Garnet is the name of a group of iron aluminum silicate minerals. Only a few types of garnets have gemstone quality, and most garnets are used as industrial abrasives for grinding and polishing.

Almandite is the main industrial abrasive because of its high specific gravity and hardness. Spessartite and Pyrope are also used as industrial garnet abrasives.

Garnet mining

Garnets are relatively durable minerals. They are often concentrated in soils and sediments that form when garnet-containing rocks are weathered and eroded. These alluvial garnets are the mining target as they are easy to mine by mechanical processing.

For example, at the Emerald Creek mine in Idaho, the garnet mineral is recovered from stream gravels from slots cut by backhoes.

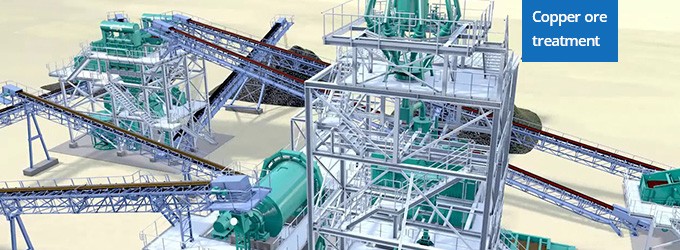

Garnet processing plant

By processing into particles, garnet can be used as industrial abrasives.

How to process garnet? First of all, please do the mineral testing to learn more about the properties of garnet.

There are two main states of garnet:- Embedded in the rock, which means that garnet and its accompanying gangue coexist.

- Distributed in placer and completely dissociated from the sand.

1. How to process garnet rock mine?

Garnet rock mine has a low dissociation degree of monomers. Therefore, the combined beneficiation methods (magnetic separation, gravity separation, and flotation separation) are required.

Note that gravity separation is used for coarse-grained garnets. Magnetic separation is used for separating medium and fine-grained garnets. Flotation separation produces the highest-grade garnets.

- Crushing process

- Screening process

- Grinding process

- Gravity separation

- Magnetic separation

- Flotation separation

- Drying process

First, the large garnet rock is crushed by a jaw crusher to reduce mineral particle size. Then, it enters an impact crusher for fine crushing.

Get the latest product price

The finely crushed garnet is screened by a circular vibrating screen. If the size of the material meets the requirements, it will enter the grinding process.

Get the latest product price

Garnet is further ground using a ball mill until the monomers dissociated. The output size can reach 0.074 mm or 325 mesh.

Get the latest product price

Use a jig to remove low-density minerals, such as feldspar, mica, amphibole, pyroxene, and quartz.

Get the latest product price

Use a strong magnetic separator to recover the magnetic garnet particles and remove a small amount of feldspar, quartz, sillimanite, etc.

Get the latest product price

Use a flotation machine to separate quartz, sericite, scheelite, and sillimanite. By using cationic and anionic collectors, flocculants, slime inhibitors, and dispersants, we can maximize garnet grade and recovery. The flotation water circulation system is also improved.

Get the latest product price

The concentrate is then dried by a dryer and sorted. The particles are screened into various market sizes and packaged for distribution.

Get the latest product price

2. How to process garnet placer?

The garnet placer has low grade and large particles. Therefore, it cannot be processed in a conventional manner.

- Washing process

- Screening process

- Gravity beneficiation

- Final products

Garnet needs to be washed first by a trommel screen because most of the placer contains more soil impurities. It is difficult to distinguish between garnet and waste rock.

Get the latest product price

After washing, garnet presents a colorful and smooth color, then large-grained garnets are selected by manual selection. You can also use a vibrating screen.

Get the latest product price

The fine-grained garnets are recovered by a jig. The recyclable particle size is 0-30 mm. This ensures the integrity of crystal particles and improves the beneficiation efficiency.

Get the latest product price

Finally, garnets are sent to factories for final processing and packaging.

Get the latest product price

Industrial Uses of Garnet Abrasives

Garnets is the heaviest and hardest abrasive that can withstand the highest cutting speed and keep dust low. Its crystalline shape provides fast cutting action and long life.

Garnet sandpaper is the original application, which is widely used in woodworking shops. It is also used in abrasive belts, wheels and belts, and similar products. In America, New York and Idaho are important sources of garnet abrasives.

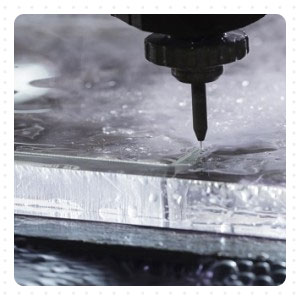

Garnet abrasive blasting aims to smooth or remove oxidation products from materials such as metal, brick, and stone, without damaging the surface. It is much faster than sanding by hand or a sander and can clean small and intricate surfaces.

Garnet abrasives are also used for waterjet cutting. It can cut metals, ceramics, or stones at a low temperature. Manufacturing and mining industries use it for rock excavation, drilling, and demolition of concrete construction.