Most crushing plants are built around four core types of stone crushers: jaw crusher, cone crusher, impact crusher, and hammer crusher.

Whether you are processing hard rock, soft stone, or construction waste, a stone crusher or rock crusher machine can help you achieve efficient material reduction.

Quick comparison of 4 stone crushers

The table below highlights the key differences between the four most common stone crusher machines to help you quickly choose the right crushing equipment.

| Crusher type | Best for | Material hardness | Key advantage |

| Jaw crusher | Primary crushing | All (soft to extra hard) | Massive feed size |

| Cone crusher | Secondary/tertiary | Hard & abrasive | Low wear cost |

| Impact crusher | Secondary crushing | Soft to medium | Premium cubical shape |

| Hammer crusher | One-step crushing | Soft to medium | Low investment cost |

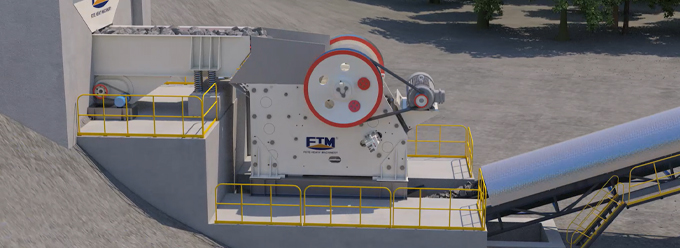

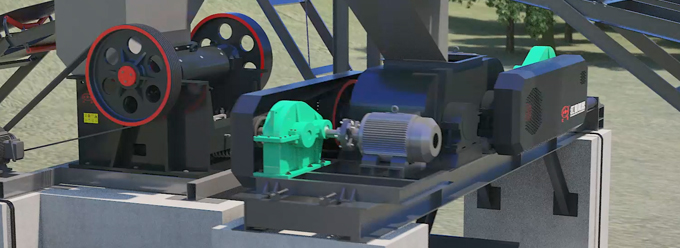

Jaw crusher – Reliable primary crushing machine

Jaw crushers are among the most commonly used rock crushers and are typically applied as primary crushing machines. They reduce large stones by compressive force between a fixed jaw plate and a moving jaw plate.

They can process large feed sizes and hard materials such as granite, basalt, iron ore, and other metal ores.

For many crushing plants, the jaw crusher forms the foundation of the entire production line and is the preferred rock crusher machine for primary crushing in large stone and metal processing facilities.

Advantages of jaw crushers

- Large feed opening: Typically handles feed sizes of 500–1,500 mm, with a crushing ratio of 3–6, suitable for oversized rock.

- Simple structure: Fewer moving parts ensure high uptime even in harsh working conditions.

- Low maintenance cost: Wear parts such as fixed jaw plates and movable jaw plates are easy to inspect and replace.

Disadvantages of jaw crushers

Jaw crushers mainly produce coarse material with less uniform particle shape compared to impact crushers. To achieve finer aggregate sizes, additional secondary or tertiary crushers are usually required.

Popular jaw crusher models Get a quote

| Model | Max feed size (mm) | Capacity (t/h) | Application |

| PE 400×600 | ≤340 | 16–64 | Small crushing plants |

| PE 600×900 | ≤500 | 65–160 | Quarry & concrete crushing |

| PE 750×1060 | ≤630 | 110–320 | Mining & aggregate plants |

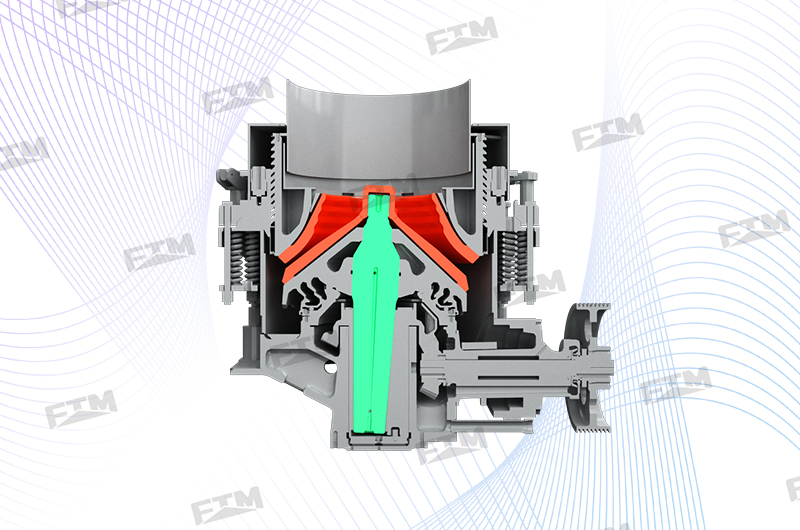

Cone crusher – Efficient secondary and tertiary crusher

For secondary and tertiary crushing of hard, abrasive materials, the Cone Crusher is the industry standard. It works by "compressing" the stone between a gyrating mantle and a stationary bowl liner.

