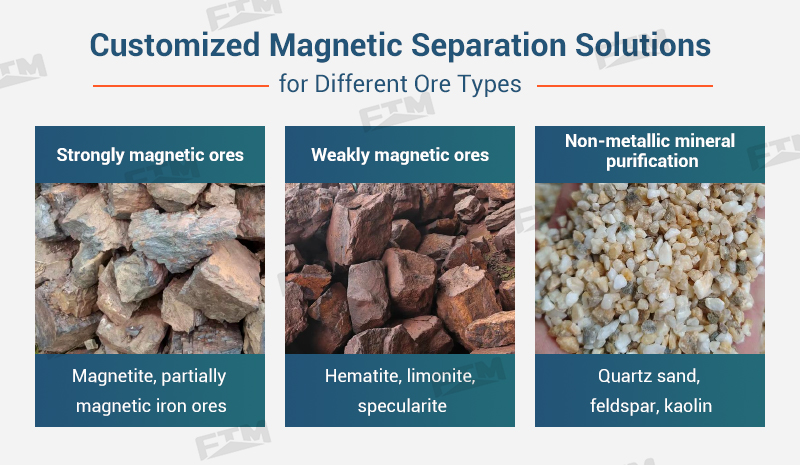

Customized magnetic separation solutions for different ore types

Different ores require different magnetic separation methods.

With over 40 years of mineral processing experience, we classify and tailor magnetic separation solutions by ore type to ensure the best match between your plant and your deposit.

A. Strongly magnetic ores

Typical ores: Magnetite, partially magnetic iron ores

For strongly magnetic ores, we apply Low-Intensity Magnetic Separation (LIMS) technology, which is ideal for large-capacity, continuous operations.

Solutions:

- Wet drum magnetic separators suitable for both coarse and fine particles

- Multi-stage flowsheet (roughing, cleaning, scavenging) for stable concentrate quality

- Simple structure with high reliability and low maintenance requirements

Key benefits for you:

- High processing capacity, ideal for large-scale iron ore projects

- Stable concentrate grade, suitable for downstream smelting

- Low operating cost per ton and fast return on investment

B. Weakly magnetic ores

Typical ores: Hematite, limonite, specularite

Weakly magnetic ores are traditionally difficult to recover. To address this challenge, we utilize Wet High-Intensity Magnetic Separation (WHIMS) technology.

Solutions:

- High-gradient magnetic field for effective separation of weakly magnetic minerals

- Excellent recovery performance for fine and ultra-fine particles

- Can be integrated with grinding and classification systems for optimized results

Key benefits for you:

- Significantly improved recovery of weakly magnetic minerals

- Lower tailings grade and reduced metal losses

- Makes previously marginal deposits economically viable

C. Non-metallic mineral purification

Typical materials: Quartz sand, feldspar, kaolin

In industrial minerals processing, the focus is on purity rather than volume. We provide dedicated magnetic separation solutions for efficient iron removal.

Solutions:

- High-gradient magnetic separation for removing trace iron impurities

- Available in both dry and wet processing configurations

- Stable operation without altering the physical or chemical properties of the material

Key benefits for you:

- Higher whiteness and product purity

- Materials suitable for glass, ceramics, and other high-value applications

- Increased product value and profit margin per ton

| Magnetic property | Typical minerals | Common separation method |

| Strong magnetic minerals | Magnetite, pyrrhotite, franklinite | Low-intensity magnetic separation |

| Weakly magnetic minerals | Hematite, limonite, specularite, ilmenite, wolframite | High-intensity / high-gradient magnetic separation |

| Non-magnetic minerals | Quartz, feldspar, kaolin, calcite, fluorite, gypsum | Magnetic impurity removal |

The magnetic separation process: Efficiency in every step

A well-designed magnetic separation process is essential for achieving high recovery and low operating costs. By optimizing crushing, grinding, magnetic separation, and dewatering stages, the plant delivers stable performance and efficient mineral recovery.

1. Crushing & screening

The raw ore is crushed and screened to achieve the optimal liberation size while minimizing fines generation. Proper size control at this stage reduces unnecessary grinding and helps lower overall energy consumption.

2. Grinding & classification

The crushed material is ground and classified to meet the exact particle size requirements of magnetic separation. Classification ensures that only properly sized material enters the magnetic circuit, preventing efficiency loss caused by over- or under-grinding.

3. Magnetic separation

The core of the process consists of multi-stage magnetic separation, typically including roughing and cleaning stages. Roughing stage rapidly recovers magnetic minerals at high throughput. Cleaning stage further upgrades the concentrate to achieve the target grade.

4. Dewatering

The final concentrate is dehydrated to produce a high-quality, dry concentrate ready for shipment. Efficient dehydration improves processing efficiency and reduces logistics costs.

Project references – Magnetic separation plants

1. Iron ore magnetic separation | Australia

Hematite and limonite ores, 10–15 TPH

Concentrate grade improved to 67–68% Fe, with recovery up to 95%.

Custom magnetic separation circuits were designed to maximize iron recovery and minimize metal loss.

2. Manganese ore magnetic separation | South Africa

Manganese ore, 51 TPH

Mn concentrate grade increased to 41.23% with a recovery rate of 93.6%.

A washing, jigging, and high-intensity magnetic separation process ensured efficient manganese recovery.

3. Tungsten ore magnetic separation | Vietnam

Wolframite ore with tin, 15 TPH

Tungsten and tin concentrates were successfully separated, achieving 80–85% recovery.

Staged wet high-intensity magnetic separation was applied for precise mineral separation.

Start your magnetic separation project with confidence

Every ore is different. A properly designed magnetic separation process is essential for maximizing mineral recovery and plant efficiency. Contact us to receive a customized magnetic separation plant solution based on your ore characteristics. Contact us today