The shaking table is a gravity separation machine that uses the combined action of mechanical vibration and water washing to separate granular materials according to density.

In gravity separation, the shaking table (gravity concentrating table) is the most widely used and efficient sorting equipment for fine ore separation.

The shaking table beneficiation can not only be used as an independent beneficiation method, but also is often combined with methods such as jigging, flotation separation, and magnetic separation by the centrifugal concentrator, spiral classifier, spiral chute, and other beneficiation equipment.

What is the shaking table mineral processing?

The shaking table is mainly used to separate and recover gold, iron, manganese,copper, chromium,tungsten, molybdenum, tin, tantalum, niobium, and other rare metal and precious metal ores.

In addition, it can separate coal and purify non-metallic minerals, such as talc, limestone, garnet, and pyrophyllite. Before the flotation separation, it can also be used for processing the nonferrous ores.

The FTM Machinery Shaking Table can be used for roughing, concentration, and sweeping to separate coarse sand (2–0.5 mm), fine sand (0.5–0.074 mm), sludge (within 0.074 mm), and other different particle sizes. It is very effective for selecting fine-grained materials below 1 mm, especially below 0.1 mm.

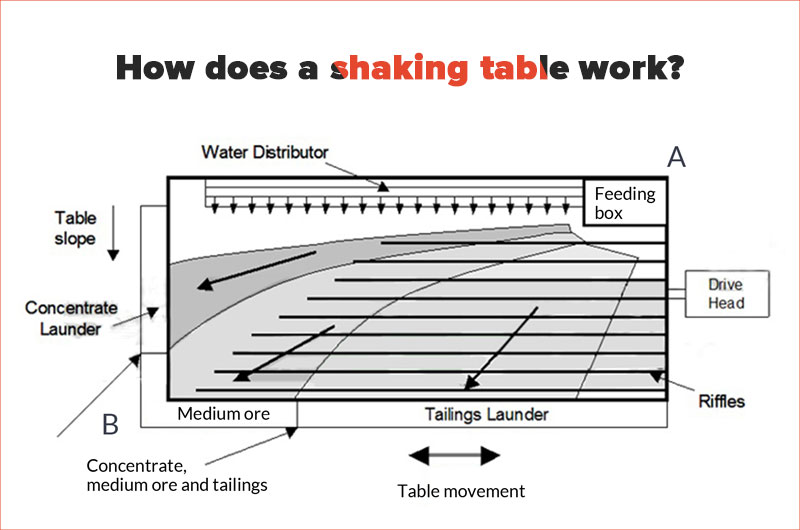

How does a shaking table work?

The beneficiation process of shaking table is carried out on an inclined bed with riveted strips. It looks like a table that vibrates back and forth while separating valuable minerals from waste minerals.

Shaking table mechanism:

The material flows from the feeding chute to the bed surface. Since the groove on the bed surface is longitudinal and perpendicular to the direction of water flow, the ore particles will be loosened and stratified by the action of water and bed surface vibration in the bed strips or grooves.

The light mineral particles in the upper layer are subject to great impact force, and most of them move downwardly along the bed surface to become tailings. Accordingly, this side of the bed surface is called the tailings side.

The heavy mineral particles at the bottom of the bed move longitudinally by differential movement of the bed surface, and are discharged from the opposite of the transmission end to become concentrate. The corresponding position of the bed surface is called the concentrate end.

The horizontal and longitudinal effects of mineral particles of different densities and particle sizes on the bed surface are different. The materials finally spread out in a fan shape on the bed surface, and a variety of products of different quality can be obtained.

The following is a video using the shaking table for goldwire recovery:

