High-efficiency flotation starts with FTM Machinery

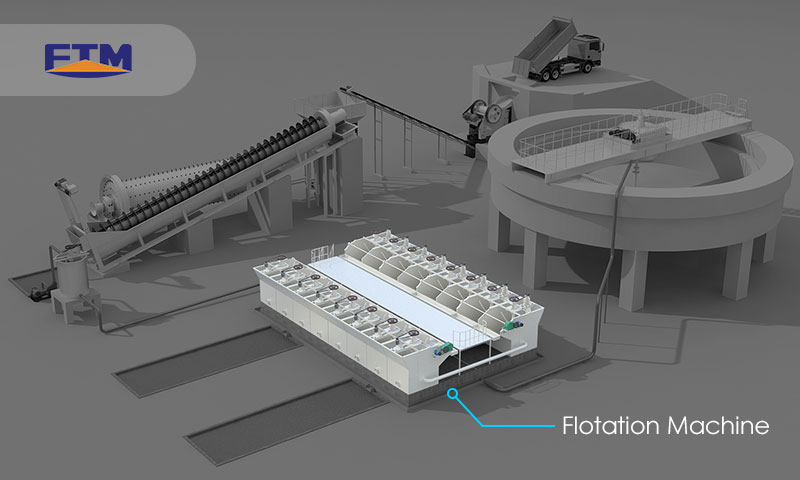

A flotation machine is a key mineral processing device that separates valuable minerals from impurities. Through aeration and agitation, mineral particles attach to bubbles and rise to the surface, producing high-grade concentrates.

Choosing an FTM Machinery flotation machine means:

- Higher recovery rates – less metal loss

- Lower energy consumption – 20–30% reduction in operating costs

- Stable performance – reliable structure, easy maintenance, low downtime

- Proven worldwide – trusted in 160+ countries, long-term use in mining operations

Wide applications of our flotation machines

Flotation machines deliver efficient and reliable separation across a wide range of minerals:

- Non-ferrous metal ores: copper, lead, zinc, nickel, cobalt, molybdenum, antimony, tungsten

- Non-metallic minerals: graphite, apatite, barite, coal, fluorite, quartz, mica

- Precious metal ores: gold, silver

- Ferrous metal ores: hematite, ilmenite

- Salt minerals: potash, rock salt

Whether for a small flotation plant or a large-scale flotation process, we provides flotation equipment designed for high efficiency, long service life, and maximum recovery.

FTM Machinery – four series of flotation machines

FTM Machinery flotation equipment is available in two main types:

- Self-aspirated flotation machines: Use impeller rotation to create negative pressure, automatically drawing in air and slurry. No external blower is required. Simple structure, easy to operate.

- Forced-air flotation machines: Rely on an external air blower, providing larger air intake and higher flotation efficiency. Ideal for large-scale flotation plants.

We offer four main series of flotation machines to meet different flotation process needs: SF, BF, KYF, and XCF.

1. SF flotation machine (Self-aspirated)

The SF flotation machine delivers large air intake with low power consumption. Each cell performs suction, slurry intake, and flotation independently.

Best for small to medium-sized mines. Low investment cost & simple maintenance

Key features:

- Flexible configuration – can work as a single flotation cell or in a flotation plant flow.

- Dual backward-curved impeller blades create two-way slurry circulation, reducing coarse particle sedimentation.

- Automatic slurry level control for stable flotation process.

- Front cell design minimizes dead zones, speeds up froth flow.

Hot-selling models and parameters: Get Latest Price

| Model | Effective Volume (m³) | Processing Capacity (m³/min) | Main Shaft Motor Power (kW) |

| SF-0.37 | 0.37 | 0.2–0.4 | 1.5 |

| SF-1.2 | 1.2 | 0.6–1.6 | 5.5 |

| SF-4 | 4 | 2–4 | 15 |

| SF-8 | 8 | 4–8 | 30 |

| SF-10 | 10 | 5–10 | 30 |

2. BF flotation machine (Self-aspirated)

The BF flotation machine is an upgraded version of the SF series, featuring an optimized cell design to prevent slurry dead zones.

The upgraded impeller uses a closed double-cone design, improving slurry circulation and flotation efficiency. Ideal for mines needing higher concentrate quality and lower operating costs.

Key features:

- Saves 30–50% energy compared with conventional mechanical flotation machines.

- Higher separation precision – reduces ash content in coal concentrate by 1–2%.

- Built-in slurry level auto-control and electrical system for finer froth

- Impeller self-cleans debris during operation

- Wear-resistant rubber parts extend service life and reduce flotation parts replacement.

