Rotary dryers are powerful industrial drying machines designed for processing bulk solids. Known for their large processing capacity, durability, and adaptability, rotary drying machines are the ideal choice across industries including fertilizer production, mining, construction, and biomass processing.

Whether you need to dry your fertilizer for effective granulation, dry sand for better quality, dry limestone for higher grinding efficiency, or reduce the moisture content of biomass raw materials for easier briquetting, FTM Machinery Rotary Dryer is your choice for all.

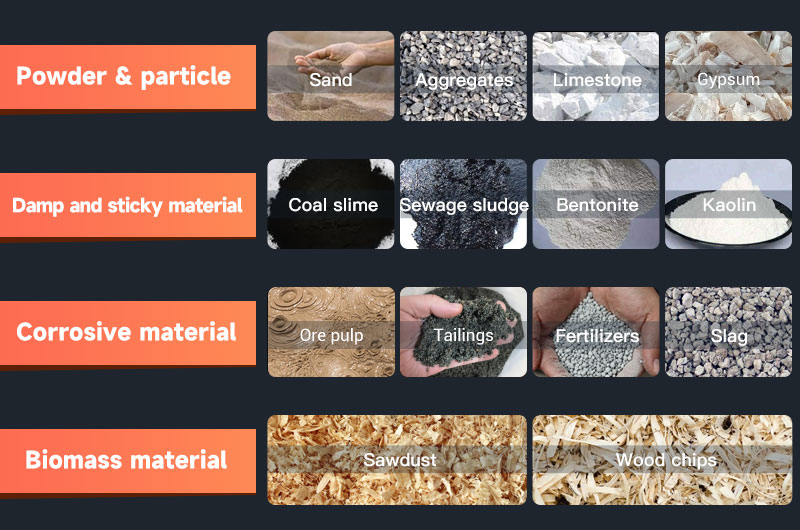

What materials can be dried with a rotary dryer?

- Powder and particles: wet sand, M sand, silica sand, aggregates, limestone, raw coal, coal gangue, fly ash, coke, iron ore, gold ore, gypsum, dolomite, phosphate rock, mica, mineral filter cake, cement, etc.

- Damp and sticky materials: coal slime, coal slurry, coal slag, slag mud, sewage sludge, industrial sludge, domestic sludge, urban sludge, river sludge, chemical plant sludge, clay, bentonite, kaolin, activated clay, porcelain clay, etc.

- Corrosive materials: organic fertilizer, compound fertilizer, potash fertilizer, phosphate fertilizer, ore pulp, slag, steel slag, tailings, barium chloride, ammonium nitrate, etc.

- Biomass materials: sawdust, wood chips.

Rotary dryers for sale

FTM Machinery rotary dryers are available in direct and indirect configurations to suit different material types and industrial applications.

Direct rotary dryer

A direct rotary dryer dries material through direct contact with hot gases. This method is efficient for bulk drying of non-sensitive materials.

Features:

- Ideal for non-sensitive materials, such as coal, sand, limestone, clay, wood chips, sludge, etc

- Commonly used in fertilizer, mining, chemical, and agricultural industries

- Offers higher thermal efficiency and greater adaptability to various material types

- Suitable for large-scale, high-capacity drying perations

Best-selling models and parameters:

| Spec./m (Dia.×Length) | Shell Cubage (m³) | Capacity (t/h) | Highest Inlet Air Temperature (℃) |

| Φ1.2×8.0 | 9.0 | 1.9–2.4 | 700–800 |

| Φ1.5×15 | 26.5 | 5.7–7.1 | 700–800 |

| Φ2.2×12 | 45.6 | 9.7–12.2 | 700–800 |

| Φ2.4×14 | 63.3 | 13.5–16.9 | 700–800 |

| Φ2.4×22 | 99.5 | 21.2–26.5 | 700–800 |

| Φ3.0×25 | 176.6 | 37.7–47.1 | 700–800 |

| Φ3.6×28 | 285 | 60.8–76.0 | 700–800 |

Indirect rotary dryer

Indirect dryers transfer heat through the drum shell without direct contact between hot air and material, making them suitable for temperature-sensitive or hazardous materials.

