The purification of quartz sand is very difficult, mainly because it contains some impurity minerals, some of which containing iron elements, such as goethite, hematite, limonite, ilmenite, pyrrhotite, tourmaline, amphibole, biotite and so on.

These impurities greatly reduced the use-value of quartz sand, so the removal of iron from quartz sand is very important. The following introduces 7 methods and equipment for removing iron from quartz sand.

Quartz sand

1. Gravity separation method

Gravity separation can usually be used effectively for the entire particle size range of quartz sand. When the iron in quartz sand is mainly in the form of heavy minerals (relative density > 2.9), gravity selection should be considered firstly. But gravity separation is difficult for mixed particles, flaky particles, light mineral particles and medium-density minerals.

Criteria for gravity separation: E = (heavy mineral density-medium density)/(light mineral density-medium density).

When E > 2.5, gravity separation can be easily adopted;

when it decreases, the efficiency of gravity separation decreases;

when it < 1.25, gravity beneficiation will be not suitable. The commonly used equipment is the spiral chute and shaking table.

Spiral chute Get Latest Price

Spiral chute gravity separation can be used when the material contains a particularly small amount of heavy mineral impurities (such as zircon). The greater the specific gravity difference of minerals, the higher the degree of separation.

Fote spiral chute

When the spiral chute is used for beneficiation, the quartz mortar can be divided into three parts: granular heavy mineral area, granular quartz sand area, flaky and light quartz sand area. In this way, not only the heavy minerals in quartz sand can be removed by the spiral chute, but the mica minerals can also be removed partially.

Advantages of spiral chute:

- 1 Reasonable structure, simple installation and small floor space.

- 2 It is made of chlorinated plastic with great advantages of lightweight, moisture-proof and corrosion-resistant.

- 3 The spiral chute is highly adaptable. The feeding capacity, the concentration of ore, the particle size and grade of the original quartz sand have almost no influence on the beneficiation results.

- 4 Large processing capacity, high work efficiency, low cost and energy saving.

- 5 Good processing effect. It is reflected in stable beneficiation, clear separation, large processing capacity, high efficiency and high enrichment ratio of beneficiation.

- 6 The spiral chute itself has no moving parts, no power consumption, and almost no noise. In addition to the high quality of the quartz sand and no washing water, it has achieved the dual effect of environmental protection and energy-saving.

Shaking table Get Latest Price

The shaking table is a kind of practical gravity separation equipment with high-cost performance. The content of mica in quartz sand can be effectively reduced by the shaking table.

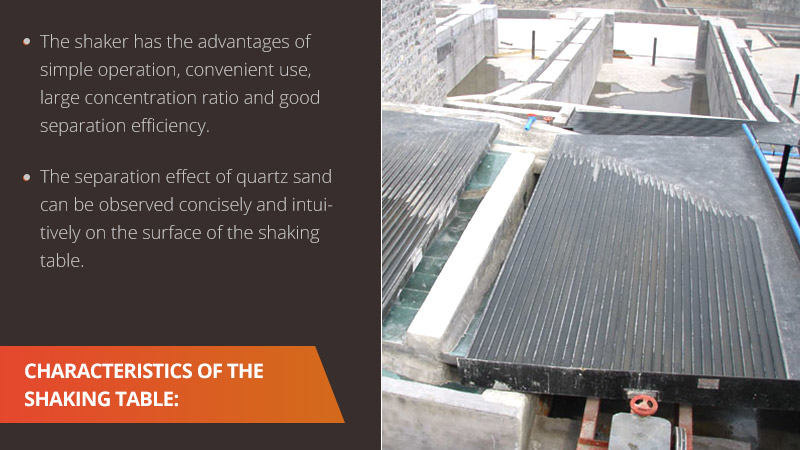

Characteristics of the shaking table

Characteristics of the shaking table:

- The shaker has the advantages of simple operation, convenient use, large concentration ratio and good separation efficiency.

- The separation effect of quartz sand can be observed concisely and intuitively on the surface of the shaking table.

- Quartz sand can be divided into concentrate, medium ore and tailings at one time after being processed by the shaking table, and discharged from different areas.

- If there are many tailings, they can be sorted again to increase production and avoid waste.

2. Magnetic separation method

Quartz, the main mineral in quartz sand, is a diamagnetic substance that cannot be magnetized in a magnetic field. The iron-containing impurity minerals in quartz sand, such as hematite, limonite, magnetite, goethite, etc., are mostly magnetic.

The magnetic separation process is to take advantage of such difference in nature to remove these iron-containing impurities from quartz sand.

