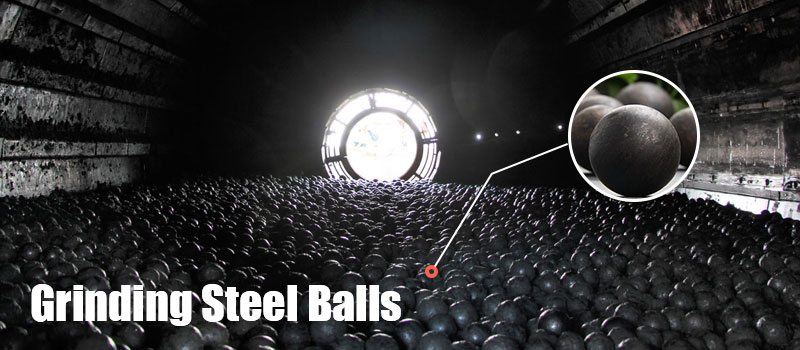

What are grinding steel balls?

Grinding steel balls are the grinding media and the core components of a ball mill. They can directly affect the grinding efficiency of the whole ore processing plant and the final product quality.

During the grinding process, grinding steel balls are used for mixing and milling materials (such as minerals, paints, and chemicals) into fine powders.

Types of grinding steel balls

As grinding steel balls need good abrasion resistance and enough impact toughness, and cannot be broken, FTM Machinery has done hardness test, chemical composition inspection and internal quality inspection for each ball.

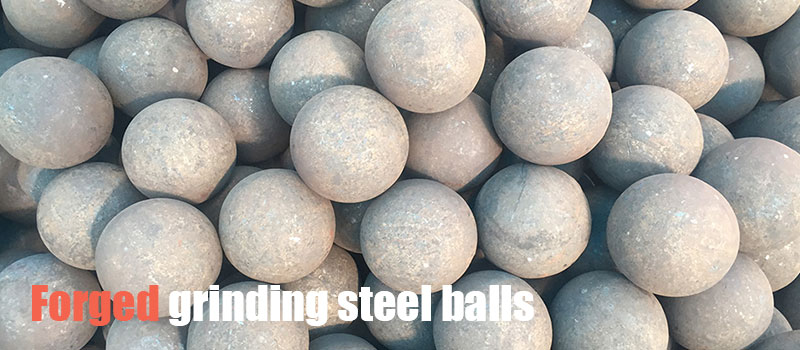

According to the manufacturing process, ball mill steel balls for mining are divided into forged grinding steel balls and cast grinding steel balls.

1. Forged grinding steel balls

Want higher grinding efficiency? For gold mining or cement industry? Then you can choose forged grinding steel balls, which are available in all stages of milling.

FTM Machinery forged steel ball can be divided into low carbon, medium carbon, high carbon steel ball based on the carbon percentage.

The carbon content is below 1.0%. The chromium content is 0.1%–0.5% (Generally do not contain chromium).

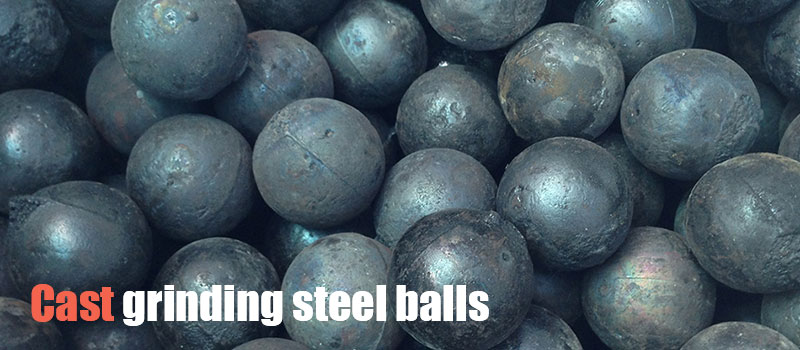

2. Cast grinding steel balls

As another type of grinding media, cast grinding steel balls can provide Cr (1%–28%), hardness (HRC40–66), and Diameter (10–150 mm) alloy cast steel balls.

They can be divided into low chromium, medium chromium, high chromium, super high chromium grinding ball (CR12%–28%).