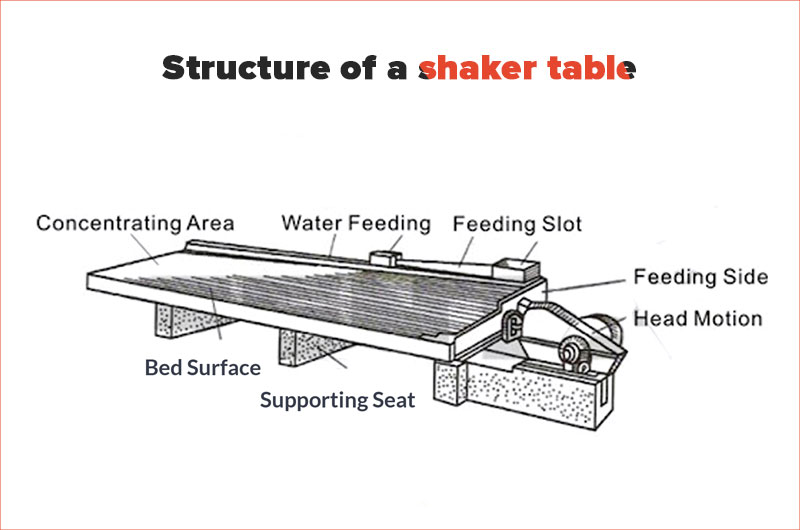

What is the structure of a shaking table?

The basic structure of a shaking table is divided into three parts: the bed surface, the drive head, and the frame or append framework. The longitudinal reciprocating motion of the bed surface is realized through the crank-link transmission mechanism.

1. Bed surface

Unlike other bed surfaces in the market, the FTM Machienry Shaking Table is designed to withstand the harsh conditions of the mining industry. The bed surface is made of polyurethane glass fiber reinforced plastic(FRP)wrapped steel frame. And the working surface is a special wear-resistant layer.

Along the longitudinal direction, there are many parallel bed strips or grooves on the bed surface. FTM Machinery Shaking Table can be divided into three types: rectangular bed bar for coarse sand, trapezoid bed bar for fine sand, and groove bed bar for Sludge.

There is a feeding chute on the upper right of the bed surface, the length of which is about 1/3–1/4 of the total length. There are many small holes on one side of the feeding chute so that the slurry can be evenly distributed on the bed surface.

Connected to the feeding chute is the flushing tank, which accounts for 2/3–3/4 of the total length of the bed surface. Many small holes are made on the side of the tank so that the flushing water can be evenly fed along the longitudinal direction of the bed.

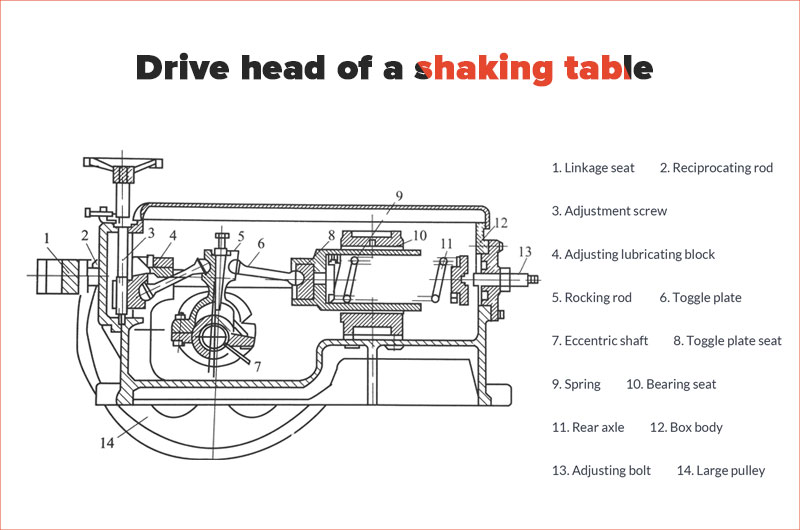

2. Drive head (Driving mechanism)

The drive head of the shaking table is driven by an electric motor and connected with the bed surface by a pull rod to make the bed surface reciprocate asymmetrically along the longitudinal direction.

- When the bed surface advances, its speed changes from slow to fast and then quickly stops.

- When the bed surface retreats, its speed increases rapidly from zero to the maximum and then decreases slowly to zero.

3. Frame or append framework

The supporting mode of the bed surface can be divided into seated type or suspension type.

- The seated type means that the bed surface is directly connected to the bracket, and a slope adjustment device is installed on the bracket to adjust the lateral slope of the bed surface.

- The suspension type refers to hanging the bed surface on the bracket with a wire rope. The bed surface is suspended in the air, and its slope is adjusted by adjusting the tightness of the wire rope.

Unique advantages of FTM Machinery Shaking Tables

The FTM Machinery Shaking Table is a 6-S type shaking table, which has the following unique advantages:

- Separating precisely is its prominent advantage. We can obtain the final concentrate, medium ore, and tailing after the first separation from the raw minerals.