Hot-selling models and parameters: Get Latest Price

| Model | Effective Volume (m³) | Processing Capacity (m³/min) | Main Shaft Motor Power (kW) |

| BF-2.0 | 2 | 1–2 | 7.5 |

| BF-6.0 | 6 | 3–6 | 18.5 |

| BF-16 | 16 | 8–16 | 37/45 |

| BF-20 | 20 | 10–20 | 37/45 |

| BF-24 | 24 | 12–24 | 45 |

3. KYF flotation machine (Forced-air)

The KYF flotation machine features a unique U-shaped cell, hollow shaft air injection, and a suspended stator.

Its innovative conical impeller with backward-curved blades, similar to a high-speed centrifugal pump, enhances slurry circulation and bubble dispersion. Perfect for large-scale flotation plants and high-capacity operations.

Key features:

- Super-large capacity – up to 38 m³/min per cell.

- Low pressure head, low energy consumption, and simple structure.

- Easy flotation parts replacement and maintenance, minimizing downtime.

- Built-in air distributor ensures finer and more even bubble distribution

Hot-selling models and parameters: Get Latest Price

| Model | Effective Volume (m³) | Processing Capacity (m³/min) | Main Shaft Motor Power (kW) |

| KYF-3 | 3 | 0.6–3 | 7.5 |

| KYF-4 | 4 | 1.2–4 | 11 |

| KYF-8 | 8 | 3–8 | 15 |

| KYF-24 | 24 | 4–24 | 30 |

| KYF-38 | 38 | 10–38 | 37 |

4. XCF flotation machine (Forced-air)

The XCF flotation machine is usually paired with KYF series cells in series or parallel configurations, increasing flexibility in flotation process design.

Key features:

- Special stator creates a negative pressure zone for self-suction of slurry, improving flotation stability.

- Works in tandem with KYF to boost overall aeration efficiency and recovery rate.

- Best suited for medium-to-large flotation plants requiring high-efficiency continuous operation.

Hot-selling models and parameters: Get Latest Price

| Model | Effective Volume (m³) | Processing Capacity (m³/min) | Main Shaft Motor Power (kW) |

| XCF-1 | 1 | 0.2–1 | 5.5 |

| XCF-2 | 2 | 0.4–2 | 7.5 |

| XCF-3 | 3 | 0.6–3 | 11 |

| XCF-4 | 4 | 1.2–4 | 15 |

| XCF-16 | 16 | 4–16 | 37 |

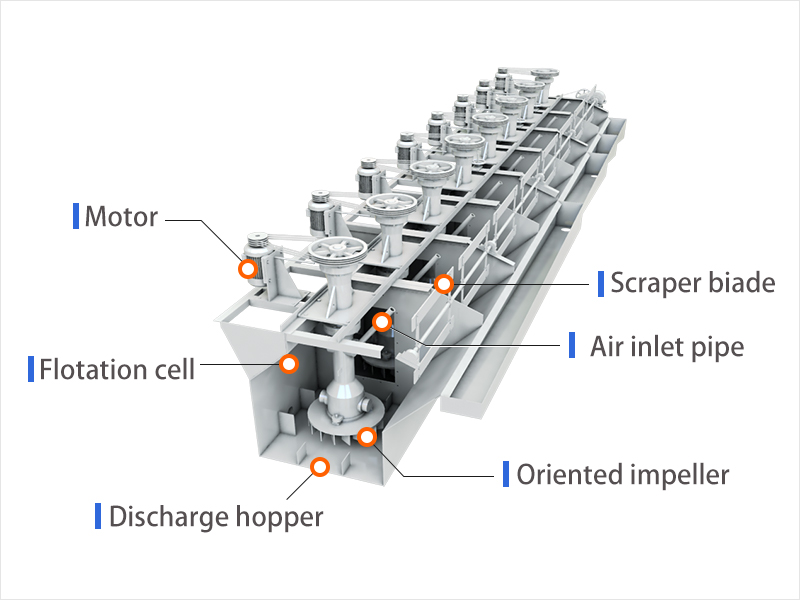

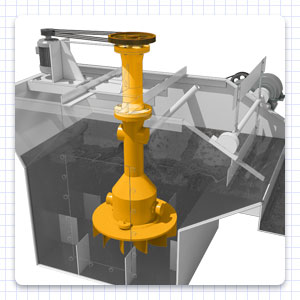

Core structure of the flotation machine

The core of a flotation machine lies in mixing, aeration, and froth separation, relying on the coordinated action of the flotation cell, mixing device, aeration device, and foam discharging device to achieve efficient mineral separation.

1. Flotation cell

It has a slurry inlet and a gate device for adjusting the slurry surface. It is mainly composed of a tank welded with steel plate and a gate welded with steel plate and round steel.

Cells are connected via middling boxes and gates to control slurry flow across multiple flotation cells.

2. Mixing device

Comprising the impeller, stator, and main shaft, the mixing device stirs the slurry and draws in and disperses air.

The stator stabilizes slurry flow and disperses bubbles finely, while the main shaft transmits power from the motor to the impeller.

