Gold has always been one of the most popular metals in the world. The crazy gold rush makes it sought after by various gold mining companies, mineral experts, and amateur gold prospectors.

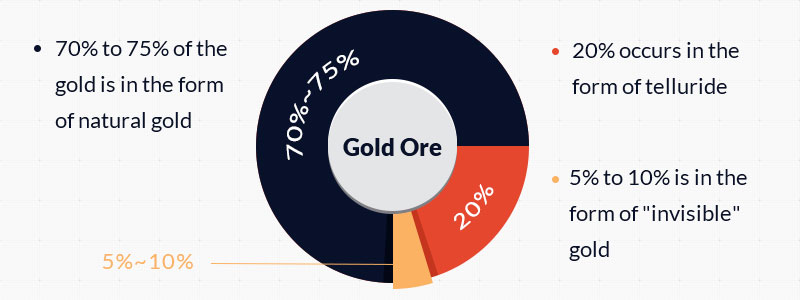

About 70%–75% of the gold deposits are natural gold, and 20% are Au-Ag telluride. The remaining 5%–10% is "invisible" gold ore, symbiotic in quartz ore, silver ore, pyrite, pyrrhotite, sphalerite, gangue, arsenopyrite, gangue, and other minerals.

Below, we'll explore the eight major types of gold ores and then discuss the main beneficiation methods used to extract gold from them.

Eight types of gold ores

In South Africa, Witwatersrand Basin has the world's largest placer gold deposit. Brazil's gold ores exist with diamonds. In Australia, gold is present wherever pyrites can be found.

Once you understand what type of gold ore you have, choosing the right beneficiation method becomes simple—and your recovery rate can instantly jump to 85–95%.

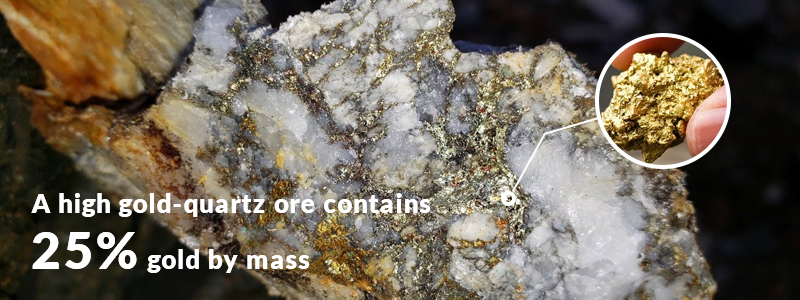

1. Quartz gold ore

Gold has long been found in the fractures and cracks of quartz stone and can occur in large veins during hard rock mining. Gold from quartz veins is one of the rarest natural gold.

Quartz appears as small stones in large cracks in riverbeds or mountain slopes and has crystals in different colors such as white, yellow, pink, purple, gray, or black. The most common types of gold quartz ore are rose quartz gold ore and rainbow gold ore.

2. Silver-gold ore

Gold silver ore is rich in silver sulfide and free gold. High-grade silver ore usually has a much lower base metal content. Volcanic activity accompanied by plate subduction will form superheated gold and silver deposits.

For example, most superheated gold and silver deposits in Japan form through the precipitation of gold from fountains.

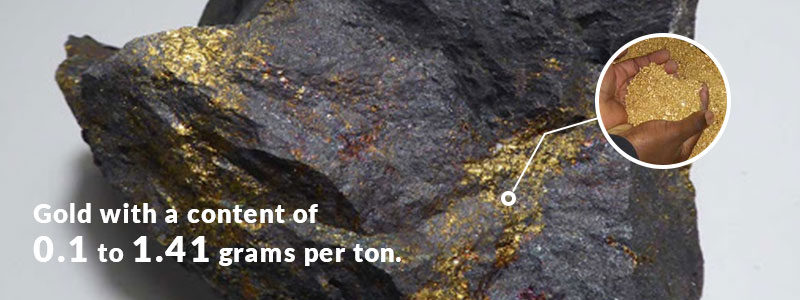

3. Iron oxide copper gold ore

Iron oxide copper gold ore refers to the symbiosis of copper ore and gold ore in gold ore in some form. Its amount is about 10 million to 4 billion tons. IOCG ore contains copper with a grade of 0.2% to 5% and gold with a content of 0.1 to 1.41 grams per ton.

Iron oxide copper gold ore tends to be conical on the edge of granite or appears as long banded breccia or massive iron oxide ore in faults or shears.

