What is the high efficiency concentrator?

The high efficiency concentrator is mainly used for dewatering flotation concentrate and tailings in dressing plants, and also for concentration and purification of liquid containing solid particles in metallurgy, chemical industry, coal, building materials and sewage treatment industries.

Fote high efficiency concentrator,new dewatering equipment

In fact, it is not just settling equipment, but new dewatering equipment combining the filtration characteristics of the mud layer.

What is the structure of the high efficiency concentrator?

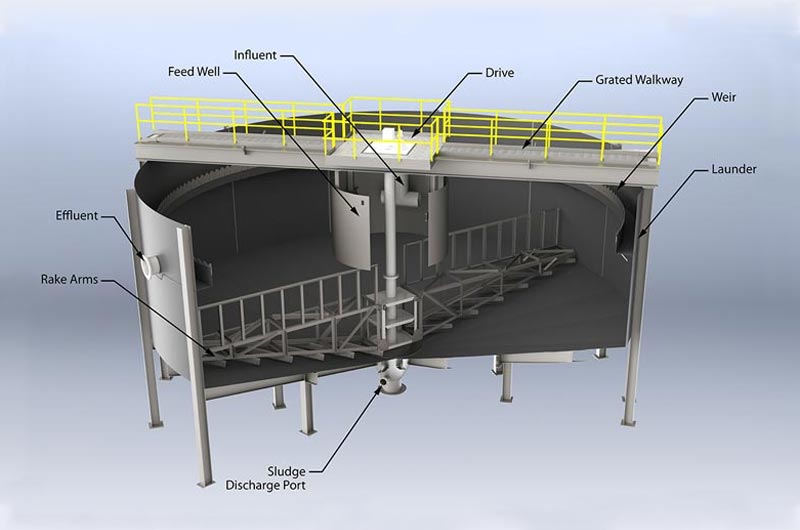

High-efficiency concentrators are generally composed of thickening tanks, rake arms, transmission devices, degassing tanks, feeding devices, discharging port, etc. As shown below:

Structure of the high efficiency concentrator

How does the high efficiency concentrator work?

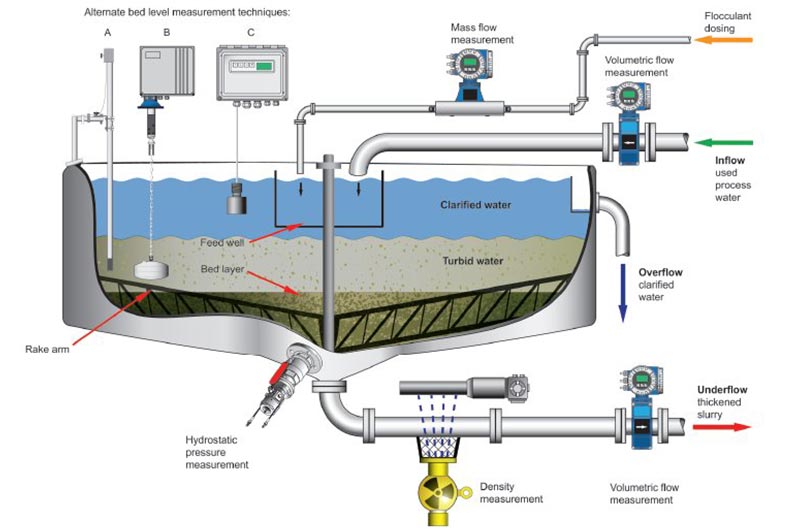

Before the slurry is sent to the high efficiency concentrator, most of the gas contained in it is removed in the deaerating tank.

Then the slurry is sent to the mixing device from the feed pipe and is fully mixed with an appropriate amount of flocculant to form a good flocculation state.

How does the high efficiency concentrator work

Then, it enters the pre-formed high concentrations of sediment layer at the bottom of the concentration tank. At this time:

- The flocculated slurry settles to the bottom of the tank.

- The slurry water rises through the sedimentation layer.