3. Aeration device:

Air is drawn through an inlet pipe when the impeller rotates, creating a negative pressure in the impeller cavity. This disperses air into the slurry, forming bubble clusters for effective froth flotation.

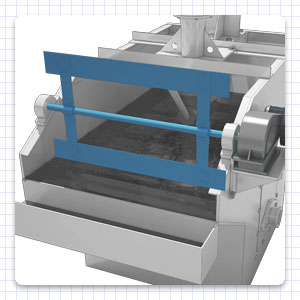

4. Foam discharging device

Driven by a motor and reducer, one or more scraper shafts slowly rotate, removing the mineral-rich froth from the slurry surface as concentrate. Scraper speed and depth are adjustable for optimal flotation efficiency.

How the flotation machine works?

The flotation machine separates valuable minerals by mixing and aeration, allowing mineral particles to fully interact with bubbles. The flotation process steps are as follows:

- 1The motor drives the impeller, creating negative pressure to draw in air.

- 2Air is dispersed into bubbles and mixed with the slurry.

- 3Minerals selectively attach to bubbles after reagent treatment.

- 4Mineralized bubbles rise to the froth layer.

- 5The scraper removes the froth, producing high-grade concentrate.

Watch the flotation machine in action video

Factors affecting the flotation process

Several factors influence flotation efficiency, with the most important being mineral particle size, slurry concentration, temperature, reagents, and water quality.

1. Mineral particle size (Grinding fineness)

The optimal flotation fineness varies with ore type. Too coarse or too fine particles reduce recovery.

Coarse particles include sulfide minerals at 0.2–0.25 mm, natural sulfide ores at 0.5–1 mm, and coal at 1–2 mm. Fine particles can reach 5–10 microns. For many clients, grinding gold and copper ores to 200 mesh provides the best flotation results.

2. Slurry concentration

Pulp density refers to the solid content in the slurry, typically around 30%. For roughing, it ranges from 25–45%, usually 28–30%; for cleaning, 10–20%; and for scavenging, 20–40%.

Coarse or dense ores generally use higher slurry concentrations, while fine ores use lower concentrations. Scavenging slurry concentration is usually determined by roughing and not controlled separately.

3. Slurry temperature

Reagent efficiency is temperature-dependent. Some reagents work best at specific temperatures. Certain flotation processes may require higher slurry temperatures to improve recovery.

4. Reagent addition and adjustment

Reagents are critical in flotation. Proper selection, dosage, and addition sequence of collectors, frothers, and modifiers determine separation efficiency. Optimal conditions are established through testing.

5. Water quality

Flotation occurs in an aqueous medium, so water quality directly affects reagent performance and mineral surface properties. Common water types: soft water (most used), hard water, saline water, and recycled water.

6. Flotation process flow

The flotation flow (roughing → scavenging → concentrating) must be tailored to ore characteristics and optimized through laboratory tests to achieve the best technical and economic results.

Customer case – U.S. copper ore flotation plant

Our client, a large copper mining company in Arizona, USA, processes ore primarily containing copper, with minor molybdenum. The ore includes both oxidized and sulfide copper, making the flotation process challenging.

The client required multiple flotation systems that could achieve high recovery rates while maintaining low energy consumption to improve overall concentrate grade.

- Ore grade: ~0.9% Cu

- Grinding fineness: 85% passing 200 mesh

- Flotation process: 1 stage roughing – 2 stages scavenging – 2 stages concentration

- Equipment configuration: KYF flotation machine, XCF flotation machine

Results:

The copper recovery increased from 78% to 88%, while the concentrate grade improved from 21% to 24%. Unit energy consumption dropped by 25%, and equipment maintenance intervals doubled. Annual copper concentrate production rose by approximately 15,000 tons, delivering significant economic benefits.

Customer feedback:

"FTM Machinery flotation machines solved our long-standing low recovery issues. The equipment runs stably, consumes less energy, and greatly reduces operating costs."

FAQs

1. What auxiliary equipment is needed for a flotation machine?

- A flotation system generally requires a ball mill, classifier, thickener, reagent mixing tank, dewatering equipment, and filter.

2. What are the key points for maintaining a flotation machine?

- a. Regularly inspect the impeller, stator, and cell for wear.

- b. Keep all drive components well-lubricated.

- c. Ensure air pipelines are clear.

- d. Monitor the slurry level to maintain normal operation.

3. What should I do if my flotation machine's capacity drops?

- a. Check if the air inlet is blocked or the liquid level control is malfunctioning.

- b. Inspect feed lines for blockages or disconnections.

- c. Ensure drive belts are not slipping and bearings are not overheating.

- d. Verify impeller speed; adjust or replace belts if necessary.

- e. Check the hollow shaft air intake and adjust if too large.

Download Flotation Separator

852.98 KB

Download Flotation Separator

852.98 KB