Features:

- No direct exposure to exhaust gases

- Perfect for hazardous, combustible, or temperature-sensitive materials

- Commonly used for drying pulp, grains, pigments, and other fine or volatile substances

- Ensures product purity and prevents contamination

Best-selling models and parameters:

| Shell Diameter×Shell Length Items | Shell Length (m) | Shell cubage (m³) | Highest Inlet Air Temperature (℃) |

| Φ1.5×15m | 15 | 20.27 | 850 |

| Φ1.5×19m | 19 | 25.68 | 850 |

| Φ1.8×21m | 21 | 35.91 | 850 |

| Φ1.8×25m | 25 | 42.75 | 850 |

| Φ2.2×21m | 21 | 58.10 | 850 |

| Φ2.2×25m | 25 | 69.15 | 850 |

Design and features of FTM Machinery rotary dryers

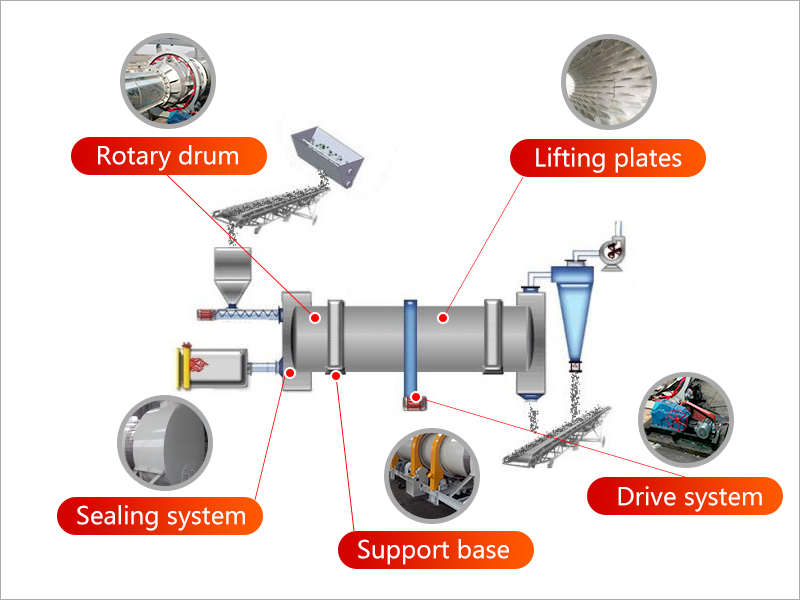

Structure and parts of rotary dryer

The rotary dryer has a simple structure, is easy to install and operate, has a low failure rate, and is easy to maintain.

It consists of a horizontal alloy steel rotary drum, lifting plates, drive system, support base, and sealing system. A dust collector and energy-efficient exhaust are equipped to minimize heat loss and prevent dust dispersion.

The rotary dryer working principle is based on the constant agitation of the material inside a heated rotating drum. Hot air flows through the drum, making full contact with the material, evaporating moisture and maintaining material quality when necessary.

The slightly inclined drum uses gravity to move minerals while rotating lifting plates lift and spread them for better heat contact. This motion breaks up clumps, ensuring uniform drying and a consistent particle size with a smoother surface.

Features and advantages of rotary dryers

As one of the leading rotary dryer manufacturers in China, FTM Machinery delivers industrial dryers that stand out for the following features:

1. Robust design

Industrial materials like ore, coal, fertilizer, and sludge require robust equipment. The drying drum and internal lifting device are made of 10 mm thick 20g boiler-grade wear-resistant manganese steel, extending the service life by 3–4 times and lowering maintenance costs.

The sealed system effectively prevents heat loss and dust flying, and is equipped with a dust collector and environmentally friendly and energy-saving heating and exhaust systems.

2. High processing capacity

FTM Machinery rotary dryers are designed for heavy duty applications, handling large volumes of sticky materials without sticking to the walls.