-

Low crushing ratio: The resistance to flaking and crushing is 10 times than that of other forged balls. The number of impacts of falling balls can reach more than100,000 times. The actual crushing rate is less than 0.5%, close to no crushing.

- Good surface finish: The ball surface is not allowed to have casting defects, such as cracks, obvious pores, inclusions, shrinkage holes, cold insulation, elephant skin, etc.

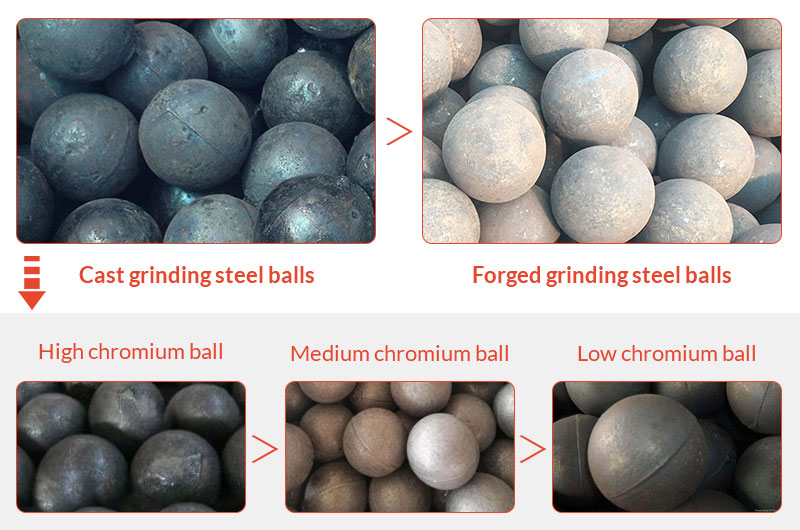

Forged VS Cast grinding steel balls

Two types of grinding steel balls have different wear degree, as they are processed by different heat treatment methods.

- Forged grinding steel ball: Water quenching is often used for forging steel balls, so its broken rate is high.

- Cast grinding steel ball: It adopts high-temperature quenching and tempering treatment to make the grinding balls more tough and wear-resistant.

Cast grinding steel balls > forged grinding steel ball. And among the cast steel balls, high chromium ball > medium chromium ball > low chromium ball.

Why choose FTM Machinery grinding steel balls?

- Higher hardness:The surface hardness of FTM Machinery forged balls can reach 55–65HRC. The volume hardness can reach 50–62HRC.

- High impact resistance: Each FTM Machinery grinding steel ball is a solid steel ball, from surface to center. All the indicators have reached the leading standards of mining machinery.

- The chemical composition is consistent with the newest standards with regard to high C and low gas level.

- Round steel balls: FTM Machinery balls are round steel balls with precise dimensions.

Sizes of FTM Machinery grinding steel balls

Each grinding balls are round balls with precise dimensions. The sizes of FTM Machinery grinding steel balls can be designed according to customer requirements.

Generally, the ball diameter is between 20 mm and 125 mm. You can also design 10 mm, 11 mm or other diameters of steel balls.

- Small steel balls: 40 mm or 60 mm

- Medium balls: 80 mm

- Large steel balls: 100 mm or 120 mm

- Super large balls: 130 mm to 150 mm

Theoretically, when the filling amount of steel grinding balls in the cylinder of the ball mill is 40%, the ball mill can obtain an ideal output.

However, in actual production, the filling rate of steel grinding balls in the cylinder of the ball mill is around 35%, that is to keep the volume of balls in the cylinder slightly lower than the horizontal centerline of the ball mill.

How are FTM Machinery grinding steel balls manufactured?

All FTM Machinery grinding steel balls are manufactured according to both international and national standards (e.g., DSTU8538, GOST7524). This can effectively reduce unnecessary ball consumption and improve the grinding efficiency.

Grinding steel balls are made by a series of processing methods: rough, heating, forging (rolling) into balls, then are hardened by heat treatment.

- 1Rough: Steel grinding balls use bearing scrap steel as raw material, with a large amount of copper, molybdenum, nickel and other precious metal elements added to make the structure more compact. After checking, the round steel bar is cut into steel ball billets in fixed lengths;

- 2Heating: Steel ball billets are heated to an appropriate temperature in a continuous heating furnace;

- 3Forging (rolling) into balls: The red-hot billets are sent to steel ball mills, then rotates forward between two rolls with spiral-shaped holes to be continuously rolled into balls. Each steel ball mill can roll 60 to 360 balls per minute;

- 4Heat treatment: By adopting the most advanced and reasonable oil quenching production line, the rolled red-hot steel balls will immediately undergo quenching-tempering heat treatment;

- 5Final check and pack: After the final check, steel grinding balls are sent to the warehouse for packing. Then the products are sold to customers.

