Copper ore processing is a complex process that begins with the mining of the ore and ends with a refined form for industry use.

Mined copper ore must first be concentrated to remove gangue or unwanted materials embedded in the ore. It's called ore beneficiation.

Popular copper ore beneficiation methods include gravity separation, froth flotation, magnetic separation and chemical beneficiation.

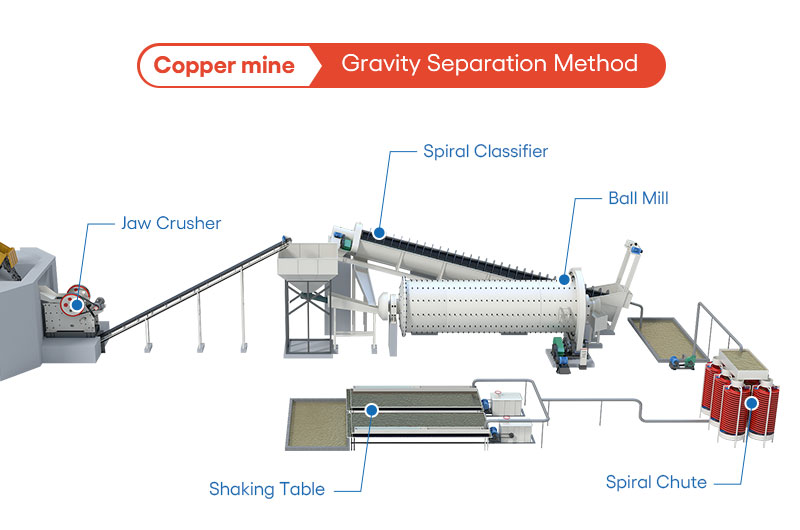

Gravity Separation Method

Applicable copper ores: Copper ore with simple structure and coarse particle size, especially dense copper oxide ore.

Common beneficiation techniques include dense media separation, spiral classifier and shaking table beneficiation.

Copper mine: gravity separation method

Copper Ore Processing Plant in Indonesia: Gravity Separation

Copper oxide ores mined in the copper mine in Indonesia are bulky (0–250 mm) and contain clay. The customer requires the processing output to be 10 TPH and a copper ore recovery rate as high as possible.

Ore processing flow:

- 1 Crushing: Use stone crushers to crush the copper ore to 0–5 mm or 0–9 mm.

- 2 Washing: Use a spiral classifier to wash away the clay and screen out copper ore with a qualified particle size.

- 3 Grinding: The electromagnetic feeder sends the copper ore with qualified particle size to the ball mill for grinding.

- 4 Concentrating: Pump the copper ore slurry to the spiral chute with a slurry pump, and then to the shaking table for rough copper concentrate.

Note: In most cases, the gravity separation can only be used as a coarse concentration method to coarsely concentrate low-grade copper ore by discarding tailings before the flotation process. It cannot be used as a copper separation method for obtaining the final copper concentrates.

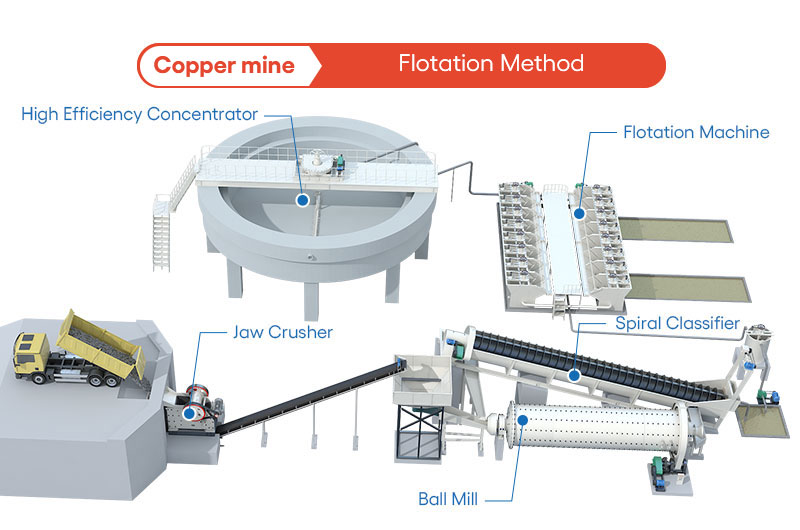

Froth Flotation Method

Froth flotation is the main copper ore separation method.

