What is a spiral chute?

A spiral chute, also called mineral spiral separator, is a kind of gravity separation equipment. It makes use of the inertial centrifugal force generated by the ore pulp in the spiral rotation motion to separate light and heavy minerals.

A spiral chute combines the features of a spiral concentrator, vibrating table, and centrifugal concentrator. It is the best equipment for mining and beneficiation, especially for placer mining on seashores, riversides, sand beaches, and streams.

What materials can a spiral chute process?

The spiral chute can be used to separate fine-grained minerals with a difference in specific gravity and a particle size of 0.3–0.02 mm. Applicable materials are gold placer, iron ore, magnetite, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore, tantalum ore, niobium ore, antimony ore, and other non-ferrous metals, rare metals, non-metallic minerals.

Contact an engineer for a mineral test and know about the spiral chute price!

Applications of the spiral chute

The spiral chute is a versatile gravity separation machine that can be used in various application fields.

- Rare and non-ferrous metal sorting

- Recovery of heavy mineral tailings

- Mineral processing plants

- Placer mining and separating

- Aggregate and building materials

- Silicate products

- Cement industry

- Metal recycling plants

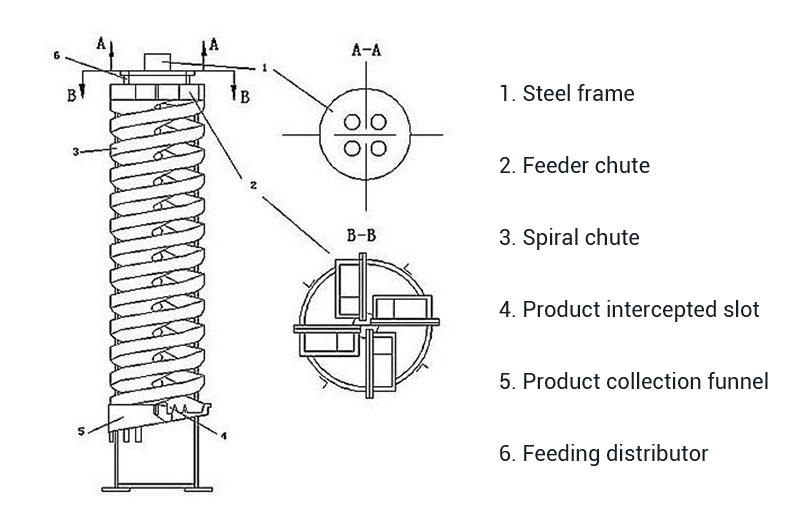

The structure of the spiral chute

The spiral chute parts have a distributor and feed chute in the upper part and a product interceptor and collection chute in the lower part. The entire equipment is framed vertically with steel frames.

The spiral chute is similar to the thread shape. The movement of the materials inside can be divided into three stages: the material introduction stage, the material acceleration stage, and the material uniform velocity warehouse stage. The third stage lasts the longest and is the key to materials crushing.

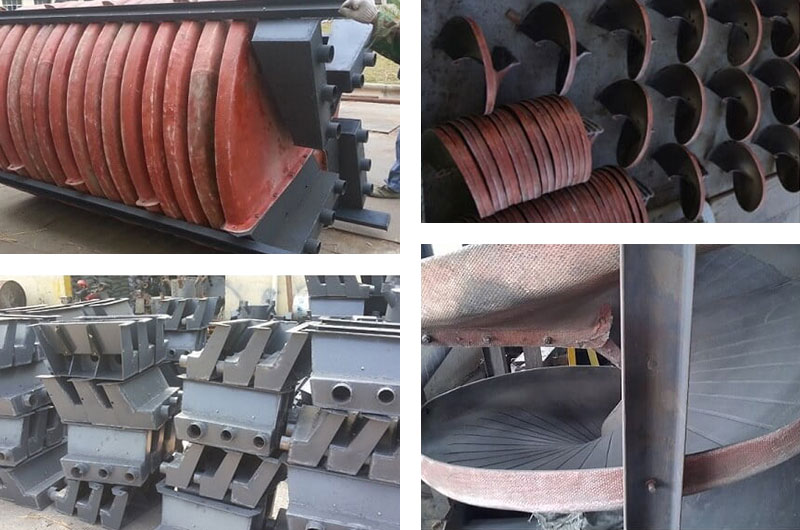

The main part of the spiral chute device is the spiral flight which is made of glass fiber-reinforced plastic. The inner surface of the spiral groove is coated with a wear-resistant lining, usually a polyurethane wear-resistant glue or an epoxy resin mixed with artificial gold steel sand.

