What is a trommel screen?

A trommel Screen, also known as a rotary drum screen or trommel screener, is a self-cleaning screening machine that separates materials by size.

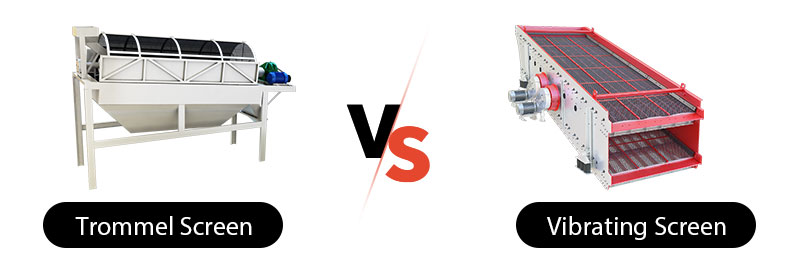

Compared with vibrating screens, trommel screens can avoid clogging and obtain high output even with dust and sticky materials.

The trommel screen is often used in conjunction with mineral processing equipment such as crushers and ball mills. It can be used in these industries:

- Stone quarry (such as granite): Used for grading large and small stones and separating soil and stone powder

- Sand and gravel field (such as quartz sand): Used for sand and gravel separation

- Coal industry (such as coal gangue): Used for separating lump coal and coal powder and washing coal

- Chemical and mineral processing industries: Used for grading large and small lumps and separating powdery materials

Trommel screens for sale

FTM Machinery, as one of the world's leading manufacturers of trommel screens, has developed a series of trommels with different input and output sizes, outputs, and mesh sizes. Choose the right trommel screen to achieve maximum screening efficiency.

Feed size and output size

The input material of the trommel screen should not be too large. It can generally screen materials with a particle size of 50–150 mm. The undersize product is less than 100 mm, with the finest reaching below 3 mm.

Capacity and screening hole

The production output of the trommel is closely related to the size of the screening holes. FTM Machinery provides different screen hole options. We can also customize it according to your needs.

- When choosing a 2 mm screening hole, the output is 12–35 t/h.

- If larger screening holes of 30 mm are selected, the output can reach 175 t/h, meeting the needs of large-scale production.

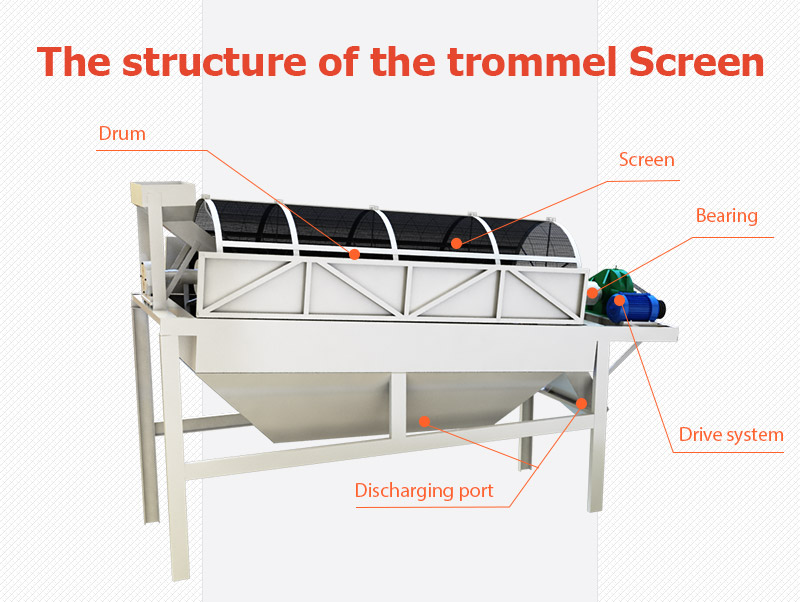

The structure of FTM Machinery Trommel Screen

The trommel screen is larger and is a cylinder with holes installed on the frame at an angle. The inclination angle is between 5–30°, close to 30° for light and fine materials, less than 20° for heavier materials, and can be reduced to 5-10° under special circumstances.

The main wearing parts of the trommel screen include the drum, screen, drive system, bearing, and discharging port.