Applicable copper ores: Copper sulfide ores such as chalcopyrite, bornite and chalcocite, as well as common copper oxide ores such as azurite, etc.

Five common flotation methods: sulphidizing flotation, fatty acid flotation, amine flotation, emulsion flotation and chelating agent—neutral oil flotation.

Froth flotation process

- 1Pump the ore pulp discharged from the ball mill to the agitation tank.

- 2Add flotation agents for rough selection into the tank. After stirring and activation, send it to the flotation machine.

- 3Add collectors, modifiers, and foaming agents into the flotation cell. Useful copper ore particles are enriched in the foam.

- 4The foam is scraped out by the scraper of the flotation machine and sent to the dehydration workshop for dehydration.

Copper Ore Processing Plant in India: Froth Flotation

The copper grade of a copper concentrator in India is 3.27%. The particle size is fine. FTM Machinery has configured a production line for customer based on the characteristics of copper mines.

copper mine: froth flotation method

Ore processing flow:

- 1 Crushing: Crush the copper ores to the proper size with a jaw crusher. Place an impact crusher for further crushing, if necessary.

- 2 Grinding: Feed the crushed copper ores in a ball mill for further grinding until -0.074 mm particle size accounting for 70%. Then, grade ore particles with a spiral classifier and send the non-standard ores back to the ball mill for further grinding.

- 3 Flotation: Put the qualified copper powder (paste) into the agitator. Adopt quicklime as pH modifiers, sodium silicate and sodium humate as gangue inhibitors, Y-89 as the collector and No. 2 oil as the foaming agent. Excellent copper concentrate separation effect can be obtained by flotation in the weakly alkaline medium.

- 4 Dehydration: Obtain the copper concentrate through precipitation in the thickener. Dehydrate and dry the concentrate with a dryer to obtain high-grade copper concentrate powder.

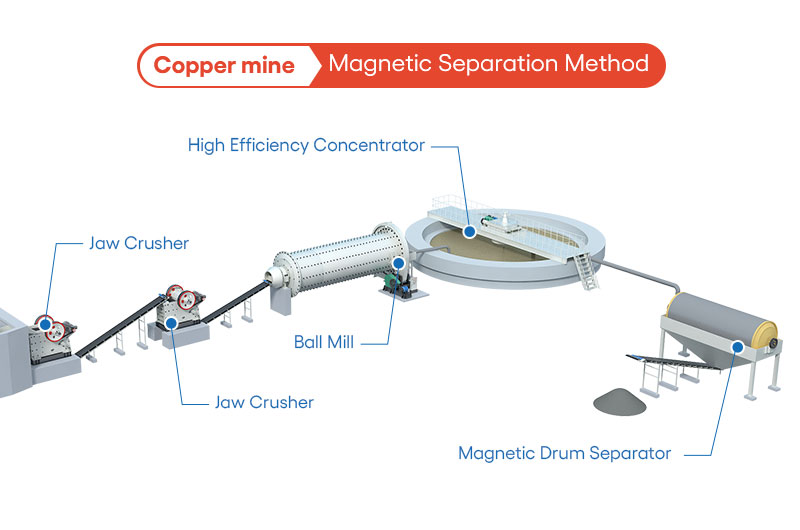

Magnetic Separation

Applicable copper ores: Copper ores containing magnetite.

After coarse and fine crushing, transport the crushed ores to the ball mill before the next step—classification. Send ore powder to concentrator to get rough copper concentrate, and finally transport concentrate to the magnetic separator for rough and fine selection.

