Most professional design knowledge

Extensive field experience

High-quality beneficiation equipment

Author : Jordan | Last Updated :

The goal of ore beneficiation, or mineral processing, is to maximize the economic value of the extracted minerals by increasing the concentration of valuable minerals and removing impurities.

When selecting a suitable beneficiation plant, several factors need to be considered to ensure its effectiveness, efficiency, and compatibility with the specific ore and project requirements.

Factors to consider are: ore characteristics, desired end product, throughput capacity, process flexibility, capital and operating costs, environmental considerations, infrastructure and site requirements, regulatory and social factors, tailings management.

FTM Machinery's engineers can comprehensively consider the above factors to design an economical and feasible ore processing flowsheet and provide corresponding mineral processing machines for customers.

Our ore beneficiation plants are sold to many countries such as India, Australia, USA, UK, Canada, Switzerland, Philippines, Malaysia, Thailand, South Africa, Sudan, Egypt, Kenya, Indonesia, Nigeria, etc.

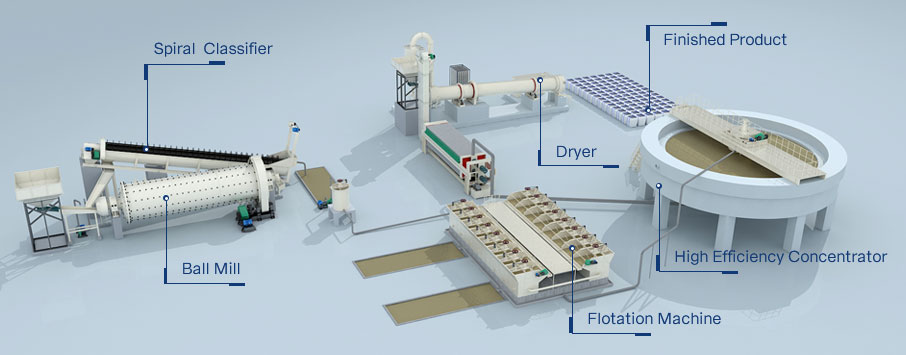

Below is an example of our copper ore beneficiation plant.

While the specific steps can vary depending on the type of ore and desired end product, here is a generalized step-by-step process in mineral processing:

Ftmmachinery can customize an ore beneficiation process for customers by adjusting the process flow, selecting appropriate equipment, optimizing process parameters, customizing tailings management strategies, and implementing automation and control systems.

Below we will share the successful cases of different ore beneficiation plants, including estimated cost, layout design, and final product effect.

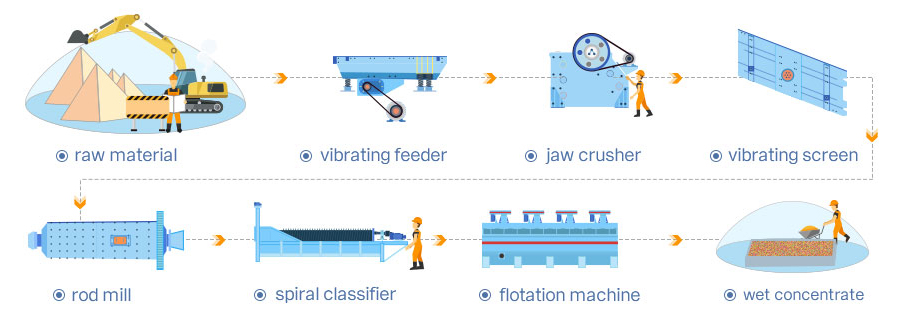

01 Case site 5 TPH low-grade gold ore beneficiation plant in India

| Capacity | 5 TPH |

| Raw material | gold ore |

| Estimated cost | $ 30000 |

| Ore grade | 1.4 g/t |

| Feeding size | 100mm |

| Beneficiation method | Flotation separation |

| Total gold recovery rate | 76% |

| Machines needed in the plant:GZD-650×2300 vibrating feeder,PE-150×250 jaw crusher,B500×22 m belt conveyor, 2YK1225 inclined vibrating screen, MBS1224rod mill, FG-3 spial classifier,XJK type flotation machine, | |

"For low-grade gold ore, this production line finally helped me achieve a recovery rate of 76%, which really surprised me."