The capacity from 1.9 to 76 tons per hour makes it ideal for applications requiring continuous, large-scale drying output.

3. High drying efficiency

The rotary dryer uses multi-layer lifting plates to form a uniform material curtain, maximizing contact with hot air.

This boosts heat transfer and reduces drying time, and achieves up to 80% thermal efficiency. It cuts the energy use by 15%–30%, and reduces the final moisture to 0%–1%.

4. Controlled drying process

The fully automatic system precisely controls drying temperature, time, and humidity.

Drying temperature ranges from 850°C (for mineral sand) to below 300°C (for sawdust and gypsum), with outlet temperatures below 60°C for easy storage.

Short drying time. Drying takes minutes to over an hour, depending on material properties. Final moisture and particle size are adjustable. For example, coal can be dried to 8% moisture and 8 mm size.

5. Tailored drying solution

The best rotary dryers are tailored to their specific application. This requires our engineers to fully consider a series of factors that may affect the design of the dryer:

material type, particle size, inlet and outlet moisture levels, required temperature range, and local conditions such as ambient temperature, humidity, and site elevation.

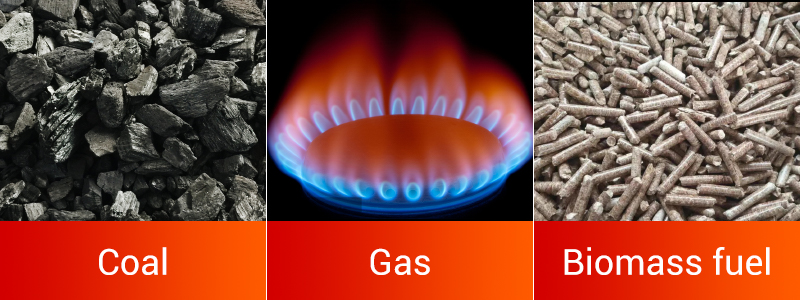

Multiple heating sources

A variety of heating sources are available. The most popular ones include coal, gas and biomass fuel. You can choose the most cost-effective and locally available fuel based on your drying process.

Coal is the most widely used and affordable fuel for industrial drying. It is divided into bituminous coal and anthracite, with an average calorific value of 5,000 kcal/kg. Most drying equipment uses anthracite, but it needs dust removal and exhaust gas treatment after drying.

Gas includes all combustible gases like natural gas, biogas, and coal gas. The calorific value is about 8,500 kcal/m3, with high combustion efficiency and low air pollution, but the overall cost is slightly higher than coal and is limited by pipelines.

Biomass fuel, made from wood chips, sawdust, and straw, has grown in popularity as a renewable energy source. With a calorific value of 3,000–4,500 kcal/kg, it offers a cleaner alternative to coal and similar costs to gas, without pipeline limitations.

Heating methods: co-current and counter-current air flow

Rotary dryers are available in two types of air-flow configurations: co-current and counter-current.

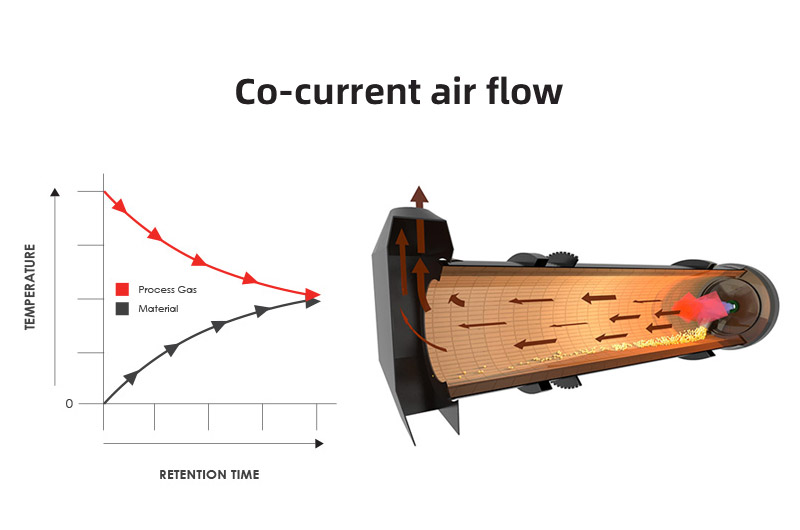

Co-current air flow

Co-current air flow means that the moving direction of the wet material is the same as the flow direction of the heating medium.