During the ascent process, due to the filtering and squeezing of the sedimentation layer, small particles will gradually condense into flocs and settle down.

The clean water will float up and become overflow to flow out from the overflow port. With the help of rake arms driven by the central drive device, the concentrated material is pushed to the discharging port to be discharged.

Advantages of high efficiency concentrators

There is a deaerating tank inside to prevent solid particles from adhering to bubbles.

The feeding tube is below the liquid surface to prevent gas from being brought into the ore.

Fote high efficiency concentrator being used for dewatering tailings in Zimbabwe

The feeding sleeve is moved down, and there is a receiving pan, so the feeding slurry falls evenly and steadily.

The horizontal feeding of traditional concentrators is changed to inclined feeding, which fundamentally eliminates the problem of feeding blockage.

There is a subcritical flow device to slow down the rising speed of the material, so that the overflow is more uniform with lower turbidity.

Why is the high-efficiency concentrator efficient?

Use of flocculant

The flocculant used in the high efficiency concentrator is polyacrylamide, which has a better flocculating effect than ordinary flocculants.

At the same time, in order to avoid the damage of the grouped flocs by the falling pulp, the flocculant is fed into the ore drum at one time after the pulp.

Feeding method

The traditional concentrator adopts the upper feeding method, so the slurry is easy to affect the precipitated slurry during the descending process.

The high-efficiency concentrator feeds ore from the bottom, which is not easy to produce fluctuations during the rising process of the slurry.

Fote high efficiency concentrator being used for dewatering gold concentrates in South Africa

Inclined plates

Many inclined plates are installed in the upper part of the high efficiency concentrator along the circumferential direction.

Under the action of the inclined plates, the flocculates quickly precipitate to the inclined plate and slide down to the bottom.

After that, the material is stirred by the stirring device and the vibration action of the vibration device installed outside the machine. A large amount of water is generated and discharged quickly.

At the same time, the solid is more compact under the action of vibration.

The inclined plate greatly improves the clarification and compression efficiency of the concentrator.

FAQ How to prevent metal loss when concentrating flotation concentrate?

①When the pulp enters the concentrated tank, spray high-pressure water to eliminate foam.

②Disperse foams by the rotation of the centrifugal pump impeller.

③A retaining ring parallel to the overflow groove is set in the concentrated tank to block foam.

④Add chemicals to accelerate the burst of the foam.

FAQ Why is it said that the most difficult to settle is the sludge? How to deal with it?

For colloidal particles with a particle size of 0.1–0.001 microns, there is actually no precipitation due to molecular force and electrostatic repulsion.

In order to improve the settling of such suspended particles (i.e., sludge), their charge must be removed. The following methods can be used in concentrators to accelerate slime settlement:

①Add electrolyte.

②Add colloidal surface-active substances (usually water glass or soda).

③Adjust the ratio of liquid to solid in the slurry.

④Heat the slurry.

Parameter

| Specification | Concentration pond (m) | Deposit square(m2) | Harrow part | Motor | Processing capacity (t/d) | Total weight(t) | |||||

| Model | Specification | Inner diameter | Depth | Pond degree | Method | Height(m) | Rotation time(min/r) | Driving | Lifting | ||

| NZS-1 | Φ1.8m | 1.8 | 1.8 | 2.54 | Manual | 0.16 | 2 | Y90L-6 1.1KW | ---- | 5.6 | 1.9 |

| NZS-3 | Φ3.6m | 3.6 | 1.8 | 10.2 | Manual | 0.35 | 2.5 | Y90L-6 1.1KW | ---- | 22.4 | 4.3 |

| NZS-6 | Φ6m | 6 | 3 | 28.3 | Manual | 0.2 | 3.7 | Y90S-4 1.1KW | ---- | 62 | 10.7 |

| NZSF-6 | Φ6m | 6 | 3 | 28.3 | Manual | ---- | 3.7 | Y90S-4 1.1KW | ---- | 62 | 5.1 |

