What is a roll crusher?

A roll crusher (also called a double roll crusher) is an efficient and energy-saving crushing machine, widely used for fine crushing and sand making of coal, limestone, clay, gangue, cement clinker, slag, shale, and various ores.

It is mainly applied to soft, brittle, or medium-hard materials for primary crushing, and is also commonly used for secondary or tertiary crushing. Roll crushers handle sticky and moist materials without clogging, while producing uniform particles with fewer fines.

Key applications of roll crushers:

- Coal processing and preparation – reduce fines and simplify crushing steps

- Cement and clinker production – pre-crushing limestone and clinker

- Mining and metallurgy – crushing brittle minerals such as bentonite, rare earth ores, bauxite, and manganese ore

- Construction materials and sand making – secondary crushing for manufactured sand with low fines content

- Chemical and glass industries – processing soda ash, waste glass, and other brittle raw materials

Compact in size and low-cost, roll crushers offer wider applications than many other types of crushers. With an adjustable discharge system, they provide flexible control over product size.

Types of roll crushers

Roll crushers can be divided into three types according to the number of rollers: single roll crusher, double roll crusher, and multi-roll crusher. Among them, the double roll crusher is the most common.

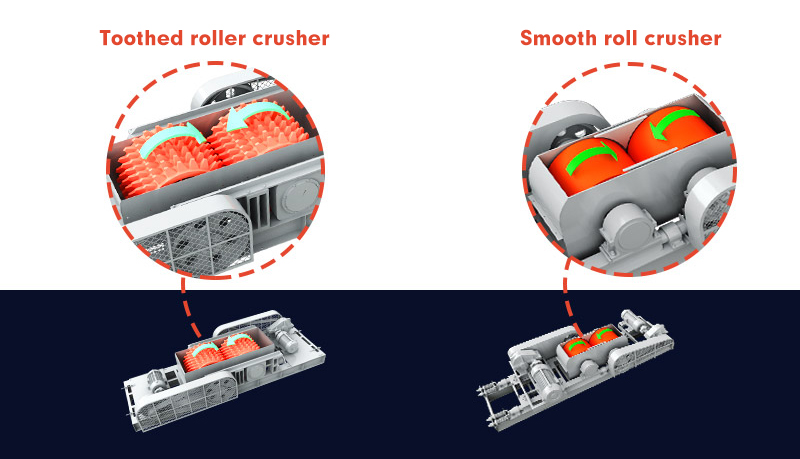

Double roll crushers come in two designs: toothed roll and smooth roll, both relying on two counter-rotating rollers to complete the crushing process.

Toothed Roll Crusher vs. Smooth Roll Crusher

- Toothed roll crusher: Uses a combination of shearing and compression. Suitable for sticky or high-moisture materials (such as clay, shale, and gangue). Less likely to clog.

- Smooth roll crusher: Relies on compression. Suitable for non-abrasive, brittle materials (such as coal and limestone). Produces uniform particles with less dust.

If the material is harder or has higher moisture content, a toothed roll crusher is recommended. If you need uniform particle size and lower dust, a smooth roll crusher is the better choice.

Here are the parameters of our roller crusher: Get a quote

| Model | Input Size(mm) | Discharging size(mm) | Processing capacity(t/h) | Motor power(kw) |

| 2PG0425 | ≤25 | 2–8 | 3–10 | 5.5×2 |

| 2PG0640 | ≤25 | 2–8 | 5–20 | 15×2 |

| 2PG0740 | ≤25 | 10–30 | 0.074–0.4 | 30×2 |

| 2PG0850 | ≤25 | 15–40 | 0.074–0.4 | 45×2 |

| 2PG1060 | ≤30 | 20–50 | 0.074–0.4 | 55×2 |

| 2PG1261 | ≤30 | 2–10 | 25–70 | 75×2 |

| 2PG1560 | ≤30 | 2–10 | 30–110 | 110×2 |

Why choose FTM Machinery roll crushers?

As a global leader in industrial crushers, FTM Machinery roll crushers are trusted worldwide and have been exported to Indonesia, Zimbabwe, Vietnam, Singapore, the United States, Pakistan, and many other countries.

With 5 key advantages, this stone crushing equipment delivers proven performance in coal, mining, cement, and aggregate industries.

1. Low over-grinding, better final product

The unique roller design enables selective crushing, breaking materials along natural cracks. Fine powder content is reduced by 15–20%, producing uniform cubic particles — perfect for coal preparation and sand making.

2. Wear-resistant rollers, longer service life

The roller surface, is made of high-manganese steel. It handles hard rocks with ease, reduces wear by 30–40%, and significantly extends service life.