Cone crushers are particularly suitable for crushing iron ore, granite, copper ore, and other hard, abrasive stones. Many modern crushing plants rely on cone crushers to meet strict aggregate grading requirements.

Advantages of cone crushers

- Low operating cost per ton: 30–50% longer liner life than other crushers, extending maintenance cycles and reducing consumable costs.

- Advanced automation: Most modern cones feature hydraulic "tramp release" systems to prevent damage from uncrushable objects.

- Continuous production: Designed for high-capacity, 24/7 operation.

Disadvantages of cone crushers

Cone crushers have higher initial investment costs and require more precise maintenance. They are not suitable for sticky or wet materials, which may cause blockages.

Popular cone crusher models Get a quote

| Model | Max feed size (mm) | Capacity (t/h) | Application |

| SC100 | ≤120 | 45–135 | Hard rock crushing plant |

| SC250 | ≤190 | 116–396 | Quarry crushing |

| SC750 | ≤295 | 394–2181 | High-capacity plants |

Impact crusher – Ideal concrete and aggregate crusher

Impact crushers use high-speed "blow bars" to shatter rocks and are widely used in aggregate production. They are commonly applied as concrete crushers, limestone crushers, and shaping machines.

Impact crushers perform exceptionally well when processing soft to medium-hard materials and recycled concrete. If you demand premium cubical aggregates for high-grade concrete or asphalt, this is your machine.

Advantages of impact crushers

- Excellent particle shape: Cubical content can reach 85–90%, with minimal internal cracks.

- Adjustable output size: Operators can easily control final product grading.

- Superior blow bar: Our blow bars are made from high-chrome alloys, offering excellent impact resistance and wear resistance.

Disadvantages of impact crushers

Impact crushers are not suitable for hard or highly abrasive wet materials, as blow bars wear quickly, resulting in higher operating costs.

Popular impact crusher models Get a quote

| Model | Max feed size (mm) | Capacity (t/h) | Application |

| PF-1210 | ≤350 | 70–130 | Concrete recycling |

| PF-1315 | ≤500 | 100–280 | Aggregate shaping |

| CI1521 | ≤350 | 200–600 | Medium crushing plants |

Hammer crusher – A cost-effective solution for soft stone

Hammer crushers combine impact and shearing forces and are typically used to crush brittle materials(600–1,800 mm) into smaller sizes in a single step.

Hammer crushers feature a simple structure and low equipment cost. They are commonly applied for coal, gypsum, limestone, and shale crushing, making them ideal for small to medium-sized limestone plants seeking an economical crushing solution.

Advantages of hammer crushers

- Simplified crushing circuit: Can eliminate one secondary crusher, reducing initial investment.

- High reduction ratio: Crushes stones up to 1 meter down to 20–25 mm in one pass.

- Low energy consumption: High throughput with relatively low energy use per ton.

Disadvantages of hammer crushers

Their output size control is less precise compared to cone crushers or impact crushers.

Popular hammer crusher models Get a quote

| Model | Capacity (t/h) | Application |

| PC 400×300 | 3–10 | Small plants |

| PC 800×600 | 10–40 | Gypsum & coal |

| PC 1200×1200 | 22–95 | Limestone crushing |

Mobile stone crusher plant – Flexible crushing solution

Many modern projects require mobility and fast installation. A mobile stone crusher plant integrates one or more crushers—such as a jaw crusher, impact crusher, or cone crusher—onto a wheeled or tracked chassis.

They are widely used in concrete recycling, urban construction sites, temporary quarries, and remote mining areas.

Mobile crushers offer flexibility, reduced civil construction costs, and easy relocation. By combining crushing, screening, and conveying into a single system, mobile crushing plants improve operational efficiency and shorten project timelines.

Get a customized crushing solution

Every mine is unique. At FTM Machinery, we don't just sell machines; we design profitable circuits. Contact our engineers today