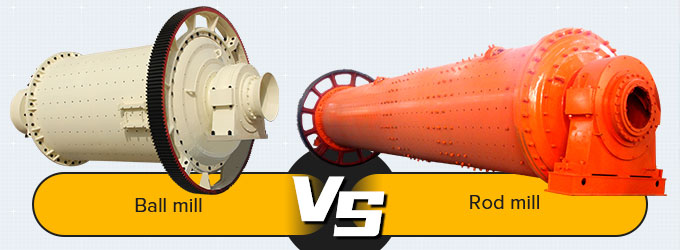

The failure of the ball mill in the grinding process will affect the output and efficiency. So, what abnormal signs will occur before the machine going to malfunction?

Here we list 17 signs to mention you that the ball mill is running and needs to be checked in.

Find the abnormal signs early is very important to prolong the ball mill service life.

1. The sign of "swollen belly"

Just like a bloated stomach, if the amount of grinding exceeds the maximum capacity and discharge capacity, it will cause the mill shell to loses its grinding capacity, and that's why we call it "swollen belly".

3Tips for mentioning you whether it is "swollen belly"

- Digital clamp-on meter indicates that the current is decreasing.

- The ball mill starts to discharge a great amount of ore blocks.

- The machine operation sound is dull, and there is no sounds of steel ball impacting.

What causes the sign of "swollen belly"

- Feeding volume is too large to exceed the maximum passing capacity of the mill.

- The granularity becomes coarse, which prolongs the time grinding the material to get the standard of discharging particle size.

- Steel balls are not added on time, which means the filling rate is low.

- Reduces water pressure at the feed opening and inefficient feed water will cause the flow velocity of the ore pulp in the ball mill slow, the ore drainage not smooth, and the more ore sand accumulating.

What should we do to solve those problems?

- 1First of all, it is necessary to do analyses including changes of nature of the ore, whether the amount of ore, water, sand and overflow size are normal. Then do the measures to deal with them.

- 2Reduce the amount of feed to the mill until the working state of the ball mill returns to normal.

- 3Appropriately reduce the amount of volume of rinse to the returned sand so that we can increase the concentration of the ore and the discharge amount.

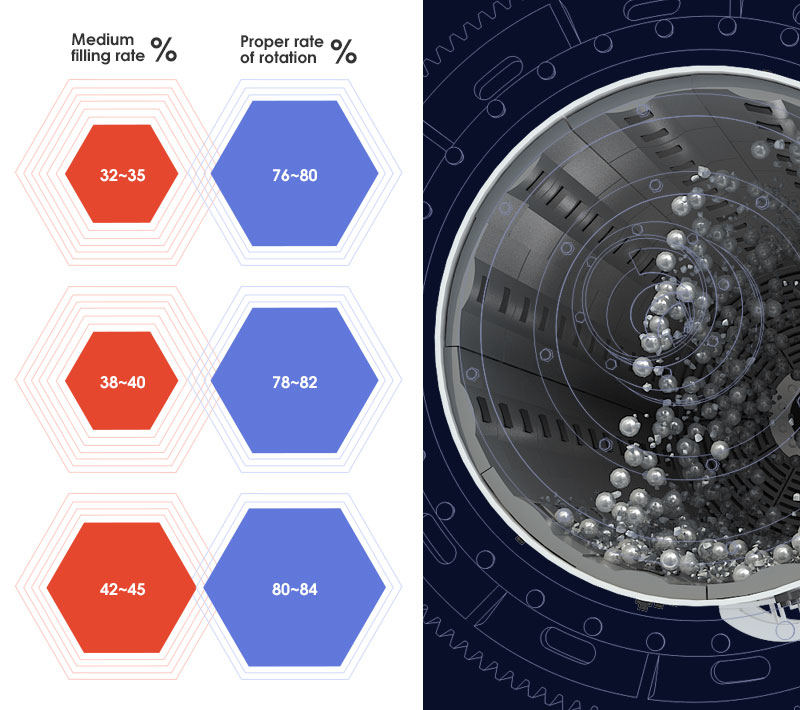

- 4Reasonable addition of grinding media. Ball filling rate- the ratio of grinding media to the volume of the mill, is so important to the mill rotation rate. The following shows their relations:

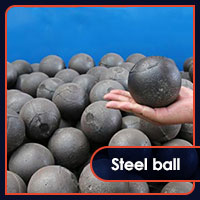

We should put proper steel balls

- 5Necessary inspections of the mill: such as whether the feeder is loose, the screws are cut, and other components are damaged.