| NZ-9 | Φ9m | 9 | 3 | 63.6 | Auto | 0.25 | 4.34 | Y132S-6 3KW | XWD0.8-3 0.8KW | 140 | 8.5 |

| NZS-9 | Φ9m | 9 | 3 | 63.6 | Manual | 0.25 | 4.34 | Y132S-6 3KW | ---- | 140 | 7.5 |

| NZS-12 | Φ12m | 12 | 3.5 | 113 | Manual | 0.25 | 5.28 | JTC752A-44 5.2KW | ---- | 250 | 11.1 |

| NZ-15 | Φ15m | 15 | 4.4 | 176 | Auto | 0.4 | 10.4J | JTC752A-44 5.2KW | Y112M-6 2.2KW | 350 | 26.0 |

| NZ-20 | Φ20m | 20 | 4.4 | 314 | Auto | 0.4 | 10.4 | Y100L1-4 5.2KW | Y112M-6 2.2KW | 960 | 28.9 |

| NZ-30 | Φ30m | 30 | 7.165 | 707 | ---- | 0.61 | 13.7 | Y672A-44 5.2KW | YCJ132-S 1.5KW | ---- | 36.6 |

| NZS-45 | Φ45m | 45 | 4.633 | 1590 | Manual | ---- | 20 | Y672A-44 5.2KW | YCJ160-S 2.2KW | 515 | 54.4 |

| NT-15 | Φ15m | 15 | 3.5 | 177 | ---- | ---- | 8.4 | Y132M2-6 5.5KW | ---- | 390 | 12.6 |

| NQ-18 | Φ18m | 18 | 3.5 | 255 | ---- | ---- | 10 | Y132M2-6 5.5KW | ---- | 560 | 11.6 |

| NQ-24 | Φ24m | 24 | 3.4 | 452 | ---- | ---- | 12.7 | Y160M-6 7.5KW | ---- | 1000 | 26.6 |

| NQ-30 | Φ30m | 30 | 3.6 | 707 | ---- | 16 | Y160M-6 7.5KW | ---- | 1570 | 30.9 | |

| NJ-38 | Φ38m | 38 | 4.9 | 1134 | ---- | ---- | 10-25 | JZT252-4 11KW | Y160M-6 7.5KW | 1600 | 63.3 |

| NT-45 | Φ45m | 45 | 5.05 | 1590 | Auto | ---- | 19.3 | Y160L-6 11KW | ---- | 2400 | 66.8 |

| NTJ-53 | Φ53m | 53 | 5.07 | 2202 | ---- | ---- | 23.18 | Y180L-6 15kw |

---- | 6250 | 89.1 |

| NT-100 | Φ100m | 100 | 5.65 | 7846 | ---- | ---- | 43 | Y180L-6 15KW | ---- | 3030 | 214.9 |

| Specification | Deposit square(m2) | Processing capacity (t/d) | |

| Model | Specification | Pond degree | |

| NZS-1 | Φ1.8m | 2.54 | 5.6 |

| NZS-3 | Φ3.6m | 10.2 | 22.4 |

| NZS-6 | Φ6m | 28.3 | 62 |

| NZSF-6 | Φ6m | 28.3 | 62 |

| NZ-9 | Φ9m | 63.6 | 140 |

| NZS-9 | Φ9m | 63.6 | 140 |

| NZS-12 | Φ12m | 113 | 250 |

| NZ-15 | Φ15m | 176 | 350 |

| NZ-20 | Φ20m | 314 | 960 |

| NZ-30 | Φ30m | 707 | ---- |

| NZS-45 | Φ45m | 1590 | 515 |

| NT-15 | Φ15m | 177 | 390 |

| NQ-18 | Φ18m | 255 | 560 |

| NQ-24 | Φ24m | 452 | 1000 |

| NQ-30 | Φ30m | 707 | 1570 |

| NJ-38 | Φ38m | 1134 | 1600 |

| NT-45 | Φ45m | 1590 | 2400 |

| NTJ-53 | Φ53m | 2202 | 6250 |

| NT-100 | Φ100m | 7846 | 3030 |