How many balls are needed in a ball mill?

Grinding steel ball proportioning can greatly affect the output and quality of ball mill. Only by ensuring a certain proportion of various balls, can they be adapted to the particle size of ground material, and achieve a good grinding effect.

So, do you know how to add balls to achieve the greatest grinding efficiency?

4 principles when adding grinding steel balls

- Processing of ore with large hardness and coarse particle size requires greater impact force and needs to be loaded with steel grinding balls of larger size. The harder the material, the larger the ball diameter;

- If the diameter of the ball mill is large, the impact force will be large. Then the diameter of steel grinding balls should be small;

- If a double-chamber partition is used, the ball diameter should be smaller than that of a single-layer partition plate with the same discharge section;

- Generally, follow the principle of "less at two ends and more in the middle", that is, four-level ball distribution, with fewer large and small steel balls, and more balls in the middle.

How to add grinding steel balls to a ball mill?

1. When you use the ball mill for the first time

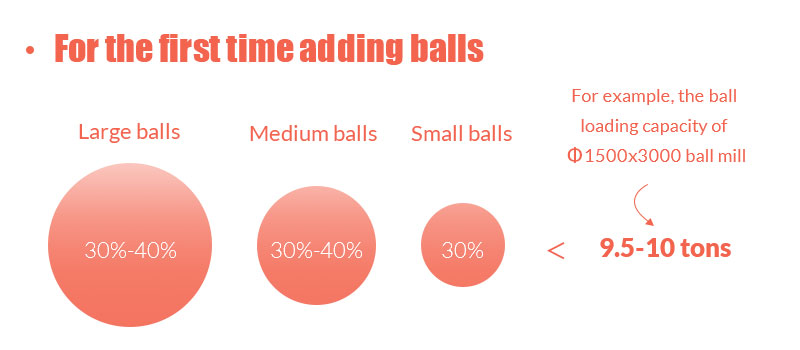

In the first time, the grinding steel balls must be added at 80% of the maximum ball loading capacity of the ball mill. And three sizes of balls, namely, large, medium and small, are required for proportioning.

Different ball mill models have different ball loading capacities. For example, the ball loading capacity of Ф1500x3000 ball mill is 9.5–10 tons. For the first time adding balls, large steel balls (120 mm and 100 mm) account for 30%–40%, medium steel balls (80 mm) are 30%–40%, and small steel balls (60 mm and 40 mm) are 30%.

After normal continuous operation for two or three days, check the meshing of the large and small gears. If everything is normal, add the remaining 20% steel grinding balls for the second time.

2. Under normal circumstances

Under normal circumstances, it is not necessary to add small steel grinding balls. When the ball mill is operating normally, friction will occur between the ball and ball, the ball and the ore, and the ball and the ball mill liner. The friction will become larger and then grind the large balls and medium balls into small ones.

However, small steel grinding balls would be added if the particle size is not implemented with a mineral monomer dissociation, and mill fineness does not reach the sorting requirements (especially flotation sorting requirements).

In addition, the steel grinding balls of the ball mill are constantly worn out during operation. In order to maintain the stable operation of the ball mill, reasonable ball replenishment must be carried out to offset and compensate for the wear and tear.

Parameter

The sizes of steel grinding balls can be designed according to customer requirements. Generally, the diameter of steel balls for sale is between 20 mm and 125 mm.

1. Small steel balls: 40 mm or 60 mm

2. Medium balls: 80 mm

3. Large steel balls: 100 mm or 120 mm

4. Super large balls: 130 mm to 150 mm

The sizes of steel grinding balls can be designed according to customer requirements. Generally, the diameter of steel balls for sale is between 20 mm and 125 mm.

1. Small steel balls: 40 mm or 60 mm

2. Medium balls: 80 mm

3. Large steel balls: 100 mm or 120 mm

4. Super large balls: 130 mm to 150 mm