2. More and more coarse materials final products

- 1It refers to the abnormal phenomenon that the fineness of the grinding product is significantly coarse and difficult to control.

- 2It generally appears on the double-cylinder open-circuit mill with a relatively small diameter.

The reasons for more coarse material

- When processing materials with small particle size and low hardness, the mentioned situation will happen if the ratio of small ball is small.

- The capacity of coarse grinding silo is over strong while the capacity of fine grinding silo is over weak.

- The amount of feeding material suddenly increases.

- The gap of the partition board is too large.

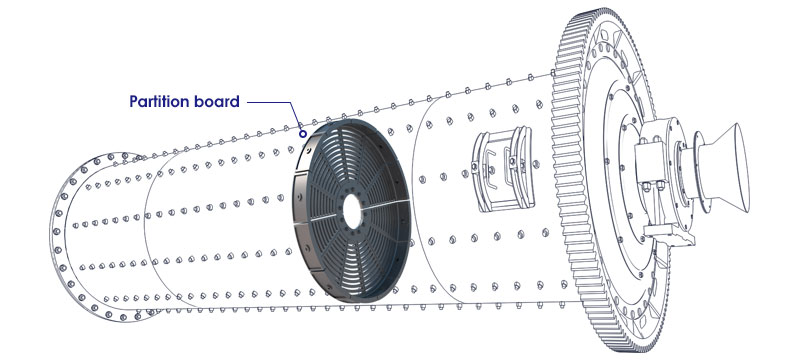

Partition board maintaining is key to stop the coarse material genetating

Solutions

- 1Properly add more small balls to adapt to the nature of ores and get better product fineness.

- 2So, we must strictly follow the standard ratio to prevent the imbalance of large and small balls.

- 3If the loading capacity of the grinding medium in the coarse chamber is too small, or the diameter of the steel ball is not large enough, we should enlarge the loading capacity to adjust the grinding grade.

- 4Keep the amount of feeding material compatible with the crushing capacity to avoid the increasing amount of feed.

3.There is a large amount of ball wear in the ball mill

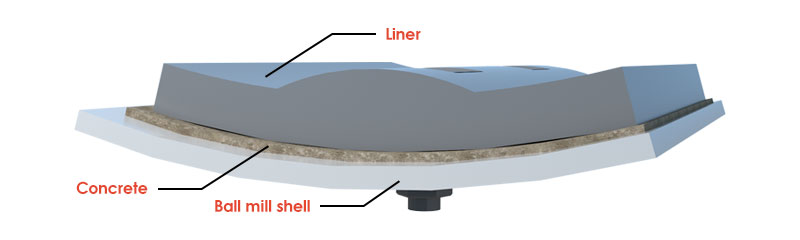

In the grinding operation, the consumption of the steel ball accounts for more than 10 times of the liner of the ball mill.Here are the reasons for it:

Quality of steel balls

The quality of the steel ball has a greater relation to ball consumption. The wear resistance of the surface layer of steel ball is quite different from that of internal, leading to the uneven speed of diameter reduction and the gradation deviation.

The above situations result in higher ball consumption, lower grinding efficiency, and less-ideal product fineness.

Too many useless balls

If there are too many useless balls, the broken ball rate will increase, and the load of the ball mill will also increase.