—— Armaan from Calcutta02 Case site 10 TPH gold ore beneficiation plant in South Africa

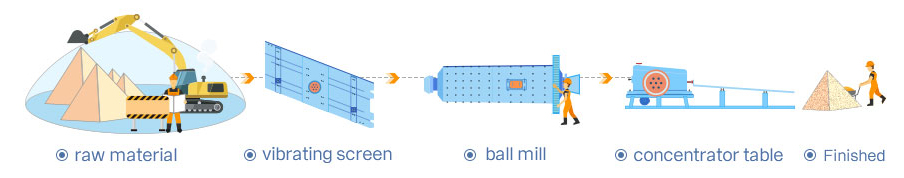

| Capacity | 10 t/h |

| Raw material: | gold ore |

| Estimated investment: | $ 32500 |

| Ore grade | 6 g/t |

| Ore beneficiation method | gravity separation |

| Concentrate content | 620 g / t |

| Total gold recovery rate | 50% |

| This beneficiation plant design: 3YK1225 circular motion vibrating screen, Ф1200×4500 ball mill,concentrator table(2 sets) | |

"The gold ore gravity separating method is not only low in cost but also efficient and no harmful to the environment."

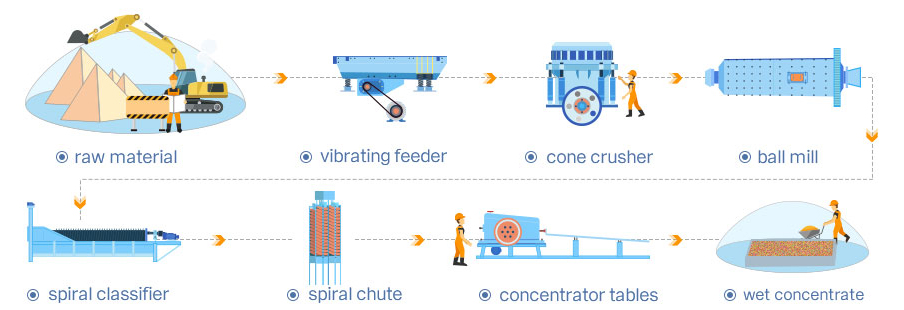

—— Khayone from Johannesburg03 Case site 20-35 TPH gold ore beneficiation plant in Egypt

| Capacity | 20-35 t/h |

| Raw material | gold ore |

| Estimated investment | $63500-85000$ |

| Before beneficiation: grade(t/g) | After beneficiation: recoveryrate(%) | |

| Gold concentrate | 33.35 | 81.80 |

| Tails | 0.68 | 9.38 |

| Raw gold ore | 3.32 | 100 |

| Gold concentrate | 34.38 | 90.62 |

| Tails | 0.34 | 19.20 |

| Raw gold ore | 3.30 | 100 |

| Needed equipment: GZD-650×2300 vibrating feeder,Φ1200 cone crusher,B500x10 m belt conveyor, Ф2200×4500 ball mill,a Fote 2280 Spiral classifier, spiral chute, Shaking table (2 sets) | ||

"This mobile gold mine processing line solved my site limitation and helped me save 66% of the cost."