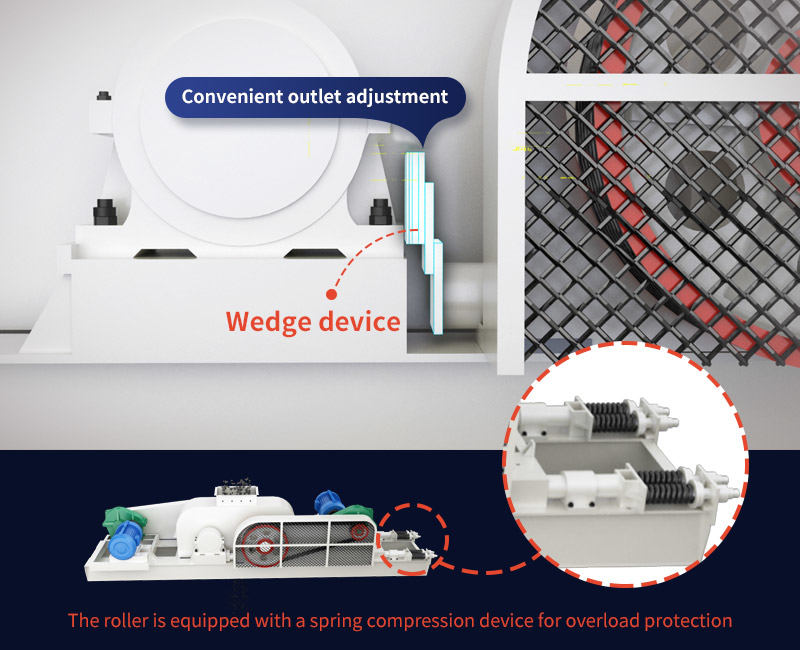

3. Adjustable discharge, easy maintenance

Equipped with wedge/shim adjustment and spring relief, the roll crusher offers 0–20 mm adjustable output and automatic protection against overload or tramp iron, reducing downtime and maintenance.

4. High reduction ratio & consistent output

Double rollers work in opposite directions, achieving a maximum reduction ratio of 4:1. A 2-inch feed can be reduced to 1/2 inch with stable and uniform size.

5. Energy saving, dust control

Centralized control with sealed dustproof design saves 30–50% energy. Built-in CPU allows remote roll gap adjustment and chamber cleaning for efficient, smart operation.

How does a roll crusher work?

The main working parts of a roll crusher are the cylindrical rollers, which are driven by a motor and supported by fixed and movable bearings.

Materials are pulled into the gap between the rollers and crushed by compression. The crushed product is discharged through the roller gap. Toothed rolls add a shearing effect, which improves handling of sticky or wet materials.

Roller crusher working principle video:

If uncrushable materials or tramp iron enter the gap, the springs allow the rollers to separate slightly, letting these materials pass through without damaging the crusher. Once cleared, the springs return the rollers to their original position, and normal crushing resumes.

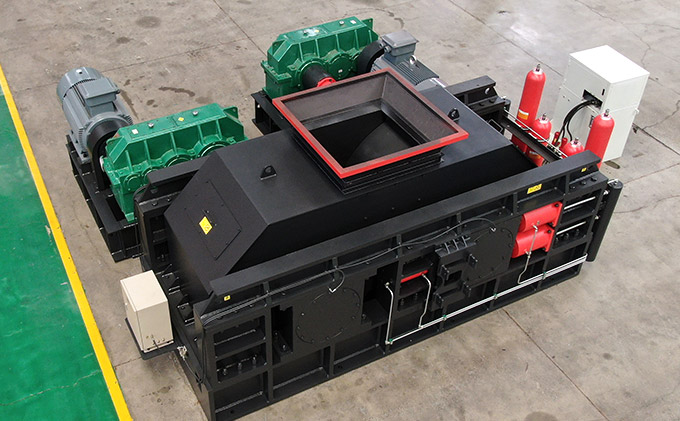

Customer case: FTM Machinery roll crusher delivered to Australia

A construction materials company in Australia needed reliable stone crushing equipment to process 60 tons of limestone per hour and produce three grades of sand: 0–5 mm, 5–10 mm, and 10–20 mm for building applications.

The customer chose the 2PG1560 roll crusher, along with supporting equipment such as a vibrating screen and sand washer. Specially designed for brittle minerals like limestone, the crusher runs smoothly and efficiently.

Project results:

- Uniform sand sizes with low dust, meeting construction standards

- Dust emissions reduced by about 20%, improving the worksite environment

- Energy consumption cut by around 30%, lowering production costs

Roll crushers for sale

At FTM Machinery, we don't just sell crushers—we deliver complete crushing solutions. With years of expertise in roll crushers and full crushing lines, we are your trusted equipment manufacturer partner for mining, cement, coal, and construction industries.

- Proven expertise – Years of experience in roll crusher and crushing line design

- Reliable quality – Premium materials & strict quality control

- Complete support – Custom solutions, spare parts, and after-sales service

- Global reach – Serving customers worldwide with local support

Contact us now and let FTM Machinery help you achieve higher productivity at lower cost.

FAQs

1. How to adjust the discharge size of a roll crusher?

- 1. Wedge adjustment: Turn the adjustable bolt to move the wedge, which pushes the movable roller away from the fixed roller, increasing the roll gap and the discharge size.

- 2. Shim adjustment: Add or remove shims to change the effective gap between the rollers for fine-tuning.

- 3. Modern solutions: Use hydraulic or PLC-driven gap control for precise remote adjustment and automatic monitoring.

2. What is the difference between a jaw crusher and a roll crusher?

- A jaw crusher is a primary crusher that crushes materials by compressing them between a fixed jaw and a moving jaw, suitable for very hard and large rocks.

- A roll crusher is used for secondary or fine crushing, using two rotating rollers (compression or shearing) to crush brittle, soft to medium-hard, or sticky materials.

3. What is the difference between a hammer crusher and a roll crusher?

- A hammer crusher breaks materials by high-speed impact, producing more fines and dust.

- A roll crusher relies on compression (and shearing in toothed types), resulting in less over-crushing, more uniform particles, and lower dust emissions.

Download Roll Crusher

1.61 MB

Download Roll Crusher

1.61 MB