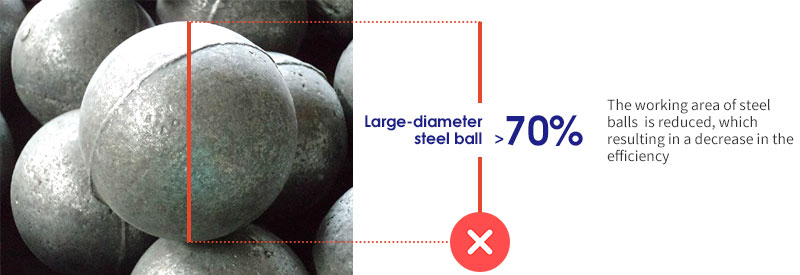

Too much large-diameter steel ball would cause wear problems

2 Ways to avoid the steel balls consumption

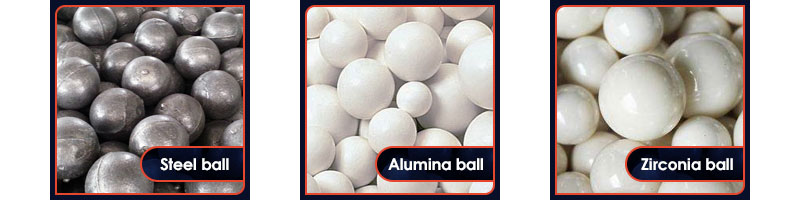

- 1Use medium with high quality and strong wear resistance. Commonly used grinding media include steel balls, alumina balls, zirconia balls, etc.

- 2Reduce the numbers of the large-diameter steel ball to less than 70%. Ensure that when the grinding medium moves in the disperser, the void ratio of the medium is not less than 40%.

The common three grinding media in the ball mill

4. Output is getting lower and lower

If we find the amount of feed too much, the hardness of the material to be ground becomes harder and the particle size larger, you get the output problems. Besides, output decrease also follows other factors.

for example, the moisture of the material to be ground is too high, the partition board or the caster joints is blocked by debris, or grinding balls and liners pasted.

Why the output production is lower than before?

- "Full grinding" of ball mills

- When the output of ball mills is getting lower and lower, the first thing to consider is whether "full grinding" occurs.

- The working time of the ball mill is too long.

- Failure to add steel balls in time

- The temperature in the ball mill shell increases

- The moisture content of the material is too high

- The proportion of grinding aid added is unreasonable.

4 Ways to improve the output production

-

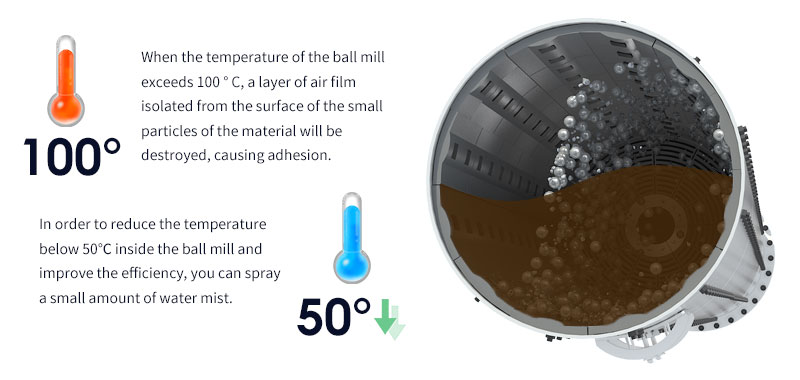

1When the temperature of the ball mill exceeds 100 ℃, a layer of air film isolated from the surface of the small particles will be destroyed, which will cause adhesion.

So, to reduce the temperature inside the mill and improve the efficiency of the milling, you can Spray a small amount of mist water into the milling bin to reduce the temperature inside the mill to below 50 ℃.

- 2The amount of grinding aid add amount in the general cement production process should not exceed 1%.

High temperature of the ball mill will affact the efficiency

- 3For every 1% increase in moisture, the output of the ball mill will be reduced by 8% -10%.

- 4 when the moisture is greater than 5%, the ball mill will be unable to perform the grinding operation.

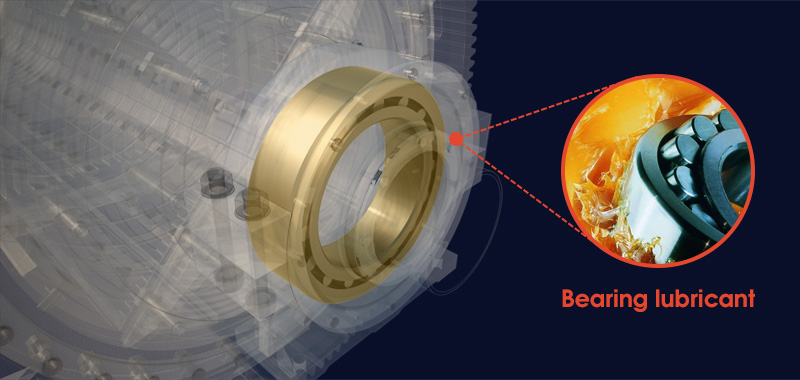

5. The bearing of the ball mill is overheated and the motor is overloaded

Reasons

High-quality bearing lubrication

- The lubricating oil grade is inconsistent with the manual or is deteriorated.

