What is a ceramic ball mill—and who needs one?

A ceramic ball mill is a precision grinding machine designed for brittle, hard, or impurity-sensitive materials.

Instead of traditional steel components, it uses ceramic liners and ceramic grinding media—eliminating metal contamination during milling. This makes it ideal for industries with strict requirements for product purity or low iron content.

Ceramic ball mills are especially well-suited for silica processing plants, ceramic manufacturers, glass producers, battery material processors, and mineral powder production facilities.

Typical applications include:

- Fine grinding of feldspar, quartz sand, clay, kaolin, zircon, and alumina

- Powder preparation for ceramics, glass, and electronics

- Processing of rare earths, non-metallic minerals, and high-purity materials

What makes a ceramic ball mill different?

The key advantages of a ceramic ball mill lie in two critical components: the ceramic liners and the ceramic grinding balls.

These upgrades improve product purity, reduce wear, and enhance overall efficiency.

1. Ceramic liners

Ceramic liners serve two primary purposes:

- They protect the mill shell from abrasion.

- They lift the grinding media to the optimal height for effective impact and grinding.

Unlike steel-lined mills that use high-manganese steel liners, ceramic ball mills are equipped with ceramic liners made primarily of alumina (Al₂O₃)—a higher-cost material that effectively prevents iron contamination.

- Chemically inert — Does not react with metal materials

- Custom thickness — Typically 50–150 mm, based on mill size

- Long service life — 3–5× longer than metal liners

- High hardness — HRA 85+, over 270× more wear-resistant than steel

- Heat resistant — Withstands continuous use at 0–250°C

- Protects product purity — Prevents iron contamination

- Low maintenance — Less downtime and fewer replacements

A case study showed that ceramic ball mill liners reduced replacement frequency by 60% over 18 months compared to steel liners.

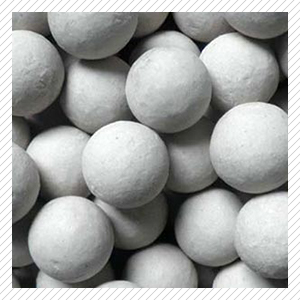

2. Ceramic grinding balls

Ceramic ball mills use high-density alumina or zirconia balls, also known as "alumina balls" due to their 90%+ Al₂O₃ content. They are white spheres with diameters ranging from 0.5 mm to 120 mm.

Available in a variety of sizes, ceramic balls can be blended based on feed size, output requirements, and material type.

- 40–60% more wear-resistant than steel balls

- No metal contamination — Ideal for ceramics, glass, quartz, and feldspar

- Stable size and shape over long-term use

- Various sizes — Enables precise particle control

- Lightweight and strong — Hard, corrosion-resistant

- Energy-efficient — Reduces energy use by 10–15% compared to steel balls

- Lower static charge — Reduces agglomeration

In pilot tests, ceramic balls retained 95% of their original size after 500 hours—compared to <80% for steel balls.

How does the ceramic ball mill work?

The ceramic ball mill uses a rotating drum lined with ceramic to grind materials. Inside the drum, ceramic grinding balls roll and collide as the drum turns. The material is crushed and ground by repeated impact and friction until it reaches the desired fineness.

This gentle but efficient process keeps heat and metal contamination to a minimum—perfect for making clean, high-quality powders.

Why choose FTM Machinery ceramic ball mill?

- Supports both dry and wet grinding, with 24-hour continuous operation.

- Achieves fine output—250 mesh or finer—in both open and closed circuits.

- Reduces energy use and wear on liners and grinding balls through automated operation.

- Increases output by 4.4% with optimized internal components.

- Lowers operating costs with minimal oil usage and no emergency oil system.

- Delivers all key spare parts quickly for fast maintenance.

- Backed by a professional service team to minimize downtime.

- All key components—like bushings, bearings, and gears—can be customized and are built to precise standards for better performance and greater safety.

Below are the specifications of ceramic ball mills to help you better match your production needs:

| Model | Feeding capacity(t/time) | Shell rotation speed(r/min) | Reference motor(kw) |

| 600×700 | 0.05 | 50 | 2.2 |

| 900×1200 | 0.2 | 38.5 | 5.5 |

| 1300×1500 | 0.5 | 33 | 7.5 |

| 1800×2000 | 1.5 | 24 | 15 |

| 2600×2800 | 5 | 16.5 | 37 |

| 3000×3800 | 10 | 14.5 | 57.2 |

| 3200×4600 | 15 | 13.5 | 75 |

Note: Chinaware, silicon, rubber or metal(the related motor power varied as per the different liner materials and grinding materials)

To learn more about the ceramic ball mill price for a specific model, get in touch with our team—we'll help you find the best solution for your budget and production goals. Contact us

Ceramic ball mills vs. steel ball mills: which is right for you?

| Feature | Ceramic ball mill | Steel ball mill |

| Grinding media | Ceramic balls | Steel balls |

| Liner material | High-purity ceramic | Manganese/alloy steel |

| Contamination risk | Extremely low (non-reactive) | High (metal leaching) |

| Best for | Ceramics, glass, pigments, high-purity materials | Mining, cement, coarse grinding |

Choose ceramic when purity, particle size, or chemical reactivity matters most.

Customer case – ceramic ball mill for feldspar & kaolin in Pakistan

A customer from Pakistan runs a small factory making ceramic powder for tiles and sanitary ware. They needed a cleaner grinding process for feldspar and kaolin, with no metal contamination.

We supplied an 1800×2000 ceramic ball mill with alumina liners and ceramic grinding balls.

Project overview:

- Location: Pakistan

- Material: Feldspar and kaolin

- Capacity: 1.5 tons per batch

- Feeding size: ≤25 mm

- Main equipment: Jaw crusher, ceramic ball mill, spiral classifier

After the production line was put into operation, output increased significantly and costs were greatly reduced, bringing strong economic benefits to the customer.

The system also achieved ultra-fine output below 250 mesh with zero iron contamination, ensuring high-purity powder quality. Additionally, energy use dropped by 15% and maintenance costs by 40%.