4. Gold sulfide ore

Gold sulfide ore is a rock gold ore with a chemical formula of Au2S. Gold sulfide ore contains fine gold locked inside pyrite or other sulfides. It does not release gold easily, making it one of the more complex gold ores.

5. Blue clay gold ore

Blue clay deposits are famous for containing placer-type free gold. Blue clay gold ore generally contains a small amount of quartz, a large amount of gold, and a lot of black sand.

So If you find blue clay contains a lot of black sand, this may be a very good sign that gold is also nearby. Alluvial gold is mostly found in blue clay and is in clay-laden gravel or between thin layers of rock.

6. Tellurium gold ore

Tellurite has high economic value and is the most important in metallurgy. Tellurium–gold deposits differ from normal gold mineralization in their significant content of tellurium‐bearing minerals with a close relation between Au and Te.

Gold-bearing minerals containing tellurium are called "tellurides". Tellurides contain calaverite, mayenite (AuTe2), potash-zinc ore (AuAgTe4), and green feldspar. They often appear in Australia's Kalgoorlie and America's California and Colorado.

7. Gold in arsenopyrite

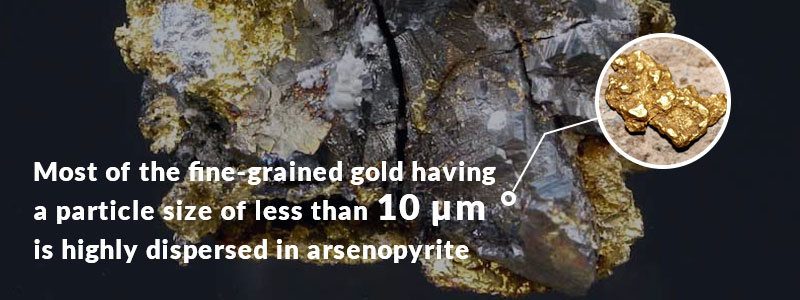

Arsenopyrite is also the main gold-bearing mineral, which is closely related to gold. Arsenopyrite often hosts ultra-fine "invisible" gold (<10 μm), locked in its crystal structure.

When the arsenopyrite ore is crushed and ground, it occurs that the pores of the ore have been cracked and the gold has been dissociated.

8. Granite gold ore

Granite and other plutonic rocks may contain scattered fine gold. These rocks form many of the world's long-lived hard-rock gold deposits.

Granite-hosted gold deposits are found in several major gold belts worldwide, including the well-known Kalgoorlie and Boddington mines in Australia, where gold occurs in quartz veins and disseminated zones around granitic intrusions.

How to process different types of gold ore?

Each year, hundreds of mine owners contact us because their recovery remains stuck at 50–70%, simply due to using the wrong process for their ore type.

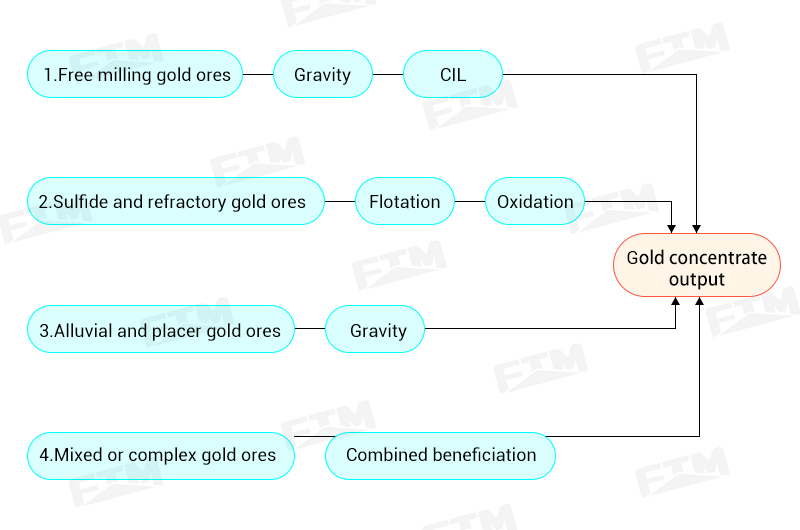

Below are the four major processing routes, designed for different gold ores. Get a free consultation

1. Free-milling gold ores

(Quartz gold, granite gold, part of silver–gold ores)

Free-milling ores are the easiest to process. They contain coarse visible gold that can be liberated simply by using a gold ore crusher and a gold ore ball mill.