1. Drum

The drum is the main component of the trommel screen and is made of steel. It is a cylindrical structure that rotates around its axis and is inclined at an angle to allow materials to tumble inside.

The trommel device must be equipped with a steel ring to prevent the deformation of the trommel screen.

2. Screen

The screen is installed inside the trommel machine and is mostly made of stainless steel. The raw materials are non-adhesive, and easy to clean, and there are no sanitary dead corners.

The size of the openings in the screen can be customized to suit the specific application and desired output size.

The screen of the trommel can be divided into the woven type and punched one with one or two layers.

| Types | Advantages | Disadvantages | Applicable materials |

| Punched plate (circular hole) |

1. Durable and widely used. 2. For materials with higher hygiene or special requirements, 304 stainless steel/carbon steel can be selected. |

Small effective area and lowest screening efficiency | 5 mm |

| Woven screen (square hole) | Middle screening efficiency |

1. Once the material is too heavy, the screen will be deformed and leakage. 2. Complex production and high cost. 3. Once damaged, it is difficult to reinforce. 4. Oblong holes are easy to make long strips and flake materials pass through, resulting in uneven product size. |

Relatively light bulk materials |

| Woven screen (oblong hole) |

1. The largest effective area and the highest screening efficiency. 2. The screen holes are not easy to be blocked. |

Relatively light plate materials |

3. Drive system

The drive system is used to rotate the drum and is powered by the motor and reducer, which drives the drum to rotate through the bearings.

The material passes through the screen from high to low due to the rotation of the drum and is successfully screened out.

The tension of the belt will loosen the screw between the reducer and the motor. You should always check the tightness of the bolt and the belt to avoid belt slip.

4. Bearing

The bearing bears the full load of the trommel machine.

Good lubrication has a great relationship with the bearing life, directly affecting the service life and operation rate of the machine.

| Types | Advantages | Disadvantages | Materials |

| Punched plate (circular hole) |

1. Durable and widely used. 2. For materials with higher hygiene or special requirements, 304 stainless steel/carbon steel can be selected. |

Small effective area and lowest screening efficiency | 5 mm |

| Woven screen (square hole) | Middle screening efficiency |

1. Once the material is too heavy, the screen will be deformed and leakage. 2. Complex production and high cost. 3. Once damaged, it is difficult to reinforce. 4. Oblong holes are easy to make long strips and flake materials pass through, resulting in uneven product size. |

Relatively light bulk materials |

| Woven screen (oblong hole) |

1. The largest effective area and the highest screening efficiency. 2. The screen holes are not easy to be blocked. |

Relatively light plate materials |

5. Discharging port

The discharge chute is located at the end of the drum and is used to discharge screened materials onto a conveyor or into a container.

The discharging port is often blocked, so its angle should be as perpendicular to the ground as possible. Its diameter should be larger to facilitate the discharge of materials.

How does a trommel screen work?

The trommel screen rolls on its own to move the material from high to bottom through the screen to complete the screening.

When the drum rotates, materials are fed into the drum. Qualified materials (undersize products) pass downward through the opening of the screen, while unqualified materials (oversize products) are discharged at the end.

Why FTM Machinery Trommel Screens?

- The first choice for screening light, moist, and sticky materials (topsoil, quartz sand, white ash, etc.).

- The unit screening capacity of the cylinder is larger than that of screening equipment of the same size.

- Equipped with sand blasting and cleaning devices to efficiently screen and clean materials to prevent screen clogging.

- Feeding methods, such as belts and funnels, can be freely designed according to the site.

- The equipment does not vibrate during operation, and the sealed isolation cover prevents dust from escaping.

- The motor has low energy consumption, large processing capacity, and the running time is half of other screen types.

- The box frame structure is designed to require only a flat surface for easy installation, disassembly, or transportation.

Customer case—Quartz sand trommel screening plant in India

| Project | Quartz sand production line |

| Processed materials | Quartz and feldspar |

| Production output | 10–280 t/h |

| Grade of concentrate | 63% |

| Required equipment | Trommel screen, jaw crusher, ceramic ball mill, spiral classifier, magnetic separator (3 sets), and concentrator |

The production uses a two-stage grinding process and an effective trommel screen to reduce ore sludge, improve grinding efficiency, increase output, and achieve the desired fineness.