- The lubricating pipeline is blocked, resulting in the lubricating oil cannot enter the lubricating point.

- The bearing or coupling is not installed correctly.

- The gap between the journal and the bush is unreasonable, which causes poor contact.

- The oil groove is damaged.

Correct ways to solve the overheated bearing and overloaded motor

- Use the correct grade of lubricating oil and replace the deteriorated lubricating oil.

- Add enough oil according to the regulations, and generally, 1/3 to 1/2 of the bearing gap is more appropriate.

- Dredge the lubrication pipeline.

- Install bearings or couplings correctly.

- Adjust the gap between the journal and the bush.

- Check the oil tank in time.

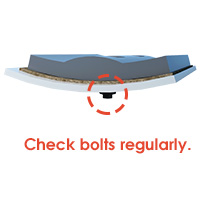

6. There are regular and loud knocking sounds during operation

Some liner bolts are not tightened, which makes the liner strikes the ball mill barrel when the ball mill rotates.Correct ways to deal with the abnormal knocking sound

Find the exact part of the ball mill according to the sound position, then tighten the loose bolts.

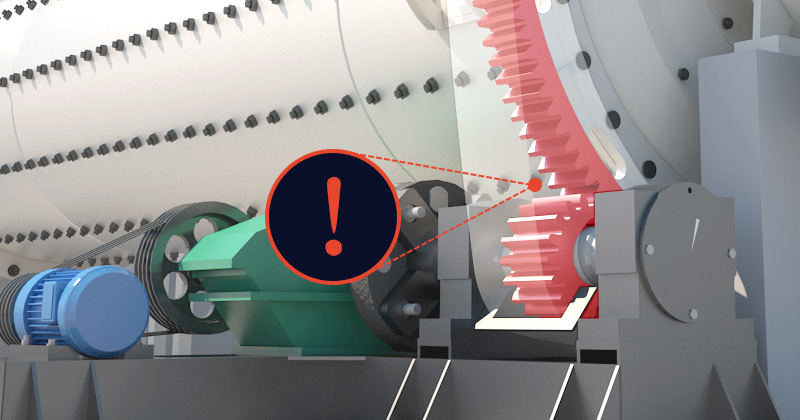

7. Abnormal vibration occurs when the motor starts reducer

What causes the vibration:

- The gap between the two wheels of the coupling is too small, which makes it difficult to compensate for the amount of movement made by the magnetic center of the motor.

- The coupling of the reducer, the motor, and the shaft do not maintain a high degree of coaxial.

- The connecting bolts of the coupling are not tightened symmetrically.

- The outer ring of the bearing is not fixed well.

Adjust the gear clearance to avoid abnormal vibration

Correct ways to avoid vibration problems

- Adjust the gear clearance as required.

- Make the two axes concentric.

- Tighten the coupling bolts with the same torque.

- Fix the bearing outer ring.

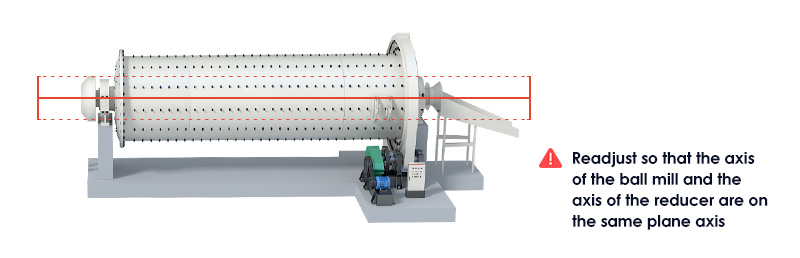

8. Huge vibration occurs when the belt speed- reducer runs

The reasons for the vibration of the belt speed-reducer

- 1The axis of the balance shaft of the ball mill and the reducer is not in a straight line.

- 2The large ball mill has a large volume and heavyweight, which causes the foundation to sink.

What we do to stop the vibration

- 1Make a readjustment so that the axis of the ball mill and the reducer are on the same plane.

- 2Set a monitoring settlement point next to the foundation to make observations and adjustments for any subsidence.

