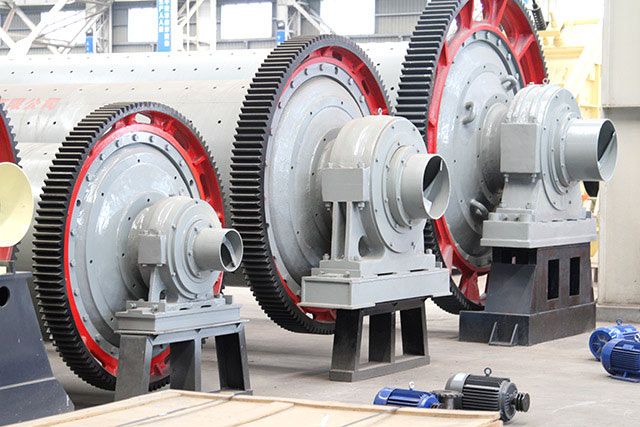

What is a ball mill?

Ball mill is a kind of grinding machine, which is the key ball milling machine used after the material has been crushed. It also has a mixing effect. This type of grinding machine has a cylindrical body with spherical grinding mediums and materials.

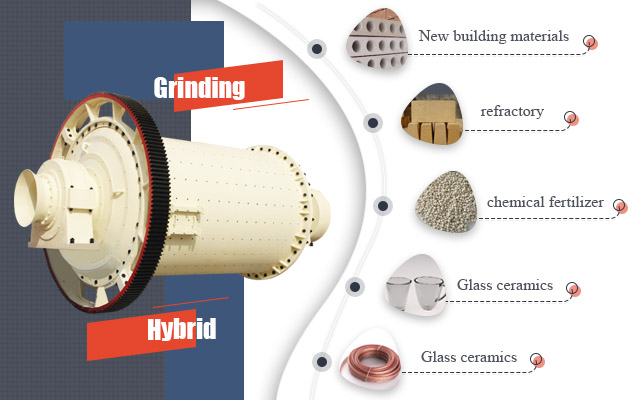

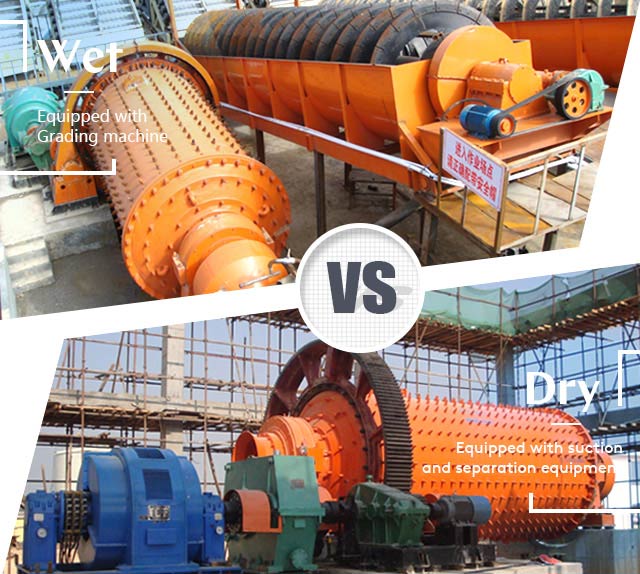

Ball mill is widely used in cement, silicate, new construction material, refractory material, chemical fertilizer, ferrous metal, non-ferrous metal and ceramics. It is widely applied to wet and dry grinding for grindable materials. Wet grinding is often equipped with a classifier, and dry grinding is configured with a suction and separation device.

Both of dry and wet ball mills are composed of feeding port, discharging port, turning part, and transmission parts such as retarder, small transmission gear, motor, electronic control. Wet grinding can be widely used as most of the minerals can be wet milled. Dry grinding is used on a smaller scale, but some materials can only be dry milled. So, what are the differences between wet and dry grinding?

Difference between wet and dry grinding

1. Difference in (ball mill) structure

Dry grinding

A dry ball mill is equipped with a cylindrical rotating device and two bins, which can rotate by gears. The discharge port is straight. There are also air intake devices, dust exhaust pipes, and dust collectors.

Wet grinding

The structure of wet ball mill is simple. The discharge port is horn-shaped. There is a screw device in it, which is convenient for discharging materials.

2. Difference in working principle

Dry grinding

Dry grinding means that when the ore is ground into required particle size, the powder will be brought out from the dry ball mill by airflow.

Dry grinding process:

- 1The material from the feeding device is evenly fed into the first bin of ball mill by the hollow shaft spiral. This bin has stepped lining or corrugated lining, which is filled with steel balls of different specifications.