Use 3 magnetic separators for separation: One for initial separation, another for rough concentration, and a third for final concentration to achieve a concentrate grade exceeding 63%.

Advantages of using trommel screen in quartz sand screening production line:

The trommel screen is more effective than the linear sieve for quartz sand magnetic separation. It effectively separates mineral particles by size as they roll, making it ideal for handling mineral powder, while the linear sieve sways or jumps forward, making it less suitable for this purpose.

Frequently asked questions about the trommel screens

1. Notes for the operation of trommel screens

-

- Installation and debugging

- a. The deviation of the machine in the horizontal range should be less than 2 mm per meter.

- b. When the equipment is stopped for more than 30 days and restarted, the motor insulation should be shaken to prevent the motor from burning.

- c. It should be determined whether the trommel screen is flexible by manual turning. If it is not, it can be adjusted by adjusting bolts.

- In operation

- a. After the machine runs for 8 hours, the bearing temperature should be below 70 degrees Celsius.

- b. Check every hour for the particle size of the discharged material, leakage, and dust.

- c. Make sure that all materials in the trommel screen have been screened before downtime.

- d. After the downtime, check the whole equipment. If any abnormality is found, it needs to be dealt with immediately.

- Downtime

- a. The trommel screen must be started without any load.

- b. After the power is turned on and the device is running normally, feed materials evenly to the feeding inlet until full load.

2. How do I choose the right mesh size for my trommel screen?

- Appropriate mesh size is crucial to achieve the desired separation or screening efficiency.

- a. Understand your application: Determine the type of material you will be screening. The characteristics of the material, such as size, moisture content, and density, will impact your mesh selection.

- b. Define your desired output: Specify your desired output by considering the particle size for separation or retention, which will guide you in selecting the appropriate mesh size range.

- c. Consider trommel drum design: Trommel screener design, length, and diameter impact screening efficiency. Therefore, match the drum size with your mesh choice.

- d. Fine-tuning: After selecting a mesh size, you can adjust the trommel screen's operating parameters, such as drum speed and incline angle, to optimize screening efficiency.

- e. Consult with experts: If you're unsure about the appropriate mesh size, consult with FTM Machinery's engineers. They can provide valuable insights based on your specific needs.

3. Trommel screen or vibrating screen, which one is better?

- Appropriate mesh size is crucial to achieve the desired separation or screening efficiency. The selection of screening equipment should be based on materials and output.

-

- a. Materials: The trommel screen excels with dusty, small, sticky, and wet materials, while the vibrating screen is ideal for dry materials with lots of stones and larger pieces.

- b. Output: The trommel screen is ideal for large production lines due to its high output and durability. Linear screens are best for fine-sized materials but have a lower output. Circular screens are perfect for medium to large production lines with high output.

Parameter

| Model | Capacity(t/h) | Power (kw) |

|

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 12 | 50 | 4 |

| YTS1240 | 14 | 60 | 4 |

| YTS1250 | 15 | 70 | 5.5 |

| YTS1530 | 18 | 75 | 5.5 |

| YTS1540 | 18 | 75 | 5.5 |

| YTS1550 | 20 | 80 | 7.5 |

| YTS1560 | 22 | 100 | 7.5 |

| YTS2040 | 25 | 120 | 11 |

| YTS2050 | 30 | 150 | 11 |

| YTS2060 | 35 | 175 | 11 |

| Model | Capacity(t/h) | Power (kw) |

|

| Sieve hole(2mm) | Sieve hole(30mm) | ||

| YTS1230 | 12 | 50 | 4 |

| YTS1240 | 14 | 60 | 4 |

| YTS1250 | 15 | 70 | 5.5 |

| YTS1530 | 18 | 75 | 5.5 |

| YTS1540 | 18 | 75 | 5.5 |

| YTS1550 | 20 | 80 | 7.5 |

| YTS1560 | 22 | 100 | 7.5 |

| YTS2040 | 25 | 120 | 11 |

| YTS2050 | 30 | 150 | 11 |

| YTS2060 | 35 | 175 | 11 |