9. The strange dull sound with the ammeter index droppings

Factors in the strange dull sound and drop of the ammeter index

- Too much-filling material with large particle size

- The moisture of the material is large, and the grate is blocked.

- The length of each tank is unreasonable.

Solutions

- Reduce the filling volume of materials.

- Reduce the moisture of the material and clean the grate.

- Adjust the proportion of grinding body and the length of each silo.

10. Reducer bearing is overheated with abnormal sounds

The reasons causing the reducer to overheat

- 1The exhaust hole of the reducer is blocked.

- 2The balance wheel and intermediate wheel of the reducer are not installed according to the specified meshing teeth.

Ball mill grinds copper in India

Do the following rules to resolve the above-mentioned problems

- 1Carry out temperature tests on the reducer bearing and clear the vent hole.

- 2correctly install the balance wheel and the intermediate wheel.

11. The main bearing temperature is too high, which even causes smoke or parts melting

What causes the over-high temperature of the main bearing

- The cylinder drive shaft is bent.

- The oil groove is too deep and the contact between the pad and the shaft prevents oil from entering the tile.

- The oil supply device fails or is interrupted.

- The viscosity of lubricating oil is unqualified.

- The main bearing cooling water is insufficient.

How to decrease the bearing temperature

- Cool first, then stop the mill to check and adjust, or increase the amount of oil.

- Repair oil supply device.

- Adjust the gap, scrape the bush, or repair the journal.

- Replace the appropriate viscosity lubricating oil.

- Increase water supply, or lower the water supply temperature.

12. Partial wear of the ball mill shell

The main reasons for the wear of ball mill shell

- The lining board is installed without misalignment.

- Non-stop running after the lining board falls off.

- There is materially scouring between the lining board and the cylinder.

Three easy-wearing parts of ball mill

The solutions to solve the problems

- Staggered lining installation.

- Repair or replace the lining board.

- Make the liner and cylinder tightly fit.

13. Gear bearing vibration, excessive noise, accompanied by an impact

Why does gear bearing become abnormal?

- The bolts of the bearing cover or bearing seat are loose.

- Excessive bearing wear

- Bad bearing installation

- The gear is over worn, and the lubricant is too dirty.

- Improper gear meshing is too large.

- Loose connection bolts of the large gears or counterpart bolts.

- Gear machining accuracy is not satisfactory.

Correct ways to maintain it

- Fasten bolts

- Replace the bearing

- Repair or replace gears, and strengthen lubrication

- Fasten bolts or replace rubber ring

14. Lubrication system oil pressure is too high or too low

The following factors will cause the problems in lubrication system

- The oil pipe is blocked or leaking oil

- Insufficient fuel supply

Right ways to change the situation

- 1Check whether the oil pipe is blocked or leaking oil, and timely repair or replace the oil pipe.

- 2Replenish fuel supply regularly

15. The ball mill fails to start, and the motor is overloaded when starting

The reasons why the ball mill fails to start

- 1There are obstacles to the rotating part.

-

2When the machine is shut down for a long time, the materials and steel balls in the ball mill are not removed in time, which makes wet materials are condensed into pieces.

So, when the machine is started, the grinding bodies are not dropped, which increases the load on the motor.

How to solve the ball mill starting problems

- 1Check and repair the motor system.

- 2Clean up obstacles in the rotating part.

- 3Clean the materials and steel ball in the ball mill and remove the agglomerated materials.

16. Gear tooth surface wears too fast

The following factors explain why that happens

- Poor lubrication or mixed with impurities, metals, etc.

- The meshing gap is too large or too small, and the contact is bad.

- The quality of gear processing does not meet the requirements.

- Mineral sand and other abrasive particles enter between the teeth.

The correct measures

- Strengthen bones or replace lubricants

- Adjust the meshing clearance

- Do regular cleaning

17. The vibration of the mill and abnormal axial movement

The reasons for the vibration of the mill and for, abnormal axial movement

- 1The sinking of the machine base causes the uneven installation of the mill.

- 2The bottom surface of the foundation is eroded due to oil leakage.

Solutions to stop the abnormal vibration

- 1Adjust the sinking part to make the ground level on the bottom of the machine.

- 2Remove the secondary grouting layer eroded by oil, and bury the anchor bolts again, then make an adjustment and tightening.