It has greater control over solid material temperature and avoidance of overheating. But it is slightly less thermally efficient than the that of the counter-current air flow.

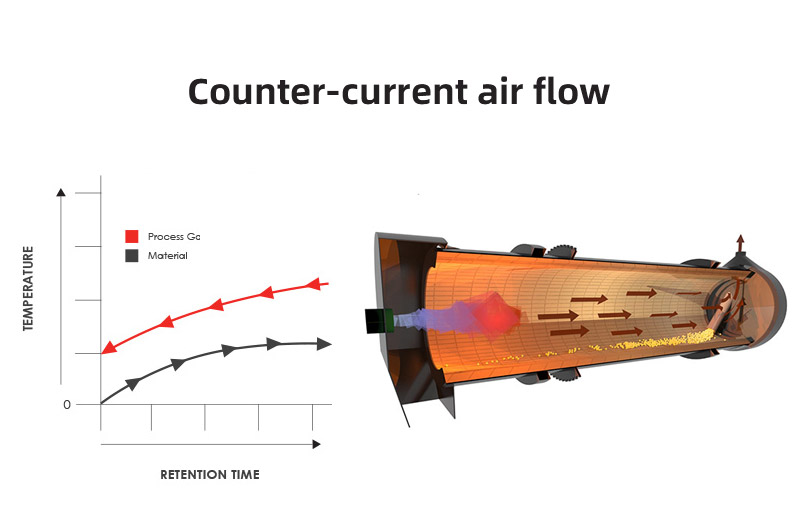

Counter-current air flow

Counter-current air flow heating means that the moving direction of the wet material is opposite to that of the heating medium.

It is more efficient but it has less control over temperature, and greater potential for overheating.

Which heating way will best suit the drying process is based on the material's characteristics and the overall drying process requirement. If you are not sure how to choose, please contact our engineers.

Customer case—rotary dryer sold in Malaysia

In 2019, a Malaysian customer purchased a complete copper slag drying line from FTM Machinery. The rotary dryer effectively removed moisture from copper slag, enhancing its usability in construction materials and metal recovery processes. This significantly contributed to reducing industrial waste and promoting sustainable resource utilization.

Here is the project information:

- Material: Copper slag

- Initial moisture: 25%–30%

- Final moisture: <5%

- Capacity: 20 tons per hour

- Maximum drying temperature: 450°C

- Auxiliary equipment: Feeder, feed conveyor, discharge conveyor, induced draft fan, hot blast stove, and dust collector

Outcome:

The drying line transformed waste copper slag into a high-value material for applications such as cement production and abrasive manufacturing. By processing 10,000 tons of copper slag, the customer reduced landfill use and recovered valuable metals, cutting industrial emissions and disposal costs—a solution aligned with both economic efficiency and environmental protection.

FAQs about rotary dryers

1. What are the advantages of using a rotary dryer over other drying methods?

- Rotary dryers offer several benefits:

- a. High drying capacity and continuous operation

- b. Energy efficiency through optimized heat transfer

- c. Capability to handle diverse material types

- d. Long service life with robust construction

- e. Scalability for both small and large operations

2. How do I choose the right size and type of rotary dryer?

- The required size of the rotary dryer depends on the material type, moisture content (inlet/outlet), desired output moisture level, processing capacity (tons per hour), and drying time. It’s best to consult with a rotary dryer manufacturer with your project details for a customized solution.

3. How do I maintain and clean a rotary dryer?

- Regular maintenance includes checking drum alignment, inspecting seals and bearings, cleaning buildup, and ensuring burner or heat source efficiency. A preventive maintenance schedule extends equipment life.