—— Abubakar04 Case site 10 TPH iron ore beneficiation plant in the USA

| Capacity | 10 t/h |

| Raw material | iron ore |

| Estimated investment | 20000$ |

| Iron ore grade | Low grade |

| Ore beneficiation method | magnetic separation |

| Opening size | 65mm |

| Concentrate content | 67.81% |

| Recovery rate | 92.69% |

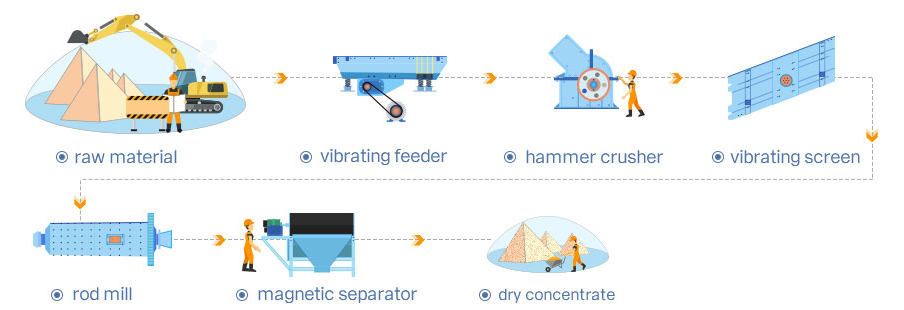

| This beneficiation plant design: GZD-650×2300 vibrating feeder,PCΦ600×400 hammer crusher,YK1225 circular motion vibrating screen,MBS1830 rod mill, CTB6012 Magnetic drum separator | |

"The stage grinding and separation processes are perfect to dress low-grade iron ore. The whole plant helps me reduce the energy consumption and costs."

—— Matt from LA05 Case site 10-50 TPH copper ore beneficiation plant in Pakistan

| Capacity | 10-50t/h |

| Raw material | copper ore |

| Estimated investment | $30000-100000$ |

| Copper ore grade | 2.5 g/t |

| Ore beneficiation method | Flotation separation |

| Concentrate content | 44.9% |

| Recovery rate | 87.04% |

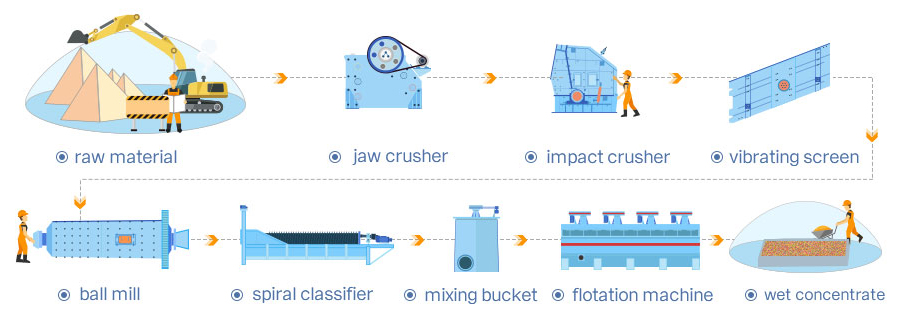

| Ore beneficiation equipment: Customized small mobile jaw crusher, Customized small mobile impact crusher, B500x10m belt conveyor, 2YK1225 circular motion vibrating screen,Ф2200×4500 ball mill,spiral classifier, mixing bucket, JJF type flotation machine. | |

"I'm glad to see that the quality of copper concentrate obtained by this beneficiation method is significantly higher than others."

—— Hasnain06 Case site 50-100 TPH manganese ore beneficiation plant in Kenya

| Capacity | 50-100t/h |

| Raw material | manganese ore |

| Estimated investment | 80000$-120000$ |

| Manganese ore grade | 17% |

| Ore beneficiation method | Two-stage high-intensity magnetic separation |

| Concentrate content | 38% |

| Recovery rate | 74% |

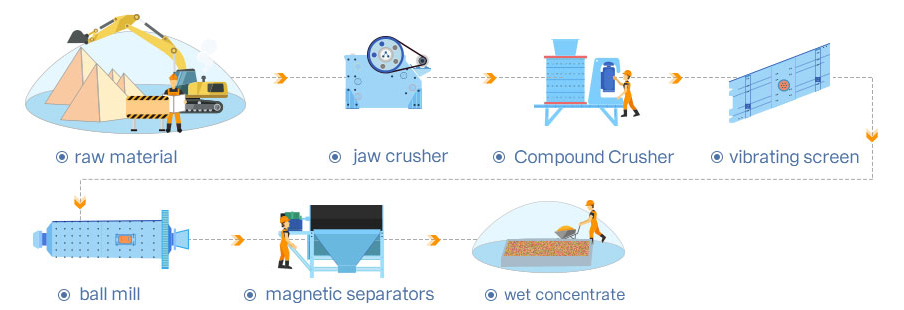

| Manganese beneficiation machines: GZD-850×3000 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher,B500x10 m belt conveyor, 2YK1535 inclined vibrating screen,Ф2700×4500 ball mill, High-strength Magnetic drum separators | |