How does a spiral chute work?

The working principle of the spiral chute is as follows:

- 1The sand pump sends the ore to the two feed inlets at the upper end of the screw, adding supplemental water to adjust the concentration of the ore pulp.

- 2The ore pulp naturally swirls from high to downward, generating a kind of inertial centrifugal force in the rotating slope.

- 3As the slurry flows down the spiral direction, minerals with high specific gravity move to the inner edge of the spiral while light materials move to the outer edge.

- 4According to the differences in the specific gravity, particle size, and shape of the ore, the ore and sand are separated by the gravity and centrifugal force of the swirling flow.

- 5The concentrates flow into the concentrate bucket. The tailings flow into the tailing bucket and then they are discharged with the sand pump, completing the process of dressing.

Why choose FTM Machinery spiral chutes?

Due to the many advantages of FTM Machinery spiral chutes, they are commonly used in the beneficiation process.

- Large processing capacity. Spiral chutes can handle large volumes of materials, making them ideal for use in industrial-scale beneficiation operations.

- High efficiency. Spiral chutes can achieve a high enrichment ratio, high separation efficiency, and high recovery rate.

- Small floor space. They are compact and take up small footprints, making them ideal for use in plants where space is limited.

- Strong adaptability. They readily accommodate fluctuations in ore content and concentration, particle size, and grade.

- Good quality. Spiral chutes are light in weight, noiseless, moisture-proof, rust-proof, and corrosion-resistant.

- Chute materials are varied. There are 3 kinds of chutes to choose from glass steel chute, wear-resistant rubber liner, and polyurethane rubber liner.

- Low operating cost. They are simple to install, easy to operate, and require less maintenance, making them a cost-effective option.

FTM Machinery supplier timely follows up on product installation and maintenance. In the fierce market competition, relying on leading technical advantages, excellent product quality, and perfect after-sales service, products are exported to more than 200 countries and areas.

Customer case: Gold mine beneficiation in Indonesian

The gold content in the gold deposit is extremely low, and it is usually necessary to use refining by gravity separation, flotation, magnetic separation, and electro-selection. At the same time, high-efficiency and energy-saving gold ore beneficiation equipment are arranged for beneficiation and enrichment.

In March 2021, a customer of a gold mine in Indonesia wanted to import spiral chutes and supporting equipment. After many comparisons, the user finally chose FTM Machinery.

FTM Machinery engineers quickly equipped users with a complete set of gold beneficiation equipment.

| Beneficiation stage | Equipment |

| Crushing process | Jaw Crusher |

| Ore washing and screening | Trommel screen |

| Gravity separation | Spiral chute |

| Magnetic separation | Magnetic separator |

So far, the set of equipment has been running stably, which has brought considerable benefits to users. Because of its high quality and low price, reliable after-sales service, and simple installation, FTM Machinery has attracted more customers.

Frequently asked questions about spiral chutes

1. How to control the volume of ore feeding?

- The feed volume of the spiral chute is the most important parameter. The volume of ore feeding can change the distribution characteristics of minerals along the width of the spiral groove.

- To control stability, the allowable fluctuation range should be less than ±5%. The ore feeding volume of LL900 is 1.2–1.8 cubic meters per hour, and that of LL1200 is 2.5–3.5 cubic meters per hour.

2. How to control the concentration of ore feeding?

- The ore concentration of the spiral chute is another influencing parameter. The material must move in a spiral trajectory from top to bottom, so the concentration of the ore must be controlled.

- The ore concentration is generally controlled between 15–35%. Exceeding this range will reduce the flow velocity of the pulp. Otherwise, it will speed up the flow velocity, which is not conducive to ore dressing, and the particle size of the finished product cannot meet the requirements.

3. Does the spiral chute cause material buildup?

- During operation, often check whether there is accumulation on the spiral groove, and clean up the accumulation in time. Rinse the surface of the tank with water once every shift to remove debris accumulated on the tank surface and ensure the normal flow of ore flow.

Parameter

| Model | Processing capacity (t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

| Model | Processing capacity (t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |