Phosphate rock is the key raw material for phosphoric acid and phosphate fertilizers. With global demand for phosphoric acid reaching 45 million tons annually, efficient phosphate rock processing is critical.

So, how exactly is phosphate rock processed? What phosphate beneficiation methods are available, and which equipment is best for phosphate crushing, grinding, and flotation?

Phosphate rock processing in four stages

To efficiently extract phosphorus from phosphate rock, a complete phosphate rock processing plant usually includes four stages: crushing – grinding – beneficiation – dehydration.

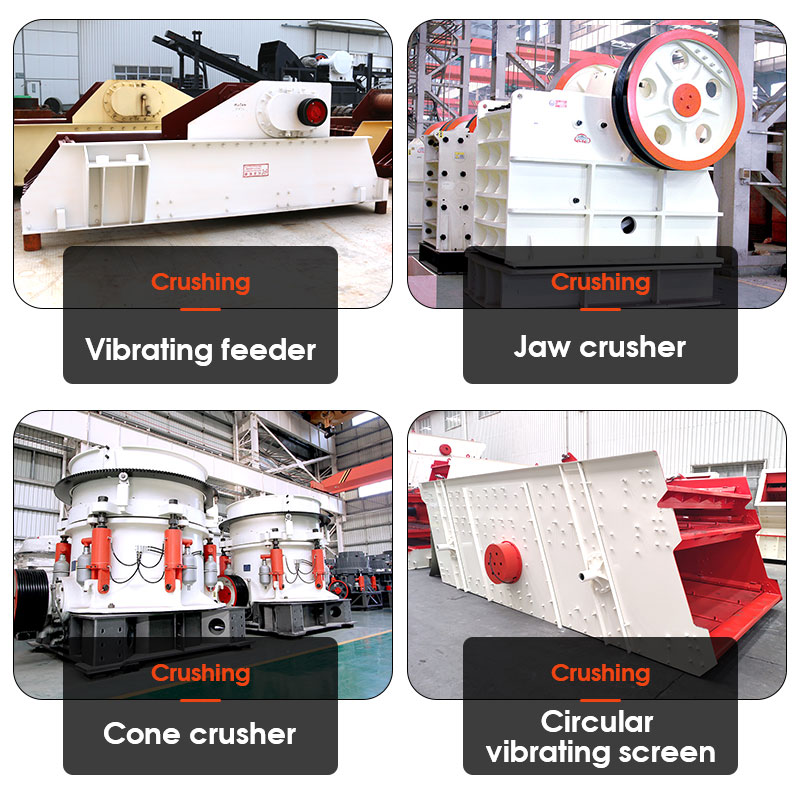

Stage 1: Crushing

Phosphate rock is transported to the raw ore bin and enters the jaw crusher through the vibrating feeder. After coarse crushing, phosphate rock enters the cone crusher again for medium and fine crushing and is screened through the circular vibrating screen.

Process equipment: Vibrating feeder → Jaw crusher → Cone crusher → Circular vibrating screen

Advantages:

- High crushing efficiency with 1,000 t/h

- Achieving coarse and fine crushing, the output size reaches 5–50 mm.

- About 70% of concentrate obtained before flotation, cutting production costs

- Easy maintenance and low construction cost.

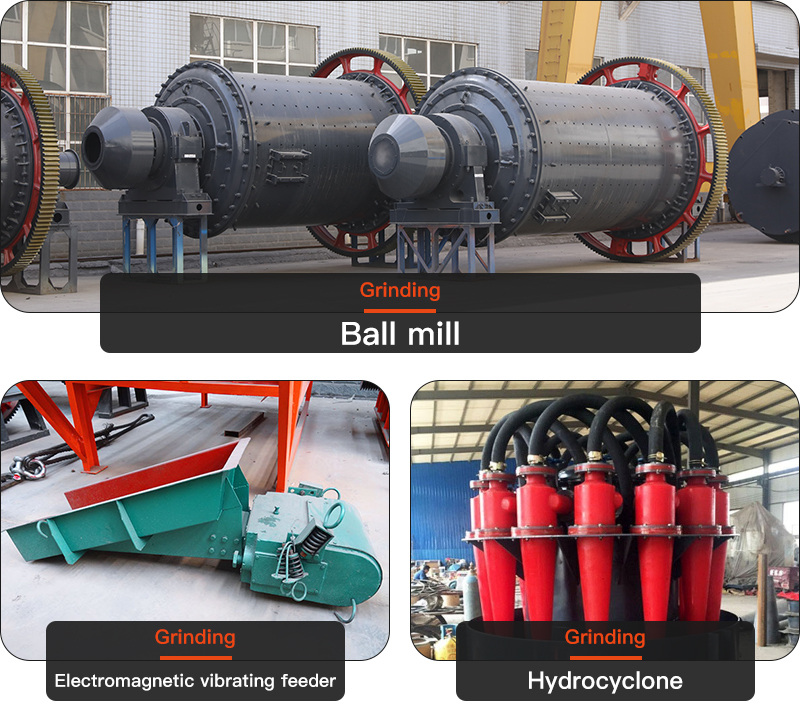

Stage 2: Grinding

This stage is a closed-circuit grinding process, which consists of a ball mill and a hydrocyclone to form a closed circuit. The material is fed to the ball mill by an electromagnetic vibrating feeder and is ground into phosphate rock powder.

Process equipment: Electromagnetic vibrating feeder → Ball mill → Hydrocyclone

Advantages:

- The discharge particle size can reach 0.075–0.4 mm

- 15% higher grinding efficiency with advanced lining and media

- The machine runs smoothly, with high intelligence and high wear resistance

- Energy-saving and environmentally friendly

Stage 3: Beneficiation

Phosphate particles from the cyclone overflow enter the flotation machine, adopting the reverse flotation process. After the process, the obtained products with high phosphorus content are phosphorus concentrates, which are pumped into the concentrate thickener.

Process equipment: Flotation machine

Advantages:

- Phosphate concentrate recovery rate can reach up to 90%

- Concentrate grade over 30%

- It integrates three functions: air suction, slurry suction, and flotation.

- Energy consumption reduced by 20%

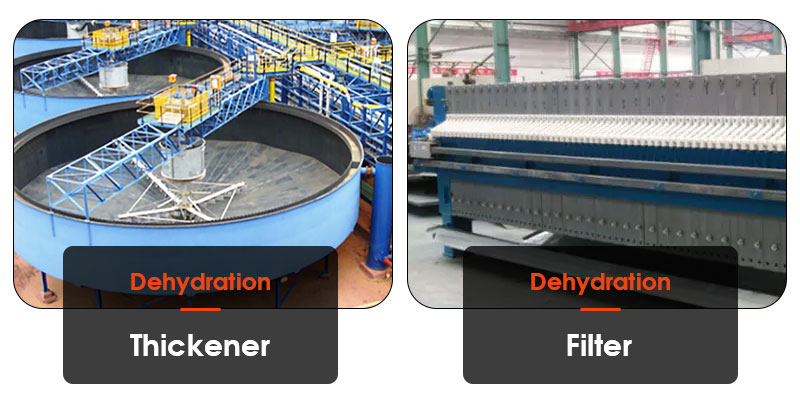

Stage 4: Dehydration

High-efficiency thickener is used to process the phosphate powders, and they are dehydrated by a vacuum filter. The phosphate concentrates are sent to the concentrate yard by a belt conveyor, and the tailings are pumped to the tailings pond.

Process equipment: Thickener → Filter

Advantages:

- Moisture content: reduced to 10–12%

- Dewatering of concentrates and tailings of phosphate ore.

- Self-control facilities and large processing capacity.

- Good environmental protection.

FTM Machinery can provide a complete range of equipment for your phosphate rock beneficiation plant — whether in crushing, grinding, flotation, or dewatering stages. Contact us today to get a customized solution.

Five common phosphate rock beneficiation methods

In addition to the widely used flotation process, different types of phosphate ore can be treated with various phosphate beneficiation methods to improve both the ore grade and the recovery rate.

Process 1: Desliming (Washing)

Typically, mined phosphate rock contains impurities such as clay, quartz, carbonates, etc., and adheres to the wet ore mud. Water washing removes the mud on the surface and separates fine ore particles, such as clay ore and fine-grained quartz. It can also remove certain soluble substances, such as sodium chloride.

Applicable ores: Weathered phosphate rock, mud-rich phosphate deposits.

Process 2: Flotation (Most commonly used phosphate beneficiation way)

By adding flotation agents, minerals are separated based on their surface chemical properties. Direct flotation: Phosphate minerals float upward, while impurities sink. Reverse flotation: Impurities float upward, while phosphates minerals sink.

Applicable ores: Siliceous phosphorite, colloidal phosphorite, sedimentary calcareous phosphorite, apatite, endogenous apatite

Process 3: Calcination

A chemical beneficiation way, it is used to remove organic matter, carbon dioxide, and some fluorine from phosphate rock so that phosphate minerals accumulate.

However, this process requires high energy consumption and comes with high costs, so it is usually applied to phosphate ores that are difficult to treat by flotation.

Applicable ores: Sedimentary calcareous phosphorite with high carbonate content (such as those containing dolomite or calcite).

Process 4: Magnetic separation

According to the different magnetism of minerals, ferromagnetic minerals are separated from non-magnetic minerals under the action of the magnetic field of the magnetic separator.

Applicable ores: Phosphorite containing magnetic minerals such as iron and titanium

Process 5: Heavy media separation

Based on the different densities of minerals, choose magnetite, ferrosilicon, or a mixture of both as a weighting agent, and make the density between phosphate and carbonate. One mineral floats up in the medium and the other sinks to separate phosphorus minerals.

Applicable ores: Carbonate phosphate rock

Phosphate rock processing plants

The composition of phosphorus minerals varies regionally. The beneficiation process depends on the specific conditions, and different phosphate processes are used. Take Saudi Arabia and Brazil as examples:

700 t/d phosphate rock project in Saudi Arabia

Saudi Arabia is rich in phosphate rock. The ore includes carbonaceous argillaceous phosphorite, colloidal phosphorite, and dolomitic phosphorite. The main minerals are collophane, fluorapatite, dolomite, quartz, calcite, pyrite, and chalcopyrite, among which the phosphorus content is 17.84%.

FTM Machinery solution: Adopt the "crushing - grinding - pre-decarburization – positive and negative flotation" process. Among them, calcination treatment is one of the effective methods for decarbonizing carbonate phosphate rock.

| Processing stage | Equipment |

| Crushing |

CJ106 jaw crusher HPM200 cone crusher |

| Grinding |

Ф2200×4500 ball mill 2FG-20 spiral classifier |

| Calcination | Φ3.0×48 rotary kiln |

|

Flotation (Sweep, rough, and fine flotation) |

XJK-type flotation machine SF-type flotation machine |

Finally, phosphorous concentrates with a grade of 30.04% were obtained, with a concentrate yield of 48.28% and a recovery rate of 78.18%.

700 t/d phosphate rock plant: Get Equipment Price

600 t/d phosphate rock plant in Brazil

Brazil has abundant phosphate rock resources with large-scale deposits. The mineral composition includes 30%–60% phosphate, 15%–40% clay, and 12%–25% quartz sand. A large amount of slime interferes with the separation and purification of phosphate minerals.

FTM Machinery solution: Adopt the process of "washing – grinding and desliming – flotation - dehydration".

| Processing stage | Equipment |

| Washing | Φ2.4×6.5 ore washing machine |

| Grinding and desliming |

Ф2100×4500 ball mill Hydrocyclone |

|

Flotation (One rough, two fine flotations) |

CTB7518 stirring tank SF-type flotation machine |

| Dehydration |

NZ-15 thickener Φ2.2×16 rotary dryer |

600 t/d phosphate rock plant: Get Equipment Price

Conclusion

With 40+ years of experience and dozens of successful phosphate projects worldwide, FTM Machinery delivers complete turnkey solutions — from crushing and grinding to flotation and dewatering.

The right solution ensures higher recovery and lower costs. Contact our engineers today for a free process design and equipment quote within 24 hours! Contact us

Phosphate rock processing FAQ

1. How much does a phosphate beneficiation plant cost?

- Costs vary by capacity, ore type, and equipment. Small phosphate plants may start from tens of thousands of dollars, while large-scale phosphate beneficiation plants can cost hundreds of thousands of dollars. Contact FTM Machinery for a customized quote.

2. Can phosphate rock processing plants be customized for small/medium mines?

- Yes. FTM Machinery offers tailored phosphate processing solutions for small and medium mines — from compact crushing and grinding lines to complete flotation and dewatering systems.

- Whether you need a 100 t/d pilot plant or a 1,000 t/d production line, we can provide tailored phosphate processing equipment to maximize efficiency and recovery.