More than 80% of all base metal concentrates worldwide are produced through flotation — and for good reason.

Flotation is incredibly adaptable. By adjusting reagents, air flow, and cell configuration, it can separate a wide variety of minerals, from copper and lead-zinc ores to lithium and rare earth elements.

What is a flotation plant — and why it matters

In a ton of ore, the metal content may be less than 1%, but flotation technology allows us to extract wealth from "waste rock".

That's where flotation plants come in — facilities designed to separate valuable minerals from gangue using air bubbles and reagents.

Common types of ores that flotation plants can process:

- Precious metal ores: Gold, silver

- Ferrous metal ores: Iron, manganese

- Non-ferrous metal ores: Copper, lead, zinc, nickel, molybdenum, cobalt, tin, aluminum

- Rare metal ores: Tungsten, lithium, niobium-tantalum, rare earth ores

- Non-metallic ores: Fluorite, apatite, graphite, talc, barite, sulfur

Efficient flotation means higher recovery, lower energy consumption, and better overall economics.

How flotation works — process & principle

The flotation process is based on the difference in surface properties between minerals. Some particles are hydrophobic (repelled by water) and easily attach to air bubbles, while others are hydrophilic (water-loving) and stay in the slurry.

In a flotation plant, this principle is applied through a series of controlled steps.

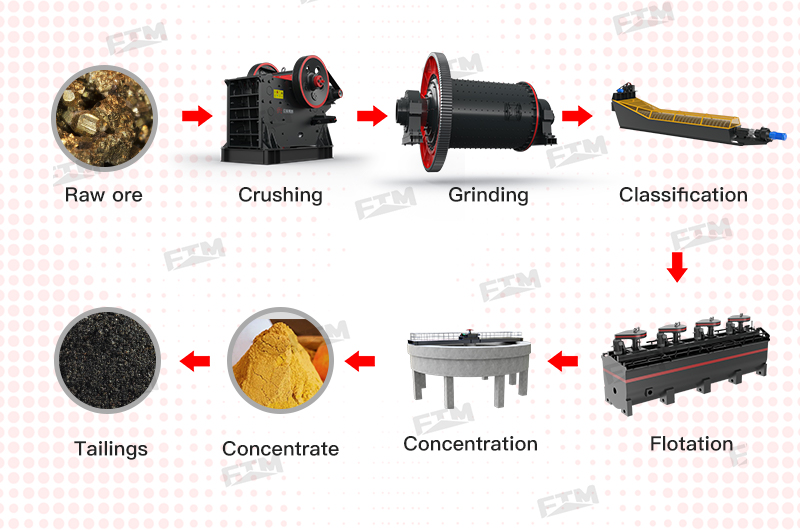

Basic flotation process flow:

- 1 Crushing & grinding: The ore is crushed and ground to a fine size to liberate valuable minerals.

- 2 Slurry preparation: Water and reagents are added to form a mineral pulp.

- 3 Flotation: Air is introduced into flotation cells. Hydrophobic minerals attach to bubbles and float to the surface, forming a froth layer.

- 4 Concentrate collection: The froth is skimmed off, forming a high-grade concentrate.

- 5 Tailings disposal: The remaining material (tailings) is safely discharged or further treated.

Mineral particle size, reagent type, bubble size, and stirring intensity all affect the flotation effect.

Flotation process by ore type

Nearly all sulfide ores are processed by flotation. Oxide ores, rare metals, and high-purity non-metallic minerals are also commonly beneficiated by flotation. Even refractory iron ores and gold-bearing sulfides often require flotation treatment.

With decades of field experience, FTM Machinery provides customized flotation solutions — tailored to ore characteristics, capacity requirements, and recovery goals. Contact our engineers

1. Copper ore flotation

Typical minerals: Chalcopyrite, Bornite, Chalcocite

Copper ore process overview:

- 1 Grinding: Liberate copper minerals (60–70% passing 0.074 mm)

- 2 Roughing: Initial collection of sulfide copper minerals

- 3 Scavenging: Recover remaining copper minerals

- 4 Cleaning: Remove Fe and S impurities to improve concentrate grade

Most copper ores are sulfide-based and show excellent floatability. Common reagents include xanthate collectors, pine oil frothers, and lime as a pH modifier (typically 8–10) for selective separation.

Modern copper flotation achieves 90–95% recovery with 20–30% Cu concentrate grade.

2. Gold & silver flotation

Typical minerals: Native gold, Pyrite, Arsenopyrite, Argentite

Flotation is often used as a fine recovery step after gravity separation — especially for fine-grained or sulfide-hosted gold and silver ores.

Typical process combinations:

- Flotation–cyanidation: Concentrate gold by flotation, then extract it via cyanidation.

- Flotation–gravity combination: Enhance recovery by integrating gravity separation before or after flotation.

Reagent system: Isoamyl xanthate or butyl xanthate (collector) + pine oil (frother) + lime (pH control).

Well-optimized flotation circuits can improve gold recovery by 5–15% and silver recovery by over 10% compared with conventional methods.

3. Lead–zinc ore flotation

Typical minerals: Galena, Sphalerite, Pyrite

Lead–zinc ores are usually complex sulfides, where minerals tend to interfere with each other during flotation. Two main strategies are commonly applied:

- Preferential flotation: Float galena first, then recover sphalerite from the tailings.