- The enrichment ratio (the ratio of concentrate grade to raw ore grade) is higher than many other mineral processing methods, up to more than 100 times.

- Qualified concentrate and waste tailing can be obtained just by one separation process.

- The ore is fan-shaped on the bed surface for easy observation and adjustment.

- Compared with other vibrating tables in the market, FTM Machinery Shaking Table adopts a big strong channel steel frame (other companies use small channel frames), wear-resistant FRP bed surface, Polypropylene materials feeding chute and collection chute (other companies don’t have), and various grooves on the table.

- It consumes no medicine and little power.

FTM Machinery Shaking Tables for sale

For large and medium-sized gold processing plants, at least one large vibrating table is needed, and its price is at least $500.

For small gold processing plants, a mini shaking table that costs $100 may meet the needs.

FTM Machinery Shaking Table mineral processing plants

1. Shaking Table for gold

A 200 TPH gold ore processing plant in Guinea mainly processes placer gold ore. It mostly exists in the form of particles, containing a small amount of clay. To recover fine gold particles as much as possible, FTM Machinery used the combined equipment of a trommel screen–jig–shaking table.

- 1The raw ore enters the trommel screen to wash a small amount of clay. Then the gold-free gravel or stones are separated and transported away by the belt conveyor.

- 2A jig is used to collect gold particles or gold nuggets with large particles of about 2–20 mm.

- 3Then, the concentrate enters a shaking table. Because the concentrate still has a little sand, using a shaking table can effectively separate sand from the gold.

2. Shaking Table for chromite

The Cr2O3 content in a certain lean chromite ore in Zimbabwe is only 8.19%. FTM Machinery has researched the beneficiation technology and equipment of the lean chromite ore, and finally decided to adopt the beneficiation method: tail discharging by the strong magnetic separation—full-grain separation by shaking table. The indicators are relatively good.

- 1 The first step is to crush and grind the chromite ore by using a jaw crusher, cone crusher, ball mill, and other equipment so that the grinding particle size of -200 mesh reaches 60%.

- 2 Then use the FTM Machinery Magnetic Separator for strong magnetic separation to remove qualified tailing with a yield of 50.21%, and the tailing grade is only 2.19%. As a result, the amount of ore entering the shaking table is reduced by half, and the number of shaking tables is greatly reduced. At the same time, after throwing the tail, it creates favorable conditions for the sorting of the shaking table and further improves the sorting index.

- 3 Then use a shaking table for selection to improve the chromite grade. Finally, the ideal indexes of 39.98% concentrate grade, 13.28% yield, 64.74% chromium recovery, and 4.07% SiO2 content can be obtained.

How to operate a shaking table?

There are several adjustments that need to be dealt with before using the shaking table.

1. Horizontal and longitudinal slope of the bed surface

Make sure that the table slope is enough and the water flow is enough. If the table is placed too steeply or the water spray is too high, the heavier particles will be swept over to the riffles.

| Types | Slope of coarse sand area | Slope of fine sand area | Slope of sludge area | Slope of bead surface |

| Installation of equipment | 1°–2° (lengthways) | 0.5°–1.0° | Basically no | 1.5°–5° (Tilt from the feeding side to the opposite side) |

| In actual operation | 2.5°–4.5° | 1.5°–3.5° | 1°–2° |

2 mm: 3. 5°–4° 0. 5 mm: 2. 5°–3. 5° 0. 1 mm: 2°–2.5° |

2. Feed size

The effective recovery particle size is 2–0.02 mm. The vibrating table with a maximum feed particle size of 2 mm is used for coarse ore, 0.5 mm is used for fine ore, and 0.074 mm is used for slime.

3. The amount of feeding ore

The amount of feeding ore is related to the granularity of the feed. If the ore grains are relatively coarse, the required amount of feeding ore is large. However, if it is too large, it will cause zoning problems. In this case, it is necessary to move the concentrate intercepting plate to increase the flushing water and the horizontal slope of the shaking table surface.

4. Feeding concentration

In general, the feeding concentration of coarse and fine-grained minerals is 20%–30% and 15%–25% respectively.

- When the rushing rapid occurs on the surface of the shaking table bed, the ore concentration can be appropriately increased.