"Large output, low cost, and efficient operation bring me lots of investment returns. "

—— Joseph from Nairobi Kenya07 Case site 150 TPH Bauxite ore beneficiation plant in Indonesia

| Capacity | 150t/h |

| Raw material | bauxite ore |

| Estimated investment | 150000$ |

| bauxite ore grade | 45% |

| Feeding size | 0-50mm |

| Moisture content | 10-13% |

| Ore beneficiation method | magnetic separation |

| Concentrate content | 67.9wt% |

| Recovery rate | 92% |

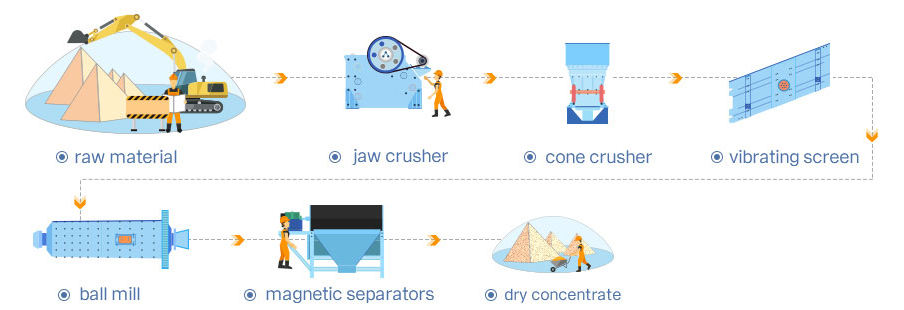

| Bauxite beneficiation equipment:GZD-1000×3600 vibrating feeder,PE-500×750 jaw crusher,Φ1200 cone crusher, B500x15 m belt conveyor, 2YK1545 vibrating screen,Ф3200×4500 ball mills, CTB1224 Magnetic drum separators. | |

"This magnetic separation method helped me to remove alumina-silica, alumina-ferrite complexes, iron and other impurities. Besides, the entire production line was running smoothly."

—— Gustidar08 Case site 50 TPH lateritic nickel ore beneficiation plant in Philippines

| Capacity | 50t/h |

| Raw material | lateritic nickel ore |

| Estimated investment | 150000$ |

| lateritic nickel ore grade | 1.29 wt% |

| Ore beneficiation method | Wet magnetic separation and forth flotation |

| Concentrate content | 8.3% |

| Recovery rate | 92% |

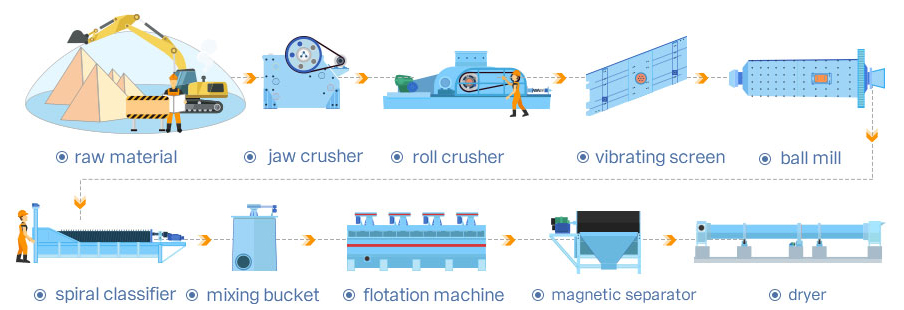

| Manganese beneficiation machines: GZD-650×2300 vibrating feeder, PE-500×750 jaw crusher,2PG1060 roll crusher,B500x16 m belt conveyor, B500x15 m belt conveyor, 3YK1230 vibrating screen,Ф2100×7000 ball mill,mixing bucket, a CTB9018 Magnetic drum separator, a SF type flotation machine, a Φ3.2×25 rotary dryer. | |

"Through wet grinding and subsequent efficient beneficiation methods, the recovery rate of laterite ore is greatly improved."