Why they are easy:

- Gold is not locked in sulfides

- Very little association with copper or arsenic

- Respond well to simple gravity + cyanidation

Best processing methods:

- 1 Gravity separation (shaking table, jig) → recovers coarse gold

- 2 Cyanidation / CIL → recovers remaining fine particles

Free-milling ores can typically reach 90–98% recovery with a simple flowsheet. Get your process plan

2. Sulfide and refractory gold ores

(Gold sulfide, arsenopyrite gold, telluride gold, IOCG copper–gold ores)

Here, gold is locked inside sulfides, tellurides, or copper minerals. Simple cyanidation will not dissolve the gold—often resulting in <40% recovery.

Correct processing route:

- 1 A flotation plant is used to concentrate sulfides and enrich gold.

- 2 Roasting, pressure oxidation, or bio-oxidation is applied to break the sulfide structure and expose gold.

- 3 CIP or CIL cyanidation recovers gold from the oxidized concentrate.

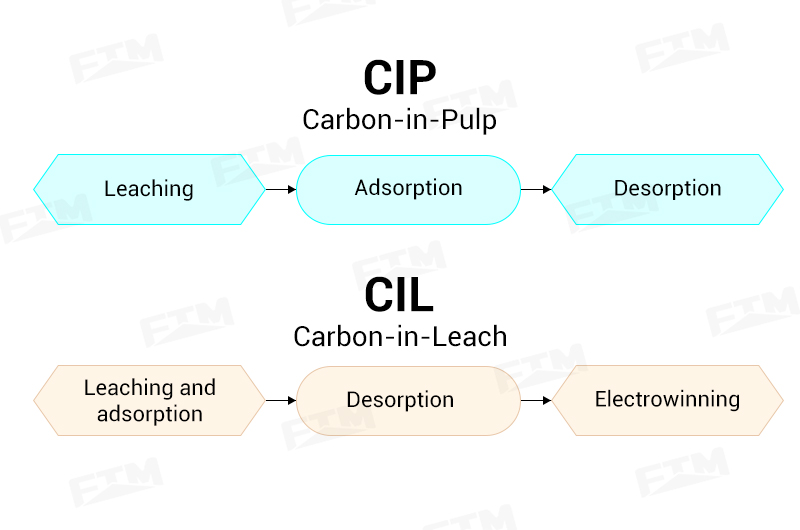

About CIP vs CIL

- CIP (Carbon-in-Pulp): leaching and adsorption occur in separate tanks → more control, high recovery

- CIL (Carbon-in-Leach): leaching + adsorption happen together → simpler, lower cost

This route is essential for increasing recovery from refractory gold ores. Get your process plan

3. Mixed or complex gold ores

(Silver–gold ores, copper–gold ores, multi-metal ores)

Many modern gold deposits contain multiple gold-bearing minerals — a mixture of free gold, sulfides, and other metal oxides.

For example, silver–gold ore and copper–gold ore often require a combination of different methods to maximize recovery.

The general approach is combined beneficiation:

- 1 Recover free gold first through gravity separation..

- 2 Use flotation machines to extract sulfide-associated gold.

- 3 Apply CIL or CIP to treat the remaining tailings and capture fine or refractory gold.

This flexible process combination helps balance recovery efficiency and operating cost, especially for low-grade or polymetallic ores. Get your process plan

4. Alluvial and placer gold ores

(Blue clay gold, riverbed and gravel gold)

Alluvial or placer deposits usually consist of sand, gravel, and clay containing free gold particles.

Why they are easy:

- No need for crushing

- Gold occurs as native particles

- No chemical leaching required

Gold can be separated by washing, sluicing, or gravity concentration. For fine alluvial gold, shaking tables or centrifugal concentrators are often used to achieve high recovery.

Because these ores are surface deposits, they are ideal for small-scale gold processing plants. Get your process plan

80–100 TPH gold processing line in Tanzania

A mine in Tanzania was working with a mixed oxidized–sulfide gold ore averaging 3.2 g/t. Their original gravity-only setup recovered less than 40% of the gold, mainly because most of the metal was locked inside sulfide minerals.

After mineral testing, the plant upgraded to a combined flotation + CIL flowsheet.

Process used: Crushing → Grinding → Flotation → Pressure oxidation → CIL → Desorption & smelting

Once the line was running, throughput reached 80–100 TPH and overall recovery increased to about 92%. The key improvement came from releasing refractory gold that gravity separation alone could never recover.

Get more gold out of every ton!

Share your gold ore type and hourly throughput and get a free process design within 24 hours.

Lower your cost per ton with our gold processing equipment! Contact us