- If there is a sand pile, the ore concentration needs to be reduced.

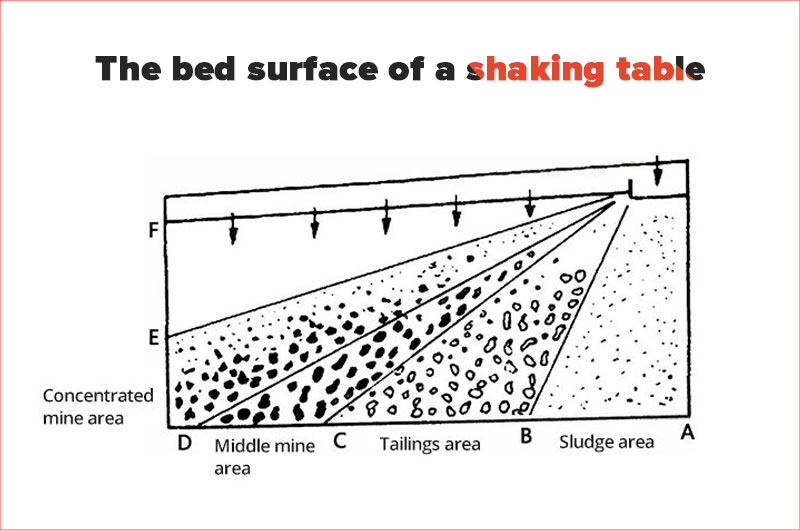

5. Partition of the bed surface of a shaking table

The bed surface is divided into a concentrating area, a middle mine area, a tailings area, and a sludge area.

- The width of the sludge area is generally 0.9–1.4 m.

- The ore flow in the tailings area must be stable without rushing rapids, and the ore bed must be covered by water.

- The middle mining area is to separate the middle mine, which is mainly controlled by adjusting the flushing water and the lateral slope.

- The concentrating area requires obvious zoning of various specific gravity minerals, so a stable and obvious boundary should be formed between the selected area and the primary selection.

6. Flushing water

The flushing water includes feeding water and washing water.

- During the operation of the shaking table, when the concentrated zone becomes narrow and the concentrate runs into the medium ore, the amount of flushing water shall be reduced.

- On the contrary, if the surface of the shaking table shows anhydrous films, it is necessary to increase the amount of flushing water.

7. Stroke and times of stroke

| Materials | Stroke | Times of stroke |

| Coarse grains in thick bed | Large | Small |

| Fine grains in thin bed | Small | Large |

Parameter

| Name | Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

| Bed surface Dimensions |

Length (mm) |

4450 | 4450 | 4450 |

| Driving part Width (mm) |

1855 | 1855 | 1855 | |

| Concentrate part Width (mm) |

1546 | 1546 | 1546 | |

| Max.feeding size(mm) |

2 | 0.5 | 0.15 | |

| Feeding amount (t/d) |

30-60 | 10-20 | 15-25 | |

| Feeding thickness (%) |

25-30 | 20-25 | 15-25 | |

| Stroke (mm) |

16-22 | 11-16 | 8-16 | |

| Frequency (f) |

45-48 | 48-53 | 50-57 | |

| Bed surface Water quantity (t/d) |

80-150 | 30-60 | 10-17 | |

| Bed surface Horizontal obliquity(°) |

2.5-4.5 | 1.5-3.5 | 1-2 | |

| Bed surface Portrait obliquity(%) |

1.4 | 0.92 | ---- | |

| Table board corner(°) |

32-42 | 40 | 42 | |

| Concentrating area(㎡) |

7.6 | 7.6 | 7.6 | |

| Bed surface Length ratio |

2.6 | 2.6 | 2.6 | |

| Shape of side-bed surface |

Rectangle | Zigzag | Triangle | |

| Motor power(kw) |

1.1 | 1.1 | 1.1 | |

| Transmission device |

Eccentricity Linkage | |||

| Name | Max.feeding size(mm) |

Bed surface Water quantity (t/d) |

| Grit concentrator table |

2 | 80-150 |

| Fine sand concentrator table |

0.5 | 30-60 |

| Sludge concentrator table |

0.15 | 10-17 |

Download Shaking Table

2.91 MB

Download Shaking Table

2.91 MB