- Bulk flotation & separation: Float a combined Pb–Zn concentrate first, then separate the two using selective depressants.

The key reagents used are xanthate and dithiophosphate collectors + sodium cyanide (to inhibit sphalerite) + lime (to adjust pH). High-quality lead concentrates can reach 55–60% Pb, and zinc concentrates can reach 45–50% Zn.

4. Non-metallic mineral flotation

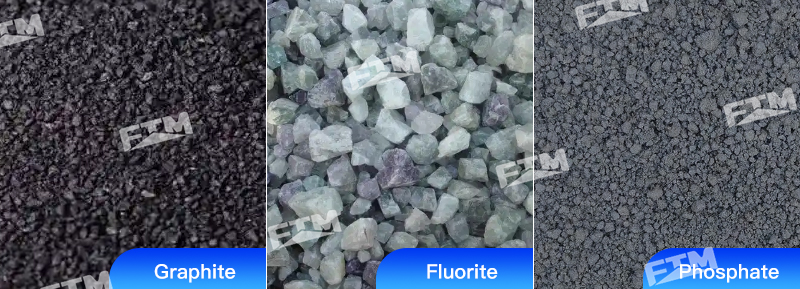

Common ores: Fluorite, Graphite, Barite, Phosphate, Talc

Flotation of non-metallic minerals focuses mainly on purification and impurity removal. The reagent system often uses fatty acid collectors or amine-based collectors depending on mineral characteristics.

Key process highlights:

- In fluorite flotation, sodium silicate is used to suppress quartz.

- In graphite flotation, multiple cleaning stages are essential to preserve crystal structure and carbon grade.

- In barite–calcite systems, temperature and pH control ensure selective separation.

High-grade non-metallic concentrates can reach 97–99% purity, meeting the requirements for chemical, ceramic, and metallurgical applications.

5. Rare metals & battery mineral flotation

Representative minerals: Spodumene, Wolframite, Lepidolite, Rare Earth Oxides

The rise of the new energy industry has made flotation of rare metals a high-demand process. These minerals often have fine particle size, poor floatability, and complex gangue, requiring precise process control.

Advanced flotation process:

- 1 Reverse flotation to remove mica, feldspar, and other gangue minerals

- 2 High-precision bubble control for better mineral attachment

- 3 Hydroxamate collectors to enhance flotation response of lithium and rare earth minerals

With optimized flotation, spodumene concentrates can reach Li₂O content above 6%, with recovery improvement of 10–20%.

Smart flotation machine for the future

Flotation equipment is at the heart of the flotation system — its performance directly determines concentrate grade and recovery.

FTM Machinery has developed a new generation of flotation solutions designed for efficiency and intelligence. Get a quote

1. Efficient design

Every component — from rotor to tank geometry — is optimized to maximize bubble–particle interaction.

The advanced XCF/KYF series air-inflated flotation cells feature an independent air dispersion system, producing finer, more uniform bubbles that enhance mineral attachment.

2. Intelligent control

Our flotation equipment integrates automated air flow regulation, reagent dosing, and froth level monitoring. Real-time feedback ensures stable concentrate grade and recovery, even under varying feed conditions.

3. Sustainability

We prioritize water recycling, low-noise operation, and corrosion-resistant materials, helping clients meet environmental standards while controlling long-term costs.

In recent copper and gold projects in Africa and South America, this approach has achieved 10–15% higher recovery and up to 20% lower reagent consumption.

Flotation plant cases with FTM Machinery

1. Copper–zinc flotation plant – Zambia

This flotation plant has a capacity of 1,000 t/d and is equipped with XCF/KYF air-inflated flotation cells.

After redesigning the flotation circuit, copper ore recovery increased by 12%, concentrate grade rose from 20% to 35%, and energy consumption decreased by 18%.

"The plant now runs more stably than ever. The automated control system has saved us energy and reagent costs."

— Plant Manager, Lusaka, Zambia

2. Graphite beneficiation plant – Brazil

The goal was to produce high-carbon graphite concentrate for battery materials. The solution used a custom reagent scheme and low-turbulence fine-particle flotation cells from FTM Machinery.

The carbon grade increased from 88% to 96.5%, reagent consumption was reduced by 22%, and water recycling reached 90%, meeting local environmental standards.

"From lab testing to commissioning, your attention to detail impressed us. Recovery exceeded our expectations."

— Process Director, Brazil

3. Gold & silver flotation–leach plant – Peru

This process uses a flotation–cyanidation combined circuit with an automated air-flow control system, with a capacity of 80 t/h.

Gold recovery increased by 9.4%, silver recovery increased by 11%, and tailings recovery reached 85%.

"The FTM Machinery team truly understood the characteristics of our ore. Both lab testing and plant commissioning were world-class."

— Technical Manager, Leach Plant

Flotation is evolving

At FTM Machinery, we have decades of experience designing and supplying flotation systems that help mines worldwide achieve cleaner, smarter, and more efficient operations.

We believe that every ton of ore deserves precise processing.

Want to know if your ore can achieve higher recovery with flotation? Contact us today to schedule a free test and process evaluation.