- 2The rotation of cylinder generates centrifugal force to bring the steel grinding ball to a certain height, and then fall. After the material is coarsely ground in the first bin, it will enter the second bin through the single-layer partition plate.

- 3This bin is embedded with a flat liner. The grinding steel balls inside will further grind the material, then the powder is discharged through the discharge grate to complete the grinding.

Please notice that dry grinding needs dry materials, so we can't add water or other liquids during the dry milling process.

Wet grinding

Wet grinding means that after the ore entered the mill, it will complete the wet grinding under the interaction of grinding medium and ore.

Wet ball mill types: (According to the motion characteristics)

- Simple swing type wet ball mill

- Complex swing type wet ball mill

- Hybrid swing type wet ball mill

Wet grinding process:

- 1Wet grinding requires that water or anhydrous ethanol must be added to the material.

- 2The movement of ore is driven by water. The bulk material will be cracked under the impact and grinding of the grinding medium. As the crack gradually increases and deepens, the final material will be separated from the crack to achieve the effect of bulk material being ground.

- 3The grinding ore will be discharged through the discharge port. Then the discharged mineral is classified into the qualified product in a spiral classifier. While the coarse sand returns to the ball mill through the combined feeder for continuous grinding.

Please control the grinding concentration, as it can affect the grinding efficiency. The amount of water depends on the use of mud, the amount of clay in the formula, and the water absorption of clay.

3. Difference in applicable materials

Dry grinding

Dry grinding is suitable for materials that can react with water, which may not be used for wet grinding such as cement, marble and other building materials. Some products that require storage and sale in powder form are suitable for dry grinding. And in some arid areas, dry grinding can be used to save water.

Wet grinding

Wet grinding is suitable for most materials, such as all kinds of metal ore, non-metallic ore. As long as it is water-repellent and will not affect the quality of the finished product, the material can be used for wet grinding.

Common ore includes copper ore, iron ore, molybdenum ore, phosphate rock, feldspar mine, fluorite ore, etc. The proportion of steel balls, materials, and water in wet grinding is 4:2:1. The detailed proportion can be determined by grinding experiments.

At the same time, the size of alumina grinding balls is also required. If the ball ratio is good, then the ball milling efficiency will be greatly improved. Generally, there are large, medium and small balls, and a better ratio between them can also be obtained through experiments.

Contact us for a Free Sample Testing!

Their advantages and disadvantages

1. Dry ball mill Get Latest Price

Advantages:

- The dry ball mill adopts the slab-type grinding tail discharge, so the discharging speed is fast. The process is unhindered and not bloating. The cylinder does not need to be cooled, and its service life is long.

- The dry ball mill has many auxiliary types of equipment, which changes the structure of the original mill and makes the engine body and the underframe integrated. It can be one-time hoisting on the foundation plane during installation. The spindle is subjected to double row radial spherical roller bearings, which can reduce energy consumption by 30%.

Disadvantages:

- Dry grinding is inefficient. During the kneading process, as there is no material blocking in the cracks, the cracks will become smaller and smaller. It results in a low grinding efficiency and slower material separation.

- There may be dead angles in the mill. Once the material enters a dead angle, then it cannot be driven without water, which will result in not being ground.There may be dead angles in the ball mill. Once the material enters a dead angle, it cannot be driven without water, resulting in not being ground.

2. Wet ball mill Get Latest Price

Advantages:

- Wet grinding is more efficient. It has a higher production capacity and lower power consumption than the dry grinding.

- The material is easy to flow. The water can wash away the fine particles in time to avoid over-grinding.

- The wet ball mill has a low noise, and low environmental pollution.

- The wet ball mill has a simple transportation device with less auxiliary equipment, so the investment is about 5%-10% lower than that of a dry ball mill.

- The grinding particle size is fine and uniform. The wet ball milling can not only grind agglomerate into fine particles, but also mix the lean material and the plastic material well.

Disadvantages:

- The consumption of wet mill balls is high.

- The process of dehydration and drying increases the cost.

How do we choose the right ball mill?

1. According to the requirements of material

The dry milling process may be used when the particle size of powder is not very fine or when the ball milled product is to be stored or sold in powder form.

For example, the production of cement requires us to choose dry grinding instead of wet grinding.

2. According to the overall economic perspective of ball mill grinding

Wet grinding is widely used in mineral processing. That's because the wet ball mill has the advantages of strong materials adaptability, continuous production, large grinding ratio, and it is easy to adjust the fineness of milled products.

Most of the ball mill types sold on the market are wet ball mills, as they have high grinding fineness and good beneficiation effect.

As dry and wet ball mills both have their own advantages, we must find out the suitable grinding type to ensure the production quality and efficiency. Welcome to consult Fote company, where our professionals will give you a satisfactory answer based on your needs.