Magnetic separation method

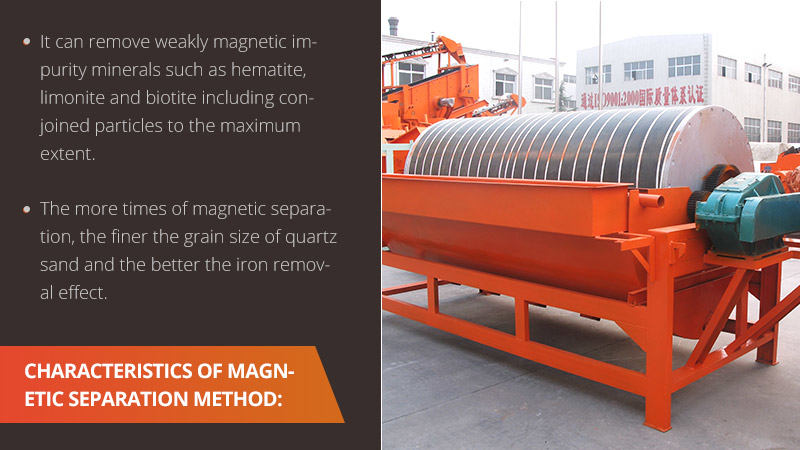

Characteristics of magnetic separation method:

- 1 It can remove weakly magnetic impurity minerals such as hematite, limonite and biotite including conjoined particles to the maximum extent.

- 2 The more times of magnetic separation, the finer the grain size of quartz sand and the better the iron removal effect.

Magnetic separator Get Latest Price

- 1 High concentrate recovery rate. The quartz sand magnetic separator has strong magnetic separation ability, good separation effect, and no concentrate loss.

- 2 A permanent magnetic system with no need for continuous excitation. Permanent magnetic system is adopted in the quartz sand magnetic separator, so the magnetism is not easy to disappear, saving cost.

- 3 Convenient production operation. The quartz sand magnetic separator is integrated with higher electrical control technology to improve work efficiency and reduce the labor intensity of operators.

- 4 High grade of concentrate. The beneficiated quartz sand concentrate has a high grade, and high purity with no impurities, which greatly improves resource utilization.

- 5 Durable. The magnetic drum is wrapped with double-layer drum leathers, which can better protect the internal structure and save maintenance costs while ensuring the magnetic force.

3. Flotation method

The quartz sand flotation method mainly removes iron-containing mineral impurities such as mica, feldspar, garnet and amphibole. A three-stage flotation process is used to remove iron-containing argillaceous, mica and feldspar minerals from quartz sand respectively.

The quartz sand flotation method

Advantages of the flotation method:

The removal of iron from minerals by flotation can achieve better results than other methods. It can not only remove iron minerals, but also particles with iron films and clay minerals.

Therefore, many quartz sand concentrators adopt flotation methods.

Flotation machine Get Latest Price

- 1 The quartz sand flotation machine adopts the automatic control system of unmanned operation, which simplifies the operation of the equipment.

- 2 Simple structure with no need of fans and ventilation ducts. Its unit volume handling capacity is 2~3 times that of conventional flotation machines.

- 3 The important parts and wearing parts of the quartz sand flotation machine are protected by wear-resistant devices, so the consumption of each part in the flotation is less and the maintenance cost is low.

- 4 In the flotation process, the equipment can keep the foam area stable with a certain thickness, and make inclusions gangue of the quartz sand off, resulting in "secondary enrichment", which is beneficial to improve the precision of the finished product.

4. Acid leaching method

If the finished quartz sand is reddish, and the iron and titanium content does not meet the product quality requirements, the acid leaching method can be used. Wash the quartz sand with water to remove powder and impurities, then carry out acid leaching before drying it.

Quartz sand acid leaching method (chemical treatment) has good iron removal effect, but the cost is higher, the technical requirements are stricter, and it is harmful to the environment. However, in order to obtain higher purity quartz sand, this chemical method will inevitably be used in the future.

5. Stirring and scrubbing

Stirring and scrubbing are accomplished by friction between particles caused by violent agitation of the blades. However, since iron oxide films are thin and strong, this method is unlikely to remove them. If necessary, chemical reagents can be added.

Stirring and scrubbing

The process has the following characteristics:

- 1 The product is of good quality and can meet the quality requirements of high-quality silica sand.

- 2 Large output, low cost and simple operation. Now some small-scale production and processing enterprises use this method to remove iron.

6. Ultrasonic cleaning method

Ultrasonic iron removal is mainly to remove the secondary iron film on the surface of the particles. When treated with ultrasonic technology for 10 min, its iron removal rate can generally reach 46% to 70%. In order to improve the effect of ultrasonic cleaning, a small number of reagents (such as sodium carbonate) and surfactants (such as water glass) can be added.

Ultrasonic iron removal is currently relatively expensive for the beneficiation of quartz sand, and it is still difficult to apply in large-scale concentrators, but for those who require high purity, low production is possible.

7. Microbial iron removal

Microbial leaching of thin-film iron or immersion iron on the surface of quartz sand particles is a new technology for iron removal, which is currently in the research stage of laboratory and small-scale experiments.

The microbial Aspergillus niger leaching has a good effect on iron removal. The removal rate of Fe2O3 is up to 88.8%, and the grade of Fe2O3 in quartz sand is as low as 0.008%.