—— Efren from Manila09 Case site 200 TPH zinc & lead ore beneficiation plant in Nigeria

| Capacity | 200t/h |

| Raw material | zinc & lead ore |

| Estimated investment | 250000$ |

| zinc & lead ore grade | Zinc 12% lead 9.05% |

| Ore beneficiation method | Flotation separation |

| Lead recovery rate | 72% |

| Zinc recovery rate | 55% |

| Total recover rate | 87.04% |

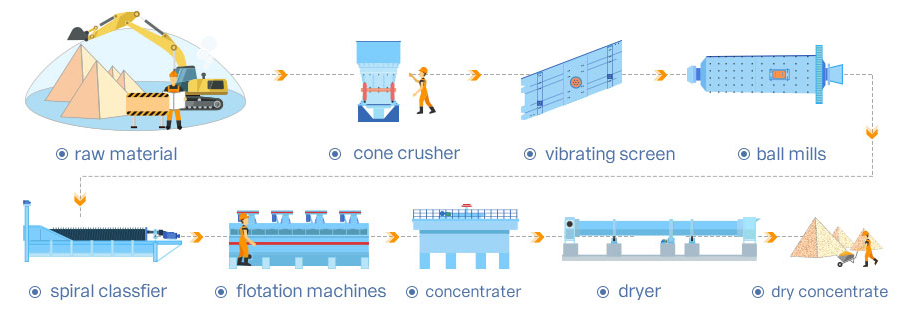

| zinc & lead ore beneficiation machines: Φ1200 cone crusher, 2YK1848 vibrating screen, Ф3600×6000 ball mills, spiral classfier, a JJF type flotation machines, concentrater, a Φ3.6×28 slag dryer. | |

"This line has powerful processing capabilities. Tailings processed by coarse flotation machine do not need to the ball mill again, which saves a lot of energy."

—— Roger10 Case site 250 TPH chrome ore beneficiation plant in Russia

| Capacity | 250t/h |

| Raw material | chrome ore |

| Estimated investment | 270000$ |

| chrome ore grade | 44% |

| Ore beneficiation method | Gravity and flotation separation |

| recovery rate | 97.4% |

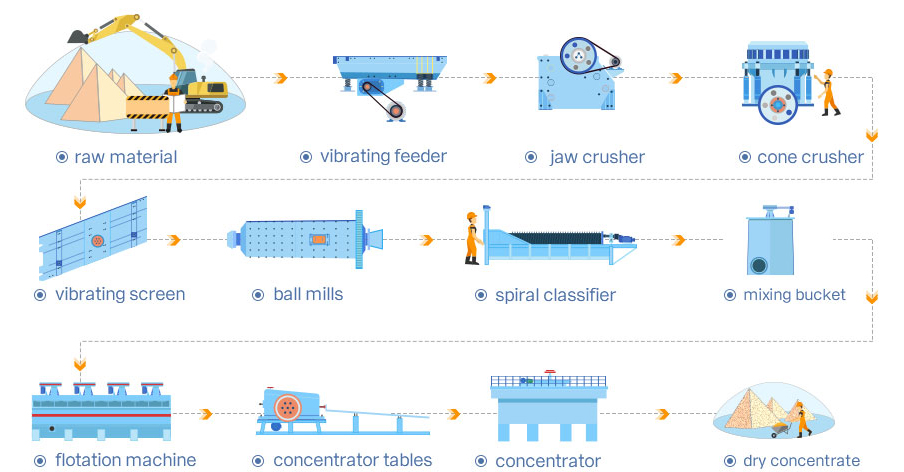

| Chrome ore beneficiation machines: GZD-1100×3600 vibrating feeder, PE-750×1060 jaw crusher, FTMHP200 hydraulic cone crusher, B500x44 m belt conveyor, 2YK1848 vibrating screen, Ф3600×6000 ball mills, mixing bucket, FG-5 spiral classifier, JJF type flotation machine, Grit concentrator tables, a NZS-12 high efficiency concentrator. | |

"The process is very effective because it can extract chromium concentrate quickly, and the grinding only takes a little time. "

—— Michail from Moscow