Copper mine: magnetic separation method

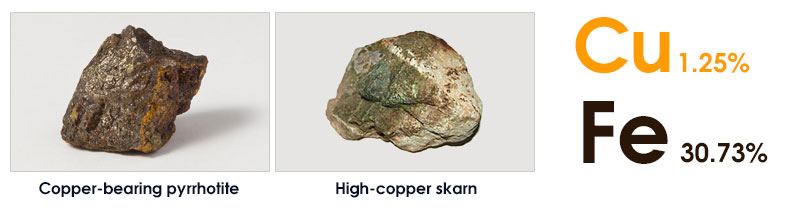

Copper Ore Processing Plant in Zimbabwe: Magnetic Separation

The copper ore of a copper mine in Zimbabwe is mainly copper-bearing pyrrhotite and high-copper skarn ore. The copper grade of the original ore is 1.25%, and its iron grade is 30.73%. The copper minerals in the ore are mainly chalcopyrite, followed by porphyry, and a small amount of chalcocite, covellite, malachite, etc.

The copper ore of a copper mine in Zimbabwe

Ore processing flow:

- 1 The crushing and grinding processes are the same as above.

- 2 Adopt selective flotation of some copper minerals and then Cu-S bulk flotation.

- 3 Separate copper and sulfur from mixed coarse concentrate after grinding.

- 4 Adopt magnetic separation of iron for copper tailings.

Finished products: 20.20% of copper concentrate grade and 93.62% of copper recovery rate. 63.85% of iron concentrate grade and 32.14% of iron recovery rate.

Chemical Processing Method

Applicable copper ores: The ore that copper is difficult to float in the form of chrysocolla, cuprite and copper ore impregnated by iron hydroxide and manganese aluminosilicate or in the form of combined copper.

The selection of chemical processing for refractory copper ores mainly depends on their phase composition, structure and surrounding rock.

- If the gangue is acid rock, and the copper mineral is the secondary copper mineral, the ore can be decomposed by dilute sulfuric acid.

- If the gangue is mainly alkaline rock, copper can be decomposed by the general ammonia leaching method when the copper is present as secondary copper mineral and metallic copper.

- If the ore contains considerable amounts of copper sulphide and native copper in addition to the secondary copper minerals, oxidizing acid leaching (hot pressure oxygen acid leaching, high salt leaching, bacterial leaching) or oxidizing roasting—acid leaching can be adopted to decompose the ore.

- If the copper in the ore is in the form of refractory copper silicate or combined copper, it can be treated by reduction roasting-ammonia leaching or segregation process.

Several chemical methods of copper mine beneficiation

The common chemical processing methods of refractory copper ores can be summarized as follows:

- 1 Leaching—replacement—electrodeposition.

- 2 Leaching—extraction—electrodeposition (LXE method) (including roasting—leaching—extraction—electrodeposition).

- 3 Leaching—precipitation—flotation (LPE method).

- 4 Segregation—flotation.

Copper Ore Processing Plant in South Africa: Chemical Separation

A copper mine in South Africa adopts the process of leaching — extraction — electrodeposition. The plant's copper ore contains oxide ores such as malachite and malachite, and sulphide ores such as chalcocite and bornite.

Ore processing flow:

- 1 Crush the ores to 6 mm.

- 2 Stir the ores with acid for acidification and pile them up into a thin layer of 2m high after a few hours.

- 3 Extract it with solution, using Lix-64N as the extraction agent, before spray washing with the remaining liquid.

- 4 Natural discharge of rich ore-bearing liquid.

- 5 Stack and process tailings.

- 6 Enrichment and recovery of copper by solution extraction — electrolytic operation.

Finished products: The copper recovery rate of oxidized ore is 9–95% and that of sulphide ore is 40–60%.

Outstanding Advantages of FTM Machinery Copper Ore Beneficiation Plant

- Good beneficiation effect and an improved grade of copper concentrate.

- Reasonable production line and high recovery rate of copper.

- Less harmful gas and odor are emitted from the medicament.

- Tailor-made design for customers to improve production efficiency.